Answers for Energy

Long Term Programs (LTP)

For Industrial Gas Turbines up to 15 MW

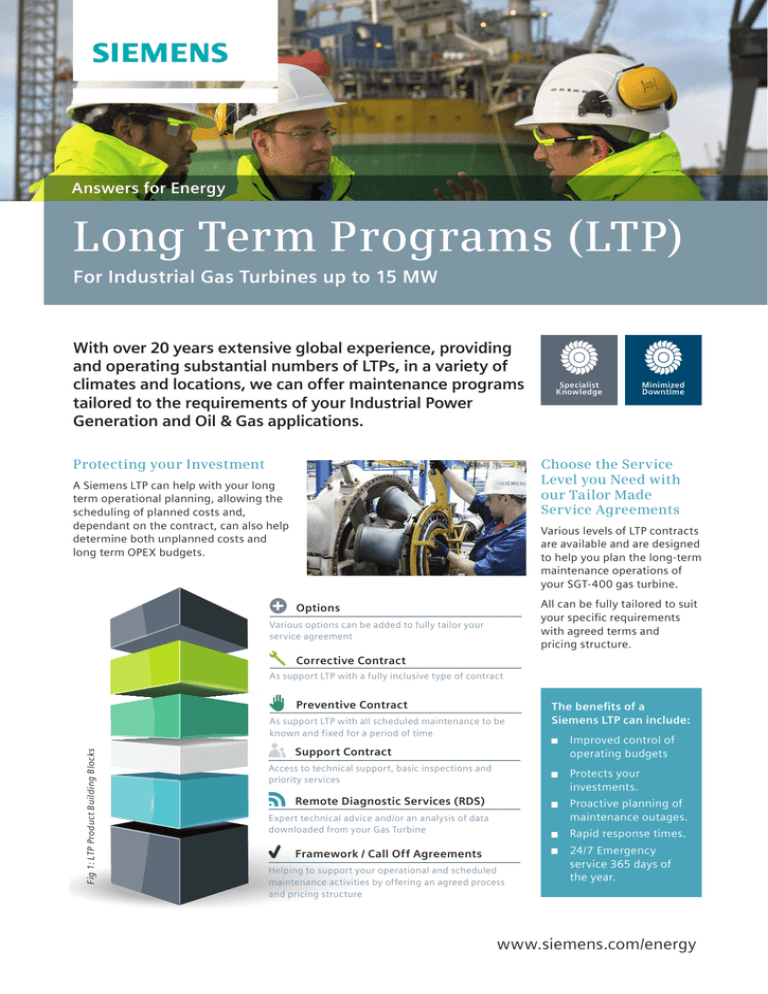

With over 20 years extensive global experience, providing

and operating substantial numbers of LTPs, in a variety of

climates and locations, we can offer maintenance programs

tailored to the requirements of your Industrial Power

Generation and Oil & Gas applications.

Protecting your Investment

Specialist

Knowledge

Minimized

Downtime

Choose the Service

Level you Need with

our Tailor Made

Service Agreements

A Siemens LTP can help with your long

term operational planning, allowing the

scheduling of planned costs and,

dependant on the contract, can also help

determine both unplanned costs and

long term OPEX budgets.

Various levels of LTP contracts

are available and are designed

to help you plan the long-term

maintenance operations of

your SGT-400 gas turbine.

All can be fully tailored to suit

your specific requirements

with agreed terms and pricing structure.

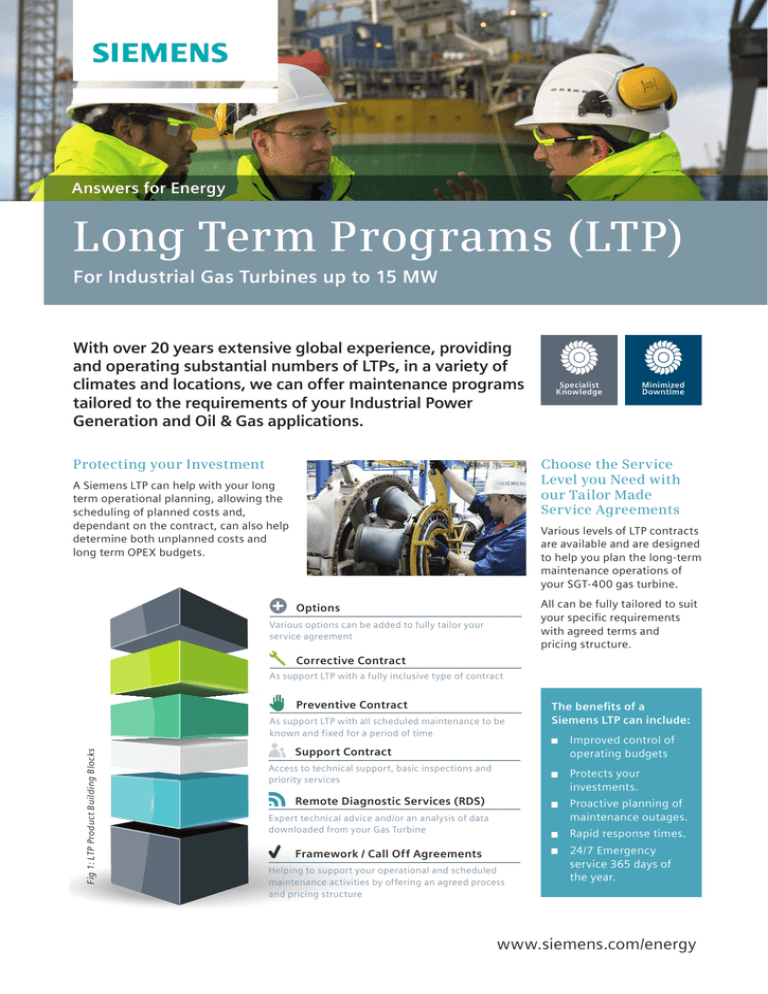

Options

Various options can be added to fully tailor your

service agreement

Corrective Contract

As support LTP with a fully inclusive type of contract

Preventive Contract

Fig 1: LTP Product Building Blocks

As support LTP with all scheduled maintenance to be

known and fixed for a period of time

Support Contract

Access to technical support, basic inspections and

priority services

The benefits of a

Siemens LTP can include:

Improved control of

operating budgets

Protects your

investments.

Remote Diagnostic Services (RDS)

Proactive planning of

maintenance outages.

Expert technical advice and/or an analysis of data

downloaded from your Gas Turbine

Rapid response times.

Framework / Call Off Agreements

Helping to support your operational and scheduled

maintenance activities by offering an agreed process

and pricing structure

24/7 Emergency

service 365 days of

the year.

www.siemens.com/energy

Siemens has an established

history and has invested

globally in facilities, products

and manpower to support the

long term contract requirements

of the Siemens gas turbine fleet

Our LTP products are designed

to help you plan the long-term

maintenance operations of your

gas turbine, with agreed terms

and pricing structure.

Support Contract

A Support LTP Contract

offers basic cover, as well as

the following:

Parts & Manpower for Annual

Scheduled ‘A’ type Inspections

Priority Service

Emergency Call Out Service

Guaranteed Mobilisation Times

Basic Hand Tool Kit

Delivery

24/7 Global Helpdesk Service

Provision of 24/7 helpdesk with

expert support via Phone or Email

Full coverage during UK office

hours

Breakdown coverage outside

office hours for operational

emergencies

Assurance of support from

experienced field personnel with

the full back-up of the OEM

Access to drawings, designs,

software records and product

improvements

Ability to connect ‘live’ to control

system via STA-RMS (if activated)

to review faults in real time

Preventive Contract

As per the Support LTP, but

includes the following:

Parts for Scheduled ‘B’ & ‘C’ type

Maintenance inspections

Manpower for Scheduled

Maintenance inspections

Service Exchange Unit at ‘C’ type

inspection

Gearbox inspection/ Overhaul

Access to Spares Held Within

Territory

Corrective Contract

As preventative LTP with

unscheduled maintenance.

The Corrective LTP is a comprehensive

contract for total maintenance

coverage.

Parts for Unscheduled

Maintenance

Manpower for Unscheduled

Maintenance

Emergency Back-up Stock Holding

Access to Loan Unit

STA-RMS (Remote Monitoring /

Diagnostics system)

Guaranteed Availability of Loan Unit

Access to 24hr Global Helpdesk Service

Annual Availability Guarantee*

Agreed Annual Downtime*

* Corrective LTP with Availability Guarantee

Each service level can be tailored to

suit your specific requirements.

Remote Diagnostic Services

(RDS)

RDS utilizes the experience that we as

the OEM has accumulated from its

operating fleet. This, coupled with

the extensive knowledge of both our

field and service engineering teams,

gives us the unique capability to

enhance the specific requirements of

your Oil & Gas, Industrial or Power

Generation application.

Available as part of our

Framework or Call Off

agreements or via our Preventive or

Corrective Service Contracts, the

Siemens Remote Diagnostic Services

(RDS) can assist you with the

professional management of your

plant’s assets to help you meet your

investment goals.

Through the daily monitoring of various

operating statistics, trending and data

analysis, tailored to your specific

machine, Siemens RDS is designed to

optimize your rotating equipment

and processes.

Framework / Call Off

Agreements

Agreements that help to support your

operational and scheduled

maintenance activities by offering

agreed supply processes for:

Asset Management via

Remote Diagnostics for

Increased Reliability

We can provide various levels of

Remote Services including 24/7 global

Helpdesk and Daily Monitoring, with

assigned Siemens engineer, providing

both summary reporting and preemptive notifications if and when

required to suit both the site

conditions and your operating

requirements.

1

Options

Any of the following aftermarket

products can be included with

the Framework or Call Off

agreements as options:

Spare parts

Maintenance (support,

preventative& corrective) kit lists

Major scheduled maintenance

options (overhauls/service

exchange units)

Adhoc Field Services

Resident engineer services

Remote Diagnostic Options

(Helpdesk through to Daily

Monitoring)

Modernization & Upgrades

Customer training

Factory Overhauls

Modernization & Upgrades

Service Exchange

Individual project management

Field Service

Contract management team

Product Training

Dedicated technical support

Remote Monitoring Services

Spare parts & tooling

management

Spare Parts

Project Management

Data Collection

at Site

2

Data Transfer (cRSP)

3

Central Data

Storage / Admin

Siemens

STA-RMS Servers

INTERNET

Customer

Access

Gateway

Customer Customer

Intranet Firewall

Siemens

Firewall

cRSP

Servers

4

Streaming

Data

HMI

Interaction

Automated

Data Processing

Agents, Dashboard

5

Final Data Analysis

Siemens Expert

8

Customer

7

Real Time Troubleshooting

6

Proactive Notifications

Diagnosis / Prognosis supplied via Reports

Fig 1: RDS Core Functions

LTP Scope

Included

Option

Framework

/ Call Off

RDS

Support

Corrective

Preventative

Parts for annual ‘A’ inspection

Manpower for annual ‘A’ inspection

Priority service

Emergency call out service

Guaranteed mobilisation of service personnel

Basic hand tool kit

Delivery

Parts for annual ‘B’ and ‘C’ inspection

Manpower for annual ‘B’ and ‘C’ inspection

Service exchange at ‘C’ inspection

Gearbox inspection / overhaul

Access to 24hr global helpdesk service

STA-RMS (Remote Monitoring Service)**

Access to spares held with in territory

Parts for unscheduled maintenance

Manpower for unscheduled maintenance

Emergency back-up stock holding

Access to loan unit

Guaranteed availability of loan unit

Annual availability guarantee

Agreed annual downtime

**subject to controls system

Fig 2: LTP Product Matrix.

For more information or to arrange

an appointment, please contact

your local CSM or our LTP experts in

Lincoln, UK

Tel: +44 (0)1522 583544

Email: lcnw.sgt.service.enquiries.

energy@siemens.com

www.siemens.com/energy

Published by and copyright © 2014:

Siemens Industrial Turbomachinery, Energy

Service Feilden House, Lincoln, LN6 3AD, UK

All rights reserved. Trademarks mentioned in this

document are the property of Siemens AG, its

affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases. The

required technical options should therefore be

specified in the contract.