Turnkey Turboset Modernization

at Nuclear Power Station Borssele

The Plant

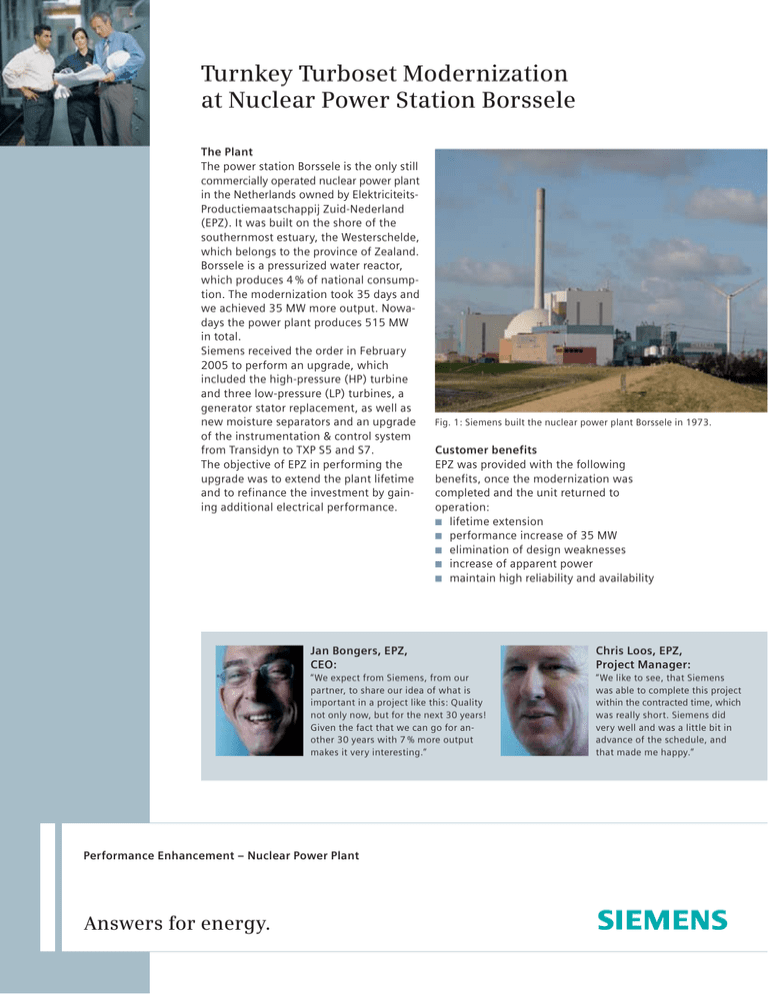

The power station Borssele is the only still

commercially operated nuclear power plant

in the Netherlands owned by ElektriciteitsProductiemaatschappij Zuid-Nederland

(EPZ). It was built on the shore of the

southernmost estuary, the Westerschelde,

which belongs to the province of Zealand.

Borssele is a pressurized water reactor,

which produces 4 % of national consumption. The modernization took 35 days and

we achieved 35 MW more output. Nowadays the power plant produces 515 MW

in total.

Siemens received the order in February

2005 to perform an upgrade, which

included the high-pressure (HP) turbine

and three low-pressure (LP) turbines, a

generator stator replacement, as well as

new moisture separators and an upgrade

of the instrumentation & control system

from Transidyn to TXP S5 and S7.

The objective of EPZ in performing the

upgrade was to extend the plant lifetime

and to refinance the investment by gaining additional electrical performance.

Customer benefits

EPZ was provided with the following

benefits, once the modernization was

completed and the unit returned to

operation:

■ lifetime extension

■ performance increase of 35 MW

■ elimination of design weaknesses

■ increase of apparent power

■ maintain high reliability and availability

Jan Bongers, EPZ,

CEO:

Chris Loos, EPZ,

Project Manager:

“We expect from Siemens, from our

partner, to share our idea of what is

important in a project like this: Quality

not only now, but for the next 30 years!

Given the fact that we can go for another 30 years with 7 % more output

makes it very interesting.”

“We like to see, that Siemens

was able to complete this project

within the contracted time, which

was really short. Siemens did

very well and was a little bit in

advance of the schedule, and

that made me happy.”

Performance Enhancement – Nuclear Power Plant

Answers for energy.

Fig. 1: Siemens built the nuclear power plant Borssele in 1973.

Features

Turbine Design Features

■ HP design features – 3DS™/3DV™ blades

Since the mid-90s, Siemens has been

supplying fully three dimensionally

designed drum stages in HP & IP turbines. These drum stages are equipped

with twisted and bowed blades called

3DS blades (Siemens trademark and

patent). A few years later Siemens introduced a highly sophisticated blading technology called 3DV. This technology optimizes the blade path by a

numerical method, which varies the

stage reaction and stage loading. This

automatically results in optimized

blade path efficiency. All these new

technologies were used for the HP

modernization.

■

LP design features

The LP turbines were modernized with

a new blade path with larger last stage

blades. This led to an increase of the

exhaust annulus area from 8 m2 (old

design) to 10 m2 per flow, which reduces the exhaust losses. 3DS blades

were used for the drum stages at the

front, and all rotating blades were designed with an integral shroud, even

the large last stage blades. The new

10 m² blade path was carefully designed with state-of-the-art and fully

three dimensional design tools like advanced computational fluid dynamic

and finite element methods for the

aerodynamic and mechanical design.

The final acceptance test and reliability

run proved the new technology.

Fig. 2: Cross-section of the turbine rope.

Generator Stator Exchange Features

To extend the lifetime of the generator

and thus maintain the high reliability and

availability of the machine, as well as to

support the uprate of the turbine, it was

necessary to replace the generator stator.

■

■

Advanced stator end-winding design

The Siemens advanced stator endwinding design reduces maintenance

efforts due to enhanced end-winding

robustness and improves end-winding

vibration behavior. Through the axially

free and tangentially as well as radially

flexible end-windings the natural

frequency of the whole end-winding

basket was lowered, which prevents

operation of the generator end-winding close to resonance.

Improved stator core end-steps

The stepped, laminated end packs and

end shields minimize axial flux penetration into the core and reduce losses.

With a new monoblock rotor, inner

casing, and stationary blade rings

manufactured with high alloy materials, the lifetime is extended. The highly effective protection measures

against droplet erosion and corrosion

are based on Siemens’ extensive experience.

Additional orders

In addition to the standard inspection, we

also received an order for special maintenance tasks on the auxiliaries and the

turbine.

The tasks on the turbine included for example the modification of the non-return

valves from hydraulic to pneumatic operation and the replacement of the fire

control dampers. The maintenance of the

auxiliaries included amongst others the

overhaul of the generator auxiliaries. The

gas dryer and the H2 equipment including

gas purity meter were replaced and the

purging gas was adapted from CO2 to

Argon, which was important to meet the

ATEX requirements.

References

This modernization of a complete turboset represented a considerable effort for

our customer and therefore also for us.

The cooperation and communication

between EPZ and Siemens as well as the

common responsibility and technical

know-how helped us to complete the

project successfully.

For more information please contact

your local Siemens sales representative.

The usage of a double shell inner casing is a further design feature.

Published by and copyright © 2009:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

www.siemens.com/energy

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

Energy Service Division

Order No. E50001-G520-A129-X-4A00

Printed in Germany

Dispo 34805, c4bs No. 7816

TH 258-090355 460326 DB 09092.0

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.