TIN PLATING USING LIQUID DYNAMIC ... by MICHAEL CHARLES ZODY

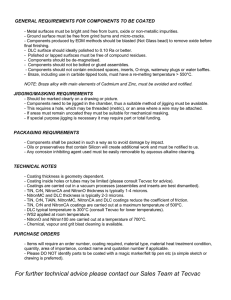

advertisement