The copying, distribution and utilization of this document as well as the communication of its

contents to others without expressed authorization is prohibited. Offenders will be held liable

for the payment of damages. All rights reserved in the event of the grant of a patent, utility

model or ornamental design registration.

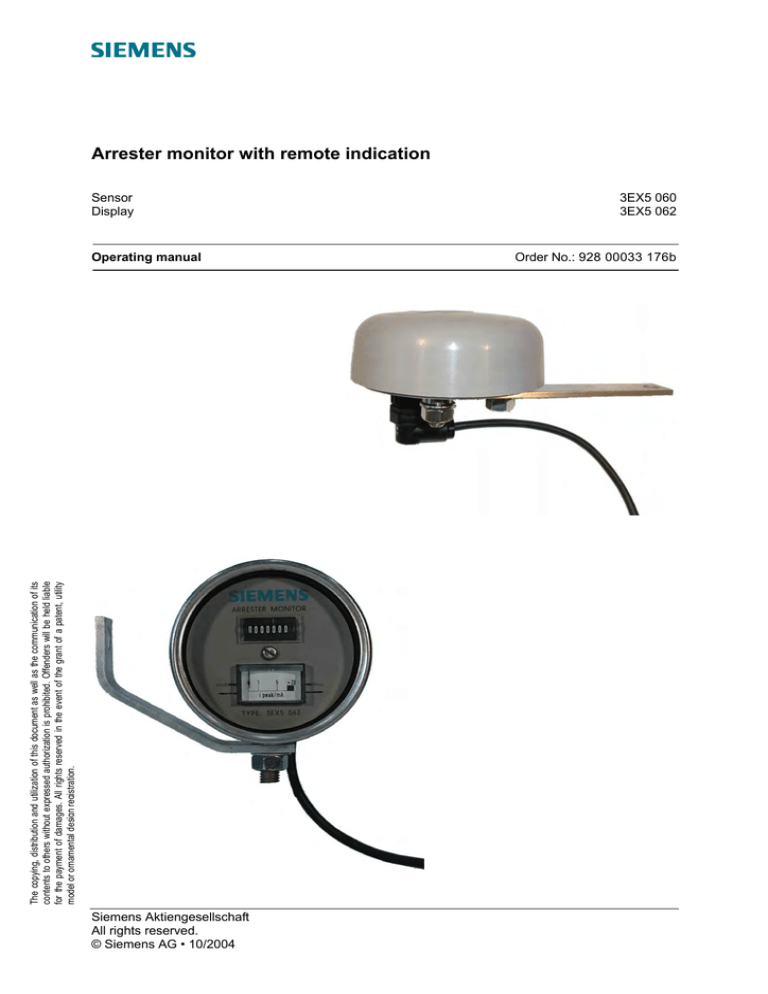

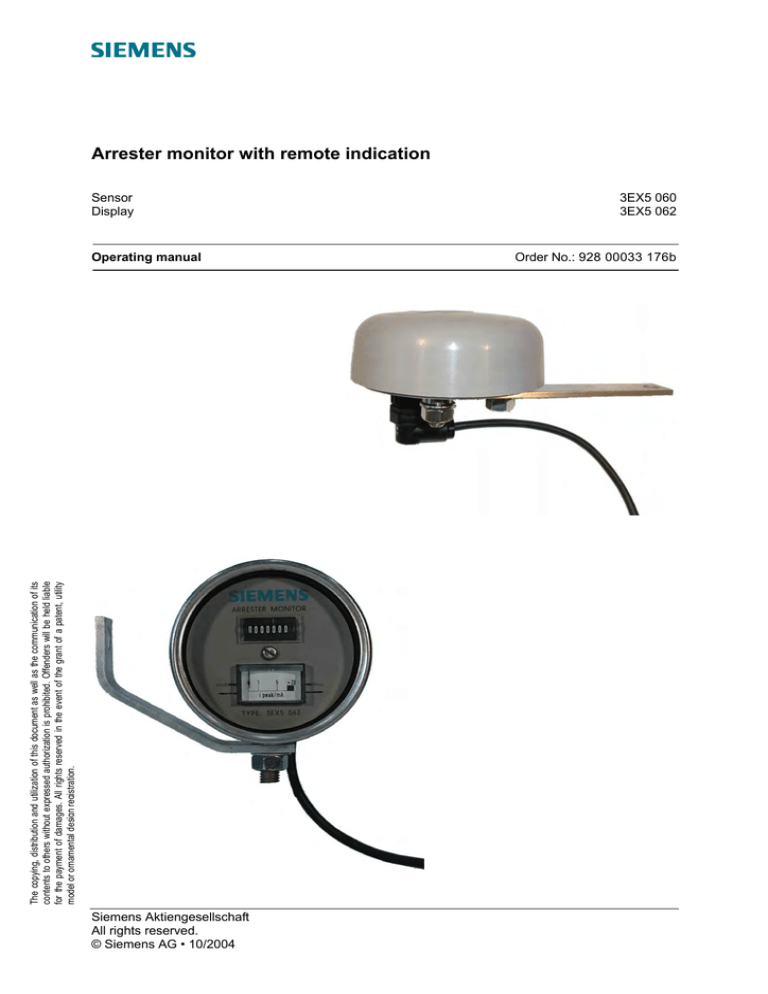

Arrester monitor with remote indication

Sensor

Display

Operating manual

Siemens Aktiengesellschaft

All rights reserved.

© Siemens AG • 10/2004

3EX5 060

3EX5 062

Order No.: 928 00033 176b

Contents

Contents ________________________________________________________________________2

General _________________________________________________________________________4

Description

4

Order code for sensor and display

4

Function description

4

Technical data

5

Transport and storage

5

Installation ______________________________________________________________________6

Sensor 3EX5 060

6

Display 3EX5 062

9

Connecting lead

Order code for connecting lead

10

10

Connection to bus systems

11

Operation ______________________________________________________________________12

Reading the surge counter

12

Reading the leakage current measuring device

13

Measurement output

14

Disposal arrester and arrester accessories___________________________________________16

2

© Siemens AG • 10/2004

The manufacturer of this surge arrester

Siemens AG

Power Transmission and Distribution Group

High Voltage Division

has introduced and applies a quality system in accordance with

DIN ISO 9001 / EN 29 001

Quality systems: Model for quality assurance This system was first demonstrated in 1989 to the

DQS (German Association for the Certification of Quality Systems).

The electrical testing laboratories and the materials technology laboratories of the manufacturer

have been certified since 1992 by the German Accreditation Body in accordance with DIN EN 45 001.

If you require further copies of the operating instructions, please order them from the appropriate Siemens office,

indicating the title and order number shown on the title page.

Published by:

In case of request:

Siemens AG

PTD H 4

D-13623 Berlin

Telephone exchange

Sales department:

Fax:

e-mail:

+49 / 30 / 386 1

+49 / 30 / 386 23061

+49 / 30 / 386 26721

mailto:Arrester@Siemens.de

Subject to change.

Note

The equipment covered by these instructions should be installed and serviced only by

competent personnel familiar with good safety practices. This instruction is written for

such personnel and is not intended as a substitute for adequate training an experience in

safe procedures.

This information is intended for the correct installation of this product. Siemens has no control over the condition

of the network, which can be greatly affected by the installation of a product. It is the responsibility of the user to

chose the appropriate method of installation. Under no circumstance is Siemens liable for any direct or indirect

damage caused by the use or misuse of this product.

© Siemens AG • 10/2004

3

General

Description

The 3EX5 06... surge arrester monitor is a monitoring device with a remote indication unit – consisting

of a sensor and a display device – for metal oxide surge arresters in both indoor and outdoor

installations. The sensor is looped into the grounding line of the arrester to be monitored.

The following functions are integrated:

! Via an mA meter, display of the leakage current flowing permanently along the arrester (peak

value measurement)

! Surge counter (electromechanical counter)

! Measurement output for oscillographic display of the arrester leakage current.

The 3EX5 060 sensor basically consists of the pickups for leakage current measurement and the

surge counters which are resin-encapsulated. The resin casting simultaneously serves as the housing.

The 3EX6 062 display unit contains the leakage current display (mA meter) and the surge counter.

They are accommodated in a stainless steel enclosure with a front panel made of glass to allow them

to be read. A socket is provided at the rear of the enclosure (measurement output). The sensor is

connected to the display unit via a special multicore screened cable (included) measuring no more

than 200 m.

Order code for sensor and display

Type

3EX5 060

3EX5 062

Description

Sensor

Display

Remarks

For display 3EX5 062

With measuring socket

Function description

3EX5 060

1

2

3

4

5

Toroidal core transformer

Protective spark gap

Resistor

Primary conductor

Evaluation electronics

Fig. 1.

Block diagram

3EX5 062

6

Connecting lead

7

8

9

Leakage current display

Leakage current measuring

socket e.g. for osciloscope

(Amphenol C16-1)

Counter

Under normal operation the arrester leakage current flows to ground via the primary conductor and the

resistor. The evaluation circuitry displays its peak value on the leakage current measurement unit.

When the arrester operates, the discharge current sent along the primary conductor induces an

impulse voltage in the secondary winding which in turn increments the counter one step. Depending

on the measurement principle used, the sensitivity of response of the counter will depend on the

virtual steepness and the duration of the discharge current.

4

© Siemens AG • 10/2004

At the resistor the discharge current causes such a large drop in voltage that the protective spark gap

responds. The voltage drop which occurs by this time does in fact take place before the peak in the

arrester discharge voltage and thus does not affect its magnitude. The voltage drop then falls to

negligibly low values.

Technical data

!

!

!

!

!

!

Leakage current display (3EX5 062):

mA meter with non-linear scale

Surge counter (3EX5 062):

Sensitivity

Current waveform 4/10 µs, 8/20 µs

Currenmt waveform 30/60 µs

Current waveform, rectangular wave discharge current

Measurement output for e.g. oscilloscope (3EX5 062 :1 :2):

Transformation ratio

.

Measurement output for peak value measurement

3EX5 060(:4 :E)

Switching contact (NC)

3EX5 060 (:5 :6)

.

Ambient temperature

0 mA … 20 mA ± 20 %

1000 A

200 A

100 A

470 mV/mA.

Rein ≥ 1 MΩ

On request

Switching voltage: 250 V AC/DC

Switching current: 1 A

Switching capacity: DC 30 W / AC 60 VA

Bounce time: approx. 1 ms

Contact time: 20 … 200 ms

-35 … +60 °C

Transport and storage

The operation indicators are supplied packed in cardboard boxes. They must be unpacked if they are

to be stored in humid conditions (such as in the tropics, for example).

© Siemens AG • 10/2004

5

Installation

Warning

Before any work starts:

! switch off and isolate

! secure against reclosing

! verify that equipment is dead

! earth and short circuit the equipment

! cover or fence off nearby live parts

Death, severe injury and considerable damage to

property and environmental damage may result if

the safety instructions are not followed.

!

Confirm that these safety measures have been carried out.

Sensor 3EX5 060

It is absolutely essential (for the proper functioning of the sensor) for the arrester to be installed on

insulating mountings. The sensor is installed on the ground connection of the arrester. Be sure not to

exceed the permitted tightening torques for the screws:

!

Mmax = 30 Nm ± 1 Nm.

The ground connection of the sensor is connected to system ground - the metal frame of the arrester,

for example. A copper wire 35 mm² in cross-section and not longer than 2 m is recommended for this

purpose. The sensor is connected to the display by means of a special lead (see Fig. 7.).

When installing this lead make sure that there is adequate clearance to live parts (at least 30 mm).

Fig. 2.

6

Installation 3EX5 060

© Siemens AG • 10/2004

Fig. 3.

View from below

If the 3EX5 060 sensor is installed in series with a tell-tale spark gap (a 3EX6 040, for example) the

sequence of the devices is important:

Connection for monitoring devices " Tell-tale spark gap " Sensor " System ground (e.g. tower base)

Fig. 4.

Installation sequence for outdoor arresters

© Siemens AG • 10/2004

7

1

2

3

4

5

Fig. 5.

a

Enclosure bushing for connecting monitoring devices

Post insulators for insulated installation of tell-tale spark gap

Tell-tale spark gap 3EX6 040

Operation sensor 3EX5 060

System ground

b

a: Installation sequence for encapsulated arresters without a tell-tale spark gap

b: Installation sequence for encapsulated arresters with a 3EX6 040 tell-tale spark gap

Note

The wiring run between the connection for monitoring devices and the ground connection

should be kept as short as possible.

8

© Siemens AG • 10/2004

Display 3EX5 062

The display can be installed at distances of up to 200 m (maximum length of connecting lead). Greater

distances are however possible on request. The display is connected to the sensor by means of a

special lead. The display enclosure must be installed so that it is grounded effectively. Be sure not to

exceed the permitted tightening torques for the screws:

!

Mmax = 30 Nm ± 1 Nm.

Fig. 6.

Installation of 3EX5 062

Warning

To ensure proper shock-hazard protection the housing of the

3EX5 062 display must be grounded effectively.

© Siemens AG • 10/2004

9

Connecting lead

Fig. 7.

Connecting lead between sensor and display

Ready-assembled connecting leads are available. If so required, you can also make up the leads

yourself. For each lead you will need a plug and an angle socket, C16 series, six-pole, manufactured

by Amphenol. The plugs and sockets can also be ordered as pairs from Siemens.

Order code for connecting lead

Type

3EX5 960-0

3EX5 963-0D

3EX5 963-0G

3EX5 963-1A

3EX5 963-1C

3EX5 963-1E

3EX5 963-1G

3EX5 963-1J

3EX5 963-2A

3EX5 963-2C

3EX5 963-2E

3EX5 963-2G

3EX5 963-2J

3EX5 963--3A

Description

Plug and socket for connecting lead

Connecting lead, 3 m

Connecting lead, 6 m

Connecting lead, 10 m

Connecting lead, 12 m

Connecting lead, 14 m

Connecting lead, 16 m

Connecting lead, 18 m

Connecting lead, 20 m

Connecting lead, 22 m

Connecting lead, 24 m

Connecting lead, 26 m

Connecting lead, 28 m

Connecting lead, 30 m

Remarks

For customer assembly

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

Pre-assembled

The following is used as lead: PVC-C-LIYCY, 3×2×0.25 mm².

The connection between the plug and socket is shown in the following diagram:

Fig. 8.

10

Connecting lead diagram

© Siemens AG • 10/2004

Connection to bus systems

The outputs of the 3EX5 060 sensor can be connected to the interface cards of the bus systems

directly or via commercially available transformers (4 - 20 mA current loop, for example) (Rin ≥ 1 MΩ).

In the event of arrester operation, an internal protective circuit in the measurement outputs limits the

voltage pulse which occurs to a value of ûimp ≤ 350 V.

Warning

Due to the voltage surges which can occur during arrester operation

you should ensure that adequate suppressor circuitry is installed in

the inputs of transformers or interface cards.

© Siemens AG • 10/2004

11

Operation

Use of the measurement output and reading the leakage current measurement device is only possible

when the system is in operation - in other words, when the system is not isolated.

Warning

Non-compliance of safety hints can course death or serious injures.

Always maintain a safe distance from live parts!

Use binoculars for reading measuring instruments and indicators, if

necessary.

Reading the surge counter

Fig. 9.

Surge counter

The surge counter displays surge arrester operation events which occur when threshold values are

exceeded.

Note

Due to routine inspection and testing having been carried out, the arrester monitor will

already display a value greater than 0 when shipped.

12

© Siemens AG • 10/2004

Reading the leakage current measuring device

Fig. 10.

Leakage current measuring device

Under normal circumstances the pointer deflection should not exceed 2/3 of the range on the scale. If

the pointer is in the range marked ‘>20’, measurement should be repeated at a later time since the

leakage current through the arrester could be falsified by foreign conductive deposits on the surface of

the arrester housing. In the same way, increased leakage currents can occur immediately after a

reading due to a temperature increase in the active part of the arrester; this problem would not

however occur with shorter periods of time.

If measurements subsequently repeated still yield the same results, you should contact the

manufacturer of the arrester.

© Siemens AG • 10/2004

13

Measurement output

Fig. 11.

Measurement output

The rear of the display unit is provided with a C16-1 socket (Amphenol) as a measurement output for

the leakage current time curve. The transformation ratio at the measurement output is ü = 470 mV/mA.

The input resistance of the connected measuring device (an oscilloscope, for example) must have a

value of Rin ≥ 1 MΩ. In the event of arrester operation, an internal protective circuit in the

measurement outputs limits the voltage pulse which occurs to a value of ûimp ≤ 350 V.

When the system is not in use, the cover cap must be replaced to protect the socket from

environmental influences. The cap is permanently attached to the socket by a plastic chain.

As a simple way of connecting an oscilloscope, a special lead (order no.: 3EX5 961-2) for connecting

the measurement output and the oscilloscope is available (not included in the scope of supply).

14

© Siemens AG • 10/2004

.

Fig. 12.

Lead 3EX5 961-2 for connecting measurement output and oscilloscope

© Siemens AG • 10/2004

15

Disposal arrester and arrester accessories

Surge arresters and the accessories are an environmentally compatible product. In disposal, priority

must be given to reuse of the materials. Environmentally acceptable disposal of the surge arresters

and the accessories is possible in line with current legislation.

The following materials have been used to make up the device: Steel, copper, aluminium, PTFE, cast

resin or cast-resin-impregnated fabric, glass-fibre-reinforced plastics, polyurethane, rubbers for

sealing, ceramics, electronic components and silicon rubber (VMQ), ceramics (porcelain, metal oxide).

The device can be recycled as mixed scrap, or, if it is dismantled as far as possible, in a more

environmentally acceptable way as sorted scrap with a mixed-scrap residual portion. The arrester

resistors of metal oxide (MO) should be disposed of as industrial waste similar to domestic garbage

(not as building rubble).

In as-supplied-by-Siemens state, the device incorporates no hazardous substances in the sense of the

pertinent regulations in Germany. If the device is to be operated outside Germany, the locally

applicable laws and regulations must be followed.

Local customer support offices will be able to answer any questions concerning disposal.

01.10.2004 10:01

16

© Siemens AG • 10/2004