THE U.S. COMMERCIAL LAUNCH INDUSTRY:

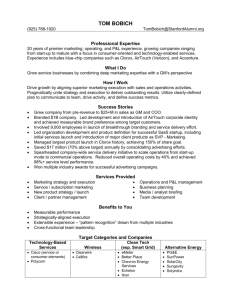

advertisement