Contaminant control in the purification of monoclonal antibodies: the

advertisement

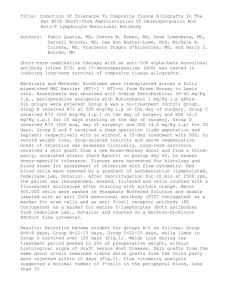

New chromatography technology to improve the antibody purification process John M. Jenco, Ph.D . Senior Principal Scientist Technical Services Group Pall Life Sciences, USA Monoclonal antibody production processes begin with the fermentation of mammalian cells that have been genetically engineered to produce a specific antibody at increasingly higher titers in various media formulations. Following the harvest of the bioreactor to separate cells from the media that contains the expressed and secreted antibody, the subsequent downstream steps must all be aimed at producing therapeutic grade monoclonal antibody in as high a yield and as high a purity as possible. The challenge for each purification step is to consistently reduce and/or eliminate common contaminants such as host cell protein, host cell DNA, virus, and endotoxin that would otherwise cause adverse reactions if administered to patients. Multiple chromatographic steps are routinely employed to address the removal of contaminants through several orthogonal mechanisms. MEP HypercelTM mixed mode chromatography, S HypercelTM cation exchange chromatography, and Mustang® Q membrane chromatography all contribute to consistently reducing contaminants while producing robust yields of monoclonal antibody. These chromatography technologies play a significant role in reducing the high level of contaminants encountered out of the bioreactor to the low levels required by regulatory authorities in the final formulated product. The risk of adverse events is mitigated, and patient safety is not compromised.