BB71 and BB72 (5.6m2 and 6.9m2)

LP Turbine Modernization

Scope of supply

When it’s time to modernize your

steam turbine, we know that improving

performance at the highest reliability is

the top priority. The Siemens BB71 and

BB72 modernization is designed to meet

this goal. Our fully integrated, monoblock

rotor uses an advanced design blade path

with an increased annulus area to help

increase your plant’s output.

The Siemens BB71 and BB72 LP

Turbine modernizations are based on a

common, proven design. The replacement

LP ­turbines for both the BB71 and BB72

share the same design features, but vary in

blade sizing and staging. The modernized

turbines are designated by their nominal

annulus exhaust areas: BB71 exhaust area

measures 5.6m2, and the BB72 exhaust

area measures 6.9m2.

Both LP designs feature:

Fully integral, monoblock rotor

Free-standing design L-0 rotating blades

with a nominal 29.5” and 32” blade

height and standard side-entry roots

of the robust Siemens design. Blade

roots are 2 to 3 times larger than

original LP turbine blades

Drum stages with rotating blades that

are integrally shrouded

Optimized exhaust flow guides

Bladepath seals on integral shrouds

are a tip-to-tip design for improved

efficiency and long-term thermal

performance

Fabricated single-piece inner cylinder

(two halves) designed for easier

installation and maintenance.

Please note the 5.6m2 modernized turbine

also applies to the BB271, BB371 and

Performance Enhancement - Steam Turbine

Answers for energy.

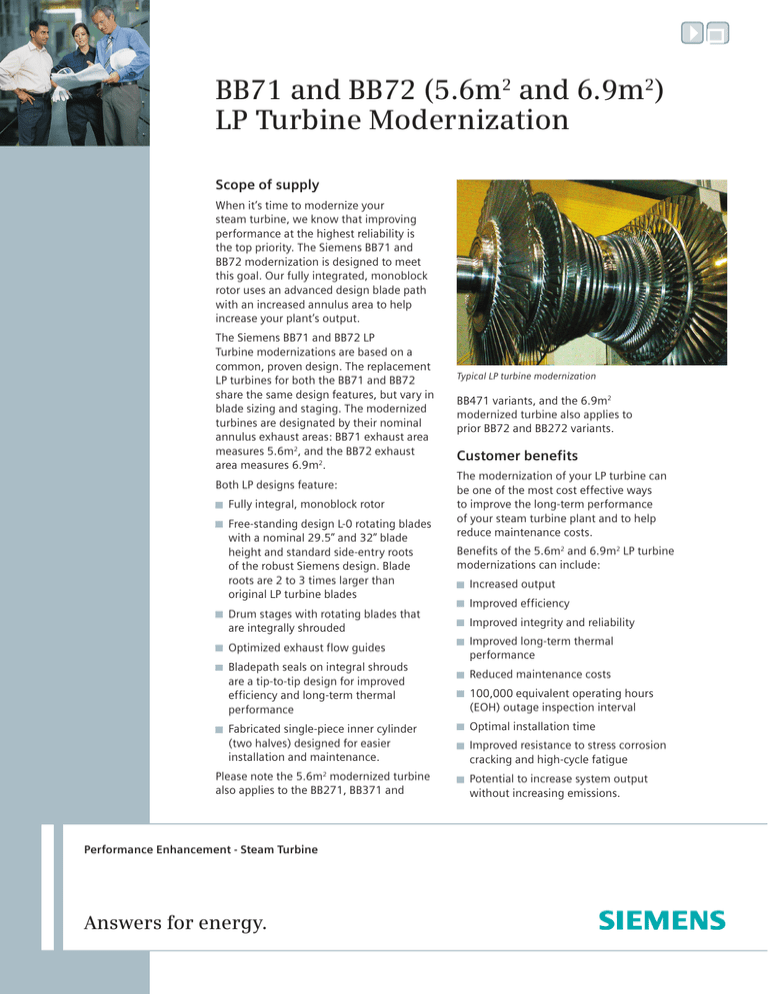

Typical LP turbine modernization

BB471 variants, and the 6.9m2

modernized turbine also applies to

prior BB72 and BB272 variants.

Customer benefits

The modernization of your LP turbine can

be one of the most cost effective ways

to improve the long-term performance

of your steam turbine plant and to help

reduce maintenance costs.

Benefits of the 5.6m2 and 6.9m2 LP turbine

modernizations can include:

Increased output

Improved efficiency

Improved integrity and reliability

Improved long-term thermal

performance

Reduced maintenance costs

100,000 equivalent operating hours

(EOH) outage inspection interval

Optimal installation time

Improved resistance to stress corrosion

cracking and high-cycle fatigue

Potential to increase system output

without increasing emissions.

Features

Bladed LP rotor

The Siemens advanced monoblock rotor

is manufactured from a single forging

with no thru-bore. This design significantly

reduces rotor body stresses, and boresonic

exams are no longer required. Material

selection and detailed design features help

avoid stress corrosion cracking that may

be found on other LP rotor designs in fossil

applications.

New, single-piece inner cylinder

fabrication

The single-piece LP inner cylinder is constructed of a combination carbon steel

casting and steel plate fabrication split at

the horizontal joint. The improved cylinder

was designed with the latest finite element

tools to help improve reliability and reduce

maintenance costs.

Advanced technology blading

Optimized 3-D rotating and stationary

blading with enhanced sealing

Fully integrated monoblock rotor features an advanced design blade path with

increased annulus area.

Additional features

Integrally shrouded, high-efficiency

blading in the front-end stages/drum

stages

Reduced exhaust losses

Free-standing 29.5” and 32” last stage

blades, giving an exhaust area of

approximately 5.6m2 and 6.9m2

respectively

Compatible with existing rotor train to

ensure system integration.

Leading edges of the LP free-standing

rotating blades are flame or laser

hardened to help reduce moisture

erosion.

8.7” HgA exhaust pressure limits at high

loads

Moisture removal features incorporated

in the design to minimize erosion.

This improved design has been

successfully installed and is in operation.

For more information, please contact

your local Siemens representative.

Published by and copyright © 2010:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

www.siemens.com/energy

For more information, contact our

Customer Support Center.

Phone: +49 180/524 70 00

Fax:

+49 180/524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

Energy Service Division

Order No. E50001-D520-A257-X-76US

Printed in USA

BU 2009917132620872F IN 0110.2

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.