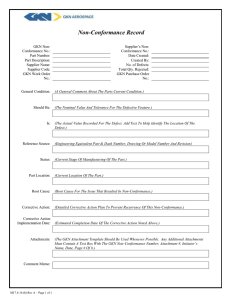

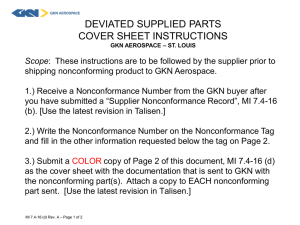

MI 7.4-18 Quality Requirements , Revision History

advertisement