A MODULAR DESIGN FOR LABORATORY MICHELE TESCIUBA

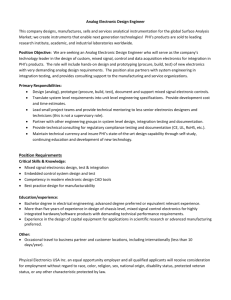

advertisement