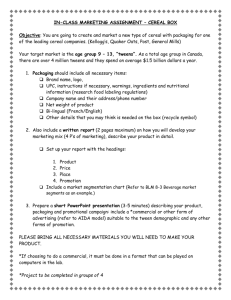

A l C

advertisement