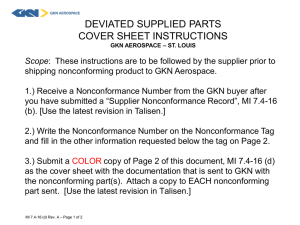

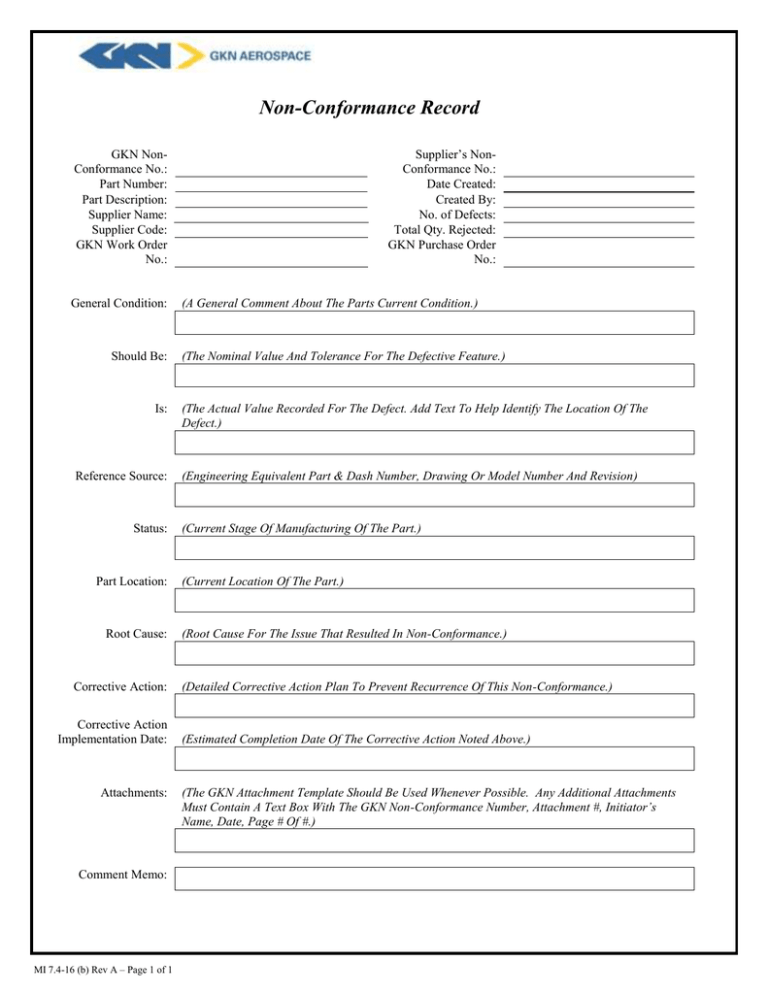

Non-Conformance Record: Aerospace Quality Control

advertisement

Non-Conformance Record Supplier’s NonConformance No.: Date Created: Created By: No. of Defects: Total Qty. Rejected: GKN Purchase Order No.: GKN NonConformance No.: Part Number: Part Description: Supplier Name: Supplier Code: GKN Work Order No.: General Condition: Should Be: Is: Reference Source: Status: Part Location: Root Cause: Corrective Action: Corrective Action Implementation Date: Attachments: Comment Memo: MI 7.4-16 (b) Rev A – Page 1 of 1 (A General Comment About The Parts Current Condition.) (The Nominal Value And Tolerance For The Defective Feature.) (The Actual Value Recorded For The Defect. Add Text To Help Identify The Location Of The Defect.) (Engineering Equivalent Part & Dash Number, Drawing Or Model Number And Revision) (Current Stage Of Manufacturing Of The Part.) (Current Location Of The Part.) (Root Cause For The Issue That Resulted In Non-Conformance.) (Detailed Corrective Action Plan To Prevent Recurrence Of This Non-Conformance.) (Estimated Completion Date Of The Corrective Action Noted Above.) (The GKN Attachment Template Should Be Used Whenever Possible. Any Additional Attachments Must Contain A Text Box With The GKN Non-Conformance Number, Attachment #, Initiator’s Name, Date, Page # Of #.)