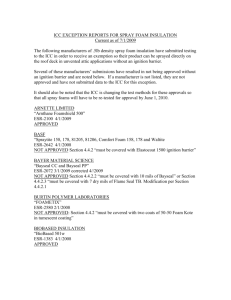

ICC-ES Evaluation Report ESR-2298*

advertisement

ICC-ES Evaluation Report ESR-2298* Reissued May 2014 This report is subject to renewal May 1, 2016. www.icc-es.org | (800) 423-6587 | (562) 699-0543 DIVISION: 07 00 00—THERMAL AND MOISTURE PROTECTION Section: 07 57 00—Coated Foam Roofing A Subsidiary of the International Code Council ® FE348-2.5, FE348-2.7, FE348-2.8 or FE348-3.0 sprayapplied polyurethane foam plastic insulations. BASF Corporation ELASTOSPRAY 81000 Series coated foam plastic roof coverings consist of liquid-applied coatings over ELASTOSPRAY 81255, 81275, 81285 and 81305 spray-applied polyurethane foam plastic insulations. REPORT HOLDER: BASF CORPORATION 1703 CROSSPOINT HOUSTON, TEXAS 77054 (888) 900-FOAM (3626) www.spf.basf.com 3.2 Spray Polyurethane Foam Plastic Insulation: EVALUATION SUBJECT: BASF CORPORATION COATED FOAM PLASTIC ROOF COVERINGS: FE348 SERIES AND ELASTOSPRAY 81000 SERIES ADDITIONAL LISTEES: UNITED COATINGS 2810 SOUTH 18TH PLACE PHOENIX, ARIZONA 85034 3.2.1 General: BASF Corporation FE348-2.5, FE3482.7, FE348-2.8 and FE348-3.0 and ELASTOSPRAY 81255, 81275, 81285 and 81305 are two-component, spray-applied, foam plastic insulations complying with ASTM C1029–Type III, and are produced in densities of 3 2.5, 2.7, 2.8 and 3.0 pcf (40.0, 43.2, 44.8 and 48.0 kg/m ), respectively. The foam plastic ingredients (Component A and Component B) are available in 55-gallon (208 L) drums and have a shelf life of nine months for Component A and three months for Component B when stored at temperatures between 50°F and 80°F (10°C and 26.7°C). 3.2.2 Surface-burning Characteristics: The foam plastic insulations have a flame-spread rating of 75 or less when tested in accordance with ASTM E84 or UL 723 at a maximum thickness of 2.0 inches (51 mm). HYDRO-STOP 1465 PIPEFITTER STREET NORTH CHARLESTON, SOUTH CAROLINA 29405 3.3 Coatings: 1.0 EVALUATION SCOPE Compliance with the following codes: ® 2012, 2009 and 2006 International Building Code (IBC) 2012, 2009 and 2006 International Energy Conservation ® Code (IECC) Properties evaluated: Physical properties Fire classification Wind resistance Impact resistance Elimination of thermal barrier (roofing) 2.0 USES The coated foam plastic roof coverings described in this report are used in construction of classified roof assemblies, as noted in Table 1. The roof covering systems recognized in this report may be used on buildings of any type of construction. 3.3.1 General: The coatings recognized in this report for use in the BASF Corporation roofing systems are United Coatings Diathon acrylic roof coating and BASF FECoat 1000 acrylic roof coating. 3.3.2 United Coatings Diathon Acrylic Roof Coating: Diathon coating is a single-component, liquid-applied, 100 percent acrylic elastomeric coating, produced by United Coatings. It is supplied in 5-gallon (18.9 L) pails and 55-gallon (208 L) drums and has a shelf life of 24 months when stored at temperatures between 50°F and 80°F (10°C and 26.7°C). The Diathon coating complies with ASTM D6083. 3.3.3 BASF FECoat 1000 Acrylic Roof Coating: BASF FECoat 1000 coating is a single-component, liquid-applied, 100 percent acrylic elastomeric coating. It is supplied in 5-gallon (18.9 L) pails and 55-gallon (208 L) drums and has a shelf life of 24 months when stored at temperatures between 50°F and 80°F (10°C and 26.7°C). The BASF FECoat 1000 coating complies with ASTM D6083. 3.4 Impact and Foot Traffic Resistance: 3.0 DESCRIPTION 3.1 General: BASF Corporation FE348 Series coated foam plastic roof coverings consist of liquid-applied coatings over The coated foam plastic roof coverings described in this report comply with the Resistance to Foot Traffic Test in Section 5.5 of FM 4470. *Corrected June 2014 ICC-ES Evaluation Reports are not to be construed as representing aesthetics or any other attributes not specifically addressed, nor are they to be construed as an endorsement of the subject of the report or a recommendation for its use. There is no warranty by ICC Evaluation Service, LLC, express or implied, as to any finding or other matter in this report, or as to any product covered by the report. 1000 Copyright © 2014 Page 1 of 3 ESR-2298 | Most Widely Accepted and Trusted 4.0 INSTALLATION 4.1 Preparation of Substrates: The substrates to be covered must be free of all grease, oil, loose particles, moisture, and other foreign materials. Areas not receiving a foam plastic insulation application must be masked off or otherwise protected from overspray. The application of primers, when used, must be in accordance with the spray foam roofing manufacturer’s installation instructions. 4.2 Substrates: 4.2.1 Combustible Substrates: Combustible substrates 15 /32-inch-thick (11.9 mm), codemust be minimum complying, exterior-grade or Exposure 1 plywood (US DOC PS1). All plywood edges must be supported in accordance with the requirements set forth in IBC Section 2603.4.1.5. 4.2.2 Noncombustible Substrates: 4.2.2.1 Cementitious Substrates: Structural concrete substrates must have a minimum compressive strength of 2500 psi (17 237 kPa). Cementitious decks must be thoroughly cured and must be subjected to specialized treatment, such as wire brushing or commercial sandblasting, or must be chemically cleaned to ensure adequate bonding. 4.2.2.2 Metal Substrates: Minimum No. 22 gage galvanized steel [0.030 inch (0.76 mm)] deck. Metal decks must be cleaned of any adhesion inhibitors, and gaps in end or sidelaps must be sealed with an approved sealant. 4.3 Roof Slope: The polyurethane foam plastic insulation must be sprayapplied to form roof slopes that have a minimum slope of 1 /4:12 (2 percent) and a maximum roof slope as specified in Table 1. 4.4 Foam Plastic Insulation Application: The polyurethane foam plastic insulations described in Section 3.2 are applied at a 1:1 ratio by volume of the A and B components to one of the substrates described in Section 4.2, using foam-spraying equipment and processing parameters recommended by BASF Corporation. Application of the foam plastic insulation must be performed when the following conditions are met: Substrate temperature is at least 50°F (10°C); Ambient temperature is at least 50°F (10°C); Relative Humidity is below 85% RH; Dew point is more than 5°F (2.8°C) above or below the ambient temperature; Wind speed is equal to or less than 15 miles per hour (24.1 km/h). Wind barriers are needed when the wind speed is greater than 15 miles per hour (24.1 km/h). When conditions are outside the parameters noted above, consult BASF Corporation for additional guidance prior to installation. The foam plastic insulation must not be applied to wet or damp substrates, or when dew, condensation, precipitation, or freezing temperatures are expected prior to completion of the foam and coating application. Foam plastic is applied in maximum 2-inch-thick (51 mm) passes, to reach the desired thickness as noted in Table 1. The total finished thickness must be achieved within the same day. The finished surface of the foam must be smooth and free of voids, pinholes and crevices. 4.5 Application of Coating: The foam plastic insulation surface must be dry and free of all damaged foam, dirt and foreign material before Page 2 of 3 application of the coating. If the insulation surface is damaged to the point where cracks, voids or large depressions appear, additional insulation must be applied to create a satisfactory surface. After the insulation has developed sufficient strength to support foot traffic, but within 72 hours, the coating must be brush-, roller-, or spray-applied at the application rates noted in Table 1. The ambient temperature must be at least 50°F (10°C) during coating application, and above 32°F (0°C) for the 24-hour period after application. The coating must not be applied when dew, condensation, precipitation or freezing temperatures are anticipated prior to completion of the coating application. The application of primers, when used, must be in accordance with the spray foam roofing manufacturer’s installation instructions. 4.6 Thermal Barrier: The classified roof assemblies noted in Table 1, containing BASF Corporation FE348-2.5, FE348-2.7, FE348-2.8 and FE348-3.0 and ELASTOSPRAY 81255, 81275, 81285 and 81305 foam plastic insulation are recognized for use without a thermal barrier based on testing in accordance with UL 1256, as set forth in IBC Section 2603.4.1.5. 4.7 Fire Classification: 4.7.1 New Construction: Roof covering systems, as noted in Table 1, when installed in accordance with this report, are Class A or Class B roof coverings in accordance with ASTM E108 or UL 790. 4.7.2 Reroofing: Prior to installation of new roof coverings, inspection in accordance with IBC Section 1510, and approval from the code official having jurisdiction, are required. Installation must be over uninsulated systems only. 4.8 Wind Resistance: The allowable wind uplift pressures for the coated foam plastic roof coverings are noted in Table 2. 5.0 CONDITIONS OF USE The BASF Corporation FE348 Series and ELASTOSPRAY 81000 Series coated foam plastic roof coverings described in this report comply with, or are suitable alternatives to what is specified in, the code indicated in Section 1.0 of this report, subject to the following conditions: 5.1 Installation and application of the coated foam plastic roof coverings must comply with the code, the report holder’s published installation instructions, and this report. The instructions within this report govern if there are any conflicts between the report holder’s installation instructions and this report. 5.2 The spray-applied foam roofing insulation must be applied by installers trained or approved by BASF Corporation or trained by the Spray Polyurethane Foam Alliance. 5.3 Where moderate or heavy foot traffic occurs for maintenance of equipment, or is otherwise necessary, the roof covering must be adequately protected to prevent damage or wearing of the surface. 5.4 Foam plastic insulation must be separated from the interior of the building by an approved thermal barrier in accordance with IBC Section 2603.4, except as noted in Section 4.6. 5.5 The allowable wind uplift pressures listed in Table 2 are for the roof covering only. The deck and supporting structure to which the roof covering is attached must be designed to withstand the applicable wind pressures determined in accordance with ASCE 7. ESR-2298 | Most Widely Accepted and Trusted Page 3 of 3 5.6 Flashing must be installed at wall and roof intersections, at gutters and around roof openings, as required by IBC Section 1503.2. 5.7 The evaluation of the foam plastic insulation as a vapor retarder is outside the scope of this report. 5.8 The polyurethane foam plastic insulation components are manufactured in Houston, Texas under a quality control program with inspections by ICC-ES. The roof coatings are manufactured in Phoenix, Arizona, and North Charleston, South Carolina under quality control programs with inspections by ICC-ES. 6.0 EVIDENCE SUBMITTED 6.1 Data in accordance with the ICC-ES Acceptance Criteria for Spray-Applied Foam Plastic Insulation (AC377), dated November 2012 (editorially revised April 2013). 6.2 Reports of tests on United Coatings Diathon and BASF FECoat 1000 in accordance with ASTM D6083. 6.3 Reports of tests in accordance with Section 5.5 of FM 4470. 6.4 Reports of tests in accordance with ASTM E108 (UL 790). 6.5 Reports of tests in accordance with ASTM E84 (UL 723) 6.6 Reports of tests in accordance with UL 1256. 7.0 IDENTIFICATION Each container of polyurethane foam plastic insulation bears a label with the BASF Corporation, name and address; the product name (FE348 or ELASTOSPRAY 81XXXX); the component type [A (FE800A or ELASTOSPRAY 8000A and/or Isocyanate) or B (FE348 or ELASTOSPRAY 81XXXX and/or Resin)]; the density (Component B only); the flame-spread index; the evaluation report number (ESR-2298), the shelf life; and the date of manufacture. Each container of Diathon acrylic roof coating is labeled with the United Coatings name, the product name (Diathon), the date of manufacture, the shelf life, and the evaluation report number (ESR-2298). Each container of FECoat 1000 acrylic roof coating is labeled with the BASF Corporation, name; the product name (FECoat 1000); the date of manufacture; the shelf life; and the evaluation report number (ESR-2298). TABLE 1—FIRE CLASSIFICATION—COATED FOAM ROOF ASSEMBLIES SYSTEM FIRE SUBSTRATE MAXIMUM NO. CLASSIFICATION ROOF SLOPE FOAM PLASTIC INSULATION Designation 1F A Noncombustible 1 /2:12 2F A Noncombustible 3:12 15 3F B /32-inch-thick plywood 4F A Noncombustible /2:12 Thickness (inches) Designation TOP SURFACING Application Rate No. 11 granules, 30 pounds per 2 100 ft (Optional) 2 (Maximum) 1 1 COATING FE348-2.5, 2.7, 4 2.8 and 3.0 (Maximum) or ELASTOSPRAY 81255, 81275, 81285 and 81305 1 (Minimum) Diathon or FECoat 1000 Two coats at 1 1 /2 gallons 2 per 100 ft each No. 11 granules, 30 pounds per 2 100 ft No. 11 granules, 30 pounds per 2 100 ft (Optional) 4 (Maximum) 2:12 2 2 — 2 For SI: 1 inch = 25.4 mm; 1 gallon per 100 square feet = 0.41 L/m ; 1 gallon = 3.785 L; 1 ft = 0.0929 m . TABLE 2—WIND RESISTANCE—COATED FOAM ROOF COVERINGS SYSTEM NO. ALLOWABLE WIND UPLIFT (psf) SUBSTRATE FOAM PLASTIC INSULATION 1W 187 Structural concrete FE348-2.5, 2.7, 2.8 and 3.0 or ELASTOSPRAY 81255, 81275, 81285 and 81305 2 (Minimum) 2W 105 Steel deck FE348-2.5, 2.7, 2.8 and 3.0 or ELASTOSPRAY 81255, 81275, 81285 and 81305 1 (Minimum - above top of deck) DESIGNATION 2 For SI: 1 inch = 25.4 mm; 1 psf = 4.882 kg/m . 1 1 Coating must be one of the following: 1 2 (a) United Coatings Diathon applied in two coats at 1 /2 gallons per 100 ft per coat. 1 2 (b) BASF FECoat 1000 applied in two coats at 1 /2 gallons per 100 ft per coat. THICKNESS (inches)