TARA Tandem Mirror PFC/JA-83-4 02139 Administrative Plan

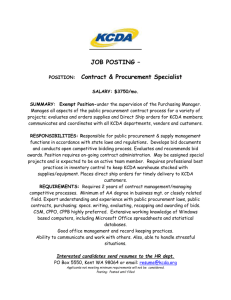

advertisement

PFC/JA-83-4 TARA Tandem Mirror Administrative Plan Plasma Fusion Center Massachusetts Institute of Technology, Cambridge, MA 02139 Massachusetts Institute of Technology Plasma Fusion Center TARA Tandem Mirror Administrative Plan May 28, 1982 Revision 1: June 11, 1982 Revision 2: December 8, 1982 MASSACHUSETTS INSTITUTE OF TECHNOLOGY PLASMA FUSION CENTER TARA TANDEM MIRROR ADMINISTRATIVE PLAN MAY 28, 1982 11, 1982 2: DECEMBER 3. 1982 REVISION 1: JUNE REVISION CONTENTS 1. Purpose of the Administrative Plan 2. TARA Project Objectives and Technical lBasclines 2.1 TA RA Project Objectives (Level 1) . 2.2 TARA Project Objctivcs (Level 2) 3. Organizadon and MIT Managemcnt Procedures 3.1 Organization 3.2 M IT Managemcnt Procedures 4. Reporting and Review Procedures 4.1 Monthly Progress Report 4.2 Quarterly Review 4.3 Six-MoaNith Review 4.4 Special Reviews 5. Baseline Dcfinitions mnd Change Mechanisms 6. Definition of End of Major Project 7. Change Procedures for Administrative Plan 8. Approval of Administrative Plan Appendix A. Milestones and Initial Summary Networks Appendix B. TARA Work Breakdown Strmcture Appendix C. Cost Baseline I TA RA AWlNI NISTR ATIVE PLAN I. PURPOSE OF TI IE AI)MINISTRATIVE PLAN This plan describes the Massachusctts Institute of Technology (MIT) management procedures that will be used to guide and monitor fabrication of the TARA projcct. This plan identifies die reporting and review procedures for the projcct:cstablishcs technical. cost, and schedule basclincs: and specifies a system for effecting changes to the established basclincs. Organizational relationships between MIT project management, DOE's Chicago Operations Office (CORO), and Office of Fusion Energy (OFE) arc outlined and responsibilitics and approval procedures defined. Basclines and procedures described in the plan will be used by DOE to monitor progress of the project and to recognize potential problems so that timely actions can minimize their impact on the project's swift and economical completion. 2. TARA PROJECT OBJECTIVES ANI) TECHNICAL BASELINFS The TARA project is based on the MIT proposals to DOF entitled, "Construction of TARA Tandem Mirror Facility", dated November 1980. and "Phase I Renovation of the Plasma Fusion Center Nabisco Facility", dated July 19S0, and as amendcd by the following: (1) January 5. 1981 letter from MIT to DOE, Davidson to Ellis. (2) March 1981 reviscd proposal for "Construction ofTARA Tandem Mirror Facility with an Ion Anchor". (3) April 1981 letter proposal for a revised, lower cost, descoped program. (4) June 1981 "Dcscopcd TARA Project and Program Plan". 2.1 TAR A Project Objectives (Level 1) The purpose of the project is to fabricate a suitable facility in which the following mirror program objectives can be pursued: (1) Investigate the bcnefits of axisymmetry and alternative magnet design to the national fusion mirror program. (2) D)cmonstratc achieving IMHD stability and potential barrier formation in a tandem mirror, in separate magnetic cells. (3) Demonstrate the feasibility of the hot electron anchor conccpt. 2 2.2 TARA Project Objective (Level 2) The project is defincd by the-specifications listed in Table 1, which arc discussed in the proposals listed hercinabove. 3 Table 1 PROJECT SPECIFICATIONS Item I. Specification Magnet Subsystem 1. Gencral Specifications Two minimum B bascball anchors Magnet system Two solenoid plug sections Two transition sections Central solenoidal cell 2. 3. Construction Internally cooled copper conductor Power supplies SCR-transformer Pulse length 1 sec. flat top minimum Duty cycle 5-min Force restraint External coil case in anchors Anchor Anchor magnets Baseball (formerly TMX plugs) Anchor mirror field 8-16kG Anchor central field 4-8kG Axial mirror ratio 2.0 Length between anchors 1384 cm Plug Plug magnet set Four solenoids/each plug Plug mirror field 30-50kG Plug central field 5.5kG Axial mirror ratio 6-10 Length between plug mirrors 241.5 cm 4 4. 5. II. Central Cell Central cell magnets 18 solenoids, SO cm ID Central cell field 2kG-SkG Length between inner mirrors 566 cm Transition / Recircularization Coils 2 pairs of planar coils Magnet Power Subsystems 1. 1 ca., 13.8kV fused disconnect Power Distribution and 600 ft feeder cable 1 ca. 13.8kV, 750MVA breaker 27 ca., no load fused 13.8kV disconnects 1 ca.. soft start system I ca., power factor correction with surge protection network 2. 8ea.. 3M VA. 13.8kV-480v taped pulse Power Conversion transformers 11 ea., 3.0 MW, 600 VDC SCR controllers 4 ea., 2000 Amp, LC filters 3. Interface with TARA controls and Controls data acquisition systems III. Vacuum Subsystems 1. Tanks Construction Welded aluminum Volume 70 x 10 3t Surface 300 m2 Assembly Flanged Vacuum seals 0-rings Diagnostic access Ports, rectangular, round Tank loads I-ATM vacuum Magnetic forces Eddy current forces 5 2. Liquid-Nitrogen-Cooled Panels Neutral bcam source / dump tanks Vol. ca. 6000t Surface ca., 30 in 2 Total number 4 (descoped) 3. Linear construction Welded aluminum Temp. range 77 0 k < T < 373*k Maximum getter heat load 20kW Duty cycle 2 min. in 5 min. Gcttcring Quantity 100 Ti resistive getters Lifetime 500 shots Quantity 40 E-bcam ''i getters Crucible lifetime 500 shots LN2 panels, 300"k surfaces Coated surfaces IV. Facility Subsystem (Site Preparation) 1. Housing for TARA Buildings NW21 M.I.T. Apparatus in cell Magnets, neutral beams, vacuum vessel, diagnostics 2. Cell location West side of NW-21 Cell size 40' X 145' Centerline elevation 9' Shielding Walls - 24" cement to 16' 12" cement to ceiling 4" cement on ceiling Concrete cell Concrete block Local shielding Electric power, magnet power Utilities Electric power, magnet power Cooling water, LN 2 C3 Compressed air. hot and cold water 6 3. External Vacuum System 120 CFM mechanical pump Roughing system 516 CFM Roots blower booster pump 2-450 t/s Turbomolecular Holding system 2-7000 /s cryo pumps 2H R to 104 Torr Pump down time 4H R to 5 x 10V. Torr Injector Subsystem 3 sloshing beams cach plug Source layout (alternate location anchor) Common flange, neutral beam Source mounting source tank 8 filament supplies 12v-3kA Neutral beam power supplies 8 arc supplies 150v-3kA Arc and filament Power supply location Arc and filament adjacent to sources in cell. Acceleration and Deacceleration: in Penthouse next to experiment cell Gas boxes VI. New magnetic cusp boxes RF Subsystem 1. ICRF transmitters 3 units 3-30 MHz, 1 MW ea 2. ICRF antennas 1 in each cell (anchors, plugs, central cell) 3. ICRF Pulsed Po-ver 3 cap. banks (100 KJ ea.) and charging supplies 4. 1 VGA-8050 A, 28 GHz, 200 kW ECRH Gyrotron plug electron heating with associated waveguide feed to machine 7 5. 3 ca. VA 911's, 10.6 G Hz, 10 kW ea. ECRH Klystrons with associated waveguides and components to couple by open guide to anchors and central cell 6. 85 kV, 100 k, cap. bank with hard Gyrotron Pulse Power tube switch'and charging supplies 7. 3 ea., 15kV, 2A DC supplies unregulated Klystron C.W. Power VII. Basic Diagnostics 1. One system in one plug; extendable Thomson Scattering to a second pass plug measurement 2. 3. Charge exchange neutral energy One in plug analyzers One in central cell Interferometers in all regions 10 units at 70 GC 7 units at 35 C 4 units at 24 GC 24 channels of up/down counting receivers 4. Misc. diagnostics Small flange mounted in various Langmuir probes regions of machine Gridded end loss analyzers Neutral beam attenuation detectors RF probes, electrostatic and magnetic 5. Diamagnetic loops and Hall probes Magnetic field measurements in Large diameter loops surrounding the all cells plasma in several locations Hall probes for direct B and A B measurements 6. Hard x-ray diagnostic for electron anchor 8 VIII. Data System 1. CAMAC serial highway Jorway PDP-11 DMA interface CAMAC controller 9ANSI/IEEE 595) Data rate to 5M Bytes per sec on serial highway consisting of up to 62 crates 2. Acquisition computer system PDP 11/24 with 256 K Bytes of for CAMAC I/0 control memory, 20M Bytes of disk storage and network communication link 3. Timesharing computer system VAX 11/750 with IM Byte memory, for storing, retrieving and 124M Bytes disk storage, 1600 bpi analyzing experimental data ANSI compatible tape drive, and network 4. Graphics input/output devices ?lot-10 compatible graphics for display of data and program video terminals with VT-100 development functions; provisions for local hard copy of graphic and text IX. Control Systems 1. Systems to be controlled Magnet power Utilities Vacuum systems Neutral beams ICRF ECRF Simple diagnostics Specialized diagnostics 2. Hard wired personnel safety Hard wired interlocks interlocks with mechanical interlocks on all 13.8kV switch gear equipment All power systems self protected by internal and appropriate external hard wired interlocks 9 3. CAMAC sequencer 48 channels of CAMAC based slow real time sequencer channels 72 channels of CAMAC based fast triggered sequencer channels 4. Power up system All power systems to be turned on and off from a central commercially built microprocessor based control system in control room. Local remote switches installed on each power system 5. Status and interlock system All power systems to be interlocked and status monitored by a commercially built microprocessor based control system in the control room 6. AC power sources Substation A: power for diagnostics and electrical noise sensitive equipment Substation B: power, for sub megawatt pulsed loads Magnet power for megawatt level pulsed neutral beam arc and magnet loads Clean ground 208V for all diagnostic systems Building ground referenced power for all other power 10 3. ORGANIZATION ANI) MIT MiANAGEMENT PROCEDURES 3.1 3.1.1 ORGANIZATION MIT Organization A portion of the MIT organization chart for MFE operations relevant to the TARA project appears in Figures 1 & 2. The TARA project manager is responsible for the overall execution of the project. An assistant for project control aids the project manager in the planning of the project and in monitorin'g and reporting the progress. The project engineers and scientists are responsible for all subsystems in the project and for their integration, and will coordinate the electrical and mechanical aspects of each subsystem. Physics assignments in specific areas are made by the TARA project manager. Purchasing and procurement services are provided by the MIT purchasing field office and central purchasing. After the project manager's approval, purchase requisitions are forwarded to MIT purchasing for placement of orders. Major procurement status is followed by the assistant to the project manager. All others are followed by the responsible engineer or scientist. TARA management also calls on the MIT Safety Office for assistance on safety aspects of the design and on other parts of the MDF as needed. 3.1.2 Interface with DOE The project interface with DOE will occur through the Mirror Confinement Systems Division of the Office of Fusion Energy at DOE Headquarters and through the CORO contracting officer. Figure 3 shows the relevant organization chart for OFE. The primary liaison for project monitoring will be between the MIT project manager and the DOE personnel identified as TARA program management. 3.1.3. Responsibilities of Projcect Participants OFE has responsibility for the overall DOE management of the program and for approval of program objectives and changes thereof. OFE is further responsible for providing the necessary funding for accomplishment of the project, for monitoring cost and schedule, and for assuring implzmentation of the administrative plan. CORO is responsible for the contracting officer monitoring responsibilities. MIT is responsible for project design and fabrication, as authorizcd within approved cost and schedule guidelines. MIT is also responsible for management of the project within the framework of this administrative plan. 11 a S - ae a a a e 1 a a.. .: - . a =a a a a* Is * .k *- - -. - a - - as. s- Sw a - a U a C C a S 5 Is U .- - a a - C CC . Isa~ U: -au I -SC a a-a 54 2 -a U a: ad 3' a aU ad -a e = a ., Ca ~.. a Is. g ., - ~ = a a a - L7-i 92 * C2 5 . 4 a ag2 - S* - ea ai - C*- a: e- S* Lb CC =E - ' .a : a I- - - S Sa .. C. S-. - - rS .. 5 - Ca C U. I=C - a - CI *: . e.- U- - aC C al CC. a a aa C a S - a-a a aC C * C C. -~2 a C a 5 -a- I. . a - aa s3 Ca& a .. - a a - Lb C a 2 SC CC - - a ~ - ala C. U Cm 3 ~ U - 3 Ca" ,a - LI *= = l.a a~'; ~a - 2 C - aC - * - a a'. -I la 'C a..,.. CaS ~; a I - * '. = .. I - - - a a ' 1- - **.. 12 LIa == a 2 C Is a S - : Cg - Ca LrJ ~ a a C Lb~ .. Ia 5 2 I t ) u C) (~~L) Q) Q ) .. 0 ) I- -j ' 4 ,3)4 = cu L 4-) L# Li W- Oa <I--~~* LuW C) S-- v L) = ci cit 0 CL 04- + C) vi C C.-) ) -< -H E r4 > >1 > -0 4) ;)* <0 C) I-J CE <.~S.~4 - O Office of Energy Research Director A. Trivelpiece Office of Fusion Energy Associate Director, John Clarke Division of Mirror Confinement Systems Other Divisions Acting Director W.R. Ellis TARA Program Manager R. Price Fig. 3. OFE Organization at DOE Headquarters 14 3.2 MIT MANAGEMENT PROCEDURES 3.2.1. Dcsign Mectings In the initial phase of the project, design meetings of MIT personnel will be held on a regular basis, at approximately weekly intervals. The time and agenda for each meeting will be set by the MIT project manager. Participants will include all mechanical and electrical design personnel, physics staff, and other MIT personnel as required for specific problems (example: Hazards Control for safety questions). Attendance at each meeting will include all personnel necessary to contribute to the specific topics on the agenda. The purpose of these meetings is, in general, to: (1) establish detailed design parameters consistent with physics requirements, including preliminary design and final design reviews as appropriate, (2) identify design problems, (3) discuss progress in design, procurement, fabrication, and assembly, and (4) discuss design changes and the overall impact of proposed changes. 3.2.2 Construction Meeting Meetings of the MIT construction staff of each subsystem will be held on a regular basis at approximately weekly intervals. Time of the meeting will be set by the project manager. The purpose of the meetings is to: (1) assign effort to design problems, and (2) ensure communication and coordination among the various parts of the project. 3.2.3 Project Network MIT will establish a network schedule for each subsystem. The subsytcm networks will be used as an aid in determining the construction schedule, manpower requirements, and costing schedule and to help identify critical-path items. This analysis will be updated at the discretion of the MIT project manager but no less frequently than to meet the requirements of the quarterly review (Section 4.2). The initial major project networks appear in Appendix A. 3.2.4 Work Breakdown Structure (WBS) A WBS for the TARA project has been made and is in Appendix B. This breakdown represents a fundamental project outline and constitutes a base from which all project structural activities will evolve. These activities will include project organization, work-task assignment, schedule planning, budgeting and cost accounting, and project record filing. 15 >4 Ln 0.L= 0 0 0) LL. 0 U.. S-. 3C cr > a) cn () 0 m) W S- zV - >- 41. 4+C U U, 9"-4- U U) W C) CL 00. CL 4-I .9-S) (z > 0- S- 4.) a. C 3) -n cm)0 )>o M)C I LCM S-.. 4'-) r > C-U0uC 4- W ~Q 10CC - '0 -01a)' 4- I C r.- .fu.9 V)) 0. - C- 4J - 0 +) 04).)-4- 0~ U) >) .9- 4..) cu0 C (1 ~ 40 W 4J4A= r 04"o t >) w 4-J 1LJ.0 ~~~~ 0 0 4-PO 1-j Um )c 04--.- 0). 4JW - 4-U Q0 0. (a .9-0 . 4J&J.0a0 fr ) 0 4- 4. REPORTING AND REVIEW PR OCEDURKS 4.1 MONTH LY PROGRESS R FPORTS A written monthly report to OFE and CORO will be due cach month and will consist of the following: (l) Presentation in tabular form of costs by subsystem (Level-2), for die current fiscal year and for the project total. Listings will include cost plan, manpower plan, contract management summary report and cost management report in accordance with contract requirements. (2) Narrative discussion as necessary to clarify the cost data, to detail the pfogress, and to relate progress to the milestones and project schedule. (3) Narrative will include a statement of procurement status for all major items and for the total project. The procurement report may be in tabular form. 4.2. QUA IZTERLY REVIEW Thcre will be a quarterly review of te cost, schedule. procurement. and overall project status. This review will be based on the written monthly reports and will include oral presentations and discussions as nccessary. L.cvc;-2 cost and schedule data will be presented, including network updates. Tlie quarterly review is alternately superseded by the six-month review (Section 4.3). Quarterly reviews will occur during the months of May and November where feasible. 4.3 SIX-MONTH REVIEW 'Ilie six-month reviews will include a written report and an oral presentation by M IT for (1) technical update, (2) cost status and projections, (3) schedule review and projection, and (4) procurement status Six-month reviews will occur approximately during the months of August and February 4.4 SPFCIAL REVIEWS If requested by any of the participants, there may be special reviews if warranted by information and developments during die quarterly and six month reviews. 5. IASELINE DEFINITlIONS AND CHANGE MECHANISMS Tho changc control plan defincs the mechanisms whereby changes to die echnical, cost, and schedule haselines shall be formally imnplcmented. Changes to the project I.evel I technical objcctives, as defined in Section 2.1 of this documient, shall be 17 proposed to OFE by MIT, with a copy to the CORO contracting officer. Thc proposals shall identify and discuss the reasons for the proposed change, and include M IT's estimate of the impacts. if any, on total cost and project schedule. OFE shall evaluate the technical and programmatic impacts of the proposed change and, if appropriate, recommend that the CORO contracting officer modify the contracL Significant changes to the project Level 2 technical baseline shall be proposed by MIT to OFE. OFE shall issue the appropriate approval to MIT, copy to CORO. The project second-level technical baseline is defined in the project specifications of Section 2.2 of this document. A significant change to this baseline shall be defined as one which would impact a subelement cost by more than $300K, or the project schedule by more than 2 months. Changes to the project second-level technical baseline which are not significant shall be approved by the MIT TARA project manager. The technical baseline shall be revised and re-issued as appropriate. All changes above Level 3 will be reflected in the monthly MIT status report. The original baseline schedule is given in Appendix A. This includes the project milestones (Level 2 schedule), as well as the initial major project subsystem networks. The original Level 2 cost baseline is given in Appendix C. The baseline definitions and change mechanisms described in this section are summarized in Table 2. This table gives the technical.cost, and schedule baseline definitions and approval requirements for each level. 6. DEFINiTION OF E-ND OF MAJOR PROJEC' The TARA project will be considered completed as far as the approved funding is concerned when DOE is satisfied through performance tests and in overall assessment that the project meets the specified technical performance, as amended, and that operating and safety criteria are satisfied. Specifically, the construction project will be considered to be completed when the following criteria are met: All subsystems as specified in Section 2.2 are in place and operable, and MIT safety requirements are satisfied. 7. CHANGE PROCEDURES FOR ADMINISTRATIVE PLAN Revisions and/or changes to the Administrative Plan may be initiated by DOE (OFE and/or CORO) or by MIT, when sufficient cause exists. Any changes in this administrative plan must have the concurrence of both DOE and MIT. 18 8. APPROVAL OF ADMINISTRATIVE PLAN This plan is adopted and approved and will remain in. effect until the completion of the TARA project subject to changes that may occur by the procedure of Section 7. R.E. Price, TARA Program Manager Division of Mirror Confinement Systems Office of Fusion Energy U.S. Department of Energy R.C. Davidson, Director Plasma Fusion Center Massachusetts Institute of Technology R.S. Post, TARA Project Manager Division of Mirror Confinement Plasma Fusion Center Massachusetts Institute of Technology -19- APPENDIX A. MILESTONES AND INITIAL SUMMARY NETWORKS 0 O 4 N N 0 C% iI 04. co1 41 '. A.1 C CU r4 H (U I I I N 0% r-f H (U N N 0 0% r-4 N r- Co E z 0% r-4 N N M C., CO C. Ch 0% 0% 0% 0N 0% w $4 A S (U E I I I N CO m CO H 0 0 H IC (U r-4 0. 0 0. 0 o o I I I N - 0 0 0 r-4 T-4 P-4 CU . r-4 r-4 D <. '" I I 0% 0% . I 0 F- li .4( I I I I I I I M 0 u 0 4).> W N N N- N N N c% HO 0% 0% 0 C% r-I C 0 r-I C( 0H F4 S.'U 0 Co 0-H cn u w J.5 cn 0% 0% 0% (U z 4. 1.4 0 to 0 *n* r-4 0 C 0 I '0 pv H W U.4 41 0 0Co 00 u C 0-.' HO 41j 00 0 u .40 0 sO 0. I-' c Pw (U CU w 0.4 0 C0 0a) 4. CO 0 H H-i 0 r-I 00 ot- 0 uo 0co 4.1 E- C -Co 1 -C1 0-i H 4. 0a) 0 0 14 0.4 Mr-i 0CCQ (U C Cw 4.1 2 . . 0 M -u 01.4 20 41 00 C) C 45 1. H Z C2 0 (U ,,0 0 0W 4.1 0 N 0 (U Co UH 00 1.4 O O 0 H 0 0 0 . V400. -L) OH .7 0 u 4.1 0) r 0 90 Co ci 0 0 0. 0.(U 0 I1~ H 0.4.1 0. 01-' 0 0 Ou2 S0U S> r-. ~ 20M 2 u 4 0 0 0 0 o 41 H -H4 C6 co 4 -' 4.1 0 40. 0. C-) Co 0 .0 0 0 0 0 w4 C., 0 S2 HO D .1 HO0 H 441 4c '4.4 4.4 0& 0 0 41 u (0O M (U S0 -0 U 0 -Hi 0 CU (U H 0 0 *0 -pq 0 410 0 m H Cu 4.4 CU cc 0H a V4 41 0 COC C: 0 4J 44 0 to 93 w Cs o c0 > u 4-) 0 AUC. j cc r-4 $4 H U 0 0 0tS. V4 -r4 .0 0 4.1 w -r4 r 0 0 4 0H 0. 2 0% CU 0 a (a 41 0. n ) w 0 41 0 H C HG u 0 0 ,0 C H CU 0 CU H HG 0 00 CU -0 0 0 0G 0 0 H H -a C Co 0 ~00M 0 0 0 0 -45 0c 44 .3 0 C0 0 u 10 0)0 O.2 00m 00O H rHi II.1 0> 4J ) 41c 0 mH m 00 0 c 0 G 0 N :1 00 0% aHl co H7 N 04-i O 0 CU41.- rd 0 I - eiO.4-J 0 C 0 C ~ 0% o c o I I1 I I I 0 0 0 0 00 0% OD HPr-4H lH -O .- ) to CCc 0 H 0 0 -~ E- .0 0 wC $4 Q0 .0 4LW 0 41) 0 4 H S tr C:~ 0 i r- r. co .0U -4 0) 4 4- ) 0 H0 1 9.3 40 H :14 W > u) mH 0V r. C 0 0)0 - 0 c 41 w0C to3 (d0C w rq CC H L 0 C) r.. C <- 0- 0 4-4 w .4 03 to 0 - 4-42 0 0 OZ .0 0 r. 0 -H 1-4 .0 rz 0o 41) . P4QHHr ~H 0 w0 0. z 4.10 0d H4 4)0 1-3 0- H 4 (d00 Hq 0d w -0 co 0 0 0 0 - CC CO Hw w H) r 4). W HOm. cc Ix 0 4.) Pi $4 0 > 4-1 W w 414C)4-1 ,)4 - # 0 U.4 0 0 - H Z 4.) 0 Hi) Cir 0 0.0C) C4 0. -Hi 00x 0 0 a) -4 '- q ) H 4.3 0) 0. 0 H a 4-J 0 HI m H w -4-W 43 (D 4.1 41) Q) w~ 1- 0 00 0. 43 M. 0.0Q 00> 0 00 H H 04 r 41 x 3 C -q o r- 4 0 00 0 -140 14) E4u 4 4-4 Ho H r 0. w ca 0d c0w0 H 0 4 0 >H 0 z CO 4 C 4 C%4 0 H 4 tC00O) : TV~I U- 00 V4~ 0. >E-4 cor I-' co 0 ;n b 0 c rqca a 0 C. u~ -4 00 00 -- 4 0~ 0 .0.e-4wcaC co L -H r- 0 0co M-H U P. CD -H w.4 4Jo. 41 a) ca 01un U ~- 0 C) 0~J to a $4 0$. 447QPa a) Q4U C.) 001-H 4 .. 41W0 0. i 0 -- r 0 - 0 -- COr4 0D0 0t P 0 0 r J 00 0 b 0r -P ~ C *vH lz U 0U 4Ca) 4C . 0 4 0J 04W4 r MAGNET' SYSTEM MILESTONE LIST 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Begin evaluation of coil options Complete magnet system design requirements Begin fabrication of plug coils Complete fabrication of plug coils Begin fabrication of central cell coils Complete fabrication of central cell coils Begin fabrication of transition coils Complete fabrication of transition coils Begin preparations for TMX coils Complete design of TMX coil modifications Complete TNX coil modifications c- LL. ILL- 0 ICD I z 10 00 '.4 .00 LJ~ 4 cc 0 0 0 Go1i. CU OW U-4 "00 Nk 44 0 Cj~ 0 U, 0 0 4-4 '44 co> co4 0d an- . La 1 0 0 ~ *9.4 -- I.'- 0 .0 0 0 LL. 0> 'U- 5.4 C14 * ri'~ HE- rLn U 0~-4 '.4 0 0. P4 0 0 u a)0 44 CU. c.,J 0 e 0 44 0 0 4-I 0 0 0 4 0 r40 E-i4 u 0- 0 c 00. ~)1.a0 41 2 4H >E-4 0. 4 o 4-4 0 14 M . 4 H W0 C:1 ,4 4 4-4 W 0.01.w 44 wo 0n 4.4 ... U4 0 -r4 0 - 04 P4 0 __1-il' E- H 0 0) 4J.4. 0 0 * 00 - * c L co 4Jp40 o.>J0400,.41 -dq 0D r4 4-r4 4) 0 H rS0.0 i CD 9 C4 00 U Hv; H D CD0 U t C4 U, U- oc 4J (1 V.Q) 'o1 10 V-4 d wO -i cz C-) H co 0 . to M w co -4* U.. r- . C)~~C 000d -O~ -4 ca a) ~ -~ c ----- 'aCo. a $.a o0-34 001 Q) o r"r 0 a) 4-1 ~ w 00 0 ~ -ld Aj to c 4 : 1 0C 41 0 -H0 0C c d Wd 00 C 0j 00 0 co CoD cc) ± o AJo 0W0 0C 44 V 00= 0 LI U.. 0*4 01 A). Cd Co WZ c %64 o z u d .. 4 01 J-o, E-- Cd 0 > " ".7441to0& L c bo cc t Aito 0 w W wu 00 -0 Co -0 0 41 03 _ VACUUM SYSTEM MILESTONE LIST 1. Begin evaluation of vacuum system options 2. Begin detailed design of vacuum system components 3. Begin fabrication of central cell (CC) tank 4. Complete fabrication of CC tanks 5. Begin fabrication of dished heads for plug tanks 6. Begin fabrication of .plug tanks 7. Complete fabrication of plug tanks 8. Begin fabrication of transition tanks 9. Complete fabrication of transition tanks 10. Begin fabrication of anchor tanks 11. Complete fabrication of anchor tanks 12. Begin fabrication of fan tanks 13. Complete fabrication of fan tanks 14. Begin fabrication of neutral beam (NB) tanks 15. Complete fabrication of NB tanks 16. Begin design of pumping, getter, LN2 transfer and E-beam systems 17. Complete procurement of pumping, getter, LN 2 transfer and E-beam- systems I I I 0 CL -H 0 CJ ) U)4O V)Jm -p.4 0 0 ~r4 a)0 PN U) co LL. U- 0 0) Cl. 4J m -H0 U0 m 41) ;0~4 P4 0 :3to- 0 0A 0 4 vcv) 'I ro ?A C> F ~0 0 Z I -4 E-4 44 -A 0 4 w0. 0- 0 0 0 10U 0 0~ U0. U14 ULUj- 441 0 COH. r4 044 Liq U1) m 0 U) P. 41) 0 0) 1 .r4W . 0) .1 H o 00 41 W PQ1$ 1-4 0. 0 0) 0,, mu .. 1.04 41 0 00 0 co U) r 1 0 -r-4 wp. 0Q 4 C4 -; 1; m WO9 0 0 LA a) - -4 H 0 H 0 U3 Li a) 0 C 0 4 0 0 CC) 41 LL. rj) CL to L&.. CL a u 2 to F - H 0 C) 1.1 i 0 0 ~0 0 w I 0 41a w aa U 0 0) '-i H (D 0 0 0 0 '-4 C-, -4 U w cr, 0'o P4 0 u. 0. HC) a) 0 2 0 U.. 0 H C.) ad ~~co M z. C4 z-4 0 0r HJ Li. 0E Hr 0 0 0 Ho -H 00 CD I-, - - - r., L a z co -H L1 4J i (1 (1 Q) 0.4 -a -wM 5 o u w w0 v C4 - 41 4 J0 SO i C 0 - - lz 0 -ri 0 0 C6 S . a) 'ca& ji o >1 M D5 5~~~ 0 C 0 -0 L 4 4.JM C 0 0 c to 14 u Cd H 0. 0 0. 5 O . u C) Li 0 M H ,0 z OM m to0 -m C -ri 0 0 H 0 - - -- --- 0 H C) 0 0 e H O H H M. 0 0 4J M L -n I - M -- . cJ CC) - NEUTRAL BEAM INJECTOR MILESTONE LIST 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Initiate Neutral Beam (NB) prototype activity Test Stand (TS) under vacuum Initiate procurement for TS diagnostics and beam dumps Begin mounting TS diagnostics Begin prototype source assembly Complete TS and initiate-NB prototype testing Finalize TARA source design Complete specifications of TARA NB sources Initiate procurement of NB power supply (PS)components Start assembly of NB PS components Complete assembly of all NB power supplies Begin installation of beamlines and connection of sources to experiment Complete connection of NB to experiment . I Begin evaluation of neutralization and shielding options Begin design and construction of neutralizers and shields Begin installation of neutralizers and shields Begin evaluation of Ti evaporation options Begin design of Ti evaporators and sublimation pump Begin construction of Ti evaporators and sublimation pump Begin installation of Ti evaporators and sublimation pump U- LI) cm, r4 . 4.j 1 .- ~~~~-~i G LOU)f c0C l 4 41 iJJJ 0 0') U cm -- 9: 0 0 p > - 0 c H 4J 0- 41i 4 U a__ 0- U- 0_ 41(dw-cf Q-- U >, 0\J 00 0, -Gw~ 0, - 0---q ~ -~ CU w >N 0 o 1- 0~E-4 0 C) toC6 0 1 10 wU ~ - - RF POWER MILESTONE LIST 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Begin analysis, tests, design development, and evaluation of ion cyclotron resonance heating (ICRH) power, antennas, and matching networks Select source configuation Complete installation of ICRH system Complete construction of prototype ICRH antenna Begin procurement/fabrication, assembly, and testing of prototype 28GC electron cyclotrdn heating (ECH) system 28GC ECH power supply system test Complete first Complete installation of 28GC ECH system Begin procurement, assembly, and testing of first klystron system for ECH Complete testing of first klystron system for ECH Begin design of ECH cavity Begin construction and test of ECH cavity Complete test of ECH cavity Complete installation of ECH systems In I .I 0 Cu -0 '-4.-I Cu '-4 Cu J-iCu U, *- *r.4 0 L. C - -0 Cuh. Q) '-I 1-I i -I I/) I 0 co 0 c 0 w 0 44 OCu 044 0 4) caCu 4 41C 0 C. A 0 u E Ci Ir- o Se U, 0U, CP, 0 0 U 0 0 Cu ~U 0 co 0 u 0 CuCC -a 0 4- U -a --- 0 0 '-4- CU ca 0 0 0 -4 ) C, Ui ~LI I Ln I I - I 0- -oo 0 CU 1 2 0 0 Cu Cu 9-4 U 0 41 0 0o Cu *0 o o oe 0 C 44-. to Cu U- 4-4 0 U, '-4 -.4 0 U C" C 0 -14 0 U 4-' Cu C t-4 ai 0m k.:, __LKI 0 4C to 0. to 0$ O N C - 0 1-4 -' 4 0 W 4-4 44 Cu 00 -'-I 0 -0 0 -H Lll) n U 0 .r40 .- 0 u 4C Sco ' DIAGNOSTIC MILESTONE LIST 1. Begin design of hot electron anchor diagnostics 2. Begin procurement and fabrication of hot electron anchor diagnostics 3. Begin installation and calibration of hot electron anchor diagnostics 4. Complete hot electron anchor diagnostics 5. Begin design of central cell diagnostics 6. Begin procurement and fabrication of central cell interferometers 7. Begin installation of central cell interferometers 8. Begin procurement and fabrication of central cell diagmagnetic loops and pin diode array; complete design and specifications of MDF diagnostics set 9. Begin installation and calibration of central cell diagmagnetic loops and pin diode array 10. Complete installation of base diagnostics 11. Begin design of ion anchor diagnostics 12. Begin installation of ion anchor diagnostics 13. Complete installation of ion anchor diagnostics 14. Begin design of Thomson scattering and central cell time of flight (TOF) analyzers 15. Begin procurement and fabrication of Thomson scattering and central cell TOF analyzers 16. Begin assembly, installation, and alignment of Thomson scattering and central cell TOF analyzers 17. Complete installation of diagnostics 3/16/82 11.0 1 I 1 LLZ LL- 41 - -I.--, - - ~2Y~~ -4. 0 - iv)1 co 0 cucu (U(u r-i jj U)U) r4 1i m "Zol SO co 41 to m .0 0 Cu .J (n C., I-I 0 0 4-i 0 0 r-i a pq Cu 4-i 0 0 1-I C4 0o E- S cc 0 14 co C',: Li- C,, 4JI cn U, 10 0 E-4 4-i 41a C- 0. 0 5 4,1 '-o 0 c., u1i U Q) cc 40 0o s-a W -I-I 0 0 Itn I 1-4 C3 0 0 cc -4 w~ 0 -. -11 -j .,4 w. < cz (1) t 0W C\J 0co -- 'r4 - V2 0z J' co 0 -H o 0 0 Q4 0 w ____ bo P4 -. V -li .0 4) m- 0 r-4 > I 5:- 0 Cuq C:-- OE10 0. >-. 0 0 r 00 V 41 m o- *u bo>r ej m > t :.4 0 w 0 U-. I 0 . .rq tz.----0 W- m 0" 0. P LL. _I_ 0 s-I 0 w m - C O DATA SYSTEMS MILESTONE LIST 1. Begin data subsystem design and specification 2. Begin procurement of commercial hardware/systems 3. Begin installation and checkout of commercial hardware/systems 4. Begin network integration 5. Complete design of data system topology 6. Complete specification of Data Acquisition System (DAS) 7. Complete design of DAS 8. Complete coding of DAS and DBM, begin system integration 9. Complete data system integration 10. Complete data system tests 11. Complete specification of Data Base Manager (DBM) 12. Complete design of DBM 13. Complete design of controls concept 14. Complete design of slow control data and status monitoring system 15. Begin installation and testing of slow control data and status monitoring system 16. Complete control system 17. Complete specification of interlocks 18. Complete design of interlocks 19. Begin installation and test of interlocks 20. Complete design and evaluation of timer 21. Complete fabrication of timer 22. Begin installation of timer 23. Complete specification of power system controls 24. Complete procurement of power system controls I I vi I cli 41 $4 4.) U) tm. 1' >N 0V2 ml" co -- 41 cd U- CO 0 C60 4) 4,J 0 41 0 u co 424 to 0 (D Li U Co (1) C60 0 4J cz "_4-4 0 -H 4.j ca ji -"q r-I -r-i u 0 Cd 44 0) 0 0 C 41 > 8 cd 4-1 w r- -H tj LL 0101 9 '-4 u :1 0 0 0 0 0 w 4) 41 to = 4J -rq Z C: a) -A E.-z tt im. V 0 E -f C 0 r. -rq Qj cc $4 0 -12. 0 4-i 0 41 41 41 Ch J-j r_ (1) = 0 0 14.4 r= 0 0 0 -C.I. 0 0 OE cz c4) -W "0 m 0 >.. co 0 (1) -41 cc w 00 (U 41 Cil W -H CO a) cc " tv -0 Ckc " f: T :3 to 0 0- -4 41 0 41i -4 ca ' 41i 0 -4 ~ >~ 0 0 0 I 0 -H 4J$4 ' a)-J. 0 w U)- 0 4 v -rq 00 () -r4U -OA -i 00 0C 0 0Et co ~ 44 221 4 . 4 4-i. 0) -4c 41 -4 -v.U) m 0 4JO 0 s-I to54 0 0w: 4-i W co' C-) 0 4-I Z.4 4-1 4J0413 2ow > 0) C. 0 TII .00 0 cc 0 'HO -H 041 w 0 -4 ______ -4, -4 0 Q0" if w 00 0 z 0 L Q 0 0 0 ~ LL 0 4H2 -4to 0 5- C).-- S44 U 1 __Lill 0~ ci lLn .j 0 o Ic, coJ -4 -d 74 0 .i 41i fr4 0) ~ n*4- a) 0 0 *0 CO -4 0) 0 0 ~ co U - -*-1- ~ cy,< H b 67 -ri o 0J P4* C3 o E-44 0m 0) p.4 4 00 0 i00aA 0 coCl ON - P W m 0 S~ z Q)W P4 pq - go U-U~ 4 0 0 00 0 0 0 r-4 I0 r 0 C-) op.-4 / 0 A Cj 000,, ~ -, Ci APPENDIX B TARA WORK BR EAKDOWN STRUCIURE 1.0 MAGNET SUBSYSTEM 1.1 1.2 1.3 1.4 Analysis and Conccptual Design 1.1.1 Magnetic field analysis 1.1.2 Calculate magnctic forces: normal and fault 1.1.3 Power/copper trade-off considerations 1.1.4 Magnetic alignment method dcvclopment (mechanical/trimn coils) 1.1.5 Alignment scnsitivity study General Magnet Preparation 1.2.1 Cond tctor/instilation/coil specifications 1.2.2 Conductor procurement 1.2.3 Ship and receive TMX anchors Outside CEE Coil 1.3.1 Confirm use of TMX outside CF.E 1.3.2 Evaluation of need for additional outboard race-track J.3.3 'rest and repair leaks 1.3.4 Lead stack modification (of'lTMX) 1.3.5 Procure winding (if additional race-track required) 1.3.6 Cooling manifolding 1.3.7 Coil axis determination Anchor Base Ball Set 1.4.1 Confirm use ofTMX coils 1.4.2 Electrical test 1.4.3 Test and repair leaks 1.4.4 Stack modification and repair 1.4.5 Cooli ng mani folding I 1.4.6 1.5 1.6 Coil axis confirmation and determination Inside CEE Coil 1.5.1 Confirm use of TMX inside CEE 1.5.2 Test and repair leaks 1.5.3 Stack modification and repair 1.5.4 Cooling manifolding 1.5.5 Coil axis confirmation and dctermination Transition Recircularizer 1.6.1 Coil design 1.6.2 Coil procurement 1.6.3 Acceptance tests 1.6.4 Mechanical support 1.6.5 - Lead parts 1.6.6 Cooling manifolding 1.6.7 Coii axis dctermination High Field Plug Solenoid Sets f.7 1.8 1.7.1 Coil design 1.7.2 Coil procurement 1.7.3 Acceptance tests 1.7.4 Mechanical support 1.7.5 Lead parts 1.7.6 Cooling manifolding 1.7.7 Coil axis determination Mirror Boost Solenoid Sets 1.8.1 Coil design 1.8.2 Coil procurement 1.8.3 Acceptance tests 2 1.9 1.10 2.0 1.8.4 Mechanical support 1.8.5 Lead parts 1.8.6 Cooling manifolding 1.8.7 Coil axis determination Center-Cell Set 1.9.1 Coil design 1.9.2 Coil'lprocurement 1.9.3 Acceptance tests 1.9.4 mechanicial support 1.9.5 Lead parts 1.9.6 Cooling manifolding 1.9.7 Coil axis determination Installation 1.10.1 Installation fixtures 1.10.2 Coil set insuillation 1.10.3 LCW hookup 1.10.4 Umbilical and lead installation 1.10.5 Preliminary machine axis alignment 1.10.6 Mechanical tests 1.10.7 Magnet tests MAGNET POWFR SUBSYSTEM 2.1 2.2 Power System Integration 2.1.1 Enginecring and design 2.1.2 Circuit analysis 2.1.3 Building interface 2.1.4 Assembly and checkout 13.8kV FLeed Subsystem 3 2.3 2.4 2.5 3.0 2.2.1 No load fused disconnect switch 2.2.2 Substation interface 2.2.3 13.8kV cable run 13.SkV/480V Transformer Vault 2.3.1 13.8kV 750 MVA breaker 2.3.2 13.8kV switches and fused disconnects 2.3.3 13.SkV/480V transforncrs 2.3.4 Design/speci fications 2.3.5 Procurement 2.3.6 Acceptance tests 2.3.7 AC cable runs SCR Controllers 2.4.1 -Design/specifications 2.4.2 Procurement 2.4.3 Acceptance tests 2.4.4 DC cable runs 2.4.5 Installation Power Controls and Diagnostics 2.5.1 Control system integration 2.5.2 AC and DC fault coordination 2.5.3 Power system diagnostic VA CUUM SUBSYSTEM 3.1 Vacuum System Research and Design: Base Program 3.2 Center Cell Vessel 3.2.1 Tank module design 3.2.2 Procurement 3.2.3 Flange details 4 3.3 3.4 3.5 3.3.1 Tank design 3.3.2 Procurement 3.3.3 Flange details Inside Rccircularizer Vessel 3.4.1 Design 3.4.2 Procurement Anchor and Fan Vessel 3.5.1 Design 3.5.2 Procurement 3.5.3 Flange details 3.6 End Plug Liners 3.7 Anchor/Fan Liners 3.8 Internal LN 2 Plumbing 3.9 4.0 Plug Vessel 3.8.1 Feedihroughs 3.8.2 Internal plumbing LN 2 Systems 3.9.1 LN 2 monitors 3.9.2 LN 2 control system 3.10 Getters 3.11 Getters Power and Controls 3.12 Inner Wall Dumps 3.12.1 Water liners 3.12.2 Internal plumbing and feedthroughs 3.12.3 Water flow monitor and controls 1-ACILITY SUBSYS'l EM 4.1 Contrl Room 5 4.2 4.3 4.4 4.5 4.6 4.1.1 Overall control design 4.1.2 Module fabrication/procurement 4.1.3 Interconnection cabling 4.1.4 Monitoring functions Pit Accessories 4.2.1 Machinc support structure 4.2.2 Accass platforms 4.2.3 Stairways 4.2.4 Auxiliary crancs 4.2.5 Heating High V\acuunI Components 4.3.1 Turbo pumps 4.3.2 -Valves for IV new pumps 4.3.3 Stands 4.3.4 Traps (closed-cycle rcfrigeration) Piped Utilities 4.4.1 Vacuum foreline 4.4.2 Roughing line 4.4.3 LCW 4.4.4 LN 2 for traps 4.4.5 Compressed air Vacuum Controls 4.5.1 Interlocks 4.5.2 Gages and microswitches 4.5.3 Cabling 4.5.4 Vacuum traps Tkmporary I aydown/Asscmbly Space 6 Assembly areas 4.6.2 Storage areas 4.6.3 Equipment storage 4.6.4 Assembly crane in assernbly areas 4.7 LN 2 Distribution 4.8 Facility Safety 4.9 5.0 4.6.1 4.8.1 High voltage barriers 4.8.2 Sprinklers 4.8.3 Smoke alarms 4.8.4 Oxygen alarms 4.8.5 N 2 ventilation Facility Support 4.9.1 Machine shop 4.9.2 Welding shop 4.9.3 Vacuum shop 4.9.4 Control electronics shop 4.9.5 RF electronics shop 4.9.6 Diagnostics lab 4.9.7 Electro-mechanical technician's shop 4.9.8 Neutral beam test area 4.9.9 Staff lab 4.9.10 Central stock room 4.9.11 Administrative/purchasing offices N.B. INJECTOR SUBSYSTEM 5.1 Neutral Beam Source Prototype 5.1.1 LB. standard back 5.1.1.1 Standard hack reengineering 7 Standard back testing 5.1.2.1 Module dcsign/engincering 5.1.2.2 Single module procurement 5.1.2.3 Single module testing 5.1.2.4 Module back procurement 5.1.2.5 Module back testing/cvaluation 5.1.3.1 Reengineering 5.1.3.2 Procuremcnt 5.1.3.3 'resting 5.1.4 5.1.7 5.1.1.3 Standard ARC chambcr 5.1.3 5.1.6 Standard back procurement Filament module version of LIBL back 5.1.2 5.1.5 5.1.1.2 Bucket chamber 5.1.4.1 Bucket chamber design/cngineering 5.1.4.2 Bucket chamber procurement 5.1.4.3 Bucket testing/cvaluation Ion extractor 5.1.5.1 20kV optimization (Wolf code simulation) 5.1.5.2 Grid rail design 5.1.5.3 Grid rail and wire procurement 5.1.5.4 Extractor assembly/testing Source steering riechanism 5.1.6.1 Design 5.1.6.2 Procurement Source vacuum valve 5.1.7.1 l)csign modifications 5.1.7.2 Procurement 8 5.1.8 5.2 5.3 5.4 Source mounting plate 5.1.8.1 Design 5.1.8.2 Procurement Prototype N.B. Power Supply 5.2.1 Prototype power supply design/engineering 5.2.2 Proto filament supply construction/testing 5.2.3 Proto arc-supply construction/testing 5.2.4 I igh voltage supply construction/testing 5.2.5 System testing/cvaluation Clean Room for Source Assembly 5.3.1 Enclosure procurement 5.3.2 Clean room facilities procurement 5.3.3 -Grid alignment station procurement 5.3.3.1 TV/compu ter/optics assembly/testing 5.3.3.2 Procedures/specification establishmen N.B. Test Stand 5.4.1 Tank and pumping system procurement 5.4.1.1 5.4.2 Source mounting cover design/procurement 5.4.3 Source shielding design/procurement 5.4.4 Diagnostics 5.4.5 5.5 Ti evaporator procurement 5.4.4.1 Calorimeter design/construction 5.4.4.2 Sciopticon dcsign/consturction 5.4.4.3 Energy analyzer design/construction 5.4.4.4 SED array design/construction Neutralizer design/procuirement TARA Sources (Six Sources) 9 5.6 5.7 5.8 6.0 5.5.1 Final design 5.5.2 Procurement 5.5.3 Testing TARA N.B. Source Supplics (Six SuppliCs) 5.6.1 Final design 5.6.2 Procurement 5.6.3 Testing TARA Beamline 5.7.1 Pumping design optimization (computer simulation) 5.7.2 Final mechanical design 5.7.2.1 Tank procurement 5.7.2.2 Cryopamel procurement 5.7.2.3 ]icam aperture procurement 5.7.2.4 Attenuation/diagnostic procurement 5.7.2.5 Retractable calorimeter procurement 5.7.2.6 Burial plate procurement InJector Subsystem 5.8.1 Attachment to TARA 5.8.2 Testing/evaluation/modification SYSTFM INTEGRATION 6.1 Vacuum Pumping System 6.1.1 Acceptance of pumps 6.1.2 Restoration of surplus equipment 6.1.3 Fabrication of fore lines 6.1.4 kabrication of vent lines 6.1.5 Instrumentation and control installation/integration 6.1.6 System test 10 6.2 6.3 6.4 Vacuum Chambers 6.2.1 Leak testing and acceptance of components 6.2.2 Assembly on TARA stand 6.2.3 Mating with roughing system 6.2.4 Instrumentation installation 6.2.5 System test High Vacuum System 6.3.1 Procurement of cryopumps 6.3.2 Testing and installation 6.3.3 System test 112 Pumping System 6.4.1 Testing and acceptance of cryopanels 6.4.2 - Installation of cryopanels 6.5 6.4.3 Installation of titanium evaporators 6.4.4 Integration of evaporators with power supplies 6.4.5 1nstallaioo of piezoelectric thickness monitoring equipment 6.4.6 Installation of LN 2 transfer system 6.4.7 Integration of LN 2 controls 6.4.8 System test of H712 pumping system Magnets 6.5.1 Installation of magnets on vacuum chamber (concurrent with vacuum chamber assembly) 6.5.2 Mechanical alignment of magnets 6.5.3 Connection to power cables 6.5.4 Connection to low conductivity water 6.5.5 Installation of electrical and thermal monitoring 6.5.6 Magnetic alignment and flip coil mcasUrciments 6.5.7 Full current power tests 11 6.6 6.7 7.0 TARA Support Structure 6.6.1 Design and fabrication of support stand 6.6.2 Plumbing of low conductivity watcr and compressed air on stand 6.6.3 Flectric power raceway on stand 6.6.4 Installation of control and data cable trays 6.6.5 Installation of isolated power raceway on cable trays 6.6.6. Fabrication of false floor between control room and TARA stand Cabling 6.7.1 Installation of magnet power cables in trenches 6.7.2 Installation of control cables from cell to control room 6.7.3 Installation of data coax from CA MAC in cell to computer room 6.7.4 Installation of monitoring cabls (t% isted pairs) from cell to TRS-80 RE SUBSYSTEM 7.1 7.2 7.3 7.4 ICRI 1Transmitters 7.1.1 Acquisition of transmitters 7.1.2 Modification and testing 7.1.3 Installation at permanent site ICRH Antennas 7.2.1 Engineering and design 7.2.2 Model construction and testing 7.2.3 Prototype construction and testing 7.2.4 Final antenna construction and installation 1 1GC ECRH 7.3.1 Construction and test of klystron amplifier units 7.3.2 Construction and installation of cavities 28GC ECR H 7.4.1 Design. construction and testing of pulso modulator 12 8.0 7.4.2 Construction of gy rotron cabinet assy 7.4.3 Integration and testing of gyrotron system 7.4.4 Design, fabrication and testing of waveguide elements 7.4.5 Installation on machine DATA SYSTEMS 8.1 Commercial Systems 8.1.1 Specify commercial hardware/software 8.1.2 Justification 8.1.3 Procurement 8.1.4 Installation 8.1.5 Test Princeton CAMAC software 8.2 Data System Software 'I'opology 8.3 Data Aquisition Software 8.4 8.5 8.3.1 Requirements and specification 8.3.2 Design 8.3.3 Code development 8.3.4 Test/dcbug Data Base System 8.4.1 Requirements and specifications 8.4.2 Design 8.4.3 Code development 8.4.4 Test/debug Application Software 8.5.1 Determine initial needs 8.5.2 Modify existing applications 8.5.3 Specify future needs and standards 8.5.4 Design new applications ' 13 8.5.5 9.0 Integrate CONTROL SYSTEMS 9.1 9.2 9.3 Hard Wired Interlocks 9.1.1 Define operating procedure for encrgizing and de-energizing magnet power 9.1.2 Specify electrical and mechanical interlocks for magnet power 9.1.3 Specify internal electrical interlocks on all power systems including: - inagnet power - utilities - vacuum systems - neutral beams - ICRF - ECRF - simple diagnostics - speciali/.cd diagnostics CAM AC Sequencer 9.2.1 Design system concept 9.2.2 Specify system requirements 9.2.3 Design CAM AC modifications 9.2.4 Build CAMAC sequencer modules 9.2.5 Test scquencer modules 9.2.6 Interface sequencer modules 9.2.7 Write sequencer software Power Up System 9.3.1 Define system requirements 9.3.2 Investigate commercially available systems 9.3.3 Procure equipment 9.3.4 Write software 14 9.4 9.3.5 Install equipment 9.3.6 Test system Status and Interlock System 9.4.1 Define system requirements and invcsti-ate commercially available systems in conjunction with power up system 10.0 9.4.2 Write software 9.4.3 Interface with CAMAC diagnostic and control system DIAGNOSTICS SUBSYSTEM 10.1 10.2 10.3 10.4 Hot Electron Anchor Diagnostics 10.1.1 Conceptual design and analysis 10.1.2 Detail mechancial, electrical, and vacuum design 10.1.3 Procure components 10.1.4 Test and calibrate components and assemblies 10.1.5 Fabricate supports and vacuuM interfaces Central Cell Diagnostics 10.2.1 Conceptual design and analysis 10.2.2 Detail mechancial, elecrical, and vacuum design 10.2.3 Procure components 10.2.4 Test and calibrate components and assemblies 10.2.5 Fabricate supports and vacuum interfaces Plug Diagnostics 10.3.1 Conceptual design and analysis 10.3.2 Detail mechancial. clcctrical, and vacuum design 10.3.3 Procure components 10.3.4 Test and calibrate components and assemblies 10.3.5 Fabricate supports and vacuum interfaces Fan Tank and Mscellancous Diagnostics 10.4.1 Conceptual design and analysis 15 10.4.2 Detail mechancial, electrical, and vacuum design 10.4.3 Procure components 10.4.4 Test and calibrate components and assemblics 10.4.5 Fabricate supports and vacuum interfaces 16 0 m~ C\j o r- o ~ C) LO LO ai q al c LO 00 - ' I r- 0~i LOp C;J '-I- C Ln LO LO t0 0 co LO (ZD C4C17 I- In I 1/) I I * I M* I 00 L LL I I 0F- i" ( LAO LO 0 mA 0 (0 0 m U CD-Ft Ley I e,.j I.- F- ko~ II 0(0 M~ CY) r- U-) LA - J C~ I O mw 0 LO cy) LL. CY) LA LO 0- r- r-LO 0 0 (0 LOC WO c O LA, (0 LO LAO c] 0- 0 0l ~ M\fi C~ U- CC)oC 03 C co' -J I- 0 10 0 4-) L/) c 4-) 4-) 4w 0-0- ULJ = 4-J (L (A >) 0- ~ (AC 0 0 >1 V) 4J U 1- S-~ 4j *r- 4-) m = ~ >. U- 0 4-) a i 4- i 4-) (A (A Ul 30 (o S>) o) oAC) E 4-J S.-2 S.. Q (A to4) u = 4-j C. (L = 00 L) Cl) r_ U- 0 4-) (/1 0- 0 C-)