Enabling Effective Product Launch Decisions

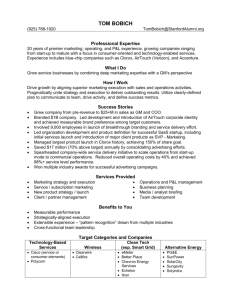

advertisement