E-

advertisement

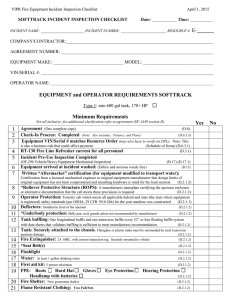

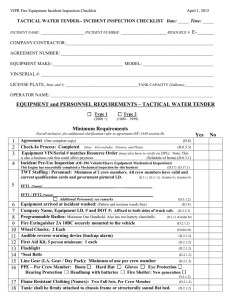

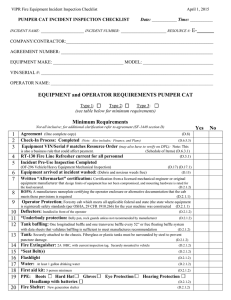

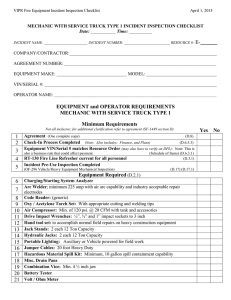

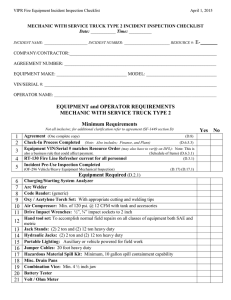

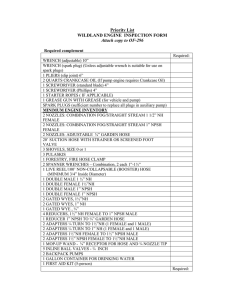

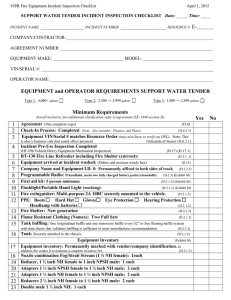

VIPR Fire Equipment Incident Inspection Checklist SKIDGINE INCIDENT INSPECTION CHECKLIST INCIDENT NAME: April 1, 2015 Date: ___________ Time: __________ ___________________ INCIDENT NUMBER: ____________________ RESOURCE #: E- COMPANY/CONTRACTOR:_________________________________________________________________ AGREEMENT NUMBER: ___________________________________________________________________ EQUIPMENT MAKE: _______________________________ MODEL: _______________________________ VIN/SERIAL #: ____________________________________________________________________________ OPERATOR NAME: ______________________________________________________________________________________ EQUIPMENT and OPERATOR REQUIREMENTS SKIDGINE Type 1 Type 2 Type 3 Type 4 (see table below for minimum requirements) Minimum Requirements Not all inclusive; for additional clarification refer to agreement (SF-1449 section D) 1 2 3 is also a business rule that could affect payment. 4 5 6 7 Yes Agreement (One complete copy) (D.8) Check-In Process: Completed (Note: Also includes; Finance, and Plans) (D.6.5.3) Equipment VIN/Serial # matches Resource Order (may also have to verify on DPL): Note: This RT-130 Fire Line Refresher current for all personnel Incident Pre-Use Inspection Completed (Schedule of Items) (D.6.3.1) (D.3.1) (OF-296 Vehicle/Heavy Equipment Mechanical Inspection) Equipment arrived at incident washed: (Debris and noxious weeds free) (D.17) (D.17.1) (D.15) Written “Aftermarket” certification: Original manufacture design limits of equipment has not been compromised, and mounting hardware is rated for the load secured. (D.2.1.2) 8 *Rollover Protective Structure (ROPS): A manufactures nameplate certifying the operator enclosure 9 or alternative documentation that the cab meets these provisions is required (D.2.1.2) Operator Protection: Forestry cab which meets all applicable federal and state (the state where equipment is registered) safety standards (per OSHA, 29 CFR 1910.266) for the year machine was constructed (D.2.1.1) (D.2.1.2) 10 Deflectors: Installed in front of the operator (D.2.1.2) 11 *Underbody protection: Belly pan, rock guards unless not recommended by manufacturer 12 Tank baffling: One longitudinal baffle and one transverse baffle every 52” or free floating baffle system 13 with data sheets that validates baffling is sufficient to meet manufactures recommendation (D.2.1.2) Tank: Securely attached to the chassis. Fiberglass or plastic tanks must be surrounded by steel to prevent puncture damage. (D.2.1.2) 14 Rubber Tires: All tires shall have sound sidewalls and adequate tire tread depth to hold tire chains. Chains are optional in the Pacific Northwest Region (R6) but required in all other Regions. 15 16 17 18 19 20 (D.2.1.2.2) Fire Extinguisher: 2A 10BC, with current inspection tag. Securely mounted to vehicle (D.2.1.2) *Seat Belt(s) (D.2.1.2) Flashlight (D.2.1.2) Water: At least 1 gallon drinking water (D.2.1.2) First aid kit: 5 person minimum (D.2.1.2) PPE: Boots Hard Hat Gloves Eye Protection Hearing Protection Headlamp with batteries (D.2.1.2) No VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 21 Fire Shelter: New generation shelter 22 Flame Resistant Clothing: Two Full Sets (D.2.1.2) (D.2.1.2) Equipment Inventory 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 (Exhibit M) Hose Reel: Operational, minimum 150 feet of 1 inch hard line hose (D.2.1.2.2) Hose, 1 inch: Minimum of 300’ type 1 &2, 300’ type 3 &4 (D.2.1.2.2) Hose, 1 ½”: Minimum of 300’ type 1 &2 (D.2.1.2.2) Hose Clamp: Forestry type. 1 each Spanner Wrench: Combination 1 inch to 2 inch. 1 each Nozzles: Combination fog / straight stream. 2 each. Fitting: Double Male, 1 inch NPSH. 1 each Fitting: Double Female, 1 inch NPSH. 1 each Adapter: 1 inch NH Female to 1inch NPSH Male. 1 each Adapter: 1 inch NPSH Female to 1 inch NH Male. 1 each Reducer: 1 ½ inch NH Female to 1 inch NPSH Male. 1 each Reducer: 1 inch NPSH to ¾ inch (garden hose). 1 each Shovel: 1 each Pulaski: 1 each Discharge Outlet: 1 ½” NH Type 1 &2, 1” NPSH Type 3 &4 (D.2.1.2.2) Fill Pipe: 4 inch minimum Dump Valve: 3 inch minimum. Capable of dumping into a port-a-tank Pump: Pump Type Auxiliary or Power Take Off (PTO) (D.2.1.2) Auxiliary pump (if equipped): Fuel to operate pump, minimum 5 gallons and Pump accessories ( i.e. Pliers, Oil, Screwdrivers etc.) 42 43 44 45 --46 47 48 49 Pump: Discharge Pressure Gauge Pump: 20 foot suction hose Lighting: Minimum 2 rear, 2 forward Back-Up Alarm: Audible reverse warning device. ****(Optional/Attributes)**** Winch Grapple (Type 3 or 4 only) Foam Proportioner System: Manual Automatic Compressed Air Foam System: Drop Tank Skidgine: Type 3 & 4 only, must have a log grapple *Item may be waived if inspection successfully performed on the OF-296 Equipment meets agreement specifications (D.2.1.2) (D.2.1.2) ----(D.2.1.2.2) (D.6.2) (D.2.1.2.2) ( D.6.2) (D.2.1.2.1) (D.2.1.2.2) Equipment does not meet agreement specifications Inspector: Date: (Print and sign) Contractor: Date: (Print and sign) Contractor given the opportunity to correct noted deficiencies (See Remarks) Contactor successfully corrected noted deficiencies Inspector: Date: ----- VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 REMARKS:__________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________