Energy Management and Funding Sources at Water Infrastructure Facilities

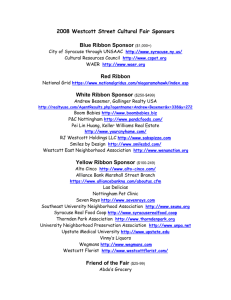

advertisement

Energy Management and Funding Sources at Water Infrastructure Facilities Photovoltaic and Microturbine facilities at the Westcott Tank Project Matt Marko – CH2MHill Zack Knight – CH2MHill Eric Murdock – City of Syracuse Water Department Mike Ryan - Mohawk Valley Water Authority The Big Picture • Westcott Tanks Project description Funding sources Addition of the energy component Green vs green Energy and Water – an overview • Fundamental equations of energy in fluid dynamics • Historical aspects in Syracuse water system • -Gravity flow Photovoltaics • Historical • -1905 • -1954 • -today Incorporation of Photovoltaics into the project •The Tuesday morning meeting • -The zero carbon footprint. • -Studying energy • -Making energy Green Innovation Grant Program (GIGP) • Administered by New York State Environmental Facilities Corporation (NYSEFC) as part of the ARRA (Stimulus) • 90% grant for shovel-ready “green” drinking water and clean water projects • $44.4M committed in first round; a second round (Fall 2010) is expected to award another $15M • Syracuse obtained grants for 50kW photovoltaic (PV) system and 56kW hydroturbine (HT) system at Westcott • Projects required design and construction contractor procurement complete within 4 months of announcement of award 50kW PV System Design • 50kW (DC) size selected to meet existing power demands at site • Performance-based specification • Minimum qualifications for installation contractor established due to high-voltage direct current (DC) electronics • Wind design criteria is important; at Westcott the design wind speed was 90 mph • A ballasted (versus anchored) system was chosen by the contractor, which is feasible for design wind speeds of up to 130 mph 50kW PV System Design (continued) • Shading factor (accounts for any obstructions of the sun) was negligible, thus a stationary array was chosen (tracking systems are available but reduce efficiency) • A new 3-phase service was added due to requirements for the HT and future UV plant at site (3-phase DC-AC inverters are also more cost efficient) • Other design considerations: – – – – – – Tilt angle (a footprint-wind lift tradeoff) Minimum voltage drop Warranty Communications requirements Utility interconnection application / requirements DC vs. AC specified wattage PV System Layout • The South Tank was chosen (shorter conduit runs) • The array will have 216 monocrystalline panels (thin film panel technology was not considered to minimize footprint) • The array footprint is approximately 10,000 square feet with a 10 tilt angle • Each tank is approximately 375-foot in diameter, or 100,000 square feet, providing space to expand to at least 250kW per tank • Spare conduit provided to expand the South Tank system up to 250kW in the future Simulated PV Layout Anticipated Appearance (Note – tilt angle at Westcott will be lower) PV System Financial Summary * * *Assumes system life of 25 years with no scrap value PV System Cash Flow Diagram PV System Environmental Impact Analysis • Over an assumed 25-year life cycle, the system will reduce greenhouse gas emissions by 972 tons CO2/year*, equivalent to the other CO2 productions listed below *Assumes 1.37 lb CO2/kWh of conventional energy and an average PV system output of 56,760 kWh/yr. 56kW Hydroturbine (HT) System Design • Skaneateles Lake, at approximately 864 feet USGS, is approximately 245 feet above the overflow elevation at Westcott Reservoir • Excess hydraulic head is removed at key points in the Syracuse supply conduit system, which is approximately 18 miles long • The HT system is designed to remove between 55-80 feet (25-35 psi) of head • System will have two (2) 10” Cornell turbines capable of conveying a combined 11 MGD City of Syracuse Water Supply System Westcott Supply Conduit Hydraulic Grade Line HT Equipment Design • Much of the HT market is focused on large volume and/or high head, often open channel flow projects near dams and lakes • Small, in-pipe hydroturbines (also called microturbines) are niche market for pump manufacturers (account for <5% of sales) • HT package vendors, which provide a mostly “skid-mounted” system (generator, switchgear, hydraulic powering unit, etc.), are also a niche market • Niche markets can limit options and have schedule impacts HT Layout, Valving, and Control • 42-inch reservoir inlet/outlet piping, reduced to 16-inch and ultimately 10-inch turbine inlet • Straight inlet run reduces thrust into turbine; after turbine turns 90° to outlet • Inlet valve provided with turbine package, which closes in a power outage • Outlet valve in vault for remote control and SCADA monitoring • Buried butterfly valves on outlet provides redundancy and manual shutdown capability Hydroturbine Vault 3D Model Westcott Hydroturbine Performance Curve Hydroturbine Other Design Considerations • • • • • Thrust restraint: grooved couplings before and after flanged turbine system ends Vault structural and sump design Man entry and equipment hatches Electrical design between turbine panel and utility service panel/meter Must submit application to power utility – turbine is considered an induction generator and requires a utility planning/grid study and design review prior to interconnection and net metering Turbine System Elevation Cut Sheet Project Photos (Courtesy of Canyon Hydro) 55kW Cornell turbine inside dam vault Cornell turbine – alternative layout 28kW Pelton turbine; discharge to WTP clearwell 245kW Pelton turbine between reservoir and WTP Westcott RE Project Progress • • • PV system is pending installation of the 3-phase power service and activation by utility HT system electrical in utility review and in the process of being manufactured; vault and piping complete Both systems anticipated to be active late Fall 2010 RE Project Challenges • Available resources • Available land area • Environmental impacts – wildlife – wetlands • Public acceptance – visual impacts • Electrical interconnection Future RE for Syracuse Water Department • A future UV treatment facility will add up to 150kW continuous power demand at Westcott, for which additional tank-mounted PV arrays could provide more RE • Woodland Reservoir not viable for turbines • Additional solar or small wind projects feasible at other City properties In Summary… Why consider RE at your utility? • • • • • • Short lead time for most projects Capital cost is coming down Incentives are available Reduce environmental footprint of operations Maximizing use of site renewable resources Provide a hedge against utility rate increases Questions?