More power reliably into the grid

thanks to adapted electrical systems

at Niederaussem

Electrical Solutions Reference

Instrumentation, Controls & Electrical

SPPA-E3000 Power Upgrade Package

optimally aids to adapt the electrical

components and systems during the turbine

upgrade at the Niederaussem power plant.

The Plant

The first unit of a new lignite-fired base-load

power plant went into operation in 1963 at the

RWE Power AG site in Niederaussem. The plant

has undergone continual expansion ever since.

It currently comprises nine units and with a total

net capacity of 3680 MW it is one of the largest

lignite-fired power plants in Europe.

The Result

■ Reliable transmission of the

increased power into the

grid

■ High planning and

scheduling reliability thanks

to trouble-free project

execution with Siemens as

the central partner

protection made the medium-voltage system

to be able to cope with the extended lifetime.

The entire MV protection system was replaced

and integrated in the new I&C via IEC 61850.

This direct integration of the electrical

components into SPPA-T3000 produces a

uniform and innovative operation and

monitoring system with increased diagnostic

and analysis capabilities.

With Siemens as a central partner for all the

issues relating to modernization of the electrical

systems, it was possible to complete the on-site

changeout, including dismantling, installation

and commissioning, in only 10 weeks.

The Task

The "MOD 600" retrofit program for lifetime

extension and for more profitable operation of

the two 600-MW units G and H at the

Niederaussem power plant also included the

uprating of the turbine. To cope with this

increased power output, the electrical systems

in the plant had to be adapted.

Our Solution

An I&C modernization based on SPPA-T3000

and an uprating of the LP turbine were required

in order to achieve the objectives of the retrofit

program. As far as the necessary modernization

of electrical systems was concerned, Siemens

had the competitive edge over the competitors

in all the sub-packages of the contract.

Price, competence and a comprehensive and

economically sound solution won us the tender.

The turnkey SPPA-E3000 Power Upgrade

Package, which is customized for use with each

individual plant, included an upgrade of the

generator bus ducting to enable the increased

generator current to be reliably transferred to the

grid. The LV switchgear was also replaced while

using the existing power and control cables.

Modernization of the unit auxiliary supply

“We are totally satisfied both

with the result and with the

execution of the electrical

project. The close cooperation

between our personnel and the

on-site Siemens project team

made it possible to adhere to

the tight time schedule and the

equally tight budget.”

Tilman Bechthold

Power Plant Manager at Niederaussem

RWE Power AG

Answers for energy.

Retrofit of generator bus ducting

A core component of the overall project

was the uprating of the turbine.

The generator had the necessary reserves,

but the bus ducting had come up against

its performance limits. This was confirmed

by thermographic testing of the generator

bus ducting.

For this reason RWE opted for complete

servicing and modernization of the

generator bus ducting. Silver-plated

flexible connectors were installed in the

generator connection to reduce losses.

Because the existing current transformers

were no longer able to accurately convert

the increased current subsequent to the

uprating, they were replaced with transformers with a higher primary current. The

voltage transformers were also replaced,

as these were close to the end of their

service life.

New insulators and seals were fitted

throughout, in addition to a number of

other internal components.

Connection of generator bus ducting

Replacement of low-voltage switchgear

The low-voltage switchgear no longer

satisfied current standards and was also

replaced as part of the project.

The new switchgear with a total of 150

panels and over 1000 load feeders had

to be reinstalled in the same place.

Extensive preparatory measures, both at

the Siemens factory and on site, were

necessary in order to reliably complete

the work within the scheduled changeout

time. The new switchgear was assembled

at the factory in a full-scale simulation

and tested prior to acceptance by the

customer. This included wiring of the

cross-panel inter-locks, connection of the

automatic transfer gear and assembly of

the I&C equipment.

All the interlocks and automatic transfer

gear and the interaction with the I&C were

tested bit for bit in this configuration.

The switchgear panels were then

delivered directly to Niederaussem for

installation and connection. This ensured

that commissioning could be carried out in

the shortest possible time.

SIVACON encapsulated low-voltage

switchgear

Retrofit for medium-voltage switchgear

and integration in the process I&C based

on IEC 61850

The upcoming inspection and overhaul of

the switchgear panels and circuit breakers

in the medium-voltage switchgear was

performed in the course of the project.

However, the replacement of the

protection system was the main focus of

the medium-voltage retrofit. Protection

devices from the Siemens SIPROTEC family

were used. These devices are equipped

with IEC 61850 interfaces and could

therefore be integrated directly in

SPPA-T3000 without the need for any

further modification.

Further information from the unit auxiliary

supply systems, e. g. the low-voltage

switchgear, the automatic transfer gear

and many other components, was

acquired using system components from

the SICAM 1703 range and transferred to

the I&C by means of an Ethernet link and

IEC 61850.

The direct integration of the electrical

components in the process I&C permits

extensive analysis in the event of a fault.

When SIPROTEC devices are used, this is

further enhanced by a time resolution of

1 ms and, more importantly, by a high

time accuracy of < 1 ms between the

individual field devices.

Published by and copyright © 2012:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

E304_FR_PUP_Niederaussem_e_V2-0

Order no. E50001-G230-A284-X-4A00

For more information contact

sppa-e3000.energy@siemens.com

www.siemens.com/energy/sppa-e3000

Siemens AG

Fossil Power Generation

Instrumentation, Controls & Electrical

Siemensallee 84

76187 Karlsruhe, Germany

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

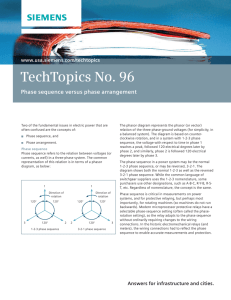

Extract from an overview diagram from

SPPA-T3000

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.