System Characterization and Online

advertisement

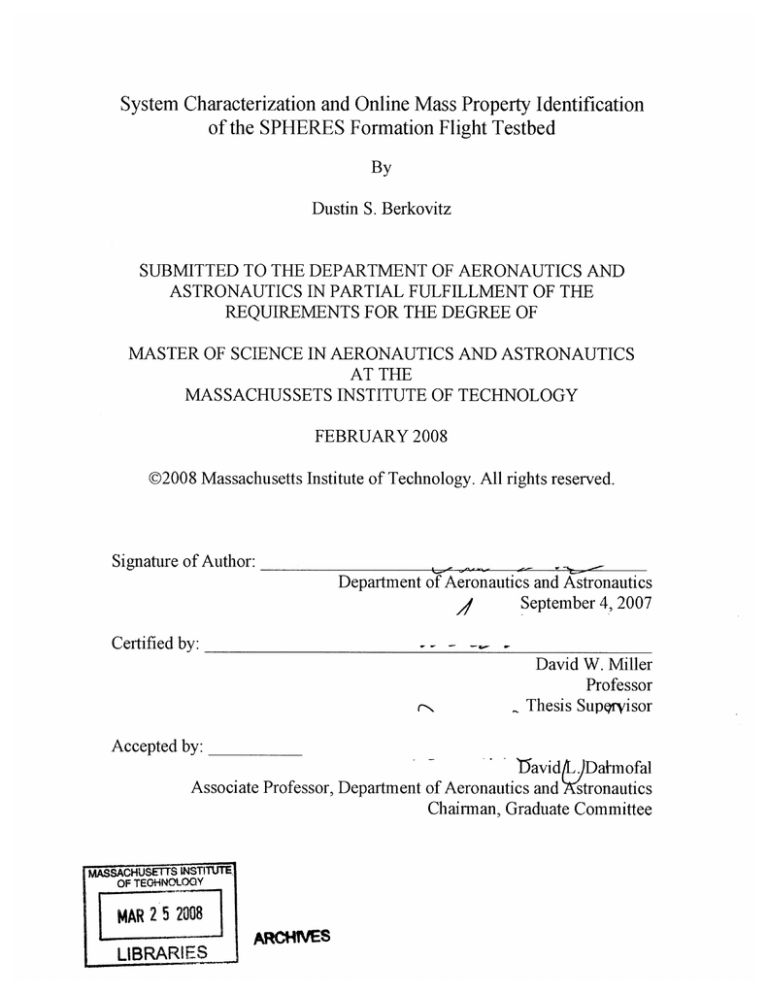

System Characterization and Online Mass Property Identification

of the SPHERES Formation Flight Testbed

By

Dustin S. Berkovitz

SUBMITTED TO THE DEPARTMENT OF AERONAUTICS AND

ASTRONAUTICS IN PARTIAL FULFILLMENT OF THE

REQUIREMENTS FOR THE DEGREE OF

MASTER OF SCIENCE IN AERONAUTICS AND ASTRONAUTICS

AT THE

MASSACHUSSETS INSTITUTE OF TECHNOLOGY

FEBRUARY 2008

©2008 Massachusetts Institute of Technology. All rights reserved.

Signature of Author:

Department of Aeronautics and Astronautics

/

September 4, 2007

Certified by:

David W. Miller

Professor

Thesis Supgryisor

Accepted by:

I3avid.)Dahnmofal

Associate Professor, Department of Aeronautics and Kstronautics

Chairman, Graduate Committee

..

_8"

MASACHUSETM-tNSTITUT

OF TECHNOLOGY

MAR 2 5 2008

LIB.RARIES

ARCHNES

System Characterization and Online Mass Property Identification

of the SPHERES Formation Flight Testbed

By

Dustin S. Berkovitz

Submitted to the Department of Aeronautics and Astronautics

on September 4, 2007, in partial fulfillment of the

requirements for the degree of Master of Science in Aeronautics and Astronautics

Abstract

The National Aeronautics and Space Administration (NASA) and other entities in the

aerospace industry have recently been considering distributed architectures for many

space applications, such as space-based interferometry. Whether the craft in such a

system are structurally connected or flown in tight formation, distribution allows for

higher redundancy in case of failures as well as reducing the minimum payload footprint

for launch. Designed to fly in precise formation, the SPHERES satellites rely on accurate

system characteristics such as thruster strength and vehicle mass and inertia. The

SPHERES testbed is described and the applications for formation flight are presented.

Mass properties of the SPHERES satellites are examined because of their impact on

control determination, with comparison between CAD model estimates and empirically

determined values. The sensor and actuator suite, essential for closed-loop control, are

also identified and characterized. A recursive least squares algorithm for determining

mass properties in real time is explained and implemented both offline and online with

results from test flights aboard NASA's KC-135 micro-gravity aircraft (Reduced Gravity

Airplane, RGA).

Thesis Supervisor: David W. Miller

Title: Professor

Acknowledgments

The mass property identification algorithm discussed in this thesis is derived and

formulated by Edward Wilson, Chris Lages, and Robert Mah of NASA Ames Research

Center. Some data and results using the AMES implementation of the algorithm are

included and referenced.

I'd like to thank my friends and family, my parents and Katie Shirley for supporting me

through this lengthy process. I also am grateful to my graduate advisor, David Miller, for

putting up with me for the past 6 years. Also, thanks to my lab mates in the Space

Systems Lab for making work fun; especially Alvar Saenz-Otero and Simon Nolet for

reviewing this thesis on their own time.

Contents

A bstract

.............................................

List of Figures ...............

...................

.....

9

...........................

... ................................

12

List of Tables .................................................................

Nomenclature ...................

Chapter 1

....

.........................

1,2 SPHERES Hardware Overview.........................

.........

1.2. I

Inertial Sensors ..........

1.2.2

Propulsion System ........

1.2.3

Ultrasound-based Positioning System ..................

15

................. 17

.............

....... ...................... 17

.............................

1.3 Current Programs ......................................

................ 18

.................. 18

............................19

1.4 System Characterization Motivation .....................

SPHERES Mass Properties ..............

2.1 Mass Properties Overview ......

13

.................................

15

Introduction ................

1.1 SPHERES Background ........................................................ ........

Chapter 2

3

........... 21

.......................

24

........................................... 24

......................... 26

2.2 Measuring Center of Mass ............................

2.2.1

CoM Error Sources .............

..............

................

2.3 M easuring M oment of Inertia ..................................

27

............... 27

......

.......................28

2.3.1

Torsional Pendulum Modeling ........................

2.3.2

Test Procedure .....

2.3.3

Products of Inertia ..............

2.3.4

Results ..................................

2.3.5

Alternate Method for Measuring Inertia ..................................... 34

2.3.6

Inertia Measurement Error Analysis .......

2.3.7

Empirical Mass Properties Conclusion ...............

Chapter 3

..................... ......

....... .................

............. 32

.............

............................. 33

.....

................

35

............ 42

....

................. 44

Thruster Characterization .................

............ 44

3.1 Propulsion System Overview ............................... ..........

....................................... 45

3.2 Propulsion Hardware ..............

3.3 Pulse-width Modulation Scheme ..............

............ 47

....................

3.4 Propulsion Limitations ......................................................

.......... 51

51

3.5 Measuring Nominal Thrust Vector .....................................

3.6 Thrust Latency ...............................

3.7 Multiple Thruster Pressure Drop .............

.....................

..............

3.8 Sensor Characterization ...........................................

Chapter 4

32

........

53

.............. 56

58

Mass Property Identification ............. ................................... 61

4.1 Online M ass Property Identification .................................................... 61

4.2 Theory and Equations ..............

........................................

4.3 KC-135 Micro-gravity Testing.....................

6

............ 63

.................. 65

4.4 Algorithm Development ........................................

........

.......... 69

4.4.1

Gyro Filtering and Interpolation ..................

4.4.2

Angular Acceleration Estimation.............................71

4.4.3

Mass Property Identification .......

4.4.4

C Code Implementation ................. ........

Chapter 5

.... ...

Conclusion .................................

5.1 Thesis Summary ...........................

......

,....

............... 86

Tuning Fork Gyroscopes................... .....

A.2 Modeling Rate Sensing .................

..............

93

................................ 93

.....

........................ 94

...

..................... 96

Fuel Slosh ..............................................

B. 1 Propellant Properties ..................................

.

........................

99

.......................99

.................

B.3 Modeling Fuel Slosh .................................................

B.4 Modeling Input ..................

89

.

A.3 Application to SPHERES ......................

B.2 Fuel Slosh on SPHERES

............. 87

.........................................

.

84

...................... 84

............................................

A. Background Physics ...................

Appendix B

.................... 79

.

Bibliography ........................

Appendix A

....... ........................... 76

...........................

5.2 Conclusions ..............................................

5.3 Future Work ......................

..............70

100

101

...............

............... 103

B .5 Resu lts ....................................................................................... 104

Appendix C

SPHERES Satellite Properties ................

...

............... 107

C. 1 CoM Offset .............................................. ................... 107

C.2 M oment of Inertia...................

................................................... 108

C.3 Thrust Strengths ...................

................

C.4 Thrust Directions ......

.........................

Appendix D

MATLAB Code ..........

.................... ............

............

........

......................

108

109

110

D. 1 Mass Property ID Code .................................................... 110

D.2 Interpolation Scheme ...................................................

D.3 Gyro Filter ......................................

D.4 Angular Acceleration Estimator .......

...

113

........

..................

...........

114

.............. 115

D.5 Batch Mass Property ID ......................................

117

D.6 Recursive Mass Property ID .........

119

Appendix E

C Code ...............

...............................

.......................... . .......

E.1 Mass Property ID Code .................................

E.2 Angular Acceleration Kalman Filter .................

E.3 Mass ID - low level .

.............

.................. 126

................126

.............141

........................................... 146

List of Figures

1.1

SPHERES Flight Satellite

1.2

Ultrasound Beacon

1.3

Standard Feedback Control Representation

2.1

SPHERES Satellite Hanging in a Torsional Pendulum

2.2

Model of One String of the Torsional Pendulum

2.3

Equal Arc-lengths Assumption

2.4

X-Gyro Data from SPHERE SN 2 on the Torsional Pendulum

3.1

Solenoid Valve Thruster 2

3.2

PWM Mixer Code Block Diagram

3.3

Thrust Correction for Simultaneous Firings

3.4

SPHERES Body Axes

3.5

Thrust Latency in Solenoid Valve

3.6

Applied Impulse From Difference in Thruster Latency

3.7

Sample of 6ms Solenoid Delay

3.8

System Pressure Propagation Test Setup

3.9

Pressure Change Propagation Data

3.10

Inertial Measurement Unit Specifications

3.11

Filtered 338 Hz Gyro Noise

3.12

FFT of Gyro Ringing

4.1

Ideal Maneuvers for Inertia and CoM Identification

4.2

Three-Axis Gyro Data From RGA Test

4.3

Concatenated RGA Gyro Data

4.4

AMES/Intellization Mass Property RGA Results [Wilson, 2003]

4.5

Filtered Gyro Data Standard Deviation

4.6

Kalman Filter Process

4.7

Angular Acceleration Estimation Comparison

4.8

Estimation Routine Variances

4.9

Sample Ixx Convergence

4.10

MATLAB vs. Visual C Acceleration Estimation Results

4.11

Visual C vs. Online Embedded C Mass ID Results

4.12

Z-Axis Gyro Data From Online Mass ID Test

4.13

Online Mass Property Estimate Convergence

A. 1

Tuning Fork Gyro

A.2

Gyro Sensing Model

A.3

12 Hz Gyro Noise

A.4

38 Hz Gyro Noise

B. 1

Observed Fuel Slosh in Gyro Data

B.2

Linearized Fuel Slosh Model

B.3

Simplified Fuel Slosh Model

B.4

Fuel Slosh Model Input

B.5

Model Output

List of Tables

2.1

Measured CM Offset vs. CAD Values

2.2

Measured Moment of Inertia vs. CAD Values

2.3

Nonlinear Spring Constant Values

3.1

Thruster Dependencies [Chen, 2002]

3.2

Thruster Locations w.r.t. Geometric Center (GC)

3.3

Thruster Strength and Direction for SPHERE SN 2

4.1

RGA Mass Property Results

4.2

Standard Deviations for Line-fits of Varying Order

B.1

Worst-case Effect of Fuel Slosh on Mass Properties

C.1

CoM Offset

C.2

Moment of Inertia

C.3

Thrust Strengths

C.4

Thrust Directions

Nomenclature

DSP

Digital Signal Processor

ISS

International Space Station

MIT

Massachusetts Institute of Technology

NASA

National Aeronautics and Space Administration

PWM

Pulse-width Modulation

SPHERES

Synchronized Position Hold, Engage, Reorient, Experimental Satellites

SSL

Space Systems Laboratory

CM/CoM

Center of Mass

GC

Geometric Center

DOF

Degrees of Freedom

CAD

Computer-aided Design

C02

Carbon Dioxide

ID

Identification (as in "Mass Property Identification")

(R)LS

(Recursive) Least Squares

IMU

Inertial Measurement Unit

KC

NASA's micro-gravity aircraft, KC-135

KF

Kalman Filter

P

Estimate error covariance

Q

Process error covariance

R

Measurement error covariance

I

Moment of inertia

g

Damping ratio

K

Spring constant

b

Damping coefficient

E

Young's modulus

o"

Stress (Hooke's Law); standard deviation

Pseudo-inverse operator

0, c, a

Angular acceleration

i

Estimate of true value, x

Chapter 1

Introduction

1.1

SPHERES Background

SPHERES (Synchronized Position-Hold, Engage, Reorient Experimental Satellites) is a

high fidelity test-bed designed to help develop and mature algorithms for formation flight

and autonomous docking. The test-bed includes three satellites with full six degrees of

freedom (6-DOF) control authority and a relative and absolute positioning system.

SPHERES is meant to be a low risk platform for testing experimental spacecraft

navigation [10, 15, 16].

The SPHERES program began as an undergraduate design course in the Department of

Aeronautics and Astronautics at the Massachusetts Institute of Technology (MIT).

Juniors and seniors were asked to design and build a platform for testing formation flight

algorithms over a span of three academic terms. Because of the growing interest in

formation flying satellites in the aerospace industry, many interested parties such as the

Defense Advanced Research Projects Agency (DARPA), National Aeronautics and Space

Administration (NASA), and Lockheed Martin invested in SPHERES as a graduate

research program.

The SPHERES satellites were redesigned and rebuilt with the

intention of operating for an extended period of time aboard the International Space

Station (ISS). They have been tested extensively at the MIT Space System Laboratory's

(SSL) float table (2D configuration) and in micro-gravity aboard NASA's Reduced

Gravity Airplane (RGA). Three SPHERES satellites and accompanying test equipment

were launched to ISS throughout 2006.

Figure 1.1 SPHERES Flight Satellite

This thesis first presents an overview of the SPHERES testbed hardware, including the

satellites themselves as well as the ultrasonic positioning system equipment. Next, it

presents the offline and online characterization of key system parameters of the

SPHERES testbed. First, mass properties of the SPHERES satellites are examined, with

comparison between CAD model estimates and empirically determined values (Chapter

2). Next, experiments performed to characterize the SPHERES satellite's propulsion

system and sensor suite are detailed (Chapter 3).

Finally, online mass property

identification algorithm is introduced and compared with previous results (Chapter 4).

1.2

SPHERES Hardware Overview

The SPHERES hardware was designed and built collaboratively by the MIT Space

Systems Laboratory and Payload Systems Inc. There are five identical satellites in

operation (two for ground testing at MIT, three for experiments aboard the ISS). Each

SPHERES satellite has an aluminum truss-work skeleton that provides mounting points

for the avionics, propulsion system, and sensors. A color-coded, translucent plastic shell

protects this equipment and helps provide easy identification.

The subsystems relevant to this thesis are described below. Other subsystems include the

CPU and signal processing, power, communications, and the control laptop with the GUI,

but will not be introduced here. Refer to [13, 16] for more information.

1.2.1

Inertial Sensors

Each SPHERES satellite has six inertial sensors, three accelerometers and three

gyroscopes. The three Honeywell accelerometers are mounted in three orthogonal axes

in the body frame. They are designed to measure a fine resolution of linear acceleration

produced by the onboard thrusters. While this is ideal in micro-gravity, accelerometer

data is unreliable at the 2D MIT facility (the accelerometers are saturated by the presence

of gravity when the satellite is tilted by more than one degree).

Similarly, three

gyroscopes are mounted on each axis to provide angular rate information.

1.2.2

Propulsion System

SPHERES satellites accelerate using a cold-gas propulsion system (carbon dioxide,

CO2). The multi-phase C02 is stored at 860 psi in a tank located in the middle of the

satellite. The gas is regulated to 35 psi and fed through an expansion capacitor to the 12

solenoid-actuated valve thrusters. When a command to fire is sent through the Digital

Signal Processor (DSP) to the firing circuit, the corresponding thruster solenoid is

actuated, allowing the pressurized CO2 to escape and provide thrust. The 12 thrusters

can be commanded either ON or OFF (no intermediate settings or throttle) and are

controlled via pulse-width modulation (PWM). They are located around the satellite so

as to provide full, uncoupled control in 6 Degrees of Freedom (6-DOF).

1.2.3

Ultrasound-based Positioning System

Most space systems have some way to measure absolute position (e.g., star-trackers or

GPS). A localized system involving ultrasonics was developed for SPHERES in order to

operate inside the ISS. Given a priori knowledge of the pre-programmed delays in the

beacons, the DSP computes the time-of-flight of the ultrasound pings, which travel at the

speed of sound.

The time-of-flight is used by an Extended Kalman Filter (EKF) to

estimate absolute translational and angular position and velocity.

Figure 1.2 Ultrasound Beacon

Each SPHERES satellite is equipped with its own onboard beacon to allow for satelliteto-satellite relative ranging and bearing angles (more accurate for close proximity

maneuvers).

1.3

Current Programs

SPHERES is designed as a flexible platform for testing autonomous spacecraft

algorithms, specifically targeting rendezvous and proximity operations (RPO) and

formation flight. Related ideas include such topics as servicing spacecraft [14], spacetethers [6], formation flying interferometers [11] and space-network topology [19]. The

SPHERES project offers an opportunity to do research in this area as a low cost, low risk,

and high fidelity hardware simulation.

By operating inside the ISS, the SPHERES

testbed exploits the micro-gravity environment to represent the dynamics of docking

missions while protecting itself from getting lost in space when real or simulated failures

occur.

Space-based interferometry is an especially interesting topic because of the consistent

demand for higher resolution pictures in space. In order to get better quality images from

orbiting telescopes like Hubble, the diameter of the primary mirror would have to grow in

size. However, a telescope with a larger mirror would not fit in any launch vehicle

available today.

Rather than designing and building a launch vehicle with a higher

payload volume, interferometry can be used to get comparable quality images using

multiple smaller telescopes arranged in a precise pattern.

Spacecraft autonomy is a very powerful concept. Without the need for human assistance,

satellites can operate efficiently for longer lifetimes in orbit. Fault Detection Isolation

and Recovery (FDIR) is a big step towards fully autonomous spacecraft [20]. Systems

with FDIR can detect failures in their components and adjust accordingly to fulfill their

primary objectives. A more specific example of this applied to SPHERES is thruster

FDIR. Using the firing commands given by the software and the measured dynamics

from the onboard sensors, an FDIR algorithm can isolate thruster failures and alter future

firing commands with this failure taken into account.

Another, more basic fundamental of autonomy is estimation. The more accurate the

information is in the state vector, the better the control performance can be. The goal in

autonomous estimation is to identify relevant system parameters online (especially

changing ones like fuel mass).

A mass property identification algorithm has been

developed for testing on the SPHERES testbed [21].

It has the ability to give a

continually updating estimate of the Center of Mass (CoM) and Moment of Inertia by

using thruster commands and gyroscope data. These estimated values then impact how

commanded forces and torques are manifested as thruster ON/OFF times.

This wide variety of research topics is the focus of the SPHERES project. Many

algorithms have gone through multiple levels of iteration, with offline testing in

MATLAB and other computational tools, and online testing on the SPHERES satellites at

the 2D testbed at MIT as well as several flights on NASA's RGA micro-gravity

"laboratory" and aboard the ISS.

1.4

System Characterization Motivation

It is an inevitable consequence of the manufacturing process that misalignments,

asymmetries, and other minor flaws are created that affect the performance of any

assembly. Though all SPHERES satellites are meant to be identical, there are slight

inconsistencies that cause each to behave differently. Correcting or accounting for these

errors can be addressed in multiple ways, including but not limited to using stochastic

values or designing controllers to compensate for sensor noise or uncertainty in specific

parameters of the plant model.

Regardless of which methods are employed, the

underlying truth holds that the more that is known about the system, the easier it will be

to control and improve performance. Efficient use of consumables (pressurized gas and

batteries) is a universally important issue for space applications, and is crucial for

extending the life of SPHERES as test-bed aboard the ISS, as well as countless other

space vehicles.

The first part of our strategy for improving system performance is to make SPHERES

behave the best possible in open loop. This is accomplished by fully characterizing the

propulsion system (Actuator) and the vehicle itself (Plant). This system characterization

is used to calibrate and tune the control software and allow the SPHERES satellite to

perform open loop maneuvers, like flying straight, with better accuracy.

However, there is only so much we can accomplish with characterization and calibration

while SPHERES is on the ground. Some system parameters like CoM and Inertia will

change as fuel is depleted (or in cases of other satellites, when components are deployed

or jettisoned or docking with another spacecraft has occurred). Online estimation of

these parameters can extend mission lifetime by allowing more accurate maneuvers and

by using the on-board fuel more efficiently. An online mass property identification

algorithm developed at the NASA AMES Research Center [Lages, Wilson, Mah] [21]

has been implemented for use on SPHERES to identify CoM and Inertia. In addition, the

Inertial Measurement Units (Sensor) used to close the loop are examined.

Figure 1.3 depicts a standard control-loop representation with the feedback as a dashed

line to signify an open loop system. The input to the control software is in the form of

desired state (position, attitude, velocity and angular rates). This is transformed to body

forces and torques and then passed through a "mixer" to get thruster ON/OFF times for

each of the 12 thrusters. The thrusters apply forces and moments on the plant and the

inertial sensors measure angular rates and linear acceleration.

.... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ...

S0

X

!

:

... ... .

Controller

0

--0

. .. .. . .. .. . .. .. . .. .. . .. .. .. . .. ..

4,--

aI

. .. .. . .. ..

Output

I

Jr

Figure 1.3 Standard Control-Loop Representation

We use this representation as a model for the organization of the SPHERES System

Characterization in Chapters 2 and 3.

The Plant, Sensors, and Actuators are fixed

(already built/purchased), so our only form of correction is in the control software. After

presenting predicted and empirically measured values for key system parameters, online

mass property identification is introduced and compared with previous results (Chapter

4).

Chapter 2

SPHERES Mass Properties

2.1

Mass Properties Overview

Modem spacecraft are designed using computer-aided design tools such as ProEngineer

and Solidworks.

Many CNC workshop machines can replicate parts directly from

imported CAD files. This allows for a high level of fidelity between the conceived

design and the ultimate product. However accurate the machine, there are bound to be

inconsistencies between "identical" pieces. CAD estimated values for mass properties

could be unreliable because of this assumption.

Also, some parts (like electronics

boards) are modeled crudely and thus do not truly represent their effect on mass, CoM,

and Inertia of the assembled satellite.

Still other errors can arise from hollow

components that are approximated as solid objects. The most important error source

from CAD drawings is assembly of components.

Most of the time, fixation devices

(screws, rivets, bolts, nuts, soldering joints, etc.) are not modeled in a CAD drawing, and

the assembled parts are assumed to be perfectly assembled, when in fact we know that

there is always clearance in a bolt hole and the bolt is likely not to be centered in the hole.

These error sources, along with discrepancies introduced from the manufacture and

assembly processes, indicate that there is plenty of room for improvement in the accuracy

of our mass property estimates.

Table 2.1 shows the discrepancy between predicted

(CAD modeling) and measured CoM offset of one the SPHERES satellites.

I

CAD Model

Measured

0.49

-1.24

3.98

0.37

-1.52

3.32

0.48

-1.19

1.08

0.82

-0.99

1.07

Table 2.1 Measured CM Offset vs. CAD Values

These tests were repeated for all five SPHERES satellites with a full C02 tank (Wet) and

an empty tank (Dry). How the gas settles and sloshes does have an impact on CoM and

Inertia but will not be discussed in detail here (refer to Appendix B).

2.2

Measuring Center of Mass (CoM)

To get a more reliable estimate of the SPHERES satellite mass properties (Plant

parameters), a test stand was built that holds a SPHERES satellite rigid, while keeping its

center of geometry in a very precise, known location (Figure 2.1). The stand consists of

an aluminum plate with various mounting points and four rectangular posts that allow

access to screw into the frame of the SPHERES satellite. A SPHERES satellite can be

mounted along any primary axis to this stand. It was designed to attach to the top of a 6DOF load cell (for measuring thruster strengths and CoM) and to a torsional pendulum

harness (for measuring moment of inertia).

The primary function of the load cell is to measure forces and torques applied to it.

Before each CoM test, the signals from all six channels (corresponding to each DOF)

were recorded using a SigLab Data Acquisition System.

These measurements were

averaged and saved as bias estimates. The same was done with the empty test stand. By

positioning the center of geometry of the SPHERES satellite directly over the center of

the load cell, we can determine the torque applied by the CoM offset of the satellite alone

(removing the other recorded biases).

From the two horizontal moments applied on the load cell, we get the CoM offset in two

axes. For the

3 rd

coordinate, the SPHERES satellite is rotated so it's mounted on its side

and the moments are measured again.

2.2.1

CoM Error Sources

When measuring offsets on the order of millimeters, any slight misalignment will drown

out the true value. The test stand was meticulously designed and each test carefully

performed, but errors on that scale of magnitude are difficult to avoid completely. The

four screws that secure the test stand to the load cell are M4x.7 (Metric screws, 4.0mm in

diameter, 0.7 threads per mm). The through-holes on the test plate were made with the

recommended clearance of 4.5mm, leaving 0.5mm of play. With CoM values ranging

from 0-3mm, this is a significant source of error. By assuming the error bias is close to

zero mean, averaging over many tests: can provide reasonable estimates.

2.3

Measuring Moment of Inertia

The principal moments of inertia were measured using a trifilar torsional pendulum. An

aluminum mounting plate supports a satellite while hanging by three strings from another

plate bolted to the ceiling.

A specially modified outer shell was used to allow a

SPHERES satellite to be mounted in six different orientations. The two aluminum plates

were designed to allow leveling in both horizontal axes.

The top plate is mounted in two locations to a metal rail secured to the ceiling. By

adjusting these two mounting points, the top plate can be leveled along the axis

perpendicular to the rail. To level the other horizontal axis, there are two thumbscrews

that can be torqued into the ceiling, raising or lowering either side of the plate. The three

8 ft. long strands of fishing line are tied to steel bolts screwed into the ceiling-mounted

plate. They are threaded through a fine hole drilled through the length of each bolt to

minimize lateral strain on the strings.

The opposite end of each string is tied to aluminum mounting adapters. Similar to the

steel bolts at the top, the strings are threaded through a small hole in the center of the

adapter. The bottom of the adapter is threaded with a standard %-20 thread, which is

used to secure it to the bottom plate where the SPHERES satellite is mounted, as shown

in Figure 2.1. The threaded adapter also allows for independent leveling of the bottom

plate, which is important for inertia tests. Three mounting points, though coupled, can

still allow the leveling of both horizontal axes.

Figure 2.1 SPHERES Satellite

Hanging in a Torsional

2.3.1

Torsional Pendulum Modeling

The motion of a trifilar torsional pendulum is a nonlinear problem because the strings

restrict each other's movement and are therefore coupled. This causes the test object to

lift slightly as the pendulum oscillates. The test equipment and conditions were designed

to minimize the effect of these phenomena on the measured inertia (long strings of >8 ft;

string length >> mounting plate radius; small oscillations of <200 amplitude). In order to

determine the equations of motion, a simplified conceptual model will be used. Figure

2.2 is a force diagram representation of one of the three suspension strings modeled as a

simple pendulum in 2-D.

Force equilibrium along the axes parallel and normal to the string:

YF = T -mg cos 0= 0

(2.1)

SF

1 = mg sin 0 = fm0

y

T

m9

Figure 2.2 Model of One String of the

Torsional Pendulum

Solving for T: T = mg cos b (assumes even distribution of weight between the three

strings). Since the string is attached to a plate with negligible vertical mobility, Fx is

assumed to be the torque applied to the mounting plate.

xFx =Tsin

= mgcosOsinO

(2.2)

From the rotational equations of motion: rxF = 1M, where r is the radius of the circle

defined by the three string mounting points, I is the rotational inertia of the entire rotating

assembly, and 0 is the angle through which the mounting plate has turned. Substituting

for F and including a damping term gives:

-mgr cos 0 sin 0 - !; = MI

(2.3)

Since the strings are so long and the angle that the pendulum rotates through is so small,

the arcs of the two angles 0 and 0 are approximated as equal: O==Or.

approximation is shown in Figure 2.3:

These arc-lengths

assumed equivalent

Figure 2.3 Equal Arc-lengths Assumption

'

r

This

This produces a non-linear damped harmonic oscillator:

1 ++g0+mgrcos r0 sin(

) =0

(2.4)

The type of string used was a long, thin monofilament line with very small energy

dissipation (assumed massless). Also, energy loss to drag from the ambient air is small

due to the circular profile of the satellite and the low angular velocities. For these

reasons, the damping term was considered negligible.

Inputs will be of the form of an initial displacement 40 from the pendulum's equilibrium

point such that 0= 00cos ( . Substituting for 0,and solving for I:

I=

mgr

"o62COS( C)

cos( 0 cos(C)

(.

sin r90 cos(C)

)

(2.5)

(t 1

As was mentioned earlier, this test is designed to run for small values of 0 = 0ocos a .

Using small angle approximations for sine and cosine (~ << 1 and

r9

O<<1), Equation

(2.5) becomes:

m gr

I = mg

I0

For this particular setup, the values are:

m - mass = 7.172kg

g - 9.8m s2

r -radius = 0.146 1m

I -length - 2.47m

I0 -baselnertia= 0.0448kgm2

o- frequency

(2,6)

2.3.2

Test Procedure

The test: object is weighed before every experiment. After weighing, it is secured on the

mounting plate, then the plate is leveled using a dual axis high precision level. The last

pre-test procedure is measuring the length of the strings.

Finally, an oscillation is

initiated by turning the pendulum through a slight angle and releasing, being careful not

to impart any translational motion. Using Equation (2.6), it is possible to determine the

inertia of the object about that axis by measuring the frequency of oscillation. Inertia

measurements with only the test stand were performed to remove the bias of the stand.

2.3.3

Products of Inertia

This method was helpful to determine the primary moments of inertia, but not the offaxis terms. It is possible to use the same experimental setup to find the off-axis terms

using Mohr's Circle [3]. The Principal Axes of an object are defined as the axes around

which the products of inertia are zero. If a test object were mounted so that it could be

incrementally rotated around the x-axis, and inertia estimates were taken for many

different combinations of axes in the Y-Z plane, the resulting values would be sinusoidal.

The maximum and minimum values of this sinusoid (in 3-D) correspond to the Principal

Axes. If the object were rotated through an angle B in the Y-Z plane, the measured

inertia is related to the product of inertia by Equation (2.7).

IBrz = Iz sin 2 B+ Iy, cos 2 B-IPz sin2B

(2.7)

The minimum number of measurements necessary to determine products of inertia is six;

assuming three orthogonal axes are used for a basis. One measurement about X, Y, and

Z is needed as well as one each about axes 45 degrees between the X-Y, Y-Z, and Z-X

axes.

Unfortunately this: method requires more mounting configurations than are available on

the current test stand, and so the products of inertia were not measured empirically.

Since the SPHERES satellites are designed to be symmetric, the off-axis terms are a

couple orders of magnitude below the primary inertias (according to the CAD predictions

and online mass property results) and thus much more prone to mounting errors and

mathematical assumptions.

2.3.4 Results

Table (2.2) shows sample inertia data for one satellite, comparing CAD predictions to

empirically measured values. As seen in the table, they are similar but vary by nontrivial

amounts. The discrepancy is expected because of the inherent inaccuracy of CAD

predictions for heterogeneous objects. The error analysis described in Section 2.3.6 and

the results from the online mass property identification algorithm verify that the empirical

values are better candidates for measures of truth.

I

Measured

CAD Model

2.30

2.19

2.57

2.45

10.5%

2.42

2.31

2.25

2.15

7.6%

2.14

2.13

2.03

2.03

5.4%

0.01

0.01

n/a

n/a

n/a

-0.03

-0.03

n/a

n/a

n/a

-0

-0

n/a

n/a

n/a

Table 2.2 Measured Moment of Inertia vs. CAD Values

2.3.5

Alternate Method for Measuring Inertia

An alternate method for measuring inertia was attempted. The strategy is to approximate

the entire torsional pendulum as a torsional spring with spring constant K.

r =10 =K-O

9= A sin(ot)

I=

(2.8)

K

The procedure in this case is to measure K by testing an object of known inertia and use

that K value for all future tests. It turns out however that this is an over-simplification of

the torsional spring since, when compared to Equation (2.6), K depends on m and m

which is not constant:

K=

mngr

2

(2.9)

If the spring were linear, it would exhibit strain displacement proportional to applied

stress and K would be constant.

behavior.

Table 2.3 shows data supporting this nonlinear

The first row includes data from a torsional pendulum test with just the

mounting plate.

The second row is from a test with a SPHERES satellite mounted

(inertia values are validated from CAD models and online estimation).

0.0448

0.0674

2.286

2.933

0.2341

0.5802

Table 2.3 Nonlinear Spring Constant Values

The estimates for off-axis terms of inertia have come from running an offline version of

AMES/Intellizations's

gyro-based

mass

property

identification

algorithm

[21].

Gyroscope data collected in micro-gravity on the RGA provided the necessary

information to determine off axis inertias. The algorithm itself is discussed in full detail

in Chapter 4.

2.3.6

Inertia Measurement Error Analysis

The moment of inertia characterization is vulnerable to many error sources ranging from

the background math and physics to the test implementation and execution.

Mathematical Approximation (equal arc lengths, small angle, no damping)

To properly reduce Equation (2.4), the arc lengths Of and Or are assumed equal. This is

a slightly less "risky" assumption than using small angle approximations for 0 and (b.

Since 0 is the larger angle, it has the highest potential for error under the small angle

assumption. Showing that the small angle assumption for 0 is negligible will then prove

the equal arc-lengths assumption negligible as well. As part of the test procedure, the

maximum value of 0 is 20 degrees (0.349 rad). The length of the arc defined by 0 is

rO = 0.025499m.

2r sin -

The length of the chord that approximates this arc is

= 0.025467m, which is an error of 0.000259m (0.5%). Inertia varies linearly

with this error, so none of the angle assumptions will affect inertia by more than 0.5%.

The equations used also assume that the damping is negligible. The damping ratio can be

determined by examining the rate of descent of the oscillation amplitude.

I

; = 2 •ln(at1

(2.10)

The percent error in measured inertia is equal to 100;2 [3]. The data in Figure 2.4 was

taken for the X-axis inertia of SPHERE SN 2.

SN 2 lxx Measurement Data

2400

2300

2200

.4

4

2100

.4.

2000

4*

4

1900

,i.

1800

1 7n

0

o

I

I

500

1000

Update Number (50 Hz)

1500

Figure 2.4 X-Gyro Data From SPHERES SN 2 on the Torsional Pendulum

Over these 13 oscillations, the amplitude dropped from 306 to 299 counts:

n=13

a0 =306

a = 299

S26In 30

(2.11)

99) = 2.833e

error = 100ý 2 = 8.0267e-6%

There would need to be much more severe damping to have a noticeable impact on

inertia measurement.

Mounting error and string load distribution

There are a number of reasons why the axis of rotation might not coincide with the CoM

of the test object. Among them are mounting error, offset between the geometric center

and the CoM, and string load distribution. The transformation for inertia about parallel

axes is used to characterize the effect of this misalignment:

I B = I + mrA,

(2.12)

According to the "Mass Properties Measurement Handbook" [Boynton, Wiener] [3],

offsets around 1% of the radius of gyration are negligible, which is 1.461mm. The most

obvious source of misalignment is mounting error. The mounting plate and test stand

were: designed in CAD and machined to 0.001 in tolerances (0.254 mm) to hold a

SPHERES satellite securely in the middle of the three strings. Another possibility is that

the CoM of the satellite is not at the center of geometry. Most CoM measurements have

fallen in the range of 0-3 mm and are on the order of negligible errors. A third source

comes from the load distribution in the strings. If the tension in the strings is not equal

the axis of gyration will not be centered, imitating a CoM offset error. This is why care is

taken before each test to level the mounting plate. Having one comer of the mounting

plate lower than the others would tilt the measurement axis and could change the

pendulum's equilibrium point.

Such errors would cause the inertia to vary by md 2 (Equation 2.12) where d is the

distance between the CoM and the axis of gyration. A conservative estimate of 1 cm for

d results in an inertia error of SI = 0.000717kg .m 2 (1.025%).

Elasticity in the string

The inertia measurement equation is a function of the length of the strings holding the

test plate. Since the strings are stretching and contracting through these oscillations, this

length is not truly a constant. The string used was nylon fishing line with a Young's

Modulus of approximately 3 GPa.

A nominal value for load would be 23.52 N

m 1

(7.2kgx9.8 -- x-, assuming equal load on all three strings). Using a diameter of 2mm,

s 3

the cross-sectional area of the string is 3.14e-6m2 . From Hooke's law:

E=

E

= 0.002496

(2.13)

1

According to Equation (2.6), inertia varies with string length as -. In the range of values

of e used for these tests, the relationship is close to linear (-1% change in £ leads to

-1% change in I). For example, using a nominal string length of 2.6m, S&= 0.0065m.

This translates into a change of I equal to SI =0.000175kg.m2 , or a 0.7% error. As

shown earlier, the strain in the strings does not vary linearly with the applied stress,

making Hooke's law invalid. However, since the error due to string stretching is so

small, the effect of this linear approximation is negligible.

Measurement Error (weight, string length, oscillation period)

The period was measured by using a stopwatch to time 10, 20, and 50 oscillations. The

time at each of these checkpoints is used to estimate the period and data is averaged. The

measured time on the stopwatch (T)is related to w by the number of oscillations. For a

test over 20 oscillations:

2r

40"

ST= -;=T

20

(2.14)

2

I=

1600n

. T

•

(2.15)

Using nominal values for m and £, I changes by I = 0.0007696kg. m2 (1.194%) with a

measurement error of ST = 0.25s. This error source was addressed by collecting data

from tests as long as 50 periods as well as averaging over 10-20 tests per SPHERES

satellite, per axis, and per wet/dry configuration. Inertia sensitivity to changes in mass

would be less than sensitivity to time errors since inertia varies linearly with mass.

Sensitivity to changes in string length was discussed earlier, with respect to string

elasticity.

Orthogonal Rotational/Translational Motion

If the SPHERES satellite is rotating or translating in any direction outside of the desired

axis (vertical rotation), more complicated equations of motion would be needed to

accurately describe this behavior. The equations of motion used assume no translational

movement, and care was taken during the experiment to minimize the amount of this

motion.

Because of the coupling in a trifilar torsional pendulum, a CoM misalignment causes

sideways motion.

The energy in the translational oscillation is not included in the

rotation frequency (and therefore not observable in inertia measurements), and the

nonlinearity of the pendulum is amplified.

Consider that the torsional pendulum acts as a simple harmonic oscillator in both degrees

of freedom of interest:

A) a disc of mass m and radius r that oscillates about its center (amplitude of 0=20')

B) a mass m on a string of length f that swings at very small amplitude (0.01m)

causing unwanted side-to-side motion

The total energy of a simple harmonic oscillator is:

1

E= K.A2

(2.16)

2

where K is the spring constant and A is the oscillation amplitude.

1

In Case A, E A = -K AA

A where

2A

2

A IcoA=

(2.17)

AA =

r

For a circular disk, I = mr

2.

From Equation (2.6),

2

ac

ingr

it

2

Substituting into

Equation (2.16) yields:

EA

1

In Case B, E, =~KA where

2

2

202

(2.18)

KB = mfLoW

K'~

A, = O.Olmeter

For a simple pendulum, co2 = g

= r

(2.19)

Substituting into Equation (2.16) yields:

1 mg(2

SMg (0.01)2

2f

(2.20)

Assuming a translational amplitude of 1cm ( A = 0.01) and a rotational amplitude of 20'

( A = 0.349 rad),

E A = 0.037005J

E, = 0.001423J

(2.21)

SI = 0.002799kg -nm2

This constitutes an inertia error of 3.845%. Alternatively, if A, = 0.005 the inertia error

is 0.961%.

2.3.7 Empirical Mass Properties Conclusion

There are two goals for empirically measuring SPHERES satellite mass properties. The

first is simply to collect accurate information about the vehicle so that the controller can

be as efficient as possible. The obvious advantage to this is more precise maneuvering

and better fuel efficiency. This plant characterization continues in Chapter 3 with an indepth characterization of the CO 2 thrusters.

The second goal is to establish a truth measure for the online mass property identification

described in Chapter 4. From section 2.3.6, almost all the error sources in inertia

calculation are around or below 1%. Adding them together as a worst-case scenario still

amounts to <5% error. Because of this, the empirical inertia values serve as adequate

truth measures for online mass ID. However, because of the small magnitude of CM

offset, it would not be surprising to see deviations on the order of the values themselves,

despite how meticulously the mount was created and the tests were performed. While

averaging over several tests can help to remove some of the error bias, the CM

measurements are not exceedingly reliable as truth measures.

Chapter 3

Thruster Characterization

3.1

Propulsion System Overview

SPHERES satellites maneuver using twelve ON/OFF solenoid valve thrusters that

provide%independent control in three axes of rotation and three axes of translation. The

fuel used is cold gas (C02) and is stored in mixed liquid/gaseous phase in a tank at the

center of the satellite.

Since it is multiphase C02, the pressure inside the gas tank

remains constant at 860 psi until all the liquid evaporates. Directly downstream of the

tank is a variable pressure regulator calibrated to provide 35 psi C02 when the regulator

is completely opened. After the regulator is a small gas capacitor that allows any liquid

CO2 to expand before reaching the plastic tubing and the thrusters themselves.

The

capacitor also helps maintain constant pressure downstream when thrusters are opened.

The C02 is then fed through a series of manifolds and tube branches to supply all 12

thrusters with gas.

3.2

Propulsion Hardware

The fuel tank was placed near the center of the satellite along the Z-axis to minimize the

error induced by fuel depletion and slosh on the CoM and moment of inertia. While the

fuel is mixed phase, the pressure inside the tank remains constant at 860 psi. Once all the

liquid has expanded into gas (occurs with -28g of C02 remaining), the tank pressure

begins to drop as more C02 is expelled. Since this only occurs when the tank is almost

empty, we can assume a constant pressure supply for almost all tests.

The gas capacitor serves two purposes: allowing solid and liquid C02 to expand to

gaseous form and to provide a small buffer for changes, in supply pressure or demand on

the regulator. Through continuous firing, the regulator will start to get cold. When this

happens, its more likely that liquid C02 will make it into the piping past the regulator,

which can damage the tubes and thrusters or produce off-nominal behavior. This has

been seen even with a warm regulator when the tank is upside-down in 1-g and in microgravity. Also, there is a time constant associated with the regulator's ability to react to

changes in demand for C02, which occurs whenever a thruster is commanded on. As gas

is expelled through that thruster, the pressure drop propagates up the system back to the

regulator, which opens wider to maintain a constant 35 psi.

compensate for this delay since it acts a small reservoir of fuel.

The capacitor helps

Figure 3.1 Solenoid Valve Thruster 2

As per the control model representation in Figure 1.3, the thrusters (Actuators) are the

most important part of the propulsion system to characterize. The thrust exerted by the

solenoid valve thrusters depends on a number of things. A summary of applied thrust

dependencies obtained by [Chen, 2002] [5] is listed in Table 3.1.

Always set to 35 psi (regulator modified with slip

ring to "bottom out" at 35 psi)

Measured with an in-line contour projector

Solenoid variation negligible.

System

Pressure

Nozzle Area

Solenoid

Mechanics

# Open

Thrusters

Temperature

Firing

Duration

Thrust varies linearly with # of open thrusters

(R2=0.9955)

Negligible

Negligible - slightly positive slope in thrust profile

(<5% change after 70 sec)

Table 3.1 Thrust Dependencies [Chen, 2002] [5]

The location of each thruster was taken from the engineering CAD model used to build

the SPHERES satellites.

Table 3.2 has the nominal positions of each thruster in

centimeters relative to the geometric center of the vehicle:

-5.16

-5.16

0.00

0.00

9.65

-9.65

-5.16

0.00

-9.65

-9.65

-5.16

0.00

-9.65

-5.16

0.00

0.00

-9.65

-5.16

0.0 -. 65

-5.65

5.16

0.00

-9.65

9.65

5.16

0.00

-9.65

5.6

0.00

0.00

9.65

5.16

0.00

-9.65

5.16

Table 3.2 Thruster Locations wrt Geometric Center (GC)

3.3

Pulse-Width Modulation Scheme

In most of the control schemes run on SPHERES, the outputs of controllers are forces

and torques.

For variable-force thrusters and reaction wheels this is a fairly

straightforward command. However, since the SPHERES thrusters are binary, a PulseWidth Modulation (PWM) scheme is used [10]. This is accomplished using a mixing

matrix to transform forces and torques to thruster ON/OFF times. Figure 3.2 describes

the mixer process end-to-end.

Controller

Command

Mixing Matrix

(MMT )-

M* =M

Resolve Opposing Thrust

Resolve Negative Values

Scale by

Maximum

xT

Dead Zone

Pulse Centering

Ii

Multiple Thruster

Correction

.I

Check

TON >0

TOFF < T

Schedule

Propulsion

Interrupt

Srigure 3.L WIVwI MViixer •ole block Diagram

The mixing matrix that transforms the command vector into thruster ON/OFF times is

constructed using the calibrated force vectors for each thruster. First, the top half of a 6

by 12 matrix is populated with the three force vector components from each thruster. On

the bottom half, instead of force there is the cross product of force and location, leaving a

vector of torques for each thruster.

F2

...

F-2y

F1z F

F2g --. F12Z

MM=MT

Next, the pseudo inverse of this matrix is obtained:

=M

(2.1)

When a command

vector is multiplied by the matrix MA, the result is a vector of length 12 of commanded

forces normalized by each thruster's nominal force (i.e. a "2" means the controller wants

that thruster to fire twice as hard as it actually can). Since SPHERES uses pulse width

modulation, these numbers are actually fractions of the control period rather than

fractions of the desired force. If any of these values is greater than 1, then they are all

scaled down so that the net direction of the commanded firing will remain the same. If

all values are below 1,then net impulse can be conserved as well.

The next step is to take the vector of thrust durations and center all the pulses about the

middle of the control period. The algorithm then accounts for multiple-thruster pressure

drop by starting with the thruster with the smallest pulse and calculating how much

impulse is lost on that thruster and extending the pulse accordingly (using the linear

relationship between number of open valves and drop in thrust [5]). From here, the

algorithm works outwards, finishing with the longest pulse. Ideally, this would be an

iterative process, but for now our mixer does this just once.

The final step is to

implement a deadband of 10 ms (minimum time needed for thrusters to open) and round

up pulse durations that are very close to the entire period.

Figure 3.3 shows a simple example of how the commanded firing durations of two

thrusters are altered to account for strength differences and the drop in system pressure

when multiple valves are open. Since the thrusters are pulse-width modulated, the firing

duration of the thruster with strength F 1 is shortened and then the pulses are centered so

that there is no residual torque applied. The total area would be kept constant as well to

have the same applied impulse.

Corrected

Thrust command is pulse

Uncorrected

c

Thri .cqf

width mnrli ilat••

F2

F2

-

hnrf~n

F

pulse to account for higher

thrust and multiple thruster

pressure drop

,F

Thrust

F2

t

Figure 3.3 Thrust Correction for Simultaneous Firings

t

3.4

Propulsion Limitations

There are a couple of limitations that complicate the SPHERES PWM system.

The

solenoid actuators have a mechanical limitation that requires a 10ms opening transient.

This means that 10ms is the minimum impulse bit for thruster commands. Also, because

of how fast the propulsion software interrupt runs, the resolution with which a thruster

can be turned off is 1 ms.

Lastly, thrusters cannot be on during any ultrasound

measurement period since they can be misinterpreted as ultrasound signals used in the

position and attitude determination system.

This requires scheduling between global

position updates and command periods.

3.5

Measuring Nominal Thrust Vector

Nominal forces from the thrusters are key parameters for SPHERES system

characterization. Each thruster was turned on and off for one second while testing on the

load cell. The measured forces and torques over time in each axis were collected with a

SigLab data acquisition system and processed with MATLAB scripts to filter out teststand vibrations, change coordinate frames, and decouple forces and moments. Force

components were averaged over the one-second pulse to create a nominal vector of

applied force in all three axes for each thruster. From this, the resultant thrust magnitude

and direction were determined.

This characterized both the nominal thrust of each

solenoid valve as well as its misalignment with the satellite body axes. These nominal

values were averaged over 200-500 tests per SPHERES satellite.

The same 6 DOF load cell and test stand used to measure the Center of Mass was used to

measure nominal thrust strengths. A test program was written to cycle through all 12

thrusters in order and loaded onto a SPHERES satellite beforehand. This vehicle, with a

full tank and batteries, was mounted upright on the test stand with the regulator knob

pointing up. The power was turned on, the-1ropulsion system was pressurized and data

collection on SigLab begun right before the "start test" command was initiated from the

ground station laptop. Each test was run 5-10 times for repeatability.

_IV.

+Z

Af

Y

Figure 3.4 SPHERES Body Axes

Because of the geometry of the SPHERES satellite and the test stand, the two thrusters

pointing down would not register correctly on the load cell. This is because the force

from those thrusters is cancelled by itself since it reacts against the test stand. Therefore,

like with the CoM tests, the satellite was rotated 90 degrees and the tests performed again

to get the last two thruster strengths.

Since the load cell is 6 DOF, the output data

included forces and torques in three axes, so the misalignment of the mounted thrusters

could be examined.

Table 3.3 shows sample thrust strength and direction numbers for SPHERE SN 2. These

tests were conducted on all five of the flight satellites. As expected, these thrust strength

2

numbers are reasonably correlated with nozzle area (R = 0.42). "Dx," "Dy," and "Dz"

form the components of a unit vector in the direction of force for a given thruster. As the

chart shows, most thrusters have a unit vector direction aligned to at least 0.996 along the

principal body axes.

0.134

0.004

0.998 -0.022 0.025

0.130

0.002

0.999 -0.001 -0.025

0.122

0.006

0.059

0.996 0.032

0.130

0.004

-0.018

0.999 0.004

0.114

0.005

0.011

0.034 0.999

0.124

0.006

-0.022 -0.012 0.999

0.134

0.004

-0.999 -0.008 0.044

0.130

0.003

-0.998 -0.009 -0.037

0.128

0.006

0.042 -0.999 0.009

0.132

0.005

-0.019 -1.000 0.004

0.126

0.006

0.004 0.060 -0.998

0.110

0.005 I -0.002 -0.030 -0.999

Table 3.3 Thruster Strength and Direction for SPHERE SN 2

3.6

Thruster Latency

Each solenoid has a latency of about 6 ms. If we assume that thruster firings will be

much longer than 6 ms (say 1-2 orders of magnitude), then the difference in delay

I

between thrusters should not be a concern. Some tests were conducted on the prototype

SPHERES satellite to get an idea for this "relative" delay between thrusters.

For

example, two thrusters in the same direction were commanded to fire and the produced

torque was measured on a load cell.

Figures 3.6 shows some samples of the torque data from the load cell. The horizontal

axis is in seconds. Every two seconds both parallel thrusters were commanded to fire for

one second. The first maneuver at t = 0 seconds had Thruster A firing 3 ms before

Thruster B. Two seconds later, Thruster A fired 2 ms before Thruster B, and so on. The

middle maneuver at t = 6 seconds is when both thrusters fired simultaneously.

By

looking for the shortest impulse in the first figure (Z-moment) or the intercept in the

second figure (X-moment), the relative delay appears to be less than 1 ms.

V

/

-

20V -

Signal to

solenoid

5V io

F

t

Id

1Oms

i

/ \' T

FO

I

I

Applied

force

t

I

54

t

Figure 3.5 Thrust Latency in Solenoid Valve

Figure 3.6 Applied Impulse From Difference in Thruster Latency

The flight SPHERES satellites have access to accelerometer data at 1 kHz, which can be

used to get a better idea of the absolute delays for each solenoid. Figure 3.7 shows an

example of solenoid delay on the order of 6ms.

TMr.DdY

I

Figure 3.7 Sample of 6ms Solenoid Delay

The possibility of using the JR3 load cell to measure the solenoid delays of the flight

SPHERES thrusters was explored. The JR3 has a bandwidth of 8 kHz and in order to

resolve a 6ms delay in thruster actuation, an effective bandwidth of 2 kHz is desired (20

counts over a 10ms period). When a mass is placed on top of the load cell, q drops:

ofg=

=

Vm

(2.2)

The stiffness of the load cell to forces in the X and Y directions is c = 18x10 3 in English

units. With a typical SPHERES satellite weight of 7.7 lb, the bandwidth of the entire

system is approximately 48 Hz. The response time of the combined SPHERES and JR3

system will drown out the solenoid latency.

3.7

Multiple Thruster Pressure Drop

Since the capacitor is not infinite in size, the supply pressure coming out of the regulator

is not constant, but dependent on the flow rate. As such, the more thrusters that are open

at a time, the lower the pressure is at each nozzle. The lower supply pressure results in a

lower produced thrust. The first SPHERES mixer assumed constant thrust, while newer

iterations, including one described in [Blanc-Pacques '05] [1] compensate for the thrust

reduction, resulting in more accurate open (and closed) loop control. This new thruster

mixer was developed using the previous thruster characterizations.

Tests to see this

effect were carried out on a mock propulsion system, pictured in Figure 3.8. This setup

includes all the components of the propulsion systems on the flight SPHERES arrayed on

a plywood board [5].

P1

P4

Thruster 1

Figure 3.8 System Pressure Propagation Test Setup

Pressure transducers were placed at 4 locations in the system to measure the propagation

of pressure loads. Figure 3.9 shows the thrust commands and the corresponding pressure

from the four transducers. From this test, it appears that the reduction in thrust is not

very dependent on how close the thrusters are in the tubing tree. The effect of the gas

capacitor can be seen here where the upstream pressure does not change much with

increased pressure demand.

System Pressure

Thruster Configuration

LJ.H

.U.LUKL

r:i

· · *·'"·'

0;

'

'··--.·!-.··"·~-;:·

•

5

~·-~····I·--`'·"-

•

rWn

-o

.

N•n

I ..

,r,*

o

10

20

30

time (s)

40

50

6o

-

10

............

"

20

30

Figure 3.9 Pressure Change Propagation Data

40

time (s)

F -upstream

P

S P downstream

i70

60

50 P4 -downstream

3.8

Sensor Characterization

Having adequately examined the Plant (SPHERES satellite) and actuators (propulsion

system and thrusters), all that remains is to look at the sensors (inertial gyroscopes and

accelerometers) to complete our system characterization. The two inertial sensors are the

BEI Gyrochip II tuning-fork gyroscope and the Honeywell Q-Flex 750 accelerometer.

There are three of each on the flight SPHERES, providing telemetry for all axes. While

the accelerometers are mentioned here for completeness, they are not used to close the

loop, and so are irrelevant to the topics in this thesis. The specifications for these sensors

are summarized in Figure 3.10.

Max Update Rate

Range

1000 Hz

+25.6 mg

Max Update Rate

1000 Hz

Range

+83 deg/s

Resolution

12.5 [tg/count

Resolution

0.0407 deg/s/count

Bandwidth

300 Hz

Bandwidth

300 Hz

Noise (0 to 10 Hz)

< 7 tg rms

Noise (10 to 500 Hz)

< 70 pg rms

Noise (0 to 100 Hz)

< 0.05 deg/s/(Hz)1/2

Figure 3.10 Inertial Measurement Unit Specifications

·

In order to take full advantage of these sensors in closed-loop control, it is beneficial to

examine the noise characteristics. In addition to the noise listed under the manufacturer's

specification, there also appears to be a high frequency ringing associated with the

gyroscope when thrusters are opened or closed. As a tuning fork gyro, the Gyrochip II

vibrates one set of tines at a "drive frequency." The other set of tines (the "pickup fork")

oscillate at a sense or "pickup frequency" only when the gyro is rotating (Coriolisinduced torque) [17]. The difference between these frequencies is known as the "deltaF"

of the gyro, which in our case is about 338 Hz. This phenomenon is explained in more

detail in Appendix A.

When this frequency is excited, say by the small impulse of opening/closing a solenoid

valve, there is a decaying oscillation of 338 Hz in the gyro data. Since this noise is tonal,

it can be filtered out fairly easily with a notch filter. Figure 3.11 shows gyro data where

this high frequency noise is especially apparent. Since this data is sampled at 1 kHz and

the noise in question is about 338 Hz, the effect of only having three samples per period

is apparent (Nyquist requires >2). Figure 3.12 shows a Fast Fourier Transform of gyro

data sampled at 1 kHz to isolate this noise peak.

25D

1......

Fii

Figure 3.11 Filtered 338 Hz Gyro Noise

A couple key characteristics of these sensors are the biases and scale factors used to

convert from counts to rad/sec and m/s 2. The biases and scale factors of each gyroscope

were computed with the help of a rate table, while the biases and scale factors for the

accelerometers were taken from manufacturer specifications.

These values are stored in

flash memory on the corresponding satellites and are automatically used when IMU

readings are converted.

FFT of signal with Ts = 0.001. DC :comrn

ponent:(0.00038837) is not shown,

0.5

0.45

0.4

0.35

0.3

0•.25

p 0.2

E

0.15

0.1

0.05

O

0

1

50

100"

A,

150

200 250

300

frequency [Hz]

350

400

450

500

Figure 3.12 FFT of Gyro Ringing

With gyro-specific scale factors and biases and online filtering of the 338 Hz noise, the

gyro output is very accurate, which is important for closed-loop control and for the online

mass property identification algorithm.

Chapter 4

Mass Property Identification

4.1

Online Mass Property Identification

Thruster values and relevant sensor calibration information remains the same over normal

operation, but mass properties of the SPHERES satellites change as fuel is depleted.

While previously measured empirical values for CoM and Inertia provide a good start for

control algorithms using these values, having them update online is preferred for more

accurate control performance.

The mass-property algorithm and equations ((4.1) through (4.8)) are taken from "On-line,

gyro-based, mass-property identification for thruster-controlled spacecraft using recursive

least squares," [Wilson, Lages, Mah] [21]. The general approach to online mass ID is to

use gyro information about rotational rate to estimate angular acceleration and system

characterization information (especially about the thrusters) to estimate applied torque.

With this information, Euler's dynamical equation is used to find inertia assuming a

center of mass offset, or find the moment arm (hence center of mass offset) assuming a

value for inertia.

The center of mass offsets can be identified with better accuracy with pure translations

along a single axis since the unbalanced effect of these offsets is much easier to see when

the range of the gyro data is small. The two major error contributors in flying along a

straight path (pure translation) are the thrust strength variation (which we've

characterized) and the center of mass offset. While identifying center of mass, the

difference in torques provided by parallel thrusters is the "signal" that provides the

algorithm with the necessary information to identify CoM.

If there are rotational

maneuvers occurring, this signal is easily lost in much higher magnitude "noise" of largescale rotations.

On the other hand, pure rotations about a single axis, provide the best data for estimating

the inertia matrix elements. The inertia associated with that axis depends on the estimated

angular acceleration during the maneuver, which is most accurate during pure rotations

since the effect of nonzero center of mass offset in the gyro data is minimized. Figure 4.1

shows a representation of these two scenarios.

z

= moment x Jorce = la

'

=J

F

I

T.i. 1

r

Lfj

p

_

mome

moment

Figure 4.1 Ideal Maneuvers for Inertia and CoM Identification

4.2

Theory and Equations

The first step in formulating the equations behind the mass ID algorithm is to take Euler's

dynamical equation, and write it in a form that allows least squares (LS) analysis, with

gyro data as our measured quantity and with CM offset and inertia as our unknowns. In

the following equations, L is the thruster locations measured from the CoM, D is the

nominal thrust directions (unit vector), F is the nominal thrust, B is the blowdown effect

from decaying thrust, and Tis a binary on/off value for each thruster.

(o= I1 ' (' - @ICo)

(3.1)

)

(3.2)

S= thrusters + Zdisturb = (L x D F + zitub

Fk = B(Fom +Fbias +

(3.3)

adom,k )Tk

The algorithm is equipped to handle disturbance torques, random variability in the

thrusters and blowdown, although for our purposes at this stage, these quantities are

considered negligible. Equations (4.1), (4.2), and (4.3) are combined to give:

Co = I' ((LxD)B(Fom +F

+

Fbi' ,ndom,k Tk

+

diturb

- OX(I

O))

(3.4)

The next step is converting this Equation (4.4) into the standard least squares form,

Ax - b. For the center of mass identification, there are a few more definitions: C is the

true center of mass and A is the CoM offset.

C = Cnom +A

L=Lom -A[1

(3.5)

. . . 1]

(3.6)

Refer to [Wilson, Lages, Mah] [21] for more detailed derivations. The final least squares

form is:

Ak

=I-1

0

-c3

2

C3

0

-C1

-- C 2

C1

0

1

x

k

bk = +-1 1(cox(+I))-I-' (LnomxD)FnomTk

A2

A3

Center of Mass LS Formula

ck - DFnoT

(3.7)

k

The vector of center of mass offsets fits well into the standard least squares form.

However, the inertia matrix is a symmetric 3x3 matrix with 6 independent terms and

needs a special transformation to conform to Ax _ b.

Also, the inverse of the inertia

matrix is identified because of the form of the equations of motion:

a,

Ak =0

0

0

a2 a3 0

I

a2

0

a1

0

0

a1 a2

I-I2

33

-0 0

a3

a3

x=

bk

k

12

ak = (L xD ) FomTk

S(LD)F)

-o

1131

-

I I3nInertia LS Formula

(3.8)

For Equations (4.8) and (4.9), the inverse inertia matrix and center of mass offsets are

identified by using the standard batch LS solution,

= (ATA) -1ATb. This is acceptable for

"off-line" data processing for computing mass property estimates.

For on-line

estimation, a recursive algorithm is used, incorporating the covariance and state update

equations:

Qk+ -1 +=Tk-IAk+1

= Xk + Qk+lAIZR+l

4.3

Ak-I

[bk+-Ak+lk-]

(3.9)

(3.10)

RGA Micro-gravity Testing

From February 5-7, 2002, the SPHERES team conducted tests aboard NASA's RGA.

Mass property identification tests were run to help with development of the algorithm as

well as to provide good, independent estimates of inertia and center of mass offsets for

each of the flight units. Two types of tests were performed to help identify the mass

properties of each SPHERES satellite. One set of tests was composed of 12 different

maneuvers: pure rotations and pure translations in each axis in both directions (2 x (3+3)

= 12). Essentially, pairs of thrusters were turned on for one second to produce pure

rotations/translations in both the negative and positive directions. The IMU data was

sampled at 100 Hz, which was the most data that could pass through the communications

system in real time.

The other set of tests had seven maneuvers, which involved turning on one thruster at a

time for one second each (maneuvers 1-6 each tested 2 different thrusters). These tests

had a sampling rate of 1 kHz and required a period of about 30 seconds to download the

IMU data afterwards. The last maneuver in this set of tests was created with the intention

of testing the robustness of the mass ID algorithm. It consisted of a series of firings of

duration varying from 0.01-0.02 seconds. Some firings included orthogonal thrusters to

excite motion around multiple axes.