Development of Polymer Cholesteric Liquid Crystal Flake Technology for Electro-Optic

advertisement

Development of Polymer Cholesteric Liquid

Crystal Flake Technology for Electro-Optic

Devices and Particle Displays

T. Z. Kosc, K. L. Marshall, A. Trajkovska-Petkoska,

C. Coon, K. Hasman, G. Babcock, R. Howe, and S. D. Jacobs

Laboratory for Laser Energetics, University of Rochester

Particles 2007

Toronto

21 August 2007

Summary

PCLC flake/fluid host suspensions are an exciting new

medium for information display

• Environmentally and physically robust particles with unique wavelengthand polarization-specific optical properties

• All materials are commercially available

• No polarizers or filters required

• Response times in 100’s of milliseconds

and drive fields as low as millivolts/μm

• Shaped flakes modified through doping

and/or with multimple layers display

improved motion uniformity, enhance

reflectivity >> 50% and altered dielectric

properties

Microencapsulation could provide flexible reflective displays and

conformal coatings with unique color and polarization properties

Presentation topics

• Cholesteric LC’s:

structure, properties, and optical effects

• PCLC flake/fluid host suspensions:

key properties and applications potential

• PCLC flake electro-optics:

experiments and theory

• Engineering PCLC flakes:

shaping and tweaking properties

• Microencapsulated suspensions:

progress toward flexible, bistable displays

• Devices and future research directions

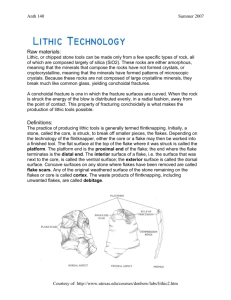

Cholesteric Liquid Crystals:

Structure, Properties and Optical Effects

Brief liquid crystal overview

Cholesteric

Nematic

n

P

Selective reflection in cholesteric LC’s is

a Bragg-like effect

λ o = navg p[cos 12 {sin −1( n1 sin ϕ i ) + sin −1( n1 sin ϕ s )}]

avg

2 n o , ch + n e , ch

3

ϕi ϕs

100

90

Transm ission (%)

n avg =

avg

80

70

60

50

40

Δλ = Δn p

30

20

10

0

300

400

500

600

700

800

Wavelength (nm)

• Reflected light is inherently circularly polarized

• Broad-band selective reflection is possible in systems with a

pitch gradient

PCLC Flake/Fluid Host Suspensions:

Key Properties and Applications Potential

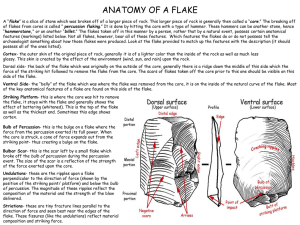

Flakes are produced by fracturing a PCLC film and

retain its unique physical and optical properties

•

Developed in early 1990’s.

The initial form is a polycrystalline solid*.

1 cm

•

A solvent-free film is cast on a silicon

substrate at an elevated temperature.

2.5 cm

•

Liquid nitrogen is poured over the substrate,

and the film fractures, forming flakes.

1 cm

*Polysiloxane materials provided by Dr. F. Kruezer, WackerChemie, Consortium für Electrochemische Industrie GmbH.

Commercial applications for PCLC flakes in

the 1990’s were mainly decorative

• Wacker polysiloxane PCLC flakes dispersed in a clear acrylic lacquer

Photos by E. Korenic, Ph.D. Thesis, University of Rochester, 1997.

The concept for an electro-optic device requires PCLC

flakes to be suspended in a fluid host

FIELD OFF

v

Glass

ITO

Fluid host

Flake

• Bright selective reflection is shifted and diminished as flakes rotate.

• Ideally, flakes uniformly reorient 90º.

+

+

v

v

FIELD ON

-

K. L. Marshall, et al , “U. S. Patent No. 6,665,042 #B1 (16 December 2003).

The unique properties of PCLC flakes open a

host of possible device applications

• Information display

– Reflective multi-color particle displays,

flexible displays, 3-D displays,

“electronic paper”

• Electro-optics and Photonics

– Switchable/ tunable color filters,

micropolarizers, modulators

• Coatings technology

– Switchable “paints”, conformal coatings,

switchable “smart windows” for energy

or privacy control

• Military/Security

– Anti-counterfeiting, signature reduction,

camouflage, encoded and encrypted

information storage

QuickTime™ and a

TIFF (Uncompressed) decompressor

are needed to see this picture.

Particle Display Technologies for

Flexible Display Applications

A wide variety of display technologies are

competing for dominance of the emerging

flexible display market

•

Particle displays

•

Liquid crystal displays

•

Organic light emitting diode (OLED)

•

Polymer light emitting diode (PLED)

•

MEM’s-based reflective displays

•

Electro-chromic displays

•

Electro-wetting technologies

Particle displays have a number of advantages

over other competing technologies . . .

•

Bistable switching

- greatly decreases power consumption and reduces drive

electronics complexity

•

Reflectivity

- low power requirements as compared to emissive

displays (OLED’s, PLED’s, ) or backlighted LCD’s

•

Environmental robustness

- optical properties are relatively insensitive to temperature

and other environmental factors

•

Flexibility

- cost-effective fabrication of large area devices by liquid

coating techniques (web, slot, die) makes roll-to-roll

manufacturing viable for large-volume applications

E-Ink technology is based on translational motion

of microencapsulated charged particles

• Charged microparticles migrate towards the top or

bottom of the microcapsule depending of the sign

of the applied voltage.

• Microcapsule diameter ranges from 50 - 200 μm

• Monochrome and two-color devices demonstrated

SiPix Microcup devices use depressions stamped into a

flexible substrate to confine an electrophoretic dispersion

• Monochrome or two-color

• Multi-color only with color filters

Gyricon devices employ charged particles

that both rotate and translate

• Microencapsulated bichromal plastic balls

(< 100 μm) have a white and an oppositely

charged black hemisphere.

• Balls rotate 180o depending on the sign of

the applied voltage, while translating toward

the electrode.

Bridgestone’s Quick Response Liquid Powder

Display is a unique electrophoretic technology

• Charged particles in air

• Require large voltages

• Chemical treatment allows dry

particles to flow like a liquid

• Video frame rate capability

• Color capability (???)

treated

untreated

. . . . but the greatest single drawback of current

particle displays is a lack of full-color capability

• Optical effect is a combination of absorption and scattering

(white or colored particles in a transparent or dyed host fluid)

• Two-color systems are relatively easy to achieve, but

obtaining multi-color devices has been much more difficult

than anticipated.

• Multi-color particle displays have been demonstrated, but

only by using color filters, which

-

degrade display’s appearance

-

reduce reflectivity by as much as 60%

-

increase manufacturing cost

No commercial particle display device is currently capable of

multi-color operation without employing color filters

PCLC flake technology offers advantages that are

unmatched by existing particle display technology

•

Selective reflection effect provides highly saturated colors without

polarizers or filters

•

Left- and right-handed PCLC materials along with other optical polymers

form layered, composite flakes with a reflectivity exceeding 50%

•

Broad-band and polarization-specific optical effects can be utilized for

unique display properties and applications

•

Drive fields are as low as millivolts/μm (applied voltage of only a few volts)

PCLC Flake Electro-Optics:

Experiment and Theory

Motion was initially observed in a DC field

For εhost > εflakes

(silicone oil host fluids)

•

Cheap, commercial fluid

•

Low conductivity

•

Commonly used for

microencapsulation

•

Flake motion is random and sensitive to changes in field polarity

•

Electric field requirements are modest (5 V/μm)

•

DC drive offers possibility for bistability

Uniform reorientation was seen using a

conductive host fluid and an AC driving field

For εhost >> εflakes

(propylene carbonate or

polyethylene glycol)

•

Commercial, but volatile fluid

•

High conductivity

•

Not commonly used for

microencapsulation

•

Flake motion is coordinated and controlled

•

Response is frequency dependent

•

Electric field requirements are very small (< 10 mVrms/μm)

•

Flakes return to original orientation when the applied field is removed

•

AC drive complicates the possibility for bistability

Maxwell-Wagner polarization is the main mechanism

for PCLC flake reorientation in an AC-field

• Interfacial polarization induces a dope moment in the presence

of an applied electric field.

+

+

-- - -

- - - - ++ + + +

_

V=0

_

+ ++

++

V=Vapp , increasing time

• Frequency dependent behavior found over three decades.

• Response shows inverse quadratic dependence on electric field strength.

Dielectric anisotropy of the PCLC material plays no role in E-O reorientation.

T. Z. Kosc,”, PhD Thesis, University of Rochester, 2003

The experimental data show an inverse quadratic

dependence on the applied field

Responce Time (s)

100

Slope of line = -2

R2 = 0.78 small

100

80

10

60

40

1

0.1

1

10

1.5

2

20

0

0

0.5

1

Voltage (VRMS)

The experimentally observed frequency dependent

behavior is not completely predicted by the model

⎛ tan(φ) ⎞

4 ηo

(a +a )

ln

⎜

⎟

2

ε h Re {K*2 K*3 } (A3 - A 2 )E o2 (a 2 A 2 +a A3 ) ⎝ tan(φo ) ⎠

Real component:

flake rotation much slower

than E-field oscillation

Imaginary component:

contains phase information

on cross product of applied

field and induced dipole

moment

Real part model

Imaginary part model

Experimental Data

1000

Response Time (s) .

2

3

2

3

100

Response Time (s)

t=

2

2

44.6

10

4.4

3.1

1

1

10

100

Frequency (Hz)

1000

10000

5

4

10

100

Frequency (Hz)

1000

Flake shape and size affect reorientation time

Reorientation Time (s

(s)

60

E

50

40

Flake surface shapes are drawn.

G

D

30

B

A

20

C

10

F

0

1

1.5

2

2.5

3

Aspect Ratio (a.u.)

•

Flakes with the largest aspect (length to width) ratio reorient the fastest.

*Optimum flake dimensions: 40 to 60 μm long, 3:1 aspect ratio, 3 to 5 μm thick

There are many aspects of the technology that

can be developed and improved

Improve flake motion uniformity

Find a method or mechanism to drive PCLC flakes back to their

original position

Find a method or mechanism for bistability

Create pixilated and multi-colored devices

Build flexible devices

Improve reflectivity and contrast of devices

There are several avenues being explored,

and some address multiple problems

“Shape” PCLC flakes

- improve flake motion uniformity

- microencapsulation

Engineer materials - PCLC flake composites

- bistability

- reverse flake motion

- improve reflectivity and contrast

Microencapsulation

- bistability

- reverse flake motion

- pixilated and multi-colored devices

- flexible devices

Specialized driving waveforms

- bistability

- reverse flake motion

Engineering PCLC Flakes:

Shaping and Tweaking Properties

Reorientation times of commercial PCLC flakes

vary due to differing size and shape

POM

X polars

SEM

10 um

50 um

Small, elongated flakes reorient faster than larger, symmetrical flakes

Specialized flakes have been manufactured to

investigate theoretical predictions and improve

device characteristics

Soft lithography using

polydimethilsiloxane molds is

employed to produces flakes of

various (uniform) sizes and shapes

PCLC materials are doped with

conductive or highly dielectric dopants

Two or more PCLC layers are fused to

greatly enhance flake reflectivity

Experimental data verifies theoretical prediction that

shaped flakes with greater aspect ratios reorient

faster

• Shaped PCLC flakes prepared

from Wacker Helicone® PCLC

• Host fluid: γ-butyrolactone

• Cell thickness: 80 μm

• Applied voltage: 3.2 Vrms (50 Hz)

• Resonse time: 280 ms

• Aspect ratios: Rectangles (3:1)

Ellipses

Squares

(2:1)

(1:1)

The physical, optical, and electrical properties of

PCLC flakes are modified with particle dopants

•

•

•

•

Increases difference between εflake and εhost

Adjust flake density

Provide color enhancement

Produce a homogeneous or non-uniform charge distribution

• Small amounts of

carbon black or carbon

nanotubes dramatically

increase flake

conductivity

Layered composite PCLC flakes could produce

reflective displays with both highly saturated

colors and reflectivity greatly exceeding 50%

A silicone oil with a high dielectric permittivity

allowed uniform reorientation using a DC field

For εhost > εflakes

(silicone oil)

•

Commercial fluid

•

Low conductivity

•

Commonly used for

microencapsulation

•

Response is frequency dependent

•

Flake motion is coordinated and controlled

•

Drive voltage requirements are very small (<5 mV/μm)

•

DC drive offers possibility for bistability

•

Motion reversal has been observed for opposite polarity

Microencapsulation of Suspensions:

Toward Flexible, Bistable Displays

Segregation of electro-active particles into

“microcompartments” has been crucial in achieving

commercial viability for particle displays

•

Prevent particle agglomeration

•

Effect bistable operation

•

Cost-effective fabrication of large area devices (roll-to-roll )

•

Enables applications in flexible displays (roll-up displays, e-paper)

•

Electrically addressable conformal coatings

Microencapsulation of the two-component

(flake and fluid) host suspensions represents a

significant challenge

PCLC flakes and silicone oil are strongly hydrophobic,

so water-based polymer binders are ideal

Direct emulsification (PVA)

Complex coacervation (gelatin)

100 μm

•

•

•

Disperse at low-shear in PVA

Knife-coat onto substrate

Dry in air or nitrogen stream

•

•

•

Form gelatin microcapsules (pH or

concentration change)

Chemically “harden” and isolate

Re-disperse in a compatible binder

Microencapsulation using silicone oils with εh > 3 requires surfactants

PCLC flakes reorientation is seen in both gelatin and

PVA microencapsulation matrices

Flake/fluid “gelcaps” in a PVA binder

Film thickness (total): 300 um

Drive voltage: 50-125 V

•

Greatest motion in large capsules and

when field polarity changes

•

Flakes become “trapped” in capsules

of comparable size

•

Flakes display “sticking” effect

• Become attached to capsule

wall

• Released with passing time,

higher voltage, opposite polarity

• Possible latching mechanism?

Building PCLC Flake Devices:

Waveforms, Pixels, and Curves

An optimized 3-V, 1.5-s saw-tooth pulse shows

acceleration compared with natural relaxation of flakes

•

•

•

•

A pulse with a sharp leading edge and a gradual trailing edge produced optimal results

Accelerated relaxation occurs within 4 seconds

Natural relaxation requires ~70 seconds to reach the same brightness level

Waiting several minutes to gain the additional brightness would not be useful for most

applications

A holding voltage lower than the drive voltage prevents

flake relaxation while consuming less power

PCLC flakes reorient most quickly at 80 Hz in this PC test system.

< 80 Hz : many flakes relax and significant amount of reflectivity regained

> 80 Hz : magnitude of the brightness barely changes from its minimum level

• 3-Vpp drive voltage

• 0.4-V holding voltage

• Free ions cannot move far at high frequencies, so the induced dipole remains.

• Holding voltages do not diminish for frequencies above 80 Hz.

ITO-coated Mylar substrates were used to

fabricate flexible devices

• Commercial PCLC flakes (40 to 60 μm long, 3:1 aspect ratio, 3 to 5 μm thick)

• Flake concentration: 4% to 5%

• Path length = 120 μm V = 3.0 Vrms*

*80 Hz sine wave

PCLC flake technology offers unique features for

particle displays and other applications

• PCLC selective reflection effect provides highly saturated

colors at low flake concentrations (3-5%) without polarizers or

filters

• Response times are on the order

of 100’s of ms

• Drive fields (mV/μm) are

remarkably low

• Microencapsulation will enable

flexible devices

• Solutions for motion reversal and

bistability are being actively

pursued

• Possibilities are limitless . . .

Acknowledgements

Laboratory for Laser Energetics

University of Rochester

U.S. Department of Energy

Office of Inertial Confinement Fusion

(Cooperative Agreement DE-FC52-92SF19460)