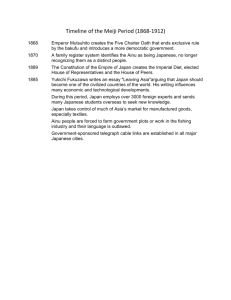

THE MIT JAPAN PROGRAM Science, Technology,

advertisement