Pump It Up:

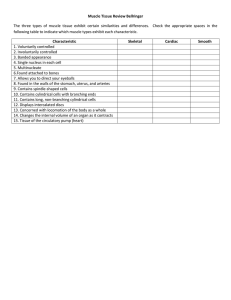

Computer Animation of a Biomechanically Based

Model of Muscle using the Finite Element Method

by

David Tzu-Wei Chen

MSEE, Stanford University (1983)

BSEE, University of Illinois (1981)

Submitted to the Media Arts and Sciences Section, School of Architecture and Planning,

in partial fulfillment of the requirements for the degree of

Doctor of Philosophy

at the

of Technology

Institute

Massachusetts

February 1992

of Technology, 1991. All rights reserved.

Institute

@Massachusetts

Author

David Chen

Media Arts and Sciences Section

October 18, 1991

Certified by

AssociteesDa

Associate Professor

Compu

Media Arts an

Accepted by

id Zeltzer

r Graphics

ciences Section

.

Stephen A. Benton

Chairperson, Departmental Committee on Graduate Students

MASSACHUSETTS WNSTITUTE

OF TECHNOLOGY

APR 28 1992

David T. Chen

Pump It Up:

Computer Animation of a Biomechanically Based

Model of Muscle using the Finite Element Method

by

David Tzu-Wei Chen

Submitted to the Media Arts and Sciences Section,

School of Architecture and Planning

on October 18, 1991

in partial fulfillment of the requirements for the degree of

Doctor of Philosophy

Abstract

This thesis examines muscle function through the process of making computer animation and developing interactive graphics applications. Muscle is the fundamental

"motor" that drives all animal motion and so is an appropriate place to begin investigations relevant to the goal of modeling human characters. The major supposition

of the thesis is that the shape changes generated by a contracting muscle will be

reproduced by accurately simulating the forces involved. To examine the hypothesis, a novel computational model of skeletal muscle is presented. The geometry

and underlying material properties of muscle are captured using the finite element

method (FEM). A biomechanical model of muscle action is used to apply non-linear

forces to the finite element mesh nodes. The techniques that are developed for fast

graphical display and interactive manipulation of finite element simulations can be

used both to design computer animations and directly incorporated into new kinds

of applications-such as surgery simulation systems-made possible by the ever increasing power of computer workstations. Results presented indicate that the twin

goals of realistic computer animation and valid biomechanical simulation of muscle can be met using the methods presented herein and can be a foundation both

for animators wishing to create anatomically based characters and biomechanical

engineers interested in studying muscle function.

Thesis Supervisor: David L. Zeltzer

Title: Associate Professor of Computer Graphics

This work was supported by NHK and by equipment grants from Hewlett-Packard.

Pump It Up

David T. Chen

3

Thesis Committee

Chairman

\

David Zeltzer

Comp er Graphics

Associate ofessor

MIT Media rts and Sciences Section

Member

Joe Rosen

Associate Professor in Plastic and Reconstructive Surgery

Dartmouth Medical School

Member.

U

Pump It Up

John Williams

Associate Professor

MIT Department of Civil Engineering

4

David T. Chen

Contents

1

2

3

Introduction

1.1 Previous Work . . . . . . . .

1.2 Elastic objects . . . . . . . . .

1.3 Goals and Contributions . . .

. . . . .

1.4 Thesis Organization

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Modeling a Single Muscle

2.1 Basic Muscle Anatomy . . . . . . . . . . . . .

2.2 Muscle Force . . . . . . . . . . . . . . . . . .

Sliding Filament Theory of Contraction

2.2.1

. . . . . . . . . .

Hill's Force Model

2.2.2

Zajac's Force Model . . . . . . . . . .

2.2.3

2.3 Muscle Shape . . . . . . . . . . . . . . . . . .

Range Camera Data . . . . . . . . . .

2.3.1

Manual Shape Input . . . . . . . . . .

2.3.2

Contour Data . . . . . . . . . . . . . .

2.3.3

2.4 Simulating a Muscle . . . . . . . . . . . . . .

The Finite Element Method

Equilibrium Equations . . . . . .

3.1

.

.

Stiffness Matrix K . . . .

3.1.1

.

Mass Matrix M . . . . . .

3.1.2

.

.

.

.

Interpolation

3.2 Isoparametric

.

Stiffness Matrix . . . . . .

3.2.1

.

Computer Graphics . . . .

3.2.2

.

Global Matrix Assembling . . . .

3.3

.

3.4 Modal Analysis . . . . . . . . . .

iations

.

Eq

Equilibrium

the

Solving

3.4.1

.

The Modal Transformation

3.4.2

.

.

.

.

.

Graphics

Computer

3.4.3

3.4.4 Deriving Modal Forces . . . . . . . . .

u

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

58

60

60

67

68

68

77

85

88

88

90

94

96

CONTENTS

Up

It Up

Pump It

CONTENTS

David T. Chen

3.4.5

4

5

Implementation

5.1 The 3d Animation/Dynamic Simulation

Tcl Language Synt ax . . . . . .

5.1.1

. . . . . . . .

3d Data Types

5.1.2

5.2 Graphics and Rendering . . . . . . . .

Objects . . . . . . . . . . . . .

5.2.1

Camera . . . . . . . . . . . . .

5.2.2

Lights . . . . . . . . . . . . . .

5.2.3

5.4

5.5

5.6

5.7

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Musculoskeletal Structure

4.1 Skeleton Kinematics . . . . . . . . . .

Denavit and Hartenberg Joints

4.1.1

Inverse Kinematics . . . . . . .

4.1.2

4.2 Muscle Coordination . . . . . . . . . .

4.3 Attachments, Collisions and Constraints

5.3

6

Mode Truncation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

104

105

105

108

110

113

.

.

.

.

.

System

.

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . .

Rendering . . . . . . . . . . . . . . . . . .

5.2.4

Numerical Math . . . . . . . . . . . . . . . . . . .

Matrix Functions . . . . . . . . . . . . . .

5.3.1

Netlib Functions . . . . . . . . . . . . . .

5.3.2

Dynamic Objects . . . . . . . . . . . . . . . . . .

User Interface . . . . . . . . . . . . . . . . . . . .

Motif Widgets . . . . . . . . . . . . . . . .

5.5.1

. . . . . . . . . . . . . . . . . .

X Events

5.5.2

User-Assisted Finite Elem ent Mesh Construction

Validating the FEM Imple mentation . . . . . . .

Methods and Results

Frog Gastrocnemius Simulation . . . . . . . . .

6.1

Force-based Finite Element Muscle Model

6.1.1

Tension-Length Experiment . . . . . . .

6.1.2

Quick Release Experiment . . . . . . . .

6.1.3

Human Gastrocnemius Simulation . . .

6.1.4

Future Work . . . . . . . . . . . . . . .

6.1.5

6.2 Computer Animation . . . . . . . . . . . . . . .

Using the FEM for Computer Animation

6.2.1

Jell-O@ Dynamics . . . . . . . . . . . .

6.2.2

GED Puff . . . . . . . . . . . . . . . . .

6.2.3

Conclusions

98

116

116

118

120

121

122

122

123

124

124

125

126

127

129

129

131

132

137

144

144

146

154

157

158

162

166

166

167

170

172

CONTENTS

Up

It Up

Pump It

CONTENTS

David T. Chen

U

A Isoparametric Interpolation

180

B Fast Interpolation

186

It Up

Up

Pump It

CONTENTS

CONTENTS

T

David T. Chen

List of Figures

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

2.19

2.20

2.21

2.22

2.23

2.24

2.25

2.26

2.27

2.28

2.29

2.30

A whole muscle adapted from [Kel7l] . . . . . . . . . . . . . . . . . . . . .

Section of muscle [Kel7l] . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The myofibril in relaxed and contracted states [Kel7l] . . . . . . . . . . .

Longitudinal muscles [Kel7l] . . . . . . . . . . . . . . . . . . . . . . . ..

Peniform muscles [Kel7l] . . . . . . . . . . . . . . .

Comparison of longitudinal and penniform shortening . . . . . . . . . . .

Physiological cross section adapted from [Kel7l] . . . . . . . . . . . . . . .

Electron micrograph showing three myofibrils in a single muscle fiber [VSL

Changes in fiber banding pattern due to contraction [VSL75] . . . . . . .

Tension-length curves . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

Gasser and Hill quick-release apparatus [GH24] . . . . . . . . . . . . . . .

Quick-release curves, plotting tension versus time [GH24] . . . . . . . . .

Muscles shortening at 5 constant speeds [GH24] . . . . . . . . . . . . . .

Tension-length curves from the jaw muscle of the Dog-Fish [LW27] . . . .

Visco-elastic muscle models [LW27] . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

Wilkie's quick-release machinery [Wil56]

Shortening due to quick-release for various isotonic loads [W il56] . . . . .

Hill's muscle model [McM84] . . . . . . . . . . . . . . . . . . . . . . . . .

Musculotendon architecture [ZTS86] . . . . . . . . . . . . . . . . . . . . .

Active and passive muscle models [ZTS86] . . . . . . . . . . . . . . . . . .

Tendon model [ZTS86) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approximating curves for muscle functions. . . . . . . . . . . . . . . . . .

Chebyshev approximated tendon model. . . . . . . . . . . . . . . . . . . .

Velocity-force function of active muscle. [ZTS86] . . . . . . . . . . . . . .

. . . . . . . . . .

Force-velocity function approximated with arctan.

Isometric normalized muscle force vs. IMT

-.

....

.

32

.

33

.

.

34

35

.

.

36

37

.

38

.

.

39

39

.

. . . . . . . . . . .

40

42

43

Isometric normalized muscle force vs. 1MT _ IT. [ZT86]

. . . . . . . . . . .

Range camera picture from Cyberware TM 3D system

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Point color picture . . . . . .

45

Reconstructed "Sturman" heads with 1984, 32512 and 8064 polygons . . . .

49

. . . . . . . . . . . . . . . . . . . . . . . . . .

50

2.31 Human biceps, 342 polygons

Pu mp It

It Up

Up

Pump

LIST OF FIGURES

LIST OF FIGURES

8

David T. Chen

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

51

52

53

54

55

56

57

. . . . . . . .

[Bathe] .

.

.

.

.

.

.

.

61

70

78

78

85

87

96

97

99

103

.

.

.

.

.

.

.

.

.

.

106

109

111

112

114

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

118

130

133

134

135

136

137

139

140

141

142

143

143

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2.32

2.33

2.34

2.35

2.36

2.37

2.38

Frog gastrocnemius, 576 polygons . . . . . . . . . . . .

Hand-derived slice through frog leg . . . . . . . . . . .

MRI slice through human calf . . . . . . . . . . . . . .

Reconstructed legs . . . . . . . . . . . . . . . . . . . . .

Medial-gastrocnemius . . . . . . . . . . . . . . . . . . .

Muscle model and muscle data after [Zaj89] and [LC87]

Muscles contract with constant volume. [McM84] . . . .

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

Four node tetrahedron element . . . . . . . . . . . . . . . . .

Twenty-node isoparametric brick, C numbering. adaptedfrom

... ... . ....................

....

Undeformed plastic

Stretched and twisted plastic . . . . . . . . . . . . . . . . . .

A bent fork . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Structure made from two tetrahedron elements . . . . . . . .

Mode shapes for twenty-node brick . . . . . . . . . . . . . .

Mode shapes for Cyberware head . . . . . . . . . . . . . . .

World space mesh forces for twenty-node brick . . . . . . . .

Modal popup menu . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4.1

4.2

4.3

4.4

4.5

Denavit and Hartenberg link parameters [Pau81] . . . . . . .

Inverse kinematically controlled skeleton motion . . . . . . .

Lower limb model for minimum time kicking problem. [AD851

Muscle acting about revolute joint. [Woo76] . . . . . . . . . .

Reaction constraints . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5.1

5.2

5.3

5.4

5.5

5.6

5.9

5.10

5.11

5.12

5.13

The 3d Animation/Simulation System . . . . . . . . . . . . .

3d dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEM mesh dialog box . . . . . . . . . . . . . . . . . . . . . .

Mesh filling Cyberware head bounding box . . . . . . . . . .

Mesh boundaries interactively shifted . . . . . . . . . . . . .

Mesh shrunken to head . . . . . . . . . . . . . . . . . . . . .

Head warped through mode-shape deformation . . . . . . . .

Uniformly loaded cantilever beam. adapted from [Den Hartog]

Plot of eigenvalues for 3 and 6 element beams. . . . . . . . .

Deflection for 3 element beam. . . . . . . . . . . . . . . . . .

Deflection for 6 element beam. . . . . . . . . . . . . . . . . .

Beam made from 6 twenty-node elements, initial state . . . .

Beam made from 6 twenty-node elements, final state . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6.1

6.2

6.3

..............

Model of single muscle fiber

gastrocnemius . . .

frog

for

used

mesh

element

Finite

Force generators for muscle and tendon . . . . . . . .

5.7

5.8

Pump It

It Up

Up

145

147

148

LIST OF FIGURES

LIST OF FIGURES

9

David T. Chen

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

6.15

Setup for tension-length experiment . . . . . . . . . . . . . . . . .

Force results from tension-length experiment. . . . . . . . . . . . .

Force results from Gasser-Hill quick release experiment. . . . . . .

Relaxed muscle deforms due to gravity. Active muscle pulled taut.

Human gastrocnemius deformed due to gravity, then pulled taut.

Volume results from tension-length experiment. . . . . . . . . . . .

Volume results from quick-release experiment. . . . . . . . . . . . .

Volume results from TL experiment with volume constraint. . . . .

Simulation results for muscle with fiber inhomogeneities. . . . . . .

Jello m otion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scene from finished Jello animation . . . . . . . . . . . . . . . . .

Blooby Puff bounce . . . . . . . . . . . . . . . . . . . . . . . . . .

Up

P ump It

Pump

It Up

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

154

156

157

159

161

162

163

163

165

169

169

171

LIST OF FIGURES

LIST OF FIGURES

10

David T. Chen

List of Tables

3.1

3.2

Local space node coordinates for isoparametric brick . . . . . . . . . . . . .

Run-time in seconds for two isoparametric interpolation implementations .

4.1

DH parameters for human left arm . . . . . . . . . . . . . . . . . . . . . . .

107

5.1

5.2

Runtime and tip deflection for 3 element beam.

Runtime and tip deflection for 6 element beam.

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

140

141

Pump It Up

LIST OF TABLES

David T. Chen

11

Chapter 1

Introduction

The specific goal of this thesis is to construct a biomechanical model for simulating the

changes in shape that a muscle undergoes during contraction. Posed in this way, the thesis

topic falls roughly into the domain of physically-based modeling for generating computer

animation. The analysis of the problem is formulated using the displacement-based finite

element method (FEM) from mechanical engineering. Thus, a large part of our work will

involve developing and codifing techniques to apply the FEM to making animation, and in

the dual case, to working out computer graphics methods that allow the effective visualization of the results of finite element simulation. Lastly, in the role of media technologist, an

effort will be made to evolve computer tools that are highly integrated and interactive; that

is, tools to enable one to easily design specific instances of structures to be simulated, to set

simulation parameters in a straightforward way, and that accommodate quick viewing of

the results that are obtained. In this light, the ultimate goal for the biomechanical muscle

model becomes not only computer animation, but to have it "take on a life of its own" and

become an autonomous tool for clinicians and physiologists interested in studying muscle

function as well as computer animators wishing to make anatomically accurate animations

Pump It Up

Introduction

12

David T. Chen

of muscled characters.

The general problem, as stated, is to model elements of the human body through

physical simulation. Modeling and animation of the human form has long been considered

a significant research area in the computer graphics field. In natural communication, our

bodies transmit information about ourselves and we take cues, both narrative and physical,

from what is seen of others. The human shape is an important and ubiquitous expressive

tool that we would like to use in computer animations. This is also a hard problem. The

human body is the antithesis of shapes that is easy to model with computer graphics. The

body does not have a rigid form that can be treated in the same way as "flying logos". The

skeletal motions of the body are subtly complex and well coordinated. Next to the skeleton

are muscles that change shape due to the complex dynamic interactions of contraction and

contact. On the surface, realistic modeling of soft, living layers of skin and the ways in

which it interfaces to the outside world is also daunting.

Komatsu [Kom86] has put forth a minimum set of conditions for a computer graphics

based human figure model,

1. The shape of the model must be smooth everywhere.

2. The three-dimensional form of the body is defined by the skeleton, which must change

flexibly at the connecting angles between bones.

3. The shape must reflect the motions of the skeleton in accord with action, and the

shape must always keep its smoothness.

4. A local change in the skeleton must affect only a small part of the shape.

5. Change of shape like the swelling of muscles must be expressed.

To meet the goals of character animation, many people have designed systems that

Pump It Up

Introduction

13

David T. Chen

greatly simplify the complete problem to make it possible to represent entire moving figures.

Typically, the geometry is modeled to achieve the effect of how the underlying anatomy

looks at the surface. The difference in this thesis is that we take a detailed look at the

anatomy by modeling the important underlying structures (ie. muscles and bone), rather

than stressing the ability to represent at the current time, a whole figure. The immediate

goal of the thesis is to accurately model individual three-dimensional muscles. This is a

"bottom up" approach, but because a physical model is created, our results can be applied both to produce realistic-looking animations of human characters and to help create

new bioengineering applications in which computer graphics display is vital. As computer

workstations become more powerful, and rendering and computation times drop, it will be

possible to extend the results from the thesis in a straightforward way. The eventual goal

then is not just character animation but to take a step towards the creation of an artificial

person that can repond convincingly as its simulated muscles are activated.

1.1

Previous Work

The approaches taken to computer modeling the shape of the human figure include,

1. geometric-rigidlimbs, like bones, in which only the static geometry is specified

2. kinematic-geometry of whole limb changes due to kinematic position of underlying

skeleton

3. elastic-modeling parts of the body as non-linear visco-elastic-plastic composite materials that change shape due to the action of forces

For the geometric case, the three methods most commonly used to represent the

geometry are polygonal meshes, volume primitives and surface patches. Fetter [Fet82] used

Pump It Up

1.1 Previous Work

14

David T. Chen

contours derived from bioster ometric data to generate the polygons in his "Fourth Man

and Woman". Human forms f -om standard volume primitives include Badler's Bubbleman

[BOT79], made from spheres. or Ginsberg and Maxwell's "cloud" figure [Max83], based

on ellipsoids. In these exampes, the shape of the limbs does not change as the character

moves.

Examples of kinematic nodels include that of Komatsu, who parameterized spline

patch control points to simul;,te a contracting biceps as the elbow is bent [Kom86]. Komatsu used four major spline patch surfaces to cover the head, chest, abdomen and legs

of a skeleton. Chadwick et.al. in [CHP89], generalized this approach by using a "layered"

technique based on free-form deformations (FFDs) to apply muscle effects onto a skeleton.

His model derives the shape

f a whole limb from the kinematic skeletal state. Abstract

muscles are parameterized as wo sets of FFDs. These FFDs are controlled by the skeleton

position to simulate the gross effects of muscle contraction at the body's surface. A simple

elastic model based on discret zed mass points joined by Hookean springs can be added on

top of this to allow for autom Ltic squash and stretch of the face or whole limbs.

Elastici models compriE e one form or another of displacement analysis of an elastic

continuum. This analysis can be characterized as static or dynamic, linear or non-linear,

isotropic or anisotropic, and s> on. The particular shape of a deformation is a function of

both the internal stresses and I trains within the elastic object and the external forces applied

to it. Examples of computer 1;raphics researchers modeling parts of the human body with

elastic analysis include Gourre t [GMTT89], who described a system for modeling the human

hand with a finite element voume meshed around bone. He formulates and solves a set of

statics equations for skin defc rmation based on bone kinematics and hand/object contact

points in a grasping task. WI ile bending and flexing of the hand flesh is nicely simulated,

'ie. visco-elastic-plastic models

Pump It Up

1.1 Previous Work

David T. Chen

15

no muscle effects or changes in the underlying shape are calculated. Pieper [Pie92], has

developed a surgical simulation system that can be used both to create animation of the

face and to simulate surgical reconstructions of the face. He performs a finite element

analysis of the skin arranged as three different layers of material.

1.2

Elastic objects

Here, single muscle masses will be modeled as visco-elastic, deformable bodies that are

subjected to non-linear forces calculated from what is known about the biomechanics of the

situation. The hope is that if these forces are simulated correctly, then the correct changes

in the muscle shape will be automatically produced and propagated to the surface. The

shape of muscle groups will be found through the constrained interaction of an ensemble of

individual muscles.

The technique used to define the dynamics of deformation for an elastic object is the

FEM. More specifically, stiffness and mass matrices derived from finite element meshes of

twenty-node brick elements will be developed to yield differential equations that control

the displacement of the mesh nodal points. The resulting second-order matrix equations

are decoupled using the modal technique so that dynamic simulations can be run relatively

rapidly on a workstation-size computer.

Because the focus of the thesis is centered around computer graphics-based applications, the geometric shape of an elastic object will be described in a standard polyhedral

format that is well suited to rendering by a graphics workstations. This emphasis leads to

the following particular problems that will need to be addressed in the course of the thesis

work. First, is to show how a FEM mesh can be used to approximate the elastic volume

defined by an input set of polyhedral geometric data. This is a discretization process. Sec-

Pump It Up

1.2 Elastic objects

David T. Chen

I6

ond is to show how the FEM mesh is used to derive the dynamic equilibrium equations

from both the shape and the material properties of the elastic volume. Third, for com2

puter graphics, is to show how the FEM mesh defines a free-form deformation that can

appropriately warp the computer graphic models as the mesh changes shape in response

to external forces. This can aid in visualizing the simulated deformations. Lastly, forces

will be developed and applied to the FEM mesh that model muscle contraction, and other

effects appropriate to computer animation such as gravity, point-to-point attachment, and

collisions between objects.

1.3

Goals and Contributions

To sum up, the goals and contributions of the thesis are

1. To make a 3D, dynamic, biomechanically valid model of muscle that can simulate

both muscle force and muscle shape.

2. Develop techniques that will allow the finite element method to be used for making computer animation of elastically deforming objects, while not compromising its

ability to approximate the dynamics of real physical structures.

3. To engineer a software testbed system that will be a useful, simple, interactive design

tool for creating new simulations and animations.

While the idea of using computer graphics techniques to produce animations of moving

human figures is not novel, the approach taken to the problem is. The development of an

accurate force based computational model to simulate muscle shape has not been attempted

in the past. The desire is to make a physically realistic model of muscle and muscle function.

2

based on twenty-node brick elements

Pump It Up

1.3 Goals and Contributions

David T. Chen

1T

Why go to all this trouble? The primary application area is making computer animation,

but, if the simulation is done with a sufficient degree of accuracy, then we also have a

tool that can be applied in other areas. Suppose a medical researcher wants to compute

the effects of a tendon transfer surgery on a muscle's ability to generate force to drive the

skeleton. He needs to have a physical model of the structures in question in order to make a

clinical analysis. The model developed in the thesis should be able to make such predictions,

while also providing a way for the clinician to visualize the results of a simulated procedure.

1.4

Thesis Organization

The rest of the thesis is organized as follows, Chapter 2 discusses muscle anatomy and the

sources of force generation within a whole muscle. Chapter 3 goes over aspects of using finite

elements to simulate elastic materials. Chapter 4 concerns the complications introduced by

considering the musculoskeletal system rather than isolated muscles. Chapter 5 discusses

the 3d software system implemented to do the thesis work. Chapter 6 develops a forcebased finite element model of muscle that simulates both muscle force and muscle shape,

and describes experiments performed using the model.

Pump It Up

1.4 Thesis Organization

18

David T. Chen

Chapter 2

Modeling a Single Muscle

This chapter contains a quick overview of skeletal muscle anatomy and dynamics [Kel7l]

[McM84] [VSL75] [CW74], presents a method from Zajac [ZTS86] [Zaj89] for computing

the amount of force generated in a muscle and discusses sources of input data that will be

used for defining the rest shapes of muscle masses. Skeletal muscle makes up from 40 to

45 percent of the total human body weight, so we expect that our emphasis on modeling

muscle will allow us to simulate shape throughout most of the body.

2.1

Basic Muscle Anatomy

Muscle connects to bone through tendons, which are bundles of connective tissue. These

connective tissues are composed largely of collagen, a fibrous protein found throughout the

body. The center part of the muscle can be called the "belly", which is surrounded by a

connective tissue sheath called the epimysium. The tendons are actually continuations of

these connective tissue sheaths that hold the muscle together. The whole muscle is held in

place within the body by extensive connective tissue layers called fascia.

Pump It Up

Modeling a Single Muscle

19

David T. Chen

Muscle Belly

Figure 2.1: A whole muscle adaptedfrom [Ke171]

The connective tissue also penetrates the muscle and divides it longitudinally into

groups of muscle fibers known as fasciculi. It is at this level of differentiation that the

muscle is supported by capillaries, veins and nerve fibers. Muscle fibers come in a wide

variety of lengths-sometimes stretching the whole length of a muscle-and are usually 10

to 100 microns in diameter. The muscle fibers are composed of still smaller elements called

myofibrils that run the whole length of the fiber. Each myofibril is about 1 to 2 microns

thick. A single muscle fiber contains on the order of hundreds to thousands of myofibrils.

It is at the level of myofibril that a discussion of the contractile mechanism for a

muscle usually begins. The myofibril is made up of sarcomeres arranged in a repeating

pattern along its length. This repeating pattern is responsible for the striations or banding

pattern often observed on skeletal muscles. The sarcomere is the actual functional unit of

contraction for the muscle. Sarcomeres are short sections-only about 1 to 2 microns longthat contract upon suitable excitation, developing tension along their longitudinal axis. The

Pump It Up

2.1 Basic Muscle Anatomy

20

David T. Chen

Figure 2.2: Section of muscle [Kel7l]

Pump It Up

2.1

Basic Muscle Anatomy

21

David T. Chen

shortening of a single muscle fiber then is due to the effect of many sarcomeres shortening

in series. A bundle of muscle fibers can be thought to be many of these force generators

arranged in parallel. Finally, the combined tension produced by bundles of muscle fibers is

transmitted to the bones through the network of connective tissue and muscle tendons.

Z membrane

Relaxed myofibril

Sarcomere

Contracted myofibril

A band

Figure 2.3: The myofibril in relaxed and contracted states [Kel7l]

2.2

Muscle Force

For a given muscle, the arrangement of muscle fibers relative to its tendon attachments

will determine the amount of shortening during contraction and thus the amount of force

generated. In general, there are two different kinds of fiber arrangements, longitudinal and

penniform. The fibers in a longitudinal muscle run parallel to each other along the entire

length of the muscle. In a penniform muscle the fibers terminate at an angle relative to the

tendon. There are several variations of penniform muscles. Unipennate muscles have their

fibers arranged obliquely to a tendon only on one side. In a bipennate configuration, the

fibers converge onto the tendon from both sides. Multipennate muscles are a combination

of both unipennate and bipennate fiber arrangements.

Pump It Up

2.2 Muscle Force

22

David T. Chen

Figure 2.4: Longitudinal muscles [Kel7l]

Unipennote

Bipennate

Figure 2.5: Peniform muscles [Kel7l]

Pump It Up

2.2 Muscle Force

23

David T. Chen

When the fibers of a longitudinal muscle shorten by an amount F,, the muscle as

a whole shortens an amount M, = F,. For a penniform muscle, the amount of muscle

shortening depends on F, and the pennation angle a. From Figure 2.6 it is clear that M, =

F, cos a. This relationship also shows that the penniform fiber arrangement approaches the

longitudinal as a approaches zero.

7A-

Ms

mimmuminiiniinuuum

MS-

Figure 2.6: Comparison of longitudinal and penniform shortening. McO, is the length after

contraction. adaptedfrom [Kel7l]

The amount of force developed by a shortening muscle depends on, among many

factors, the number of contracting muscle fibers, the size of each fiber and the internal

fiber arrangement.

The product of the number of fibers and the fiber size is itself an

important measure and is called the physiological cross section, which, for a longitudinal

muscle, can be determined by making a transverse cut through the belly of the muscle.

For a pennate muscle, the results of such a cut would depend on the length of the muscle

and a. From Figure 2.7 it can be seen that the area defined by a cut at X determines the

physiological cross section for the muscle on the left, but would not include all the fibers

Pump It Up

2.2 Muscle Force

24

David T. Chen

for the unipennate muscle on the right. To determine the cross section for the unipennate

muscle requires summing the area from cuts at A, B and C.

C

B

A

Figure 2.7: Physiological cross section adapted from [Kel7l]

In general then, a penniform fiber arrangement trades off a lesser amount of muscle

shortening for a greater number of fibers that can be involved in contraction. But pennation

angle effects the final force that a muscle can develop in yet another way. Figure 2.6 also

shows that if a muscle fiber generates a force in the direction of F, the amount of force

produced along the muscle's line of action must again be scaled by cos a.

2.2.1

Sliding Filament Theory of Contraction

The discussion above has concerned the more or less macroscopic properties of muscle

force generation. Here we will briefly touch upon the contractile mechanism within a single

sarcomere. Muscles have been differentiated into at least eight separate protein structures, of

which four play a role in contraction. The two most important of these are actin and myosin.

Pump It Up

2.2 Muscle Force

25

David T. Chen

These two contractile proteins form filaments within the sarcomere, and, when viewed in

cross section, can be seen to be packed hexagonally with six thin filaments surrounding

each thick filament. The thick myofilaments are made of myosin, the thin myofilaments are

made of actin.

Z line

H zone

I band

A band

Z line

sarcomere

thin

myofilament

thick

myofilament

Figure 2.8: Electron micrograph showing three myofibrils in a single muscle fiber [VSL75]

The idea behind the sliding filament theory of muscle contraction is that as a muscle

fiber shortens, the thin and thick myofilaments do not themselves get shorter, rather they

slide across each other. This idea was presented concurrently in the same issue of Nature

by A. F. Huxley and H. E. Huxley in 1954 [HN54] [HH54]. A. F. Huxley developed an

Pump It Up

2.2 Muscle Force

26

David T. Chen

interference microscope that allowed him to watch changes in the banding pattern of isolated

frog muscle fibers under various circumstances.

As the fiber was subjected to a purely

passive stretch or shortening, the I-bands became either longer or shorter, but the length of

the A-bands remained about the same. Under an isometric contraction with both fiber ends

fixed, the banding was essentially invariant. Under isotonic contraction, it was again the

I-bands that took up the resulting change in length. Because it was known at the time from

electron microscope studies by H. E. Huxley that the A-bands were defined by birefringent

rodlets of myosin and that the thin actin myofilaments extended through the I-bands into

the A-bands, A. F. Huxley was able to conclude that during a muscle fiber contraction, the

actin filaments were drawn into the A-bands, between the myosin rods. Furthermore, he

proposed that the known dependence of the isometric tension produced in a muscle fiber

to the fiber length is caused by the change in overlap between actin and myosin within a

sarcomere.

Z line

thin

myofilament

H zone

I band

A band

Z line

thick

myofilament

Figure 2.9: Changes in fiber banding pattern due to contraction [VSL75]

Pump It Up

2.2 Muscle Force

27

David T. Chen

2.2.2

Hill's Force Model

One of the simplest kinds of experiments that can be done to a prepared, isolated whole

muscle is to measure the force output as the muscle is stretched through a number of

constant lengths. If this is done with no stimulation, then the resulting plot of force or

tension to length is said to represent the passive elastic properties of the muscle. This

passive tension-length curve has an exponential shape in which the curve gets steeper and

steeper the more the muscle is elongated. This behavior is very similar to a rubber band

in which the material can be pulled very easily until it is all "stretched out", and then the

rubber band can feel very stiff.

If the same kind of tension-length plot is then made with the muscle fully stimulated,

then a different curve is produced that has components from both active and passive force

components. This curve, of course, should always be greater than the passive force-length

plot by itself and is called the total tension-length curve. Finally, the tension-length curve

that represents only the active muscle force is found by subtracting the passive curve from

the total curve as in Figure 2.10. The length dependence of the developed force is wholly

consistent with the sliding filament theory of muscle contraction.

Futhermore, from measurements on human subjects, A. V. Hill proposed that there

is also a velocity dependent force component that counteracts the contraction force. That

is, the force exerted by the muscle decreases as the speed of shortening increases [GH24]. It

was thought at first that this phenomenon depended on an automatic regulatory mechanism within the central nervous system, but Gasser and Hill showed through quick-release

experiments on isolated frog muscle that this damping effect was part of the "fundamental

character" of the muscle itself. Two experiments point out this result.

First, a muscle held isometrically was suddenly allowed to shorten to a new length

against no applied load. The force that was recorded fell below the amount that corre-

Pump It Up

2.2 Muscle Force

David T. Chen

28

Figure 2.10: Tension-length curves. The dotted line shows the length-tension curve of the

resting muscle. The total force recorded on tetanizing the muscle is shown by the solid line.

The extra force developed on stimulation is shown by the dashed line. The progression from

(a) to (c) results from muscles with progressively less connective tissue. [CW74]

Pump It Up

2.2 Muscle Force

29

David T. Chen

sponded to the isometric equilibrium point of the new length and only slowly developed

tension back up to that point. The apparatus to perform this experiment is shown in Figure 2.11 where the knot at K determines the final amount of shortening. Schematic versions

of the curves obtained from their quick-release experiment are shown in Figure 2.12.

ADASTABLE

JAW

K

MUSCLE

LEVER

S

Figure 2.11: Gasser and Hill quick-release apparatus [GH24]

The observation that the measured muscle force did not instantaneously reach the level

predicted by the new length indicated a damping effect within the contractile machinery.

In the second experiment, a muscle was allowed to shorten at constant velocities, and a

series of plots were made of the force required to produce that speed and the amount of

shortening that was finally experienced. The area under these tension-shortening curves

was then integrated to yield a relationship between work (force * distance) and velocity.

The work-velocity curve has a decreasing slope, which is also consistent with the idea of a

Pump It Up

2.2

Muscle Force

30

David T. Chen

ARM

7-

j-

_

_

_

Ile

o06

0

>O

TIME

-001 sEcs

8 0

CK30

Figure 2.12: Quick-release curves, plotting tension versus time [GH24]

velocity-dependent force within the muscle. These curves are illustrated in Figure 2.13.

RELATIVE SPEED OF

SHORTENING

At

A2

A3

1-47

4-5

5-1

Figure 2.13: Muscles shortening at 5 constant speeds [GH24]

Quick-release experiments also play a role in determining the so-called series elastic

element of a muscle. The series elastic component was originally proposed by Levin and

Wyman in [LW27]. They built a device that allowed them to alternately stretch and release

a muscle stimulated at a short rest length such that the passive parallel component does not

enter the picture. The tension-length curves they obtained from trials at different speeds

on the jaw muscle of a Dog-Fish is shown in Figure 2.14.

Pump It Up

2.2 Muscle Force

31

David T. Chen

A

TENS/ON

S

6

7

g 9

\DOGFISH c

M

I

C''I

I

B

/

I

234

Figure 2.14: Tension-length curves from the jaw muscle of the Dog-Fish [LW27]

The fastest release is the curve on the far left, the quickest stretch is on the far right.

If there were no series elastic component, the Dog-Fish plots would not have the exponential

shape that is observed, rather, the lines of stretch and release would be straight. Levin and

Wyman proposed the visco-elastic muscle model II on the right in Figure 2.15 to explain

their findings. Their model is an extension of Hill's original visco-elastic model (I in the

same figure) that included only the damping effects deduced from his measurements of the

relationship between force and velocity.

Wilkie in [Wil56] made very direct measurements of the series elastic component

with a quick-release type experiment. A schematic of his device is shown in Figure 2.16.

The muscle is stimulated and develops force isometrically, stretching out its series elastic

component. On release by the electromagnet at (e), the muscle is subjected to an isotonic

load defined by the weight at (c). The stop at (d) insures that the load is applied only after

release. The damping system at (f) removes mechanical vibrations in the lever system that

would otherwise upset the muscle length measurements.

Wilkie found that immediately after the release, the previously stretched series elastic

Pump It Up

2.2 Muscle Force

32

David T. Chen

Figure 2.15: Visco-elastic muscle models [LW27]

e

Figure 2.16: Wilkie's quick-release machinery [Wil56]

Pump It Up

2.2 Muscle Force

33

David T. Chen

element shortens very rapidly to a length consistent with the isotonic load that is used. Then

the contractile component shortens with a much lower velocity corresponding to the load.

These two phases of shortening are shown in Figure 2.17. The initial perpendicular drop

of length provides direct evidence for an elastic component in series with the contractile

machinery of the muscle.

2mm

SO/Sec

g wt.

Figure 2.17: Shortening due to quick-release for various isotonic loads [Wil56]

A simple mechanical model of muscle that takes into account the effects described

above is shown in Figure 2.18. This model is commonly attributed to A. V. Hill. The

active state force To is found, as discussed above, by subtracting the total force measured

at different lengths for a stimulated muscle from that found to be due to passive effects

alone. The notation To(x1, t) indicates that this force is a function of the muscle length

and time-varying activation. The passive parallel stiffness KPE has contributions due to

the penetration of connective tissue through the muscle body resulting in the fasciculus

Pump It Up

2.2 Muscle Force

34

David T. Chen

divisions and also interfiber elasticity. The parallel damping component B is most likely

due to the rate of the biochemical reactions that are responsible for contraction at the

myofilament level. The series stiffness KSE is primarily from the effect of tendon at the

muscle attachment points, but is also probably partially due to the details of myofilament

attachment within a sarcomere. The series element is very important in its ability to buffer

the rapid change from inactive to active state and also provides a mechanical energy storage

mechanism for the body in motion.

Controctile component

T

T

KSE

KPE

Sx,

-

-

x2

x

Figure 2.18: Hill's muscle model [McM84]

The Hill model while very simple, has proven enormously useful in practice in making

calculations of the force generation of muscles working against different kinds of loads.

2.2.3

Zajac's Force Model

Zajac [ZTS86] [Zaj89] has developed a "dimensionless" lumped model of a complete musculotendon actuator that can be easily scaled to model particular whole muscles. Zajac's

model is a refinement of the Hill model, and the normalized force curves that are presented

directly reflect the non-linearities that result from the action of sliding filaments. The curves

Pump It Up

2.2 Muscle Force

35

David T. Chen

for the active and passive muscle force components are taken from measurements of single

muscle fibers to ensure that tendon effects are not superimposed. Furthermore, pennation

effects are directly included, while the series elastic element not associated with tendon is

removed.

The isometric force generated in a particular actuator depends on one set of parameters that is considered constant over all actuators and another set that is musculotendon

specific. The four specific parameters are,

pennation angle

a

FO maximum isometric force of active muscle

lM

optimal muscle length at which FO is developed

lT

tendon rest length

Tendon

Tendon

LT

lu

Figure 2.19: Musculotendon architecture [ZTS86]

The active muscle is represented in Figure 2.19 by the contractile element CE. Force

Pump It Up

2.2 Muscle Force

36

David T. Chen

developed by passive muscle is from kPE and is summed with the force from CE. The effect

of the series elastic element kSE is lumped with the tendon model kT. The dimensional

units of interest are force and length. F0 and i" are the normalizing factors for these units.

A tilde above a symbol denotes that it is a normalized quantity, for example,

normalized muscle fiber length

m

Other quantities and relationships used are,

iMT

musculotendon length

IT

tendon length

IMT

_IT

+ lM cos a

Zajac gives the non-specific, dimensionless functions to model a musculotendon actuator in Figure 2.20 and Figure 2.21.

FORCE kw

1.1

___

1.0 - -

active force f4(jM)

passiwv force )FPE(iAU)

-.

-

-

-

-

-

-

0.E

LENGTH jTm

Figure 2.20: Active and passive muscle models. Normalized active muscle force FCE(1M)

and passive force PPE(M) vs. normalized muscle fiber length IM. [ZTS86]

Pump It Up

2.2 Muscle Force

37

David T. Chen

FORCE

?'

Slop. = 3,S APs

1.0

Lia

0.5 - -

- -

-

flegi..

-

To. Region

0.0

q

0.04

0.03

0.00

STRAIN .r

Figure 2.21: Tendon model. Normalized tendon force FT(JT) vs. tendon strain eT. [ZTS86]

The isometric muscle force functions can be written,

Fio(IM t)

-

PM(iM, t, a)

PCE( M

=

t) + PPE(TM)) cos a

(T(,

where a(t) is the time-varying normalized muscle activation function.

For tendon, the

normalized force is PT(eT) where eT is the tendon strain defined by,

iT _

l-Tlcos

)-

_

(lMTfMo

IT

~~

To use Zajac's muscle model, the functions FfE(M),

Cs

i

11.

a)-1T

FPE(M) and PT(ET) and their

derivatives need to be approximated. The active muscle function FCE(iM) is implemented

as an interpolating cubic spline through twelve control points from Delp [De190].

derivative function

dpCE

-/-

The

is simply the derivative of the interpolating spline. The passive

parallel force FPE(lM) is estimated with the quadratic function,

PPE(M) = 4 (M

dFPE

dl M

Pump It Up

1)2

if TM > 1 else 0

if M> 1 else 0

2.2 Muscle Force

38

David T. Chen

Plots of these two approximating functions are presented in Figure 2.22 for comparison

with Zajac's curves. The tendon model F(eT), is implemented as an order 50 Chebyshev

Figure 2.22: Solid line is spline approximated active force function. Dashed line is quadratically approximated passive component.

polynomial.

Evaluating and finding the derivatives of such polynomial functions is very

straightforward [PFTV88].

The shape of the Chebyshev approximated tendon force is

plotted in Figure 2.23.

To characterize the dynamic properties of a musculotendon actuator, it is also necessary to consider the velocity dependent nature of the muscle forces. These damping forces

are represented by the dashpot element B in Hill's model of the previous section. Zajac

depicts the velocity-force relationship as in Figure 2.24 with the dimensionless form of the

velocity ~CE. This muscle velocity is normalized with respect to the fiber rest length laM

and the maximum normalized velocity iBCE, which is a fifth parameter specific to modeling

the dynamics of a particular muscle.

For our purposes, it is necessary to find force as a function of velocity, rather than

Pump It Up

2.2 Muscle Force

39

David T. Chen

Figure 2.23: Chebyshev approximated tendon model.

vELOwrY - ;,"

FORCE

?CfEI|

Figure 2.24: Velocity-force function of active muscle. Dimensionless velocity obCE vs amount

of normalized force relative to isometric force. [ZTS86]

Pump It Up

2.2

Muscle Force

40

David T. Chen

the velocity as a function of force, as in [AD85]. Thus, Zajac's curve is turned on its side

and approximated with,

f(jCE)

_

1.65 arctan(3.1 * (~,bE + .32774)) - arctan(3.1 * .32774) + 1

which is plotted in Figure 2.25. Negative velocity is for muscle contraction, while lengthening muscle will have positive velocity. The constants are set so that the normalized force will

be 1 when the velocity is 0, the force will be 0 when the velocity is -1, and the asymptotes

are as in Figure 2.24.

Figure 2.25: Force-velocity function approximated with arctan.

Finally, in the dynamic case, the total active force from the contractile element is

seen to be a function of the activation a(t), the force function

FCE(IM),and the normalized

muscle velocity ~,CE

pCE

Pump It Up

_ f3CE

(M

_

~CE)a(t)

CE

(M

2.2 Muscle Force

41

David T. Chen

and the force in the whole muscle is

PM

= ( PCE + pPE([M)) cosa

As an example application of Zajac's model, lets calculate the maximum force that

can be generated by an isometric musculotendon actuator in steady state. First, observe

for this case that the force in the tendon should equal the force in the muscle and that

velocity effects will not come into play, so

#T(e)

and writing the tendon strain in terms of

FT

(

-MT

-

PM(l M ) = 0

IM,

(M)= G(IM )

-

Mls)

Thus, to find the isometric muscle force, it is necessary only to find the zeros of G(M).

This is easily done using a one-dimensional root finder like Newton-Raphson [PFTV88] as

long as G(IM) and the derivative G'(IM) can be evaluated for arbitrary normalized muscle

lengths

IM. Writing for G'(I),

,

= dT deT

dET diM

d(io+

diM

dFPE

cs

diM

And finally in terms of the dimensionless, consistent functions as implemented in

Figure 2.22 and Figure 2.23

G(I M )

G'(IM)

FT

=

dFt)2S

(\

+

-o

-f

(a(t)PCE(M

-

dim±

+

d-P

dim)

± PPE(M) Cosa

o

To illustrate the effect of the tendon slack length on the behavior of Zajac's model,

the zeros of G(IM) were calculated as above for varying values of IT. Plots are presented

Pump It Up

2.2 Muscle Force

42

David T. Chen

of normalized muscle force versus length for these different values of tendon rest length

in Figure 2.26. The good correspondence between the curves of this figure and the ones

presented in [ZTS86) (see Figure 2.27), we use as validation for our implementation.

Figure 2.26: Isometric normalized muscle force vs. IMT - lI.

line is 1T = 8, and dotted line is l' = 16.

2.3

Solid line is IT = 1 dashed

Muscle Shape

This thesis will test the hypothesis that to make a good simulation of the changes in

shape that a contracting muscle experiences, it is sufficient to characterize both the resting

material and the changes in force known to be important to the contractile process. The

primary benefit of this approach is that if the forces are calculated properly, then not only

will it be possible to visualize a muscle in action, but that a valid biomechanical model

will also be developed that can be used in further experimentation. For the purposes of

visualization, however, it is important to obtain accurate geometric representations of the

Pump It Up

2.3 Muscle Shape

43

David T. Chen

FORCE Vr

1.5r-

LENGTH tur-

t7

Figure 2.27: Isometric normalized muscle force vs. IMT

-

IT. [ZTS86]

rest shapes of muscle masses upon which the dynamic simulation techniques developed in

the next chapter will be run. The emphasis of the thesis is on dynamics and not geometric

modeling, so this section will serve only to point to sources from which input data has been

obtained.

Because the interest here is primarily in computer graphics based applications, the

goal in this section is to construct polygonal models that can be easily treated with standard rendering and animation routines. It will be shown in Section 3.2 how a free-form

deformation based on twenty-node isoparametric cubes can be developed to govern both

the dynamics formulation and the visualization process by defining a space that controls

how the points of these polygonal models can be warped as the simulation demands that

objects change shape. It will also be shown in Section 5.6 how these polygonal models will

be used to define the initial geometries for finite element meshes made from isoparametric

cubes.

Geometric models that have served the purposes of the dynamic simulation programs

Pump It Up

2.3 Muscle Shape

44

David T. Chen

have been prepared from a variety of sources. The first experiments were made with range

data of human heads from a Cyberware TM 3D digitizing system. Muscle rest shapes were

constructed from both the Swivel 3DTM Professional [MhLH90] modeling program on the

Macintosh and from contour stacks derived from magnetic resonance imaging (MRI) systems.

2.3.1

Range Camera Data

Range data such as that from the Cyberware camera is very simple to transform into a

polyhedral representation. Two output files are produced by the scanning system. The

first is an 8-bit range picture that represents a cylindrical arrangement of points from the

source object, the second is a 24-bit image picture that can be used to texture-map color

information back onto the scanned geometry. Two such data files from a human head' are

shown in Figure 2.28 and Figure 2.29.

The Cartesian x, y location for each pixel in the range picture encodes the cylindrical

0 and z coordinates for each sampled point, while the grayscale pixel value at each location

is the radius r for that 0 and z. The image picture is the RGB color value at each of these

digitized points. The cylindrical samples are simply transformed into 3' by

x = r cos9;

y = r sin 0;

z=z

To convert range data into polyhedral form, the total number of points and polygons

is printed, a point list is made from the range picture, and then connectivity information for

each (quadrilateral) polygon is written out. This we call an OSU file after the polyhedral

data standard created at Ohio State University. Finally, a subsidiary vertex color file is

made from the 24-bit image picture. This is illustrated by a simple C language program,

'Thanks to David Sturman for the use of his head

Pump It Up

2.3 Muscle Shape

David T. Chen

45

Figure 2.28: Range camera picture from Cyberware TM 3D system

Figure 2.29: Point color picture

Pump

Pump It

It Up

Up

2.3 Muscle Shape

2.3 Muscle Shape

46

David T. Chen

range2osu, that makes an OSU file from range data.

#include <stdio.h>

#include <math.h>

#define PI (3.14159265359)

typedef unsigned char byte;

typedef byte PIXEL[3];

range2osu( range, color, width, height, gamma, osufp, vclfp

)

10

byte *range;

PIXEL * color;

int width, height;

double gamma;

FILE *osufp, *vclfp;

{

int no-pts, no-polys;

no-pts = height * width; no-polys = (height-1)

*

width;

20

fprintf(osufp, "Xd %d\n", no-pts, no-polys);

range2pts( range, width, height, osufp );

range2quads( range, width, height, osufp );

range2vcl( color, width, height, gamma, vclfp

fflush(osufp); fflush(vclfp);

);

}

To generate the point list, range2pts first finds 6, z and r corresponding to pixel i, j.

The space is arranged so that 6 begins at 90* and increments positively in a full circle, r

is in the range [0,1] and z is [-1,1] where +z is up. The result is then transformed into R'

and printed.

range2pts( range, width, height, osufp

)

byte *range;

int width, height;

FILE *osufp;

{

int

i,

j;

double x, y, z, r, theta, thetainc;

thetainc = 2 * PI / (double)width;

for (i=0; i<height; i++)

{ z = (-2. / (double)(height - 1) * i) + 1.;

10

/* Find z from current row indx */

for (j=O, theta = PI/2.; j<width; j++, theta += thetainc)

Up

Pu mp ItIt Up

Pump

2.3 Muscle Shape

2.3 Muscle Shape

4T

David T. Chen

{ r = ((double)(range[i*width + j])) / 255.;

/* Find r from grayscale*/

x = r * cos(theta);

y = r * sin(theta);

fprintf(osufp, "%g Xg %g\n",(float)x, (float)y, (float)z);

}

}

}

20

Polygons for the OSU file are tessellated into quadrilaterals by range2quads. The

polygons are arranged along rows of points where the last polygon in each row is made to

wrap around and join with the points from the first polygon in that row. This prevents any

shading seams from the renderer.

range2quads( width, height, osufp

)

int width, height;

FILE *osufp;

{

int i, j, k;

for (i=O; i<height-1; i++)

{ k = i*width;

for (j=O; j<width-1; j++)

{ k++; fprintf(osufp, "4 %d %d %d %d\n",k, k+1, k+width+1, k+width);

}

k++;

10

fprintf(osufp, "4 %d %d %d %d\n",k, i*width+1, (i+1)*width + 1, k+width);

}

The vertex color file is made from the 24-bit image picture associated with the range

picture. Gamma control is given to set the contrast of the output vertex colors.

range2vcl( color, width, height, gamma, vclfp

)

PIXEL *color;

int width, height;

double gamma;

FILE *vclfp;

{

int i, j;

double r, g, b;

10

for (i=O; i<height; i++)

{ for (j=O; j<width; j++)

{ r = ((double)(color[i*width + j][0])) / 255.;

g = ((double)(color[i*width + j][1])) / 255.;

b = ((double)(color[i*width + j][2])) / 255.;

It Up

Pu mp It

Up

Pump

2.3 Muscle Shape

2.3 Muscle Shape

48

David T. Chen

gamma = 1./gamma;

r = pow(r, gamma); g = pow(g, gamma); b = pow(b, gamma);

r = clamp(r, 0., 1.); g = clamp(g, 0., 1.); b = clamp(b, 0., 1.);

20

fprintf(vclfp, "Xg Xg %g\n",(float)r, (float)g, (float)b);

}

}

Typically, the data sets acquired from the Cyberware process are quite large, making

full resolution models unwieldy. For example, a 512x256 size range picture will generate

an OSU file with over 130,000 polygons.

To make lower resolution, more conveniently

sized geometric models, a downsampling operation is first performed to the range and color

images, then OSU files are made using the range2osu program on the resulting smaller

pictures. Downsampling in the image-space is much simpler than trying to do the equivalent

filtering in world-space in order to make models with fewer polygons. It should be noted

that with appropriate filtering, very nice lo-res geometric models can be achieved. In fact,

for this kind of data many 2D paint and filtering operations have been found to be very

effective [Wil90]. The Adobe PhotoshopTM paint program on the Macintosh has proven

invaluable in performing the operations mentioned above, as well as allowing interactive

repair of noisy range data.

2.3.2

Manual Shape Input

Not surprisingly, often the easiest way to make a computer graphics object is to use an

interactive program such as Swivel 3 DTM Professional that can create 3D geometries through

extrusion, lathing, and skinning operations 2 . The first muscle object that was created in

the course of the thesis work was a human biceps from an anatomically accurate plastic

model. Points were digitized from the plastic model for both TOP and SIDE views. The

biceps was then "lathed" using a circular cross section. The resulting computer graphics

2

Thanks to Steve Drucker for writing the program to convert Swivel output files into OSU format

Pump It Up

2.3 Muscle Shape

49

David T. Chen

Figure 2.30: Reconstructed "Sturman" heads with 1984, 32512 and 8064 polygons

model is shown in Figure 2.31.

Since much of the experimental work involving muscle biomechanics is done using

frog muscles, the gastrocnemius muscle from a prepared frog was digitized for use in the

computer simulated biomechanical experiments discussed in Section 6.1. Some time was

spent observing Dr. Simon Gitzer at MIT in the "frog lab" making force-length measurements from the gastrocnemins of an actual animal. After these were done, the muscle was

fully dissected and measured for input into Swivel. The procedure used was much like that

for the plastic biceps, and a lathed object was created. This is shown in Figure 2.32.

Pump It Up

2.3 Muscle Shape

50

David T. Chen

Figure 2.31: Human biceps, 342 polygons

2.3.3

Contour Data

Imaging from CAT and MRI scanning systems is a relatively new but very important source

of clinical data. These systems acquire three-dimensional objects as a series of 2D slices

arranged along an axis in space. The "skinning" facility in Swivel can be used to operate

on data sets of this kind, where anatomical forms are defined by varying the shape of

the cross section along the length of the body. More sophisticated techniques such as the

marching cubes algorithm [LC87] can automatically create polygonal models of constant

density surfaces from 3D data arrays of this type.

One of the practical drawbacks of CAT and MRI systems is that they are very expensive and so access to them is limited. For this reason, an effort was made by Dr. Gitzer to

reconstruct a set of frog musculature by, in essence, making the stack of contour informa-

Pump It Up

2.3 Muscle Shape

David T. Chen

51

Figure 2.32: Frog gastrocnemius, 576 polygons

tion by hand. A frog leg was embedded in epoxy and sliced into two-dimensional sections.

Slides were made of these sections and enlargements made for digitization as a precursor to

making a 3D model. The slides were scanned into the computer and the individual muscles

differentiated by flood-filling their regions with different grayscale values. Figure 2.33 shows

one such slice.

The idea behind trying to digitize the frog musculature as described is to obtain data

for a whole musculoskeletal system, with the muscles and bones in their correct relative

in vivo positions.

Many interesting problems are introduced by considering the whole

system. Forces must be calculated for modeling contact between bone, muscles and skin.

A simulated skeleton can be driven by muscle forces calculated at the tendon attachment

points. Higher-level coordination and reflexes can be modeled. Chapter 4 will touch upon

some of these topics.

Purnp It Up

2.3 Muscle Shape

az

David T. Chen

Figure 2.33: Hand-derived slice through frog leg

The effort with the frog leg was subsequently put on hold when a polygonal data

set from an entire human left calf became available through Dr. Alan Garfinkel at UCLA.

The source for the calf model was a long sequence of MRI scans, that were carefully hand

segmented into the individual, anatomical muscle masses and then "skinned" into triangles.

Ten muscles, including the medial-gastrocnemius, the lateral-gastrocnemius, and the soleus,

and one muscle group make up the data. The tibia and fibula bones are also included.

Figure 2.34, from Dr. Garfinkel shows how the MRI scans were anatomically carved up.

The image is shown with its colormap inverted for clarity.

Because the leg data was received as files of triangle meshes, no further processing had

to be done to ready them for simulation or display. Figure 2.35 shows three different views

of the reconstructed leg. The entire data set is shown in the middle view. In the left view,

the overlying gastrocnemius muscles and the soleus are removed to show the underlying

Pump It Up

2.3 Muscle Shape

1s

David T. Chen

Figure 2.34: MRI slice through human calf

2.3 Muscle Shape

Up

Pump ItIt Up

Pump

2.3 Muscle Shape

David T. Chen

54

structures, and the tibia and fibula are shown on the right.

Figure 2.35: Reconstructed legs

The experiments done in Section 6.1.4 using this data will be centered around the

medial-gastrocnemius. This muscle was chosen both because of its large size, and because

it is on the outside, closest to the skin. Thus it should play a large part in determining the

shape of the whole leg. Figure 2.36 shows three views of the medial-gastrocnemius.

2.4

Simulating a Muscle

This section has discussed two different aspects of muscle that are essential to making a

simulation -the

first topic was muscle models, the second concerned the acquisition of

muscle data. We have shown how the Hill model was developed and discussed how Zajac's

model is a refinement. We have also described an implementation of the Zajac model. Our

Pump It Up

2.4 Simulating a Muscle

55

David T. Chen

Figure 2.36: Medial-gastrocnemius

data sources are Cyberware scans, hand-made slices, MRI slices and direct geometric output

from Swivel. All these are turned into a standard polyhedral representation for display.

To simulate the action of muscle for a computer graphics application, the model and

data must be synthesized, and for this the finite element method is used (see Figure 2.37).

The FEM will be the vehicle for our muscle model. The polyhedral data is used to define

meshes of finite elements. Dynamic equilibrium equations are derived from the mesh. Zajac's model is used to apply forces to the mesh node points. The FEM model will then

be dynamically simulated forwards and the mesh will automatically deform in response. A

free-form deformation defined by the mesh will help us visualize the resulting changes in

shape due to the contraction.

There are many things known about muscle that a computationally based muscle

should be able to predict. For the model to be interesting biomechanically, we should be

Pump It Up

2.4 Simulating a Muscle

56

David T. Chen

Muscle Model

Figure 2.37: Muscle model and muscle data after [Zaj89] and [LC87]

able to the calculate the timevarying course of the force that a muscle generates at different

lengths, and with different tendon rest lengths. The model should also be able to predict the

effect of velocity dependent forces. Thus, as a way of validating the final implementation,

an effort will be made to reproduce some of the experiments on whole muscle that lead to

the development of Hill's biomechanical model.

Besides generating force to move the bones, a 3D model of muscle should conserve

volume as its shape changes.

Because of the enclosing tendon sheath, muscle preserves

its volume as it elongates and contracts. In fact, one of the earliest recorded experiments

performed on a single prepared muscle demonstrated this effect [McM84]. Jan Swammerdam

performed the experiment illustrated in Figure 2.38 on a muscle removed from a frog in the

early 1600's. Later, the constant volume finding was extended to human muscles by Glisson

who had subjects place their arms in a water filled tube sealed at the elbow.

Pump It Up

2.4 Simulating a Muscle

David T. Chen

57