TOWARD THE SYNTHESIS OF AZIDO-CROWN ETHERS WITH UNUSUAL NITRENE REACTIVITY A THESIS

advertisement

TOWARD THE SYNTHESIS OF AZIDO-CROWN ETHERS

WITH UNUSUAL NITRENE REACTIVITY

A THESIS

SUBMITTED TO THE GRADUATE SCHOOL

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS

FOR THE DEGREE OF

MASTER OF SCIENCE

BY

MEGAN E. WILLIAMS

ADVISOR: DR. JAMES S. POOLE

BALL STATE UNIVERSITY

MUNCIE, INDIANA

JULY 2011

TOWARD THE SYNTHESIS OF AZIDO-CROWN ETHERS WITH

UNUSUAL NITRENE REACTIVITY

A THESIS

SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS

FOR THE DEGREE OF

MASTER OF SCIENCE

BY

MEGAN E. WILLIAMS

Committee Approval:

Committee Chairperson

Date

Committee Member

Date

Committee Member

Date

Department Approval:

Department Chairperson

Date

Graduate Office Check:

Dean of Graduate School

Date

Ball State University

Muncie, IN

July 2011

Acknowledgements

First and foremost I would like to thank the Ball State University Chemistry

Department for accepting my application and allowing me to pursue a Master’s degree.

The faculty members in this department have been very helpful and encouraging

throughout this journey, and I appreciate all their efforts.

I’d especially like to thank Dr. James Poole for accepting me into his research

group. His guidance and support helped get me to where I am at today and I will always

be appreciative of everything I have gained from this experience. I feel confident in

saying that he has helped shape me into a better chemist as I leave this program. I’d also

like to thank my thesis committee members, Dr. Philip Albiniak and Dr. Tykhon Zubkov

for their time and effort spent helping shape my thesis into the best that it can be.

Without support from my family and my boyfriend, Matthew Haddock, I never

would have made it through this program. I am so grateful to my parents for their loving

support, and sometimes financial, throughout my academic career, helping shape me into

the woman that I am today. Matthew has been so supportive of my pursuits at higher

education and it means so much to me that he would put some of his goals on hold while

I pursued some of mine.

The opportunity that I’ve been given to further my education has been an amazing

learning experience for life and my future pursuits in higher education and career. Thank

you to everyone involved in the process of completing this degree.

i ABSTRACT

THESIS: Toward the Synthesis of Azido-Crown Ethers with Unusual Nitrene Reactivity

STUDENT: Megan E. Williams

DEGREE: Master of Science

COLLEGE: Sciences and Humanities

DATE: July 2011

PAGES: 65

It has been shown that photolysis of 4-azidopyridine N-oxide yields the singlet

nitrene, which undergoes intersystem crossing at room temperature to generate triplet 4nitrenopyridine N-oxide. The room temperature photochemistry is dominated by triplet

nitrene chemistry leading to the formation of the azo-dimer. This unusual behavior is a

result of selective stabilization of the lowest singlet state of the nitrene by the N-oxide

group.

In this study, we wish to investigate the effect of complexation of the N-oxide

group with a metal cation on the kinetics and reactivity of 4-nitrenopyridine N-oxide and

related compounds. It is envisaged that complexation will alter the polarity of the N-oxide

bond making it less capable of spin delocalization in the nitrene.

Complexation may be achieved through two different methods: complexation

with cations in aqueous salt solutions and complexation of cations inside crown ethers.

Crown ethers provide useful models due to the selectivity of complexation with different

ions based on ring size and slower diffusion of cations away from the N-oxide group.

Progress toward the multi-step synthesis of crown ethers containing the 4azidopyridine N-oxide substructure is described herein.

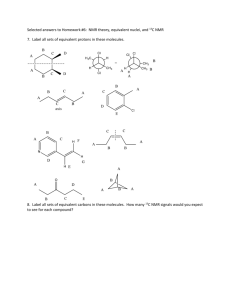

ii Table of Contents

Page #

List of Schemes

List of Figures

List of Tables

Chapter 1

Chapter 2

Chapter 3

iv

v

v

Introduction

1.1 An Overview of the Chemistry of Azides

1.2 Arylnitrenes

1.2.1 Substituted Phenylnitrenes

1.2.2 Nitrenopyridine N-oxides

1.3 Crown Ethers and Synthetic Targets

1

5

8

11

16

Experimental Methods

2.1 Materials

2.2 Instrumentation

2.3 Experimental Methods

19

19

20

Results and Discussion

3.1 Synthetic Strategies

3.2 Synthesis of 4-bromo-2,6-pyridinedimethanol

3.3 Synthesis of Compound 5

3.4 Synthesis of Compound 6

3.5 Synthesis of Compound 7

3.6 Attempts to Incorporate the Azido- group

27

28

31

32

35

38

Bibliography

Appendix A

41

Experimental Spectra

44

iii List of Schemes

Page #

Chapter 1

Introduction

Scheme 1.1

Scheme 1.2

Scheme 2

Scheme 3

Scheme 4

Scheme 5

Azide formation via diazonium salts

Azide formation via nucleophilic substitution

Azide reduction to form a primary amine

1,3-dipolar cycloaddition reactions of organic azides

Photolysis/thermolysis of phenyl azide to form phenylnitrene

Four candidate structures of reactive intermediate formed in

photolysis of phenyl azide

Mechanism of phenyl azide thermo- and photochemistry

Effect of o-substitution on cyclization reactions of phenylnitrene

Potential mechanism of the photolysis of 4-azidopyridine N-oxide

Iminyl-aminoxyl biradical stabilization of 4-nitrenopyridine Noxide

Low temperature Photoproducts of 3-azidopyridine N-oxide

Proposed Retrosynthetic Scheme for 4-azido-2,6-pyrido-18crown-6 N-oxide

Scheme 6

Scheme 7

Scheme 8

Scheme 9

Scheme 10

Scheme 11

Chapter 3

Results and Discussion

Scheme 12

Scheme 13

Scheme 14

Scheme 15

Scheme 16

Scheme 17

Scheme 18

Scheme 19

Scheme 20

Scheme 21

Retrosynthesis of 2,6-pyrido-18-crown-6 derivative 6

Synthesis of Compound 1

Synthesis of Compound 2

Synthesis of Compound 3

Synthesis of Compound 4

Synthesis of Compound 5

Attempted Syntheses of Compound 6

Attempted Syntheses of Compound 7

Attempted Synthesis of Compound 8

Synthesis of 19-azido-3,6,9,12,15-pentaoxa-21azabicyclo[15.3.1]-henicosa-1(21),17,19-triene (9)

iv 1

1

2

2

4

7

8

10

12

13

14

18

27

28

29

30

30

31

32

35

38

39

List of Figures

Page #

Chapter 1

Introduction

Figure 1

Figure 2

Figure 3

Figure 4

Strucutre of AZT

Four candidate structures of reactive intermediate formed in

photolysis of phenyl azide

Effect of o-substitution on cyclization reactions of phenylnitrene

Azido-functionalized cryptand

Chapter 3

Results and Discussion

Figure 5

NMR Comparison of 6 & 7

3

6

15

17

35

List of Tables

Page #

Chapter 1

Introduction

Table 1

Summary of Calculated EST for Nitrenes (kcal/mol)

v 12

Chapter 1 – Introduction

1.1 An Overview of the Chemistry of Azides

Organic azides (with azido functional group –N3) have received a great deal of

attention in the literature as important synthetic intermediates due to their relative ease of

formation and their useful reactivity. Two of the most common forms of azide formation

are via diazonium salts or nucleophilic subsitution.1

Aryl diazonium salts react with

azide ions without the use of catalysts to form the corresponding aryl azide (Scheme 1).

Generally, alkali metal azides or trimethylsilyl azides act as the azide source.

N

1.

N

NaN3

N3 + NaX + N2

X

2.

R

X

+

NaN3

R

N3

Scheme 1: (1) Azide formation via diazonium salts. (2) Azide formation via

nucleophilic substitution

2 Nucleophilic substitution (via SN1 or SN2) to form alkyl azides is often favorable due to

the high nucleophilicity of the azide ion (Scheme 1), and its low to moderate basicity

(pKa HN3 = 7-9).2 The most common azide source is sodium azide, although others can

be used. Leaving groups include, but are not limited to, halides, carboxylates, and

sulfonates.3

Azides are synthetically useful in reactions involving 1,3-dipolar cycloadditions and

formation of primary amines. Primary amines can be generated from the reduction of an

azide (Scheme 2).3 A wide range of different reducing agents can be used, including

LiAlH4, NaBH4, and H2/catalyst.

R

N

N

[H]

N

R

NH2

Scheme 2: Azide reduction to form a primary amine

1,3-Dipolar cycloadditions are commonly used in synthetic organic chemistry as a

method to generate heterocyclic ring systems from a variety of substrates (1,3-dipoles),

including azides (Scheme 3).4

R

R

N3

+

H

N

N

R

N3 + H

N

N

N

X

H

R

R

N

X

X

N

N

H

N

X

X

R

H

N

N

X

Scheme 3: 1,3-dipolar cycloaddition reactions of organic azides

N

H

3 Alkenes or alkynes can be used as the dipolarophile, but all that is essential is a π bond.

The reaction proceeds via stereospecific syn-addition to yield 1,2,3-triazolines from

alkenes, and triazoles from alkynes. Reaction is often facilitated by the addition of a

copper salt as catalyst: so-called “click” chemistry.5,6 When both the 1,3-dipole and the

dipolarophile are unsymmetrical, two possible products can be generated: 1,4- and 1,5regioisomers. It may be shown that both steric and electronic factors play a role in

determining regioselectivity, but frontier orbital interactions are often dominant factors.

Typically, the most energetically favorable orientation in the transition state is that which

involves complementary interaction between the frontier orbitals of the 1,3-dipole and the

dipolarophile.4 The most common additions are those dominated by interactions between

the LUMO of the dipolarophile and the HOMO of the 1,3-dipole, but reactions

dominated by opposite interactions (“inverse-demand”) are also possible.

Azides are not limited to the role of synthetic intermediate, but may be a useful

functional group in its own right. The azido- group has been investigated as a potential

pharmacophore: one specific organic azide, 3’-Azido-2’,3’-dideoxythymidine (AZT,

Figure 1), has received a great deal of attention due to its antiretroviral activity.7

O

NH

HO

N

O

O

N3

Figure 1: Structure of AZT

4 AZT was the first approved treatment for HIV/AIDS therapy introduced in the early

1990’s. It slows the spread of HIV by inhibiting the reverse transcription process in

replication. The azido group increases the lipophilic nature of AZT, allowing it to diffuse

across cell membranes and cross the blood-brain barrier. AZT does not completely stop

the spread of the virus, so it is combined with other anti-viral drugs to help prevent the

chance of resistance. Another application of azides is in the form of sources of high

energy nitrogen. For example, glycidyl azide polymer (GAP) is studied as a potential

source of high-energy nitrogen in solid propellant.8 GAP acts as a propellant fuel-binder

in the mixture of fuel and oxidizer, that when mixed, create a high-energy explosive.

Aryl azides have also received a lot of attention due to their relatively high stability

and ability to act as thermo- and photochemical precursors of nitrenes (Scheme 4).9

Nitrenes are short-lived, highly reactive species that contain a nitrogen atom with only six

electrons in its valence shell.

N3

hv

!

N

Scheme 4: Photolysis/thermolysis of phenyl azide to form phenylnitrene

Applications of the nitrene chemistry of aryl azides include organic synthesis of azepine

derivatives,10 in the formation of electrically conducting polymers, and in photoaffinity

labeling.9 Photoaffinity labeling is a method of covalently binding chemical tags to the

active sites of protein molecules.11 A labeling reagent is converted by photolysis to a

reactive intermediate and specifically binds to the active site at the instant of photolysis.

5 The role and structure of aryl nitrenes in these reactions has been studied for many years,

but a clearer understanding of these systems emerged in more recent years with the

application of laser flash photolysis (LFP),12 low temperature matrix isolated IR,13 low

temperature glassy matrix EPR,14 and high-level ab initio molecular orbital (MO)

calculations.

1.2

Aryl Nitrenes

Arylnitrenes are highly reactive, short-lived intermediates generated by the

decomposition of aryl azides. They have six valence electrons that can exist in four

different possible electronic states (Figure 2, overleaf): triplet, open-shell singlet, and two

closed-shell singlet states.

The lone pair of electrons that exists in all states occupy a hybrid orbital rich in 2s

character. The triplet and open-shell singlet state have two nonbonding electrons that

both occupy pure 2p orbitals, differentiated by their spins. The triplet state has two

unpaired electrons with parallel spins, whereas the open-shell singlet state has two

unpaired electrons with opposite spins. Of the 2p orbitals, one is a 2pπ orbital that may

overlap with the π -system in the aromatic ring, and the other is a p orbital that lies in the

plane of the ring. The two different closed-shell singlet states have paired electrons and

are generally viewed as a linear combination of two canonical forms; either the paired

electrons lie in the in-plane p orbital or the 2pπ orbital.9

6 Figure 2: Energy level diagram for the electronic states of a nitrene

The triplet state is considered the ground state and is lowest in energy followed by

the open-shell singlet state, with the closed-shell singlet state highest in energy.

Calculations indicate that the singlet-triplet energy gap (EST) for phenylnitrene (the

archetype system) is approximately 14.8 kcal/mol.15

Early studies of the photolysis of phenyl azide in solution produced a polymeric

tar.7 In the presence of primary and secondary amines formation of azepine (5) was

observed. A reactive intermediate (C6H5N) was postulated to be trapped in the presence

of diethylamine, but the structure was unclear for many years. From the product

distributions obtained, four candidate structures were proposed (Scheme 5): singlet

7 nitrene (1), triplet nitrene (2), benzazirine (3), aza-1,2,4,6-heptatetraene (cyclic

ketenimine, 4).

1N

N3

3N

N

N

NHEt2

h!

1

2

3

4

N

5

NEt2

Scheme 5: Four candidate structures of reactive intermediate formed in

photolysis of phenyl azide

With the development of research techniques, a clearer mechanistic picture (Scheme 6)

has been developed describing the photochemistry and thermochemistry of phenyl azide.9

Upon photolysis (or thermolysis), singlet nitrene (1) is formed. At temperatures above

165K, cyclization to benzazirine 3 is favored, followed by rapid ring-opening to cyclic

ketenimine 4, typically the major trappable reactive intermediate in solution at room

temperature. In the absence of good nucleophiles, 4 undergoes polymerization.

At

temperatures below 165K, intersystem crossing (ISC) to triplet nitrene 2 (which is a

temperature independent process) becomes dominant relative to cyclization (a

temperature dependent process with a non-zero activation barrier). ISC is a slow process

because spin-flip from opposite electron spins to matching spins is formally spinforbidden. ISC is followed by dimerization of the nitrene or reaction of triplet nitrene

with starting azide to form azobenzene.

8 N

1N

N3

kexp

kcyc (kR)

hv

N

>165K

3

1

4

HNEt2

<165K

kisc

3N

NH

2

NEt2

dimerizes

N

N

N

5

NEt2

Scheme 6: Mechanism of phenyl azide thermo- and photochemistry

1.2.1 Substituted Phenylnitrenes

After gaining a better understanding of the mechanism for phenyl azide

photochemistry, substitution effects were studied using nitrene and ketenimine transient

absorption spectra in the near-UV/ visible region.9 Values for kOBS (the observed rate

coefficient for the decay of singlet nitrene and/or the growth of products) were measured

by the decay or growth of absorbance at the λmax of the transient species as a function of

temperature.

Construction of an Arrhenius plot for kOBS with 1/T shows a region of

9 linearity where cyclization and ring expansion (singlet nitrene chemistry) dominates;

which becomes non-linear and effectively temperature independent at lower

temperatures, where triplet chemistry dominates (Scheme 6). This value is associated

with temperature- independent rate of intersystem crossing, with rate coefficient kISC.

The location and type of substituent has shown to affect rates of cyclization or

ISC in different ways:

p-Substitution of phenylnitrene can enhance kISC depending on the nature of the

substituent.9 Heavy atom effect, observed with bromo or iodo groups, increases kISC by a

factor of greater than 20 relative to phenylnitrene.9

Heavy atom effect is the

enhancement of the rate of a spin-forbidden process, due to significant spin-orbit

coupling in an atom of high atomic number and therefore large orbital angular

momentum.15 Strong π -donors, such as methoxy or dimethylamino groups, also increase

kISC by 2-3 orders of magnitude. The mechanism by which these enhancements occur is

not clearly understood. Substituents such as methyl, trifluoromethyl, acetyl, fluoro, and

chloro, are not sufficiently strong π-donors or acceptors to significantly influence kISC.

Under some circumstances o- and m-substitution can enhance kISC as well, and the

degree of enhancement again depends on the substituent.9 For example, mono and di-ofluoro substitution on phenyl nitrene have shown to have no influence on ISC, whereas

di-o-cyano substitution slightly accelerates kISC. An o-methyl accelerates ISC by a factor

of approximately 3, and di-o-methyl has an even greater effect.9

In the case of p-substitution and rate of cyclization/rearrangement (characterized

by rate coefficient kR), large substitutent effects are not anticipated due to the distance of

substituents from the nitrene.9 Substituents such as methyl, trifluoromethyl, halogens,

10 and acetyl have little influence on kR. The effects of strong π-donating groups were

impossible to study due to faster kISC than kR at all temperatures. p-phenyl and cyano

groups depress kR and retard the rate of cyclization significantly, due to their radical

stabilizing properties. The substituents withdraw spin density from the ring, making

cyclization, which may be envisaged as an internal biradical coupling, less favored.

Photolysis of different o-alkyl substituted phenyl azides (methyl, ethyl, isopropyl)

showed cyclization of the singlet nitrene toward the unsubstituted o-carbon, indicating

that steric effects have an influence on the barrier to ring expansion (Scheme 7).

1N

N

N

Scheme 7: Effect of o-substitution on cyclization reactions of phenylnitrene

If the nitrogen atom moves away from the alkyl group to cyclize, steric strain is released

between the two groups. Alternatively, o-cyano and o-acetylphenyl groups undergo

cyclization both away from and toward the substituent. Cyclization away from the group

can be attributed to steric effects, whereas cyclization toward the group can be attributed

to spin localization electronic effects: localization of an unpaired electron at the carbon

where the substituent is attached, favored by the radical stabilizing nature of these

substitutents.9 Mono-substituted o-fluoro substitutents cause cyclization away from the

group due to a combination of steric effects and the electronegativity of the fluorine

atom. The electronegativity of fluorine also affects cyclization toward the group. If o,o-

11 difluoro substitution is present, ring expansion is inhibited and raises the barrier to

cyclization approximately 3 kcal/mol relative to the unsubstituted system.9

1.2.2 Nitrenopyridine N-Oxides

Azidoheteroaryl N-oxides, a subclass of aryl azides, have been studied due to their

potential as antitumor agents.16 N-oxide groups are expected to enhance water solubility

of these compounds, which may also be advantageous for potential photoaffinity agents.

The 3- and 4-nitrenopyridine-1-oxide systems have been studied by LFP, matrix isolation

IR and computational methods.17,18

If photolysis of 4-azidopyridine N-oxide proceeds in a similar manner as

phenylnitrene, the nitrene could either cyclize or go through ISC to form the triplet

(Scheme 8). Alternatively, reactions involving N-oxide photochemistry may be possible

(since these groups are photoactive in their own right), but were not found to be

significant in these systems.

12 1N

N3

N

N

hv

N

N

N

O

O

O

N

O

ISC

3N

O

N

N

N

N

O

N

O

Scheme 8: Potential mechanism of the photolysis of 4-azidopyridine N-oxide.

Experimental results showed that triplet nitrene chemistry is favored, even at room

temperature; and no cyclization products were observed.17 The much smaller singlettriplet energy gap of 4-nitrenopyrdine N-oxide relative to phenylnitrene (Table 1) results

in a modest enhanced rate of ISC.

Table 1: Summary of Calculated EST for Nitrenes (kcal/mol)a

Nitrene

0K

298K

phenylnitrene

15.7

15.8

4-nitrenopyridine

16.7

16.7

3-nitrenopyridine 1-oxide

16.4

16.4

4-nitrenopyridine 1-oxide

9.8

9.9

a Calculations

performed at B3LYP/6-31G* level of theory for 4-nitrenopyridine N-oxide, 4-pyridylnitrene,

and phenylnitrene to determine relative energies (kcal/mol) at the triplet and open-shell singlet states.

Singlet state energies were estimated by the sum method of Johnson et al. [Ref. 19]

13 Calculations indicate the cyclization/ring expansion pathway is thermodynamically

disfavored due to the effect of electron configuration. The open-shell singlet state is

preferentially stabilized due to resonance contributors with iminyl-aminoxyl biradical

character (Scheme 9), which increases the barrier to cyclization.

From this it is

reasonable to assume that a significant amount of spin density in the ring lies on the Noxide atoms. Diminution of spin density at sites o- to the nitreno group also makes

cyclization less favorable.

N

N

N

N

N

N

N

N

N

N

O

O

O

O

O

Scheme 9: Iminyl-aminoxyl biradical stabilization of 4-nitrenopyridine N-oxide

In the case of 3-nitrenopyridine N-oxide, different results are expected due to the

positioning of the azide in the 3-position on the pyridine ring. At this position, stabilizing

effects due to iminyl-aminoxyl biradical character are not present, so it is expected to

behave more like a typical phenylnitrene. Calculation of EST for this species confirm that

the splitting is similar in magnitude to that of phenylnitrene.18 At low temperature

photolysis of 3-azidopyrdine 1-oxide, the triplet nitrene is obtained.18 With prolonged

photolysis; the singlet state can be accessed, yielding cyclization and ring expansion

products. These results are interesting in that both possible modes of cyclization are

observed at low temperature, but that when cyclization occurs toward the N-oxide

14 moiety, the benzazirine analogue is more thermochemically favored than the ketenimine

analog (Scheme 10), which is unusual for a simple monocyclic aryl nitrene.

N

N

O

N

O

hv

N

N3

not obs.

ISC

N

O

N

N

1N

O

3N

O

N

N

N

O

N

not obs.

O

Scheme 10: Low temperature Photoproducts of 3-azidopyridine N-oxide

LFP experiments at room temperature yield polymeric tar in the absence of a nucleophilic

trap, but with the addition of diethylamine or dibutylamine, the intermediates can be

quenched. The trapped nitrene product is highly photolabile making characterization

difficult. Further study is needed to better understand products of the 3-azido species

generated at room temperature and their photochemistry.

In this study, we wish to investigate the effect of complexation of the N-oxide

group with a metal cation on the kinetics and reactivity of 4-nitrenopyridine N-oxide and

its analogs. It is envisaged that complexation will alter the polarity and polarizability of

the N-oxide bond making it less capable of spin delocalization of the nitrene. This in turn

15 should alter the selective stabilization of the singlet nitrene by the N-oxide moiety, which

in turn may alter the observed chemistry of this intermediate. It may also be possible that

the effect of such species may not be limited to purely electrostatic interactions:

complexation with large cations (which have large spin-orbit coupling interactions), may

also result in enhanced rates of ISC. In addition, the association of a charge should

decrease the likelihood of bimolecular chemistry (ie. dimerization of the triplet, or

polymerization of the singlet) due to Coulombic repulsion, and so new modes of

reactivity may be observed.

In principle, complexation may be achieved through two different methods:

complexation with cations in aqueous salt solutions and complexation of cations inside

crown ethers (Figure 3).

N3

N3

N

O

N

O

O

M+

O

M+

O

O

O

Figure 3: Modes of complexation of cations with N-oxide

Complexation in an aqueous salt solution is a less ideal method, because the metal

cations can easily diffuse away from the N-oxide, therefore yielding inefficient

complexation or too rapid exchange of cations. Crown ethers provide a more favorable

16 method for achieving complexation due to the ability of the crown to help slow diffusion

of cations away from the N-oxide group. Also, selectivity of complexation with different

cations can be achieved based on crown ether ring size.

1.3

Crown Ethers and Synthetic Targets

Charles Pedersen at the DuPont Company discovered crown ethers in the early

1960’s.20 Simple crown ethers are named as X-crown-Y, with “X” denoting the total

number of atoms in the crown and “Y” denoting the total number of oxygen atoms. An

important characteristic of crown ethers is that they can complex with alkaline earth and

alkali metals as well as ammonium ions, by providing a stabilizing solvation shell around

these guest species. This type of interaction is known to enhance the solubility of

inorganic salts in organic solvents, which allow many reactions to be performed under

non-aqueous, aprotic conditions.20 In addition, the salvation of the cationic component of

a salt effectively sequesters it from solution, leaving a “bare” counterion, that often

exhibits enhanced reactivity toward organic substrates in solution.20

Crown ethers have been studied in their use to aid complexation of alkali cations

with aryl nitrenes and their impact on nitrene chemistry.21,22 A series of cryptand-like

molecules functionalized with intraannular azido groups (Figure 4) were studied using

LFP.

17 N

N

N3

O

O

O

Figure 4: Azido-functionalized cryptand

Initially the singlet nitrene is formed and is reasonably long-lived (~1.4 µs) as a result of

substitution in both o-positions.20 Di-substitution in o-positions are known to slow the

rate of rearrangement, shown in the case of di-o-dimethylphenylazide which has a

lifetime of ~12 ± 1 ns.9 At room temperature, ISC competes with rearrangement, and

both singlet and triplet products are observed, which is an effect of isolating the nitrene

moiety from readily reactive groups and not allowing it to cyclize. Experimental results

showed that the binding of Na+ and K+ in these systems had minimal effect on these

experimental outcomes.20,21

In the above studies, the authors were interested in the effect of direct

complexation of the nitrene by cations on the nitrene chemistry. In our case, we are

investigating the effect of complexation at a remote group (i.e. the N-oxide) on the

observed chemistry of the nitrene. We want to incorporate an azidopyridine N-oxide

moiety within a crown ether to help facilitate complexation with a metal cation.

In the retrosynthesis of the azidopyridine N-oxide (Scheme 11), the azido group

replaces a good leaving group (bromide). To form the N-oxide group, the nitrogen in the

pyridine ring must be oxidized. It is postulated that these two steps could happen in

18 either order with similar results. The crown ether would be made from a glycol and a

pyridine ring with bromomethyl (or other good leaving groups) substituents ortho- to the

pyridine nitrogen.

O

N

N3

O

O

O

O

O

Br

N

O

O

O

O

O

O

O

O

Br

N

Br

+

Br

N

O

Br

O

HO

O

O

O

O

OH

Scheme 11: Proposed Retrosynthetic Scheme for 4-azido-2,6-pyrido-18-crown-6 N-oxide

The first target crown ether is generated from tetraethylene glycol to yield an 18-crown-6

ring, which is suitable for smaller metal cations, such as Na+. Different crown ethers can

be generated from larger glycols that would be more suitable for complexation with

larger cations.

This work describes progress toward the multi-step synthesis of 4-azido-2,6pyrido-18-crown-6 N-oxide, as an archetype of the indicated crown systems.

Chapter 2 – Experimental Methods

2.1 Materials

Tetraethylene glycol and diethyl oxalate were obtained from commercial sources,

distilled under reduced pressure and stored over 3Å molecular sieves. Acetone was

distilled under argon, collected over 3Å molecular sieves and used immediately after

distillation.

All other materials were purchased from commercial sources and used

without further purification.

2.2 Instrumentation

Proton (1H) and carbon-13 (13C) nuclear magnetic resonance (NMR) spectra were

obtained on a 300 or 400 MHz JEOL Eclipse NMR Spectrometer. Chemical shifts were

reported downfield from reference (residual protonated solvent resonance) values for

CDCl3 or d6-DMSO solvents as indicated. IR spectra were obtained on a Perkin Elmer

Spectrum 100 FT-IR Spectrometer using an ATR accessory with a diamond element.

20 2.3 Experimental Methods

4-Oxo-4H-pyran-2,6-dicarboxylic acid (Chelidonic Acid, 1)23

O

HO

OH

O

O

O

Sodium metal (30.8 g, 1.34 mol) in mineral oil, washed with hexanes and blotted dry,

was slowly added over an hour to 400 mL of absolute ethanol and the resultant heated

under reflux conditions under argon for an additional hour. Half of the solution was

cooled until a precipitate formed and the other half was kept warm. Dry acetone (48.9

mL, 38.7 g, 0.67 mol) and ethyl oxalate (93.0 mL, 100 g, 0.68 mol) were added to the

cooled sodium ethoxide solution with stirring. The resultant solution was heated until

solid precipitated from solution, and the second half of the sodium ethoxide solution was

added, along with 99.1 mL (106.7 g, 0.73 mol) of ethyl oxalate. The solution was heated

on an oil bath at 110oC until 100 mL of the solvent was removed, then cooled to room

temperature. The solid sodium derivative was removed using a glass rod and treated with

a mixture of 200 mL of 32% HCl and 600 g of cracked ice. The dienol intermediate was

isolated by filtration and washed with about 65 mL of ice water. A sample of the

resulting dienol intermediate solid was removed and analyzed by IR.

IR (ATR): 2983, 2932, 2899, 2872 (methylene C-H asym/sym stretches); 1730 (C=O

stretch, ester); 1630 (C=O stretch, ketone) cm-1

The crude material was heated with 200 mL of conc. HCl on an oil bath at 95 oC

for twenty hours. The solution was cooled to 20 oC, and the product isolated by filtration,

21 then washed with ice water (2 x 50 mL). The obtained solid was dried to constant weight

to yield chelidonic acid (52.8 g, 86%) as an off-white solid, mp. 263-264 oC (lit. 267

o

C).23

1

H NMR (d6-DMSO, 400 MHz.): δ= 6.96 (H; s, 2H) ppm

13

C NMR (d6-DMSO, 100 MHz.): δ= 179.8, 161.3, 154.5, 119.4 ppm

IR (ATR): 3111, 3076 (aryl C-H stretch); 2830 (O-H stretch, broad); 1716 (C=O ketone

stretch); 1640 (C=O acid stretch) cm-1

4-hydroxy-2,6-pyridinedicarboxylic acid (Chelidamic Acid, 2)24

OH

HO

OH

N

O

O

Chelidonic acid (1, 20.0 g, 0.109 mol) was added to 100 mL of 10% aqueous ammonia

and the solution was heated on an oil bath at 95 oC for 4 h with stirring then evaporated to

dryness in vacuo. The resultant residue was dissolved in 100 mL of water and heated to a

boil with stirring. Sufficient conc. HCl (approx. 30 mL) was added to the solution to the

point of precipitation of the product. The solution was allowed to cool, and the precipitate

isolated by filtration then dried to constant mass in an oven to yield chelidamic acid (18.7

g, 95%) as an off-white solid, mp. 263-265 oC (lit. 267 oC).24

1

H NMR (d6-DMSO, 400 MHz.): δ= 7.56 (H; s, 2H); 3.81 (H; s, 3H) ppm

13

C NMR (d6-DMSO, 100 MHz.): δ= 167.2, 165.8, 149.8, 115.3 ppm

IR (ATR): 3109 (aryl C-H stretch); 2833 (O-H stretch, broad); 1648 (C=O stretch) cm-1

22 Diethyl 4-bromo-2,6-pyridinedicarboxylate (3)25

Br

O

O

N

O

O

Phosphorus tribromide (33.7 mL, 0.35 mol) was added to a vigorously stirred solution of

15.3 mL of bromine in 100 mL of petroleum ether. After stirring for a few minutes at

room temperature, the resultant bright yellow PBr5 was washed several times with

petroleum ether by decantation and dried in vacuo. Chelidamic acid (2, 20.0 g, 0.099

mol) was added to the same reaction vessel and thoroughly mixed at room temperature.

The mixture was heated at 90 oC for 3 h then cooled to room temperature. The solution

was stirred with 150 mL chloroform and filtered. Absolute ethanol (400 mL) was added

to the filtrate in small portions to quench the diacyl bromide, the resultant solution was

concentrated in vacuo, and allowed to stand overnight at 4 oC. The crude crystalline

material was recrystallized from hexane (decantation of the hexane solution from

insoluble material was required), to yield a white solid, 3 (14.6 g, 46%), m.p. 95-96 oC

(lit. 95-96 oC).25

1

H NMR (CDCl3, 400 MHz.): δ= 8.41 (H; s, 2H); 4.47 (H; q, J = 6.9 Hz, 4H); 1.44 (H; t,

J = 6.8 Hz, 6H) ppm

13

C NMR (CDCl3, 100 MHz.): δ= 163.6, 149.6, 135.0, 131.2, 62.8, 14.3 ppm

IR (ATR): 2978, 2938, 2905, 2870 (C-H asym/sym stretch); 1716 (C=O ester stretch)

cm-1

23 4-bromo-2,6-pyridinedimethanol (4)26

Br

N

OH

OH

Sodium borohydride (3.42 g, 0.090 mol) was added slowly to a suspension of diester 3

(6.04 g, 0.020 mol) in 250 mL of absolute ethanol over a period of 0.5 h. The mixture

was stirred at room temperature for 2 h, heated under reflux for 15 h, and the solvent

removed in vacuo. Saturated NaHCO3 (32 mL) was added to the residue and the mixture

brought to a boil. Water (45 mL) was added and the mixture was cooled and allowed to

stand overnight in the cold. The resulting mixture was filtered and the filtrate extracted

with chloroform (5 x 70 mL). The combined extracts were dried over sodium sulfate,

and the solvent removed in vacuo. The resultant solid was combined with the residue of

the initial filtration in a soxhlet cup and continuously extracted for 24 h with acetone.

The acetone solution was concentrated and a precipitate formed.

The product was

recrystallized from acetone to yield white crystals of 4 (2.99 g, 68%), m.p. 158-160 oC

(lit. 162-164 oC).26

1

H NMR (d6-DMSO, 400 MHz.): δ= 7.52 (H; s, 2H); 5.54 (H; t, J = 6.0 Hz, 2H); 4.52 (H;

d, J = 5.8 Hz, 4H) ppm

13

C NMR (d6-DMSO, 100 MHz.): δ= 163.8, 133.8, 121.6, 64.2 ppm

IR (ATR): 3344 (O-H stretch); 3094 (aryl C-H stretch) cm-1

24 4-Bromo-2,6-bis(bromomethyl)pyridine (5)26

Br

N

Br

Br

Phosphorous tribromide (1.625 mL, 0.017 mol) was added in one portion to a suspension

of diol 4 (2.32 g, 0.01 mol) in 110 mL of chloroform and the resultant mixture heated

under reflux for 8 hours. The mixture was cooled and neutralized with 5% NaHCO3 and

the chloroform layer was separated. The aqueous layer was extracted with chloroform (6

x 100 mL) and the combined organic extracts were dried over sodium sulfate and the

solvent removed in vacuo. The crude product was recrystallized from a mixture of

hexane and dichloromethane to yield 5 (2.29 g, 63%), as a white solid, m.p. 127-128 oC

(lit 128-129 oC).26

1

H NMR (d6-DMSO, 400 MHz.): δ= 7.81 (H; s, 2H); 4.66 (H; s, 4H) ppm

13

C NMR (d6-DMSO, 100 MHz.): δ= 158.0, 134.3, 126.2, 32.4 ppm

IR (ATR): 3059 (unsaturated ring C-H stretch) cm-1

25 19-bromo-3,6,9,12,15-pentaoxa-21-azabicyclo[15.3.1]-henicosa-1(21),17,19-triene

(6)27-29

O

Br

O

N

O

O

O

Sodium hydride (60% suspension in mineral oil, 355 mg, 2.1 eq.) was added to 500 mL

of THF and stirred at reflux. In a Schlenk flask, tribromide 5 (1.5 g, 4.4 mmol) and

tetraethylene glycol (TEG, 675 µL, 3.9 mmol) was dissolved 60 mL THF. This solution

mixture was transferred to a slow rate addition funnel via cannula, and then added

dropwise over 6 h to the NaH suspension. The reaction was allowed to stir overnight at

room temperature. The solution was filtered by vacuum filtration and the residue washed

with DCM. Solvent was removed from the filtrate in vacuo and the crude product dried

on a high-vacuum line for one hour. Partial purification was achieved by silica gel

column chromatography to yield 6 (48 mg, 2.8%), a yellow oil.

Purification by

preparative TLC (5% methanol: chloroform eluent) yielded additional 6 (297 mg, 17.2%)

as a yellow oil.

1

H NMR (d6-CDCl3, 300 MHz.): δ= 7.41 (H; s, 2H); 4.73 (H; s, 4H); 3.57-3.72 (H; m,

16H) ppm

13

C NMR (d6-CDCl3, 300 MHz.): δ= 159.9, 133.6, 123.7, 73.3, 71.3, 70.7, 70.6, 70.0

ppm

IR (ATR): 2863 (C-H stretch); 1567, 1115 cm-1

26 19-bromo-3,6,9,12,15-pentaoxa-21-azabicyclo[15.3.1]-henicosa-1(21),17,19-triene-21oxide (7)30

O

Br

N

O

O

O

O

O

Crown ether 6 (14 mg, 0.4 mmol) was dissolved in 1mL DCM and cooled to 10 oC with

stirring. 3-Chloroperoxybenzoic acid (1.5 eq) was dissolved in DCM and added to the

solution.

The reaction was stirred at 10 oC for three hours then stirred at room

temperature overnight. The solvent was removed in vacuo. Attempts to separate the

product from m-chlorobenzoic acid by chromatography were unsuccessful.

1

H NMR (d4-MeOH, 400 MHz.): δ= 7.74 (H; s, 2H); 4.86 (H; s, 4H); 3.35-3.85 (H; m,

16H) mixed with m-chlorobenzoic acid: δ= 7.96 (H; dd, J= 1.8, 1.5 Hz, 1H); 7.93 (H;

ddd, J= 7.7, 1.2 Hz, 1H); 7.59 (H; ddd, J= 7.0, 2.2, 1.1 Hz, 1H); 7.45 (H; dd, J= 7.7 Hz,

1H) ppm

13

C NMR (d4-MeOH, 100 MHz.): δ= 151.7, 125.6, 121.0, 71.7, 71.2, 70.7, 70.4, 70.3,

70.2 mixed with m-chlorobenzoic acid: δ= 166.9, 132.7, 132.6, 129.8, 129.2, 127.7 ppm

Chapter 3 – Results and Discussion

3.1

Synthetic Strategies

When considering the synthesis of 4-azido-2,6-pyrido-18-crown-6 N-oxide (6),

the primary disconnection involves the formation of the crown ether ring. The typical

approach involves the use of nucleophilic substitution, and two different synthon

combinations can be employed to generate the target compound (Scheme 12).

Br

O

O

5

A

N

Br

O

N

Br

O

Br

+

O

HO

6

O

O

O

B

Br

+

OH

4

Br

O

O

O

Br

OH

Scheme 12: Retrosynthesis of 2,6-pyrido-18-crown-6 derivative 6

OH

28 One pathway to crown ether 6 would start with a di(bromomethyl)pyridine derivative and

react it with a diol (or its mono- or di-alkoxide, Scheme 12 route A). Alternatively, one

may generate the mono- or di-alkoxide of a pyridine dimethanol, in the presence of a

dihalo or disulfonato polyether derivative obtained from tetraethylene glycol (route B).

Both methods have been successfully used to generate crown ethers in the past.31 4Bromo-2,6-pyridine dimethanol may be considered the common antecedent for both

approaches.

3.2

Synthesis of 4-bromo-2,6-pyridinedimethanol

4-Bromo-2,6-pyridine dimethanol is a synthetically accessible species that may be

prepared in good yield via a simple three-step procedure.

Chelidonic acid (1) is

generated from a Claisen condensation of acetone and 2 molar equivalents of ethyl

oxalate in a two-step process (Scheme 13).

O

O

O

+

O

O

O

O

O

NaOEt

EtOH

CO2Et

EtO2C

H2O

(HCl)

HO2C

O

O

1

O

OH

CO2Et

EtO2C

OH

Scheme 13: Synthesis of Compound 1

CO2H

29 The initial isolable Claisen product was found to exist predominantly as the dienol, rather

than diketo tautomer in chloroform solution. The dienol underwent internal nucleophilic

attack, leading to cyclization to form chelidonic acid, which precipitated from solution in

sufficiently high purity that no additional purification was required. The crude product

was dried in the oven to constant weight to yield 89% of the desired product.

Chelidamic acid (2) is generated from the reaction of 1 and 10% aqueous

ammonia in a one step process (Scheme 14).

O

OH

NH3, HCl/H2O

95oC

HO2C

O

CO2H

HOOC

1

N

2

COOH

Scheme 14: Synthesis of Compound 2

Chelidonic acid undergoes acid catalyzed aminolysis with ammonia to form the desired

dicarboxylic acid. The crude product was precipitated using concentrated HCl and was

dried in the oven to constant weight to remove water. The resulting solid was generated

in good yield (97%) and was used without additional purification.

Diethyl 4-bromo-2,6-pyridinedicarboxylate (3) is generated from the reaction of

chelidamic acid (2) with PBr5, and the resultant dicarbonyl bromide quenched with

absolute ethanol (Scheme 15, overleaf).

30 Br

OH

1. PBr5, pet. ether

2. abs. EtOH

HOOC

N

2

N

3

EtOOC

COOH

COOEt

Scheme 15: Synthesis of diester 3

Phosphorus pentabromide was generated by the reaction of phosphorus tribromide with

bromine, and used directly without any additional purification. This is an SNAr reaction,

favored by the conversion of hydroxide to a dibromophosphite leaving group by reaction

with PBr5. The formed diacyl bromide is readily quenched in ethanol to yield the diester.

The crude product was recrystallized from hexanes to produce white crystals (46% yield).

4-Bromo-2,6-pyridinedimethanol (4) is generated from the reaction of 3 with

sodium borohydride in absolute ethanol (Scheme 16).

Br

Br

1. NaBH4, EtOH

2. Na2CO3/ H2O

EtOOC

N

N

COOEt

3

OH

OH

4

Scheme 16: Synthesis of diol 4

In general, sodium borohydride is not considered a sufficiently strong reducing agent for

carboxylic esters, but cases of successful reduction of aryl and pyridyl esters to primary

alcohols have been reported.32 The product was isolated from the crude crystalline

31 precipitate by continuous (soxhlet) extraction with acetone over 24 hours. White crystals

of compound 4 precipitated out of solution upon concentration in 68% yield.

3.3

Synthesis of Tribromide 5

At this point in the synthesis, the generation of crown ether 6 can proceed via two

different methods.

The pyridinedimethanol, 4, may be reacted with a dihalo or

disulfonato polyether derivative of tetraethylene glycol to generate 6. The other option is

to react a dibromomethylpyridine with tetraethylene glycol to generate 6 (see Scheme 12,

above). In this synthesis, the di(halomethyl)pyridine/tetraethylene glycol method was

used due to the availability of published methods with good reported yields.25,26,28

Benzylic bromination is preferred, as bromide represents a better leaving group than

chloride, and is less susceptible to hydrolysis than the alternative sulfonate esters.

4-Bromo-2,6-bis(bromomethyl)pyridine (5) is generated from the reaction of diol

4 and PBr3 in a one step process (Scheme 17).

Br

Br

PBr3, CHCl3

N

OH

N

Br

OH

4

Br

5

Scheme 17: Synthesis of tribromide 5

In a manner similar in outcome to the reaction utilized to generate 3, bromo groups are

replacing hydroxyl groups.

However, the reaction is mechanistically distinct, as it

32 proceeds via a SN2 mechanism. Phosphorus tribromide is used to convert the alcohols

into dibromophosphites, a better leaving group for SN2 reactions. The crude product was

recrystallized from a mixture of DCM/hexanes (1:1) to yield 63% of the desired product.

3.4

Synthesis of Crown Ether 6

There are a number of procedures utilized in the literature for the synthesis of

species structurally similar to 6,27-29 and all generally follow variations of a central theme:

The alkoxide of the polyether diol is generated in situ with sodium hydride (considered a

strong, non-nucleophilic base), and is allowed to react with the di- (or in this case tri-)

bromide under high dilution conditions (Scheme 18). Typically such reactions proceed in

low to moderate yields. A number of approaches to the synthesis of 6 were attempted:

Br

O

NaH, THF

N

Br

5

0 oC or reflux

Br

N

O

O

O

Br

+

HO

O

O

O

O

OH

6

Scheme 18: Attempted syntheses of crown ether 6

The initial attempt was based on the procedure of Uiterwijk et al.,27 whereby

anhydrous THF solutions of tetraethylene glycol (TEG) and 5 were separately added

33 dropwise to a mixture of NaH and anhydrous THF under reflux conditions. In this

attempt a large excess of base (6.8 eq.) was inadvertently used. 8.75% of the desired

product was formed, in contrast to literature yields of 55% for an analog compound, and

15-37% for differently sized crowns. Loss of yield for 6 was in all likelihood due to the

non-optimal conditions used.

An alternative procedure, published by Tahri, et al.,28 was considered, since this

procedure utilized milder conditions (reaction was carried out at 0oC instead of under

reflux conditions). In addition, a THF solution of 5 was added dropwise to an equilibrated

mixture of TEG and sodium hydride in THF. Based on the stoichiometry, two equivalents

of base would be expected to deprotonate both sides of the glycol, but reported analog

products were generated from 1.1 equivalents of base.28 The usage of more than a single

equivalent of base in these reactions was investigated:

Reaction with large excesses of NaH (8 & 16 molar equivalents respectively) was

unsuccessful.

1

H NMR analysis of crude product mixtures gave little indication of

formation of the desired product, consistent with previous observations.

An alternative possibility considered was to allow reaction to proceed as

published with 1.1 equiv. of sodium hydride, then adding a second equivalent of base to

more closely approach the stoichiometric requirements of reaction. It was considered

important that the bases used should be as non-nucleophilic as possible, to avoid

competing substitution reactions. The bases considered were:

•

Additional sodium hydride: 1.65 and 2 molar equiv. of NaH were used. In the

case where 2 mol. equiv. NaH were used, 1.1 equiv. were used during the initial

reaction and an additional 0.9 equiv. added at 0 oC after stirring overnight.

34 Purification of the crude products was achieved using radial chromatography to

yield 27% (1.65 equiv. NaH) and 18% (2.0 equiv. NaH).

•

N,N-Diisopropylethylamine (Hünig’s base, 1 equiv.),

•

pyridine (1 equiv.), and

•

Na2CO3 (4 equiv.). The larger excess of this particular base was used to offset its

lower solubility in organic solvents.

NMR and TLC analysis of the crude products were inconclusive and the three

bases didn’t seem to provide a better alternative to NaH. Although the three bases

provided milder options to a second equivalent of NaH, there were clear downsides

related to solubility, nucleophilicity and base strength to consider.

Additional concerns regarding the water content in the anhydrous THF solvent,

and the hygroscopicity of TEG became apparent as the study proceeded; attempts to

duplicate the sodium hydride reactions described above were unsuccessful.

It was

necessary to remove the absorbed water from TEG, and this was achieved by fractional

distillation of the material in vacuo. The distillate was subsequently stored over 3Å

molecular sieves in an argon atmosphere.

A third alternative method, published by Storhoff et al.,29 was attempted. This

method involves the dropwise addition of a solution of both 5 and freshly distilled TEG

in THF to a mixture of NaH (2.1 equivalents) in THF under reflux conditions; via a slow

addition dropping funnel. This procedure gave 6 in 20% yield.

Analysis of the product yields indicates that the highest yields were generated

with 1.1-2.1 equiv. of sodium hydride. Alternative bases were not successful, nor was

the use of large excesses of base. Water absorption by TEG, makes it difficult to directly

35 compare many of the attempts to generate 6, since any water in the system will quench

NaH and lead to a lowering of the yield.

The characteristics of a successful reaction

involve using freshly distilled TEG and 2 equiv. of sodium hydride base gives yields

comparable to those in the literature for analog compounds.

3.5

Synthesis of Compound 7

There are a number of procedures utilized in the literature for the oxidation of

pyridine moieties to form N-oxides (Scheme 19).30,35,36 These species are known to

undergo nucleophilic substitution reactions with reasonable facility.

O

O

N

Br

O

O

O

[O]

N

Br

O

O

O

O

O

6

[O] =

O

7

O

O

OH

Cl

O

OH

O

peracetic acid

O

O

dimethyldioxirane

3-chloroperoxybenzoic acid

Scheme 19: Attempted Syntheses of N-oxide 7

Oxidation of crown ether 6 to form the corresponding N-oxide (7) was attempted

using peracetic acid, according to literature procedure.35 Compound 6 was added to a

mixture of glacial acetic acid and 30% w/v hydrogen peroxide and stirred for 3 h at 75

o

C. A second aliquot of 30% w/v hydrogen peroxide was added and heated for an

36 additional 3 h. NMR analysis of the crude product did not give any indication that

oxidation had taken place.

Oxidation utilizing the oxidizing agent 3-chloroperoxybenzoic acid (mchloroperbenzoic acid or mCPBA) was also attempted according to Pentimalli.30 mCPBA

(1.5 eq.) was added to a solution of 6 in dichloromethane at 10 oC. A byproduct of the

reaction, 3-chlorobenzoic acid, proved difficult to separate due to similar retention times

in a variety of different eluents. Extraction with saturated NaHCO3 was unsuccessful and

resulted in reduced yield and did not entirely remove the acid.

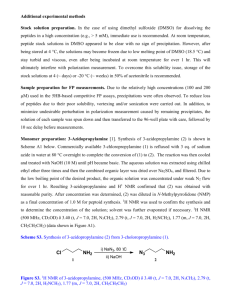

The 1H NMR spectrum of the reaction mixture was consistent with the oxidation

of the pyridine ring to form an N-oxide in comparison with the spectrum of the starting

material, 6 (Figure 5, overleaf).

A shift in peaks at the 3-position on the pyridine ring and the crown ether protons

indicates oxidation has occurred and can be supported when compared to the analogous

compounds, 2,6-dimethylpyridine and 2,6-dimethylpyridine 1-oxide and their shift in

peaks downfield with oxidation.33,34 The NMR spectra of these species indicate changes

in chemical shifts for protons at the 3-position from 6.9 to 7.5 ppm upon oxidation, and

benzylic proton chemical shifts change from 2.5 to 2.6 ppm. The crude spectrum of 7

shows a similar change in chemical shift: 7.41 to 7.64, 4.73 to 4.96 ppm. The 3chlorobenzoic acid byproduct is still present in the sample, and has resonances at 8.03,

7.92, 7.51, and 7.35 ppm.

37 9.0

"!

8.0

!"#$%&'$((((((((()

6789:;((((((((((()

0><$;"'$%8((((((()

@&'<#$."A(((((((()

@:#B$%8(((((((((()

D;$&8":%.8"'$(((()

G$B"?":%.8"'$(((()

D7;;$%8.8"'$((((()

7.06.0

D:%8$%8(((((((((()

H&8&.P:;'&8(((((()

!"#$%&'$((((((((()

H"'.?"R$((((((((()

879:;6((((((((((()

H"'.8"8#$(((((((()

0><$6"'$%9((((((()

H"'.7%"8?(((((((()

@&'<#$."A(((((((()

H"'$%?":%?((((((()

@"8$((((((((((((()

@;#C$%9(((((((((()

@<$V8;:'$8$;((((()

B6$&9";%.9"'$(((()

4.0 4.0

5.0 5.0

6.0

F$C"?";%.9"'$(((()

!"$#A.?8;$%=89((()

B766$%9.9"'$((((()

Q.&VZ.A7;&8":%((()

Q.A:'&"%((((((((()

Q.P;$Z((((((((((()

B;%9$%9(((((((((()

Q.:PP?$8((((((((()

G&9&.Q;6'&9(((((()

Q.<:"%8?((((((((()

G"'.?"S$((((((((()

Q.<;$?V&%?((((((()

G"'.9"9#$(((((((()

Q.;$?:#78":%((((()

Q.?[$$<(((((((((()

G"'.7%"9?(((((((()

D#"<<$A(((((((((()

G"'$%?";%?((((((()

/:A.;$87;%((((((()

@"9$((((((((((((()

@V&%?(((((((((((()

@<$596;'$9$6((((()

X:8&#.?V&%?(((((()

3.0

Q.N*.["A89((((((()

!"$#A.?96$%=9:((()

Q.&VZ.8"'$((((((()

R.&5Z.A76&9";%((()

Q.&%=#$(((((((((()

R.A;'&"%((((((((()

Q.<7#?$(((((((((()

]%"8"&#.[&"8((((()

R.Q6$Z((((((((((()

O9&?$.<;$?$8((((()

R.;QQ?$9((((((((()

G$VB;.=&"%((((((()

R.<;"%9?((((((((()

G$#&>&8":%.A$#&^()

R.<6$?5&%?((((((()

X$'<.=$8((((((((()

J%_#&%\.8"'$((((()

R.6$?;#79";%((((()

R.?[$$<(((((((((()

B#"<<$A(((((((((()

/;A.6$976%((((((()

@5&%?(((((((((((()

H;9&#.?5&%?(((((()

1.0

!!

!!

6.0

5.0

7.0

6.0

5.0

7.2543

7.0

4.0

3.0

X : parts per Million : 1H

4.0

3.0

3.8836

3.8744

3.8653

3.6729

3.5969

3.5878

3.5786

3.4092

8.0296

7.9426

7.9234

7.6404

7.5296

7.5094

7.3885

7.3684

7.3482

7.3427

7.2557

8.0

4.9551

0

(Millions)

1.0

7.4091

"!

3.7227

3.6696

3.6540

3.5807

3.5743

8.0

4.7308

!!

0

2.0

(Millions)

3.02.0

!!

X : parts per Million : 1H

Figure 5: NMR Comparison of crown ether 6 (top) & N-oxide 7 (m-chlorobenzoic acid

peaks denoted with ⊗ )

An alternative method for oxidation of pyridines to pyridine N-oxides involved

the use of dimethyldioxirane (DMD) as the oxidizing agent.36 Since the product of the

reaction is acetone, this procedure should provide greater ease of separation of the

reduced product away from the desired product. Access to commercially available DMD

was not available so it needed to be prepared.37,38 The reference procedure only produces

R.X+.["A9:((((((()

R.&5Z.9"'$((((((()

R.&%=#$(((((((((()

R.<7#?$(((((((((()

]%"9"&#.[&"9((((()

P:&?$.<6$?$9((((()

F$5C6.=&"%((((((()

F$#&>&9";%.A$#&^()

H$'<.=$9((((((((()

M%_#&%\.9"'$((((()

38 a 5% yield of DMD in acetone (approximately 0.1 M), and requires rigorous

condensation techniques, due to the volatility of the compound. Synthesis of DMD was

unsuccessful as confirmed by 1H NMR, probably due to inefficient cooling of the

collection apparatus.

3.6

Attempts to Incorporate the Azido- group

In principle, incorporation of the azido-group onto the crown skeleton could be

performed prior to, or after oxidation of the pyridine ring. The azido group is relatively

inert toward most standard oxidants. Oxidation of organic azides has been reported under

forcing conditions, using hypofluorous acid as an oxidant.39

Initial attempts were carried out using the crude N-oxide generated from the

mCPBA reactions (Scheme 20).

O

Br

N

O

O

O

O

O

NaN3, 95% EtOH

N3

O

N

O

O

O

O

O

8

7

Scheme 20: Attempted synthesis of target compound 8

Sodium azide (2 equiv.) was added to a mixture of 6 in 95% ethanol. IR analysis of the

crude product indicated the presence of an azide, but it was inconclusive whether it was

the desired product or residual unreacted sodium azide.

39 Alternatively, azide functionalization was attempted on crown ether 6 before

oxidation (Scheme 21).

O

Br

O

N

O

O

O

NaN3, 95% EtOH

N3

O

O

N

O

O

6

O

9

Scheme 21: Synthesis of 19-azido-3,6,9,12,15-pentaoxa-21-azabicyclo[15.3.1]-henicosa1(21),17,19-triene (9)

Sodium azide (1.5 equiv.) was added to a mixture of 6 in 95% ethanol. 1H NMR of the

product mixture did show some evidence of changes of chemical shifts relative to the

starting material. However, it was not clear whether these shifts arose from incorporation

of the azide group, or through complexation of sodium by the crown. Analysis of the

FTIR spectrum of the isolated material (isolated by filtration, and solvent removed in

vacuo over 24 h) is similarly equivocal. The FTIR shows peaks at 2112 and 2022 cm-1.

The former (a relatively low intensity peak) is consistent with the formation of an aryl

azide. The latter peak is not, but neither is it consistent with the solid state spectrum of

sodium azide, which also has peak absorption around 2120 cm-1 (in paraffin mull).

Additional study of this reaction is clearly required.

Further study and improvements in the synthesis and purification of 7 and 8 are

necessary to obtain the desired 4-azido-2,6-pyrido-18-crown-6 N-oxide product. Since

purification of 7 from 3-chlorobenzoic acid proved difficult, new methods could be

40 utilized such as preparative LC or HPLC. Also, the preparation of dimethyldioxirane

(DMD) could be improved by improving the efficiency of the cooling apparatus. With

successful generation of DMD, a new, easier to purify, method of oxidation can be

utilized. From the purification of 7, the incorporation of an azido- group can be further

studied. Successful generation of 8 can be used in future metal cation complexation and

nitrene reactivity studies.

41 Bibliography

(1)

Brase, S.; Gil, C.; Knepper, K.; Zimmermann, V, Angew. Chem. Int. Ed., 2005, 44,

5188.

(2)

Bordwell, F.G., Acc. Chem. Res., 1988, 21, 456.

(3)

Scriven, E.F.V.; Turnbull, K., Chemical Reviews, 1988, 88 (2), 297.

(4)

Carey, F.A.; Sundberg, R.J., Advanced Organic Chemistry Part A: Structure and

Mechanisms, 4th ed.; Springer: Charlottesville, Virginia, 2004, 646.

(5)

Pedersen, D.S.; Abell, A., Eur. J. Org. Chem., 2011, 2011 (13), 2399.

(6)

Rostovtsev, V.V.; Green, L.G.; Fokin, V.V.; Sharpless, K.B., Angew. Chem. Int. Ed.,

2002, 41 (14), 2596.

(7)

Camerman, A.; Mastropaolo, D.; Caerman, N., Proc. Natl. Acad. Sci. USA, 1987, 84,

8239.

(8)

Mohan, Y.M.; Mani Y.; Raju, K.M., Designed Monomers and Polymers, 2006. 9 (3),

201.

(9)

Gritsan, N.P.; Platz, M.S., Chemical Reviews, 2006, 106, 3844.

(10)

Doering, W.; Odum, R.A.; Tetrahedron, 1966, 22, 81.

(11)

Ruoho, A.E.; Kiefer, H.; Roeder, P.E.; Singer, S.J., Proc. Nat. Acad. Sci. USA, 1973,

70 (9), 2567.

(12)

Scaiano, J.C. in Reactive Intermediate Chemistry Eds. Moss, R.A.; Platz, M.S.;

Jones, M., Wiley Interscience, Hoboken, NJ 2004.

(13)

Dunkin, I.R., Matrix Isolation Techniques – A Practical Approach, Oxford

University Press, Oxford, UK 1998.

(14)

Platz, M.S. in Kinetics and Spectroscopy of Carbenes and Biradicals, Ed. Platz, M.S.,

Plenum Press, New York, 1990.

(15)

Wijeratne, N.R.; Da Fonte, M.; Ronemus, A.; Wyss, P.J; Tahmassebi, D.; Wenthold,

P.G.; J. Phys. Chem. A 2009, 113, 9467

(16) IUPAC Compendium of Chemical Terminology, 2nd Ed. (the "Gold Book").

Compiled by A. D. McNaught and A. Wilkinson. Blackwell Scientific Publications,

Oxford (1997). On-line version: http://goldbook.iupac.org (2006-) created by M. Nic,

J. Jirat, B. Kosata; updates compiled by A. Jenkins.

42 (17)

Hostetler, K.J.; Crabtree, K.N.; Poole, J.S., J. Org. Chem, 2006, 71, 9023.

(18)

Crabtree, K.N.; Hostetler, K.J.; Munsch, T.E.; Neuhaus, P.; Lahti, P.M.; Sander, W.;

Poole, J.S., J. Org. Chem, 2008, 73, 3441.

(19)

Johnson, W.T.G.; Sullivan, M.B.; Cramer, C.J. Int. J. Quantum Chem. 2001, 85, 492.

(20)

McMurray, J., Organic Chemistry, 7th ed.; Thomson Brooks/Cole: Australia, 2008,

666.

(21)

Bucher, G.; Tonshoff, C.; Nicolaides, A., J. Am. Chem. Soc., 2005, 127, 6883.

(22)

Yonekawa, S.; Goodpaster, A.M.; Abel, B.A.; Paulin, R.G.; Sexton, C.W.; Poole,

J.S.; Storhoff, B.N.; Fanwick, P.E., J. Heterocyclic Chem., 2006, 43, 689.

(23)

Riegel, E.R.; Zwilgmeyer, F., Organic Syntheses, 1937, 17, 40.

(24)

King, H.; Ware, L.L., J. Chem. Soc., 1939, 873.

(25)

Takalo, H.; Kankare, J., Acta Chemica Scandinavica, 1987, B41, 219.

(26)

Takalo, H.; Kankare, J., Acta Chemica Scandinavica, 1988, B42, 373.

(27)

Uiterwijk, J.W.H.M; van Staveren, C.J.; Reinhoudt, D.N.; den Hertog Jr., H.J.;

Kruise, L.; Harkema, S., J. Org. Chem. 1986, 51, 1575.

(28)

Tahri, A.; Cielen, E.; Van Aken, K.J.; Hoornaert, G.J.; De Schryver, F.C.; Boens, N.,

J. Chem. Soc., Perkin Trans. 2, 1999, 1739.

(29)

Barg, L.A.; Byrn, R.W.; Carr, M.D.; Nolan, D.H.; Storhoff, B.N., Organometallics,

1998, 17, 1340.

(30)

Pentimalli, L., Gazz. Chim. Ital., 1964, 94, 458.

(31)

Laidler, D.A.; Stoddart, J.F.; Patai, S.; Rappoport, Z., Synthesis of Crown Ethers and

Analogues, John Wiley & Sons Ltd., 1989, 1.

(32)

Brown, M.S.; Rapoport, H., J. Org. Chem., 1963, 28, 3261.

(33)

Fujioka, H.; Okitsu, T.; Sawama, Y.; Murata, N.; Li, R.; Kita, Y., J. Amer. Chem.

Soc., 2007, 128, 5930.

(34)

Zhong, P.; Guo, S.; Song, C., Synthetic Communications, 2004, 34 (2), 247.

(35)

Itai, T.; Kamiya, S., Chem. Pharm. Bull., 1963, 11, 1059.

(36)

Ferrer, M.; Sanchez-Baeza, F.; Messeguer, A., Tetrahedron, 1997, 53 (46), 15877.

43 (37)

Adam, W.; Bialas, J.; Hadjirarapoglon, L., Chem. Ber., 1991, 124, 2377.

(38)

Adam, W.; Chan, Y.; Cremer, D.; Gauss, J.; Scheutzow, D.; Schindler, M., J. Org.

Chem., 1987, 52, 2800.

(39)

Carmeli, M.; Rozen, S.; J. Org. Chem., 2006, 71, 4585.

44 Appendices – Table of Contents

Appendix A – Experimental Spectra

A.1

A.2

A.3

A.4

A.5

A.6

A.7

A.8

diethyl 2,4-dioxopentanedioate

A.1.1 IR (ATR)

4-oxo-4H-pyran-2,6-dicarboxylic acid (1)

A.2.1 1H NMR (in d6-DMSO)

A.2.2 13C NMR (in d6-DMSO)

A.2.3 IR (ATR)

4-hydroxy-2,6-pyridinedicarboxylic acid (2)

A.3.1 1H NMR (in d6-DMSO)

A.3.2 13C NMR (in d6-DMSO)

A.3.3 IR (ATR)

diethyl 4-bromo-2,6-pyridinedicarboxylate (3)

A.4.1 1H NMR (in CDCl3)

A.4.2 13C NMR (in CDCl3)

A.4.3 IR (ATR)

4-bromo-2,6-pyridinedimethanol (4)

A.5.1 1H NMR (in d6-DMSO)

A.5.2 13C NMR (in d6-DMSO)

A.5.3 IR (ATR)

4-bromo-2,6-bis(bromomethyl)pyridine (5)

A.6.1 1H NMR (in d6-DMSO)

A.6.2 13C NMR (in d6-DMSO)

A.6.3 IR (ATR)

19-bromo-3,6,9,12,15-pentaoxa-21-azabicyclo[15.3.1]-henicosa-1(21),17,19triene (6)

A.7.1 1H NMR (in CDCl3)

A.7.2 13C NMR (in CDCl3)

A.7.3 IR (ATR)

19-bromo-3,6,9,12,15-pentaoxa-21-azabicyclo[15.3.1]-henicosa-1(21),17,19triene-21-oxide (7)

A.8.1 1H NMR (in d4-MeOH)

A.8.2 13C NMR (in d4-MeOH)

45 A.1.1 Compound 0 – IR

I

N

CO2Et

\o

t!

ci

6

ta

!

a

!

EtO2C

\o

o\

t\

O

()

O

oo

O

\o

6

a

GI

ra

6l

O\

C

6u.)

O

O\

!.-) 9

t\

F

ql

\Ct e

6

r.l

ti

O

6

F

rn

<

A

v.)

O

ra

O

C-

30.0

20.0

10.0

0

10.0

8.0

X : parts per Million : 1H

9.0

7.0

6.9590

6.0

5.0

4.0

3.0

HO

1.92

2.5107

2.5062

2.5025

O

2.0

O

O

1.0

O

OH

0

M.V*.Y"@89((((((()(-->,Q6=

M.&3X.8"'$((((((()(A>IO-AM.&%;#$(((((((((()(+,Q@$;R

M.56#=$(((((((((()(,>I,Q6=

[%"8"&#.Y&"8((((()(-Q=R

G9&=$.5:$=$8((((()(OQ6=R

H$3B:.;&"%((((((()(-V

H$#&<&8"4%.@$#&\()(+Q=R

T$'5.;$8((((((((()(AA>VQ@F

]%^#&%Z.8"'$((((()(AQ6=R

!"$#@.=8:$%;89((()(V>OPVIE

M.&3X.@6:&8"4%((()(A>IO-AM.@4'&"%((((((((()(-2

M.K:$X((((((((((()(OVV>IPA

M.4KK=$8((((((((()(,Q55'R

M.54"%8=((((((((()(-EOP+

M.5:$=3&%=((((((()(*

M.:$=4#68"4%((((()(*>OEE-O

M.=Y$$5(((((((((()(,>VVPP*

F#"55$@(((((((((()(!7L?0

/4@.:$86:%((((((()(?3&%=(((((((((((()(-E

T48&#.=3&%=(((((()(-E

F4''$%8(((((((((()(?"%;#$(

C&8&.K4:'&8(((((()(-C(FD/G

C"'.="N$((((((((()(-EOP+

C"'.8"8#$(((((((()(-2

C"'.6%"8=(((((((()(Q55'R

C"'$%="4%=((((((()(M

?"8$((((((((((((()(03#"5=$

?5$38:4'$8$:((((()(C0LT7.U

!"#$%&'$((((((((()(*+*,-*.

76894:((((((((((()(544#$;:

0<5$:"'$%8((((((()(="%;#$.

?&'5#$."@(((((((()(34'546%

?4#B$%8(((((((((()(C/?D!CE

F:$&8"4%.8"'$(((()((,!7GH!

H$B"="4%.8"'$(((()((,!7GH!

F6::$%8.8"'$((((()((,!7GH!

A.2.1 Compound 1 – 1H

46 1

(Millions)

179.7722

160.0

X : parts per Million : 13C

170.0

161.2821

180.0

150.0

154.4993

200.0190.0

140.0

130.0

120.0

119.4001

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

110.0

HO

100.0

O

90.0

O

O

80.0

70.0

O

OH

60.0

50.0

40.0

40.2855

40.0791

39.8650

30.0

20.0

10.0

O.V*.K"?9:((((((()(A*WVQ7>R

O.&4Z.9"'$((((((()(-W2**JJV

O.&%<#$(((((((((()(2*Q?$<R

O.67#>$(((((((((()(EWVEEEEE

\%"9"&#.K&"9((((()(-Q>R

F:&>$.6;$>$9((((()(2Q7>R

G$4B;.<&"%((((((()(AJ

G$#&=&9"5%.?$#&]()(-Q>R

T$'6.<$9((((((((()(A+WEQ?3R

^%_#&%[.9"'$((((()(AQ7>R

!"$#?.>9;$%<9:((()(VW2JVHEE

O.&4Z.?7;&9"5%((()(-W2**JJV

O.?5'&"%((((((((()(-23

O.M;$Z((((((((((()(-**W,A,2

O.5MM>$9((((((((()(-**Q66'R

O.65"%9>((((((((()(2AHEJ

O.6;$>4&%>((((((()(+

O.;$>5#79"5%((((()(*WHEJH*+

O.>K$$6(((((((((()(A,W-JJV\;;.?5'&"%((((((()(-Y

\;;.M;$Z((((((((()(2VVWHJA\;;.5MM>$9((((((()(,Q66'R

3#"66$?(((((((((()(!8N@0

/5?.;$97;%((((((()(@4&%>(((((((((((()(J+E

T59&#.>4&%>(((((()(J+E

35''$%9(((((((((()(@"%<#$(F

C&9&.M5;'&9(((((()(-C(3D/FN

C"'.>"P$((((((((()(2AHEJ

C"'.9"9#$(((((((()(-23

C"'.7%"9>(((((((()(Q66'R

C"'$%>"5%>((((((()(O

@"9$((((((((((((()(04#"6>$(

@6$49;5'$9$;((((()(C0NT8.U/

!"#$%&'$((((((((()(*+*,-*./

879:5;((((((((((()(655#$<;6

0=6$;"'$%9((((((()(>"%<#$.6

@&'6#$."?(((((((()(45'657%?

@5#B$%9(((((((((()(C/@D!CE

3;$&9"5%.9"'$(((()((,!8FG!A

G$B">"5%.9"'$(((()((,!8FG!A

37;;$%9.9"'$((((()((,!8FG!A

A.2.2 Compound 1 – 13C

47 (Millions)

48 A.2.3 Compound 1 – IR

1

<>

\o

c

F

<i

6

a

t.l

n

\o

\o o\

!f

o

c.l

t

q

F

o\

o\

<f,

c.l

el

o\

dl

i+

F

=l

N!+

F

-d;\o

CL

ttt

t,o.

E

(J

_l

OH

;,

o

O

cl

6

6lh

E

I

ro

(o

E

O

O

o

o

o

CL

O

an

(!

(!

!t

_l

(,

HO

o.

ii

i

o\oornor.l<>ro'.loi.loN

OO\O\!oOt*t\\c)\Oinr.}=f,$F

Ocn

i-

1O

o\

5.0

4.0

3.0

2.0

1.0

10.0

8.0

X : parts per Million : 1H

9.0

7.0

HO

O

6.0

N

OH

5.0

O

OH

4.0

3.0

3.56

2.5052

0

2.0

1.0

0

P.K*.Y"@89((((((()(-->,R6=

P.&3X.8"'$((((((()(A>IL-AP.&%;#$(((((((((()(+,R@$;S

P.56#=$(((((((((()(,>I,R6=

[%"8"&#.Y&"8((((()(-R=S

G9&=$.5:$=$8((((()(LR6=S

H$3B:.;&"%((((((()(-M

H$#&<&8"4%.@$#&\()(+R=S

U$'5.;$8((((((((()(AL>AR@F

]%^#&%Z.8"'$((((()(AR6=S

!"$#@.=8:$%;89((()(K>LMKIE

P.&3X.@6:&8"4%((()(A>IL-AP.@4'&"%((((((((()(-2

P.N:$X((((((((((()(LKK>IMA

P.4NN=$8((((((((()(,R55'S

P.54"%8=((((((((()(-ELM+

P.5:$=3&%=((((((()(*

P.:$=4#68"4%((((()(*>LEE-L

P.=Y$$5(((((((((()(,>KKMM*

F#"55$@(((((((((()(!7O?0

/4@.:$86:%((((((()(?3&%=(((((((((((()(-E

U48&#.=3&%=(((((()(-E

F4''$%8(((((((((()(?"%;#$(

C&8&.N4:'&8(((((()(-C(FD/G

C"'.="Q$((((((((()(-ELM+

C"'.8"8#$(((((((()(-2

C"'.6%"8=(((((((()(R55'S

C"'$%="4%=((((((()(P

?"8$((((((((((((()(03#"5=$

?5$38:4'$8$:((((()(C0OU7.V

!"#$%&'$((((((((()(*+*,-*.

76894:((((((((((()(544#$;:

0<5$:"'$%8((((((()(="%;#$.

?&'5#$."@(((((((()(34'546%

?4#B$%8(((((((((()(C/?D!CE

F:$&8"4%.8"'$(((()((,!7GH!

H$B"="4%.8"'$(((()((,!7GH!

F6::$%8.8"'$((((()((,!7GH!

A.3.1 Compound 2 – 1H

49 3.8094

7.5579

0.76

(Millions)

170.0

160.0

X : parts per Million : 13C

180.0

167.1472

165.8320

200.0190.0

150.0

149.7888

140.0

130.0

120.0

110.0

HO

115.2708

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

100.0

O

90.0

N

OH

80.0

O

70.0

OH

60.0

50.0

40.0

40.0791

30.0

20.0

10.0

0

N.V*.J"?9:((((((()(A*WVQ7>R

N.&4Z.9"'$((((((()(-W2**IIV

N.&%<#$(((((((((()(2*Q?$<R

N.67#>$(((((((((()(EWVEEEEE

\%"9"&#.J&"9((((()(-Q>R

F:&>$.6;$>$9((((()(2Q7>R

G$4B;.<&"%((((((()(AI

G$#&=&9"5%.?$#&]()(-Q>R

T$'6.<$9((((((((()(A+W,Q?3R

^%_#&%[.9"'$((((()(AQ7>R

!"$#?.>9;$%<9:((()(VW2IVPEE

N.&4Z.?7;&9"5%((()(-W2**IIV

N.?5'&"%((((((((()(-23

N.L;$Z((((((((((()(-**W,A,2

N.5LL>$9((((((((()(-**Q66'R

N.65"%9>((((((((()(2APEI

N.6;$>4&%>((((((()(+

N.;$>5#79"5%((((()(*WPEIP*+

N.>J$$6(((((((((()(A,W-IIV\;;.?5'&"%((((((()(-Y

\;;.L;$Z((((((((()(2VVWPIA\;;.5LL>$9((((((()(,Q66'R

3#"66$?(((((((((()(!8M@0

/5?.;$97;%((((((()(@4&%>(((((((((((()(A****

T59&#.>4&%>(((((()(A****

35''$%9(((((((((()(@"%<#$(F

C&9&.L5;'&9(((((()(-C(3D/FM

C"'.>"O$((((((((()(2APEI

C"'.9"9#$(((((((()(-23

C"'.7%"9>(((((((()(Q66'R

C"'$%>"5%>((((((()(N

@"9$((((((((((((()(04#"6>$(

@6$49;5'$9$;((((()(C0MT8.U/

!"#$%&'$((((((((()(*+*,-*./

879:5;((((((((((()(655#$<;6

0=6$;"'$%9((((((()(>"%<#$.6

@&'6#$."?(((((((()(45'657%?

@5#B$%9(((((((((()(C/@D!CE

3;$&9"5%.9"'$(((()((E!8FG!A

G$B">"5%.9"'$(((()((E!8FG!A

37;;$%9.9"'$((((()((E!8FG!A

A.3.2 Compound 2 – 13C

50 (Millions)

51 A.3.3 Compound 2 – IR

m

q

\o

ho\

+

6l

o\

tf

N

tt

\6

N

$

s

r+

,1

nq

6

c!

o

6l

t\ F

dl

4t

$

F

o

q

!tCL

OH

ot

E

o

.;l

O

it

o

rl)

(o

(l

N

OH

E,

g

.J

o

c\

c!

Gq

!

c

\o

F

t

n

(a

!ia

o(

o\

1,

o

HO

oo

ta

a!

a!

O

\C}

IU

I

raora

ria!'.

o\

$

0.31

X : parts per Million : 1H

8.0

17.17m

8.4120

8.2512

30.0

20.0

10.0

0

O

7.0

68.06m

7.2530

O

6.0

N

Br

O

O

5.0

0.68

4.4899

4.4725

4.4542

4.0

3.0

2.0

85.98m

1.8078

1.4612

1.4438

1.4255

1.0

0

N.L*.Y"@89((((((()(-->JR6=

N.&3X.8"'$((((((()(,>KA-,N.&%;#$(((((((((()(+JR@$;S

N.56#=$(((((((((()(J>KJR6=

[%"8"&#.Y&"8((((()(-R=S

H9&=$.5:$=$8((((()(AR6=S

F$3B:.;&"%((((((()(-K

F$#&<&8"4%.@$#&\()(+R=S

U$'5.;$8((((((((()(,AR@CS

]%^#&%Z.8"'$((((()(,R6=S

!"$#@.=8:$%;89((()(L>AQLKP

N.&3X.@6:&8"4%((()(,>KA-,N.@4'&"%((((((((()(-2

N.M:$X((((((((((()(ALL>KQ,

N.4MM=$8((((((((()(JR55'S

N.54"%8=((((((((()(-PAQ+

N.5:$=3&%=((((((()(*

N.:$=4#68"4%((((()(*>APP-A

N.=Y$$5(((((((((()(J>LLQQ*

C#"55$@(((((((((()(!7D?0

/4@.:$86:%((((((()(?3&%=(((((((((((()(Q

U48&#.=3&%=(((((()(Q

C4''$%8(((((((((()(?"%;#$(

G&8&.M4:'&8(((((()(-G(CE/H

G"'.="O$((((((((()(-PAQ+

G"'.8"8#$(((((((()(-2

G"'.6%"8=(((((((()(R55'S

G"'$%="4%=((((((()(N

?"8$((((((((((((()(03#"5=$