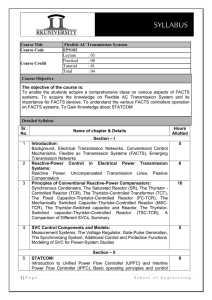

Optimal Usage of Transmission Capacity with FACTS Devices Motivation

advertisement

Optimal Usage of Transmission Capacity with FACTS Devices In the Presence of Wind Generation Rui Yang and Gabriela Hug-Glanzmann ruiy@andrew.cmu.edu, ghug@ece.cmu.edu Department of Electrical and Computer Engineering, Carnegie Mellon University Offline Simulation Simulation Results Optimization Problem Formulation • No overloading • Control variable Wind Speed (m/s) 1 Poor 0-200 0.0-5.6 Marginal 3 200-300 Fair 4 300-400 Good 5 400-500 Excellent 500-600 5.6-6.4 6.4-7.0 7.0-7.5 X TCSC ,n • Objective function • Maximizing the minimum value of the capacity margin max (min ( Pm arg in ,ij )), where Pm arg in ,ij = F 7.5-8.0 6 Outstanding 600-800 8.0-8.8 7 Superb >800 >8.8 • Areas with high availability of wind ≠ demand centers • Constraints • Power flow equations − Pij max ij F PG ,i − PL ,i − ∑ Pij= 0, QG ,i − QL ,i − ∑ Qij= 0 • Limits of the device settings • Variable power output of the wind generators max ij j Determining Key Measurements Potentials of FACTS Devices • Active power flow and current magnitude of each line • Redirect the network flows and regulate nodal voltages • Voltage angle at each bus • Allow better usage of the current transmission facilities • Current setting of the FACTS device • Able to deal with the rapid fluctuations of the wind generation Regression Analysis Proposed Solution • Polynomial fitting - a sparse solution for the coefficients wanted • Use FACTS devices to render the system more flexible • Formulate a L0-norm regularization problem A Two-stage Approach • A subset of important coefficients is identified • Develop a scheme which determines the optimal steady-state settings of the FACTS devices with respect to certain objectives only using a limited amount of information Proposed Method – A Two-stage Approach • The optimal tradeoff between the fitting accuracy and the number of measurements used is achieved Offline Simulation Optimal Power Flow (OPF) Optimal Device Settings Regression Analysis Function Load/Generation Scenarios Measurements Selection Key Measurements Online Operation Controller Values from Key Measurements Offline Simulation • Solve OPF for various generation and load scenarios • Determine function: optimal setting = f(key measurements) Online Decision Making • Evaluate the locally stored function • No online OPF calculations needed System Setup System Setup Optimal Device Setting • IEEE 14-bus system • Wind generator at Bus 2 • Load center on north side Simulations • 1000 different load/generation scenarios 0.02 0.6 0 0.4 0.1 Actual 0.2 Estimated 0 200 400 600 800 1000 1200 Load and Generation Scenarios 0 200 400 600 800 1000 1200 Load and Generation Scenarios Relative Error in the Objective Function 1400 0 200 1400 0.05 0 1400 400 600 800 1000 1200 Load and Generation Scenarios • Overloading Error in the Objective Function Objective Function 0.4 0.08 0.3 0.07 0.2 0.06 0.1 0.05 0 -0.1 -0.2 0 100 200 300 400 Load and Generation Scenarios 0.04 0.03 0.02 Actual Estimated Without TCSC -0.3 -0.4 • Orthogonal Matching Pursuit (OMP) Objective 0.8 0 j −0.9 X Line,n ≤ X TCSC ,n ≤ 0.4 X Line,n 0.04 Without TCSC 0.01 0 500 0 100 200 300 400 Load and Generation Scenarios Two – TCSC – Case 1 0.1 0.8 0.08 0.6 0.4 Actual Estimated Without TCSC 0.2 0 0 200 400 600 800 1000 1200 Load and Generation Scenarios 500 Error in the Objective Function Objective Function Minimum Capacity Margin (p.u.) 2 • Setting of the FACTS devices Error in the Objective Function 1 Error (p.u.) Density (W/m2) Relative Error Potential Error (p.u.) Class Objective Function Error (p.u.) Challenges One – TCSC – Case Minimum Capacity Margin (p.u.) Accelerated Integration of Wind Energy Resources Minimum Capacity Margin (p.u.) Motivation 0.06 0.04 0.02 1400 0 0 200 400 600 800 1000 1200 Load and Generation Scenarios Conclusions and Future Work Conclusions • 800 scenarios for training • Usage of regression analysis provides solution to determine close-tooptimal settings of the FACTS devices • 200 scenarios for testing • Proposed approach provides fast online operation without solving OPF • One TCSC in the system – TCSC in Line 1-2 • Two TCSCs in the system – TCSC1 in Line 1-2 and TCSC2 in Line 2-5 Future Work • Further investigation with larger system 1400