Role of Additives in P/M Machining Robert J. Causton Hoeganaes Corporation

advertisement

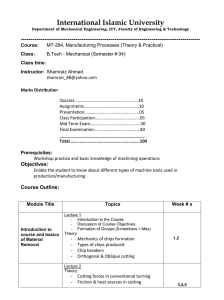

Role of Additives in P/M Machining Robert J. Causton Hoeganaes Corporation Cinnaminson, NJ 08077 Presented at PM2TEC 2002 World Congress On Powder Metallurgy and Particulate Materials June 16-21, Orlando, Florida ABSTRACT Many P/M parts are machined before final assembly. The increasing use of dedicated lines, or cells, in which many sequential operations are conducted on an assembly means that the time required to machine a P/M component will need to be reduced if it is the bottleneck in the assembly process. This paper examines the effects of three freemachining additives: boron nitride, manganese sulfide and pre-alloyed, or resulfurized, sulfur, upon the machining response of an FC-0205 P/M steel in a turning operation. The effects of the additives on tool wear, cutting forces, chip form and surface finish are compared. INTRODUCTION In the conversion of wrought and cast components to P/M processes, an increasing number of P/M steels need to be machined prior to final assembly. In several cases the machining operations are conducted as part of the production of a system, rather than discrete component. In these cases, the different machining characteristics of P/M steels, cast irons and wrought steels may cause machining of the P/M component to be the bottleneck in an entire assembly operation. In such cases there is considerable reluctance to consider further conversions to P/M components. This paper examines the role of free-machining additives: manganese sulfide, hexagonal boron nitride and prealloyed, or resulfurized powders, in improving the machining response of a standard MPIF FC-0205 P/M steel under defined turning conditions. Free machining agents are added to P/M steels to improve their machinability including factors such as tool life, metal removal rate and surface finish. Machining additives achieve this in several ways (Fig. 1) including: initiating micro-cracking of the work piece, reducing adhesion of the tool chip to the tool, built up edge formation and reducing adhesive wear that lead to crater wear (Ref. 1). Chip Tool Chip Separation Lubricant Crater Wear Work Microcracking Built-up Edge SST-95 Fig. 1: Potential Functions of a Free-machining Additive TEST PROGRAM The test program consisted of measuring the effect of the free-machining additives upon the sintered properties, microstructure and machining response in turning of an MPIF FC-0205 composition. Premix Compositions 500 pound Pilot Premixes were made with compositions shown in table 1 below. Three free machining additives were chosen for investigation: manganese sulfide (MnS), a prealloyed resulfurized iron powder (RS) and hexagonal boron nitride (BN). Manganese sulfide is a recognized free machining additive for P/M steels. Pre-alloying an iron powder with sulfur provides a finer more uniform dispersion of manganese sulfide than admixed manganese sulfide. Hexagonal boron nitride is a recognized solid lubricant that has potential as a free machining agent. The free machining additives were included at a Table 1: Premix Compositions Premix 1 2 3 4 5 6 7 Iron (%) 96.65 96.30 96.05 96.65 96.65 96.55 96.45 Copper (%) 2 2 2 2 2 2 2 Acrawax C (%) 0.75 0.75 0.75 0.75 0.75 0.75 0.75 Graphite (%) 0.60 0.60 0.60 0.60 0.60 0.60 0.60 Additive None MnS MnS RS RS BN BN Additive (%) 0 0.35 0.60 0.14 0.30 0.10 0.20 “low” and “high” level based upon previous experience. The compositions of the resulfurized powders were intended to produce similar manganese and sulfur contents to those attained by the use of admixed manganese sulfide. The resulfurized iron powders were produced as Pilot Plant heats. All other premix ingredients were standard additives used for Production premixes except for the boron nitride that was a high purity grade with similar particle size distribution as the manganese sulfide powder. Sintered Properties The sintered properties of the premixes were measured using TRS test pieces compacted to a green density of 6.8g/cm³. The test pieces were sintered at 2050ºF (1120ºC), under 90%nitrogen/hydrogen, for 30min at temperature using an Abbot belt furnace. The dimensional change from die size and TRS are shown in table lll below. The sintered carbon, nitrogen and sulfur contents of sections cut from the sintered test pieces are shown in table below. Machinability Testing The machining test was conducted using a hollow cylindrical test piece of 1.75” diameter by 1” bore and 1” length ( 44.5mm x 25.4mm x25.4mm) . The test pieces were sintered using the same conditions as the TRS test pieces. The apparent hardness of the sintered test pieces was measure using a Mitutoyo hardness tester with results shown in table below. Sections of the sintered machining test pieces were taken for Metallographic examination. The turning test was conducted using the conditions shown in table ll below. Table ll: Turning Conditions Insert Geometry Grade Speed Depth of Cut Feed Coolant SNG433 C2 300fpm 0.045” 0.0114”/rev None SNG433 C2 91.44m/min 1.14mm 0.290/rev None The three orthogonal components of the machining force were measured using a Kistler three-axis dynamometer. The flank wear was measured with a measuring optical micrometer at intervals of five cuts. The cutting test was halted after 100 cuts or tool failure. Samples of the chips generated during cutting were taken for comparison. Examples of the chips, and work piece surface after 75cuts are shown below. Photomicrographs of the tool face at the end of the test, 100 cuts are also shown. RESULTS The sintered properties of the test premixes are shown in table lll. There was little difference in the compaction pressure required for a green density of 6.8g/cm³. Table lll: Sintered Properties of FC-0205 Premixes Premix 1 2 3 4 5 6 7 Addition (%) None 0.35MnS 0.50MnS 0.14RS 0.30RS 0.1BN 0.2BN S.D. (g/cm³) 6.69 6.68 6.67 6.64 6.63 6.66 6.65 D.C. (%) +0.46 +0.47 +0.48 +0.49 +0.44 +0.49 +0.51 TRS (ksi) 122.4 122.0 116.4 102.8 112.9 108.8 110.8 Hard. (HRB) 69.6 69.5 68.7 64.0 66.3 65.2 65.3 Note Compacted to 6.8g/cm³, 2050ºF, 90%nitrogen/10%hydrogen, 30min at temperature It appears possible that adding boron nitride increases dimensional change from die size. There is no consistent effect of admixed manganese sulfide or use of resulfurized iron powders upon dimensional change in the compositions tested, although it is possible that the resulfurized powder of 0.14% sulfur content increases growth slightly. The results indicate that increasing manganese sulfide content to 0.5% may reduce TRS and apparent hardness slightly. The resulfurized powders have lower TRS and hardness than the FC-0205 reference. Introducing the boron nitride powder also reduces TRS and hardness compared to the FC-0205. The basic chemical analysis of the sintered TRS test pieces is shown in table lV. Table lV: Chemical Analysis of FC-0205 Test Pieces 1 2 3 4 5 6 7 Addition None 0.35MnS 0.50MnS 0.14S 0.3S 0.1BN 0.2BN C (%) 0.58 0.58 0.57 0.50 0.57 0.55 0.58 S %) 0.007 0.11 0.18 0.13 0.30 0.012 0.008 N (%) 0.013 0.016 0.016 0.012 0.015 0.067 0.12 The content of all the test pieces except the 0.14% sulfur resulfurized powder comply with the FC-0205 specification, although the sintered carbon content of the 0.14% resulfurized test pieces are slightly lower than anticipated. This probably accounts for part of the difference in hardness and strength shown in table lll above. The other analyses show that the test premixes comply with the target compositions. Apparent Hardness of Test Pieces The apparent hardness of the turning test pieces is lower than that of the TRS test pieces, but the free machining additives have similar relative effects. Table V: Apparent Hardness of Machining Test Pieces Premix Addition (%) Hardness (HRB) 1 2 3 4 5 6 7 None 0.35 MnS 0.50 MnS 0.14 RS 0.3 RS 0.1 BN 0.2 BN 55.3 53.7 52.1 47.7 54.7 49.2 50.8 Hardness (TRS) 69.6 69.5 68.7 64.0 66.3 65.2 65.3 It is possible that the larger cross section of the tuning test pieces combined with the higher mass loading produced lower cooling rated from sintering temperature resulting in a coarser microstructure. Microstructure of Machining Test Pieces. The microstructure of the FC-0205, in the as polished condition, with no machining additives is shown in Fig. 2a. The P/M steel possesses a good degree of sinter with very few oxides present at prior particle boundaries and slight pore rounding. When etched, Fig. 2b, the FC-0205 P/M steel possesses a microstructure of relatively coarse ferrite and pearlite. a) as polished b) etched nital/picral Fig. 2: Microstructure of FC-0205 Mix 16 no machining additives. The effects of the machining additives upon the microstructure of the FC-0205 in the as polished condition are shown in Figs 3 below. Introducing MnS (Fig. 3a and 3b) introduces light gray sulfide visible in the pores and at some prior particle boundaries. a) 0.35% MnS b) 0.50% MnS c) 0.14% S resulfurized d) Mix 4 0.3% sulfur resulfurized Fig. 3: Microstructure of FC-0205 plus free machining additives When the sulfur is pre-alloyed, the sulfide particles are more dispersed more uniformly through the microstructure and are present both at particle surfaces and within prior particles. Increasing the sulfur content, whether as MnS or by resulfurizing, increases the volume fraction of sulfide. Unfortunately there was insufficient contrast between the boron nitride particles and matrix to define the distribution of boron nitride particles. When etched the microstructures consist of ferrite plus pearlite (Fig. 4), but there may be slight changes in the amount and distribution of ferrite. The 0.14% resulfurized steel possesses slightly more ferrite than the other test pieces, possibly due to its lower carbon content. In both resulfurized powders, there are fewer coarse MnS particles at the prior particle boundaries than in the test pieces with admixed MnS a) 0.35%MnS b) 0.50%MnS c) 0.14%S Resulfurized d) 0.3%S Resulfurized e) 0.1% BN f) 0.2% BN Fig. 4: Microstructures of FC-0205 plus machining additives Etched with a mixture of nital and picral. MACHINING RESULTS The machining tests showed that introducing the free machining additives improved tool performance. They reduced tool wear, cutting forces and generally improved chip formation. Although the machining conditions promoted flank, the chief wear mechanism in all cases was crater wear. In many cases there was evidence of built up edge formation, that was reduced significantly when cutting test pieces with the 0.5% MnS addition or the 0.3%S resulfurized steel. These results are discussed separately below to illustrate the effects of the free machining additives more clearly. Cutting Test Results The cutting forces and tool wear measured during turning of the FC-0205 with no additives are shown in Fig. 5. They show that flank increased with number of cuts throughout the test. In the case of the FC-0205, the cutting tool failed after 94 cuts. Wear (0.0001") Force (lbf) 250 50 Cut Radial Feed Wear 200 40 150 30 100 20 50 10 0 0 0 20 40 60 80 100 120 Number of Cuts Fig. 5: Cutting Test Results for FC-0205 Mix 16 no machining additives Cutting forces showed considerable variation, with no consistent pattern. For FC-0205, the cutting force varied about a mean of about 170lbf, but increased rapidly just before tool failure. Radial force was lower than cutting force, a mean of about 130lbf, and in the case of the FC-0205 appeared to increase towards the end of the test before tool failure. Feed force was the lowest of the three forces, a mean of about 75lbf. Flank Wear Introducing a free machining additive increased tool life and reduced tool wear significantly. When cutting FC-0205 with no additive, flank wear increased progressively throughout the test until the tool failed after 94cuts. All free machining additive extended tool life to the end of the tests and reduced tool wear significantly (Fig. 6). The presence of 0.1% BN produced lowest flank wear after 100 cuts. 50 Wear (0.0001") 45 40 35 30 25 20 15 10 5 0 None 0.35% MnS 0.50% MnS 0.1%S RS 0.35%S RS 0.10% BN 0.20% BN Free Machining Additive Fig. 6: Flank Wear at end of Cutting Test In the current test increasing boron nitride content from 0.1 to 0.2% increased flank wear from 0.002 to 0.004”. There was little difference between the different sulfide additions in flank wear at the end of the test. Increasing MnS content from 0.35 to 0.5% reduced tool wear. However, increasing the resulfurized sulfur content from 0.14 to 0.30% had no significant influence on flank wear at the end of the test. There are considerable differences in the form of wear during the test. Introducing 0.50%MnS reduces the gradient, flank wear per cut, significantly (Fig. 7). In contrast 0.1%BN appears to produce rapid initial wear followed by a period of almost no wear. It is possible to compare the effects of the free machining agents by the coefficients of the regression equations (Ref. 2) fitted to the wear plots as shown in table Vl. Table Vl: Summary of Tool Wear Data for FC-0205 Add. (%) C M R2 None -2.74 0.481 0.977 MnS 0.35 +1.52 +0.303 0.987 Note: Assumes y= mx + c MnS 0.50 0.95 0.255 0.995 RS 0.14 0.77 0.263 0.996 RS 0.30 1.989 0.263 0.989 BN 0.1 7.47 +0.137 0.685 BN 0.2 --1.810 +0.485 -0.938 Wear (0.0001") 50 45 y = 0.4806x - 2.7374 40 R = 0.9771 2 FC-0205 35 30 25 0.50%MnS 20 0.1%BN 15 10 5 0 0 20 40 60 80 100 120 Number of Cuts Fig. 7: Effect of Additives upon Flank Wear of FC-0205 at 300fpm. The data show considerable variation in zero intercept and gradient. They show that all additives except 0.2%BN reduced the gradient of the wear plot significantly from the 0.481 measured for the FC-0205. Surprisingly the 0.1% boron nitride addition produced the lowest rate of wear, but has the lowest value of R2 , indicating that the wear rate or wear processes varied considerably during the test. The data indicate that there was little difference in wear rate between admixed or pre-alloyed sulfides. The values for intercept vary considerably. The data suggest that the presence of a free machining agent reduces the initial tool wear. The extreme value of 0.747 for the 0.1% boron nitride addition may reflect that the tool edge was damaged slightly, perhaps by impact with the test piece, during the initial cuts before the first measurement of tool wear. The negative values may indicate formation of a built up edge at an early stage in testing. The values for R2 indicating that the assumption of a linear model is good except for the 0.2%BN addition. Cutting Forces The three cutting forces varied considerably throughout the test. The cutting force was larger than the radial and feed forces. There appears to be no consistent increase in the forces through the test. Although it appears than in some tests the cutting force increases rapidly just before tool failure. There may be a correlation between the cutting and feed forces, although further analysis is necessary to confirm this. Given the variation in the data for cutting force in the current tests, it appears that they can be compared in terms of means and standard deviation. The summary of the cutting data is shown in table Vll. Table Vll: Summary of Cutting Force (lbf) for FC-0205 Add. (%) Cut. s.d None 176.7 25.1 MnS 0.35 147.4 27.0 MnS 0.50 159.6 23.1 RS 0.14 173.1 21.0 RS 0.30 132.9 33.3 BN 0.1 173.1 16.7 BN 0.2 139.2 35.5 Radial s.d. 122.2 2.2 106.9 27.1 105.2 30.6 104.5 17.9 88.6 21.5 113.8 15.5 56.2 30.6 Feed s.d. 78.9 15.2 73.3 13.0 63.4 11.9 75.8 11.2 56.6 12.2 74.9 9.75 79.7 10.8 The results suggest that introducing a free machining additive tends to reduce the cutting and radial forces but has less effect upon feed force. For the resulfurized powder and boron nitride, increasing the level of addition reduces cutting forces further. Increasing the addition of MnS from 0.35 to 0.5% does not change cutting force appreciably and there may be a slight increase. The presence of 0.14% sulfur in the resulfurized powder did not reduce forces consistently compared to the FC-0205. The cutting component of the machining forces was lowest when machining the 0.3%S resulfurized test pieces. It is possible that the data for the 0.3% sulfur content indicates a change in the cutting edge during the test (Fig. 8). It appears that the cutting force decreased during the test with the exception of some scatter that may be due to one or two test pieces. Turning FC-0205 with 0.1%BN required low a cutting force that were significantly lower than those required with 0.2%BN. The cutting force was reduced by additions of MNS and was less sensitive to the level of addition than the resulfurized or with boron nitride. All of the additives reduce the radial component of the machining force. Addition of 0.2% boron nitride produces the lowest radial force. The radial force produced in turning the 0.35%S resulfurized steel is somewhat higher. There is little difference between the radial l forces measured for the remaining materials. For boron nitride and resulfurized powders, increasing the level of addition reduces the mean radial force. Increasing the level of admixed MnS does not change the mean radial force. The presence of the machining additive had little effect upon the mean feed force that was only reduced by when turning the 0.3% S resulfurized test pieces or those with 0.5%MnS. Cutting Force (lbf) 250 y = -0.4335x + 153.22 2 R = 0.127 200 150 100 50 0 0 20 40 60 80 100 120 Number of Cuts Fig. 8: Cutting Force for 0.3%S resulfurized powder as free machining agent. CUTTING INSERT The cutting insert used for the FC-0205 shows both flank wear and significant crater wear (Fig. 9). It appears that tool failure occurred when the so much tool material was Fig. 10: Cutting Insert for FC-0205 at end of test (94 cuts) removed by the wear processes that the cutting edge could not withstand the cutting forces. There is also evidence of some adhering material from the work piece indicating that a built up edge may have formed at some point during the cutting test. In comparison the machining additives reduced the severity of the wear (Fig. 11). a) 0.35%MnS a) 0.35%MnS b) 0.50%MnS c) 0.14%S resulfurized d) 0.3%S resulfurized e) 0.1%BN f) 0.2%BN Fig. 11: Cutting Inserts at End of Test (100cuts) It appears that sulfides, whether admixed as manganese sulfide or resulfurized (Fig. 11a11d), produce less wear than boron nitride and have similar wear patterns. Introducing sulfides reduces flank wear and built up edge formation. Increasing the amount of sulfide appears to reduce the amount of crater wear and reduces adhesion of removed work piece to the cutting tool. The presence of sulfide also appears to reduce the size of a wear land or scar that extends from the cutting edge along the edge of the wear crater. Introducing boron nitride (Fig. 11e and 11f) allows the cutting tool to be covered with wear debris and allows a built up edge to form. Increasing the level of boron nitride addition reduces this effect significantly. It is not clear what the true flank wear is, since much of the cutting area is covered in debris. There appears to be less flank wear and a less defined crater when cutting with 0.2% boron nitride. CUTTING CHIPS/SWARF Machining the FC-0205 under the chosen cutting conditions produced very long, continuous swarf (Fig. 12). Individual pieces varied from 0.5 to four inches in length. 1234 Fig. 12: FC- 0205 Machining Chips after 75 cuts. At higher magnification the chips showed more evidence of heavy shear and partial fracture into shorter segments. The edges of these segments were highly deformed and fractured. Chip form changed significantly with the presence, type and amount of addition tending to change from continuous to segmented or serrated (Ref. 3). Generally, introducing the free machining agents (Fig. 13) caused the machining swarf to adopt a more regular, highly curved form. Individual pieces were helical in shape tended to be shorter in length. Adding 0.35% MnS shows his effect clearly. The majority of the swarf consists of tightly wound helical coils. Increasing the MnS content to 0.5% does not have a significant effect, but may increase the number of short fragments. a) a) 0.35% MnS b) 0.50%MnS c) 0.14%S resulfurized d) 0.30%S resulfurized e) 0.1%BN f) 0.2%BN Fig. 13: Effect of Machining Additives on Chip Form The presence of 0.14%S in the resulfurized powder has a relatively small effect upon chip form. The individual pieces are curved and vary considerably in length. Increasing the sulfur content to 0.30% causes the chips to consist of very short curved pieces generally less than 0.25” in length. Boron nitride produces changes in chip form that fall between those of admixed MnS and resulfurized powder. With an 0.1% addition, the chips are similar to those formed with 0.35%MnS, being relatively long and either curved or slightly helical in shape. Increasing the BN addition to 0.2% causes the chips to adopt a tightly wound helical form, with sections varying from 0.25 to 1.5” in length. Changing the machining additive from MnS to BN changes the surface texture of the chips particularly at the their edges. With MnS the chips possess smooth edges, whereas with BN, the edges are much rougher, appearing to carry short “needlelike” projections.” SURFACE FINISH The turning operation and the presence of a machining additive change the appearance of the surface significantly. For the FC-0205 (Fig. 14) turning closes the surface porosity. a) as sintered b) machined 75 cuts Fig. 14: Surface of FC-0205 Part It also removes the scoring introduced by compaction and ejection. Turning introduces parallel grooves defined by the nose radius of the tool and the feed per revolution. In the FC-0205 with no free machining additives, the grooves lose definition with increasing tool life, becoming shallower and somewhat “smeared” in appearance as the tool wears. The surface also contains some dark debris that is parallel to and sometimes associated with the “threads” of the machining grooves. The surface appearance of the turned parts that possess a machining additive (Fig. 15) is generally similar to that of the turned FC-0205. However, the grooves are better defined and more regular in appearance except for the parts that contain boron nitride. Introducing sulfide as admixed MnS or by pre-alloying (Fig. 15a-d) delays the effects of tool wear significantly. The surface grooves are well defined. Small copper colored particles a) 0.35%MnS b) 0.50%MnS c) 0.14%S resulfurized d) 0.30%S resulfurized e) 0.1%BN f) 0.2%BN Fig. 16: Surface of Turning Test Pieces after 75 cuts are visible that are elongated in the cutting direction. There appears to be little difference between the effects of admixed MnS or resulfurized powder. Increasing the sulfide addition appears to improve and preserve surface definition. Use of boron nitride as a free machining additive produces a surface that is intermediate between that with no sulfide additive and a low sulfide content. Increasing the BN addition from 0.1 to 0.2% increases the definition of the turning grooves. The surface lacks definition and appears either to be deformed by the turning operation, or to be partially covered by a surface layer. At both levels of BN addition, the surface contains black lines or fine cracks normal to the cutting direction. In the part that contains 0.1%BN there is an irregular distribution of relatively coarse black “particles” across the machined surface. DISCUSSION The turning test illustrated that the free machining additives performed many of the functions anticipated. Tool wear was reduced, cutting forces reduced, tool life increased and chip formation improved by the presence of the additives. They were less successful in reducing crater wear entirely. Despite the overall similarities, there were major differences in their effects of the additives particularly between the sulfides and boron nitride. When machining FC-0205 sulfides, both admixed and resulfurized, are more successful free-machining additives than boron nitride. Boron nitride, particularly as an 0.1% addition, produced somewhat higher cutting forces and was less successful in promoting chip separation and reducing built up edge formation. Despite these problems boron nitride produced low flank wear as an 0.1% addition, but not as an 0.2% boron addition. However 0.2% boron nitride may have reduced crater wear. This apparent contradiction may be due to intrinsic differences in the way chips are formed by boron nitride and sulfides, or may reflect a beneficial change in local cutting geometry caused by built up edge formation. The built up edge present on the tool provides a local reduction in rake angle. The change in angle should reduce the forces required to form and separate chips. In this respect the presence of the built up edge is beneficial since it reduces cutting forces and flank wear. It is less beneficial in chip formation and surface finish. The machined surface is less well defined, and particularly in the case of 0.1%BN, possesses adhering particles that appear to be remnants of the built up edge (Ref. 3). The sulfides, particularly at the higher additions, reduce built up edge formation and promote chip fragmentation. There also appeared to be more frequent micro-fracture within the chips formed with sulfides leading to greater chip separation and segmentation. It appears that the sulfides coat the tool face more effectively than the boron nitride providing a surface lubricant that reduces friction and local heating due to friction in addition to that from the cutting process. Examination of the chips indicates that the sulfides initiate cracks within the chips and prevent the chips adhering to the tool face. SEM examination detected high sulfur concentrations on many areas of the tool faces. More detailed examination of the chips shows that chips containing boron nitride were often blue or black in color suggesting that they reached higher temperatures than the chips formed with sulfides. The higher temperatures appear to allow separated fragments of the built up edge to form the “particles” observed on the surfaces of the machined test pieces, and possibly to the chips to form the “needlelike” projections observed on some of the larger chips. Under the cutting conditions employed there were few major differences between the admixed MnS and resulfurized powders. However, there was a much greater difference between the high and low levels of sulfur content in the case of the resulfurized powder than the MnS. The higher 0.35%S resulfurized powder was a more effective free machining agent than the lower level. It also produced very short fragmented chips and a very clean tool surface. Under the machining conditions employed the free machining additives did not entirely suppress crater wear. It is possible that other changes to the machining process, such as a coated insert with chip breaker would improve tool life and chip formation further. CONCLUSIONS The free machining additives improved the machining response of the FC-0205 significantly. The free machining additives reduced flank wear, and built up edge formation but had less effect upon crater wear Sulfides, both admixed MnS and in resulfurized powder, were more effective than boron nitride. In the resulfurized powder, the higher sulfur content was more effective particularly in chip formation. Free machining additives can change the dimensional change and mechanical properties of the FC-0205 composition. REFERENCES 1: Metal Cutting, E. M. Trent, Butterworth 2: Characterization of the Machining Operations of P/M Parts during Drilling Operations, Carl Blais, MPIF Machinability Seminar, Oct. 99. 3: Fundamentals of Modern Manufacturing, M. Groover, Wiley