Evaluating Delivery of a Monoclonal Actuated Needle-Free Injector

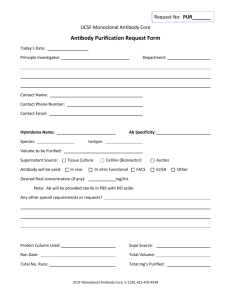

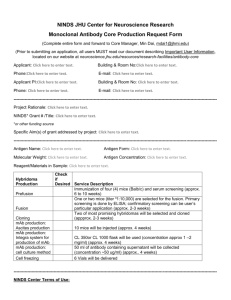

advertisement