CASE STUDY Letterkenny Army Depot:

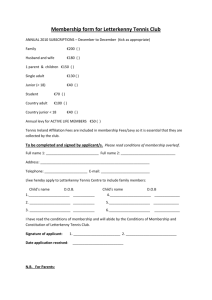

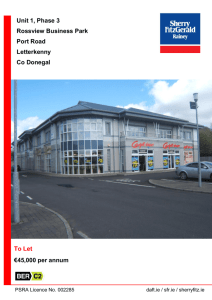

advertisement