Turbine Life Extension

For SGT-200 Industrial Gas Turbines

Answers for Energy

Component life cycle management is of primary importance when dealing with

maintenance activities, particularly with rotating equipment where failures could

lead to extensive collateral damage, loss of operation, extended downtime and

loss of revenue.

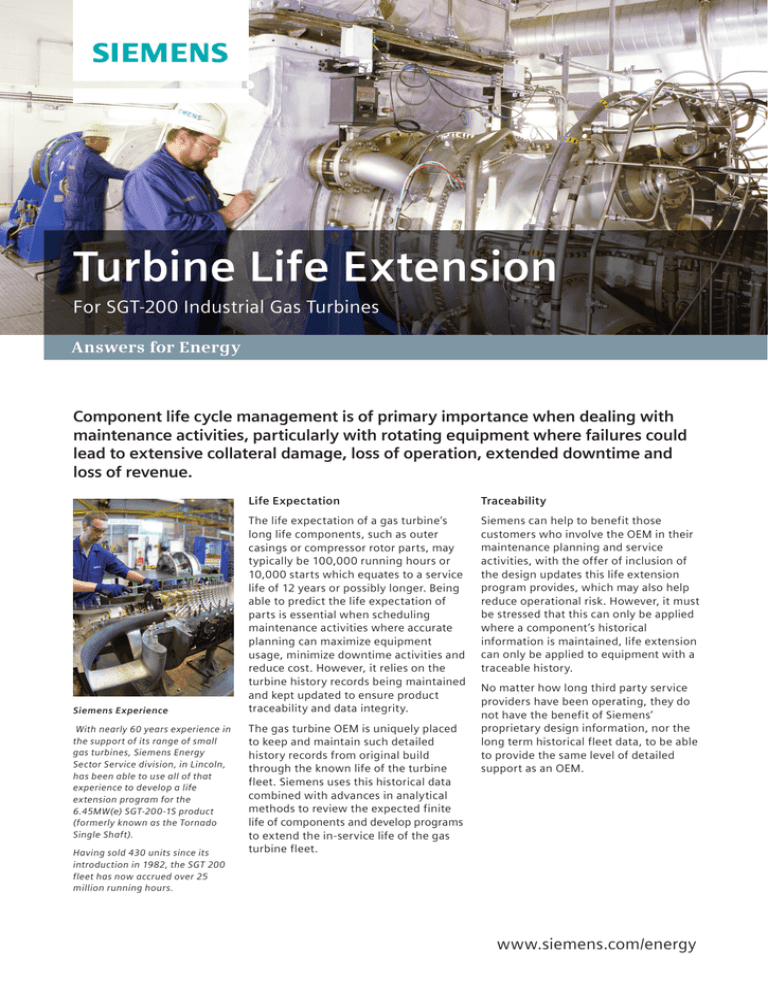

Siemens Experience

With nearly 60 years experience in

the support of its range of small

gas turbines, Siemens Energy

Sector Service division, in Lincoln,

has been able to use all of that

experience to develop a life

extension program for the

6.45MW(e) SGT-200-1S product

(formerly known as the Tornado

Single Shaft).

Having sold 430 units since its

introduction in 1982, the SGT 200

fleet has now accrued over 25

million running hours.

Life Expectation

Traceability

The life expectation of a gas turbine’s

long life components, such as outer

casings or compressor rotor parts, may

typically be 100,000 running hours or

10,000 starts which equates to a service

life of 12 years or possibly longer. Being

able to predict the life expectation of

parts is essential when scheduling

maintenance activities where accurate

planning can maximize equipment

usage, minimize downtime activities and

reduce cost. However, it relies on the

turbine history records being maintained

and kept updated to ensure product

traceability and data integrity.

Siemens can help to benefit those

customers who involve the OEM in their

maintenance planning and service

activities, with the offer of inclusion of

the design updates this life extension

program provides, which may also help

reduce operational risk. However, it must

be stressed that this can only be applied

where a component’s historical

information is maintained, life extension

can only be applied to equipment with a

traceable history.

The gas turbine OEM is uniquely placed

to keep and maintain such detailed

history records from original build

through the known life of the turbine

fleet. Siemens uses this historical data

combined with advances in analytical

methods to review the expected finite

life of components and develop programs

to extend the in-service life of the gas

turbine fleet.

No matter how long third party service

providers have been operating, they do

not have the benefit of Siemens’

proprietary design information, nor the

long term historical fleet data, to be able

to provide the same level of detailed

support as an OEM.

www.siemens.com/energy

Specific Analysis of the operation and

maintenance history by:

Obsolescence

Cost

Reduction

Health &

Safety

Review of the O&M records and the

turbine duty cycle

Selective component sampling

Benefit by

Mods & Ups

Reliability

Fuel analysis & air quality sampling etc.

Environment

IGVs and actuator system

Burners

Alternatively Siemens can offer the

following solution where there is a lack

of traceable history.

Solution

To be able to offer life extension, the

unit will need to be assessed to ensure

its integrity; this may typically cover the

following scope of supply:

Combustor assemblies

Casings

Drive train & couplings

This will establish the current life

capability and what scope of work,

including the latest modifications and

upgrades, will be recommended to attain

the customer’s required turbine life

extension.

Potential Benefits may include:

An opportunity to upgrade previous

technology to the latest standard

and/or materials

Maintain or improve power and/or

efficiency

Reduced operational risk by Trend

Analysis / Condition Health

Monitoring

Reduced downtime

Environmental legislation compliance

Reduced Life Cycle Cost

Controls upgrade to the

Siemens S7-300TM micro

controller.

HEPA intake air filtration

upgrade – improved

filtration to reduce blade

fouling and power loss.

Turbine rotor and stator blading

Continued investment by Siemens into

the advanced analysis of component life

has demonstrated that many of the long

life components can achieve up to

150,000 hours. This can be done without

compromising safety allowing a further

operational cycle before replacement.

However, it is subject to the condition

that the parts have been maintained

correctly over their operational life and

that accumulated operating hours have

been recorded accurately.

Associated Modifications &

Upgrades:

Fuel System update to

incorporate STAR

Integrated fuel valve for

smoother running.

Detailed Check:

Air Intake Filtration and ductwork

Performance

Recommendations

DLE upgrade for low NOx

emissions to meet current

and future legislation

Update by exchange units

for reduced downtime and

inclusion of latest

developments

Product Improvement and

Product Safety Bulletin

inclusion

Remote Monitoring

System to utilize the

technical capability of our

24hr Help desk and, with

the appropriate support

contract, monthly trend

analysis/condition

monitoring reports

Long Term Service

Agreement to provide the

benefits of a fully inclusive

support contract

For a customer concerned

with the safe operation of

his plant, the best way to

ensure that decisions are

based on Siemens’

proprietary information is

by agreeing and planning

the maintenance

program with the OEM.

Published by and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

www.siemens.com/energy

Energy Service Division

LCN 2013 - F33.23 LN

Printed on elementary chlorine-free

bleached paper.

All rights reserved. Trademarks mentioned in

this document are the property of Siemens AG,

its affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.