E-

advertisement

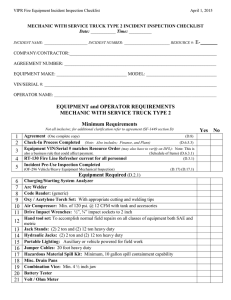

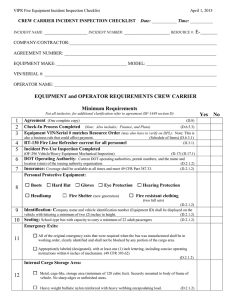

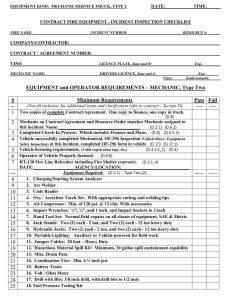

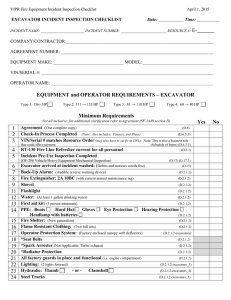

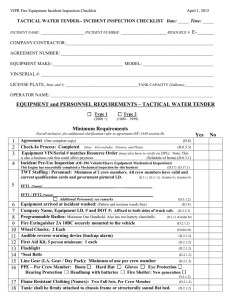

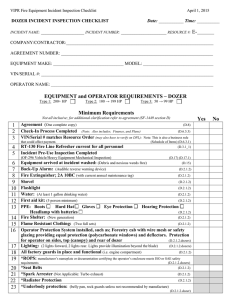

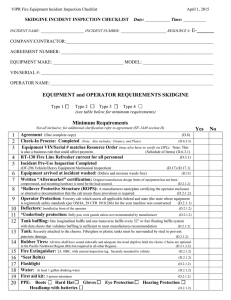

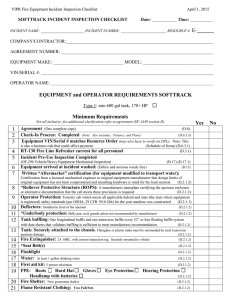

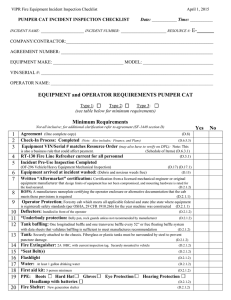

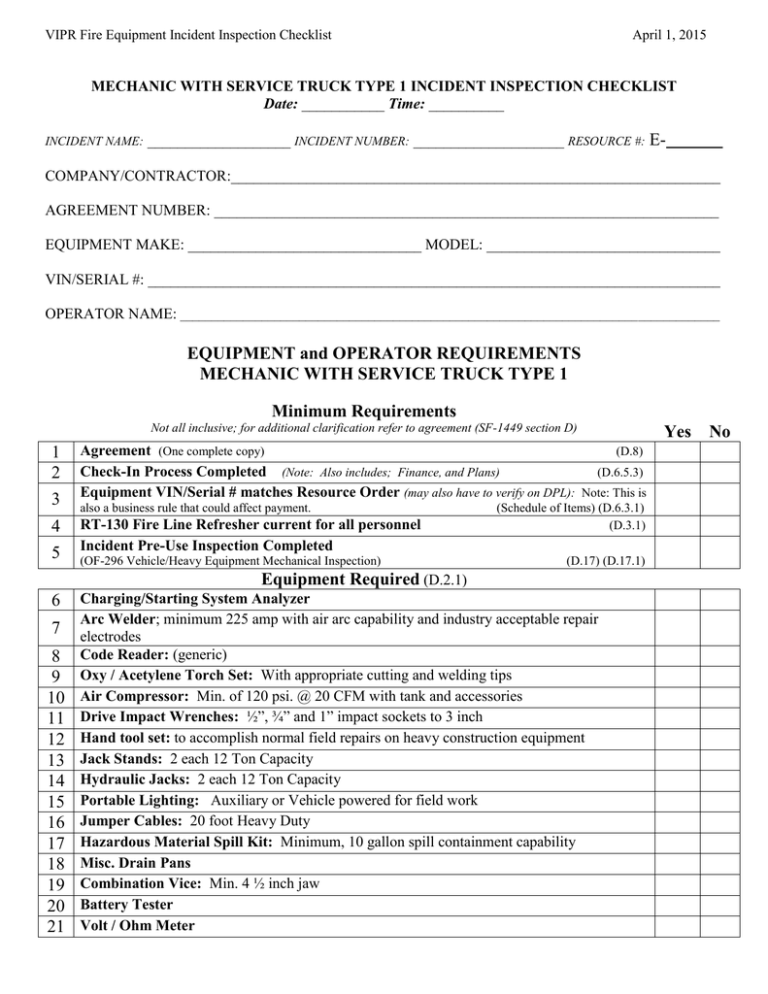

VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 MECHANIC WITH SERVICE TRUCK TYPE 1 INCIDENT INSPECTION CHECKLIST Date: ___________ Time: __________ INCIDENT NAME: ___________________ INCIDENT NUMBER: ____________________ RESOURCE #: E- COMPANY/CONTRACTOR:_________________________________________________________________ AGREEMENT NUMBER: ___________________________________________________________________ EQUIPMENT MAKE: _______________________________ MODEL: _______________________________ VIN/SERIAL #: ____________________________________________________________________________ OPERATOR NAME: ______________________________________________________________________________________ EQUIPMENT and OPERATOR REQUIREMENTS MECHANIC WITH SERVICE TRUCK TYPE 1 Minimum Requirements Not all inclusive; for additional clarification refer to agreement (SF-1449 section D) 1 2 3 4 5 Agreement (One complete copy) (D.8) Check-In Process Completed (Note: Also includes; Finance, and Plans) (D.6.5.3) Equipment VIN/Serial # matches Resource Order (may also have to verify on DPL): Note: This is also a business rule that could affect payment. RT-130 Fire Line Refresher current for all personnel Incident Pre-Use Inspection Completed (OF-296 Vehicle/Heavy Equipment Mechanical Inspection) (Schedule of Items) (D.6.3.1) (D.3.1) (D.17) (D.17.1) Equipment Required (D.2.1) 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Charging/Starting System Analyzer Arc Welder; minimum 225 amp with air arc capability and industry acceptable repair electrodes Code Reader: (generic) Oxy / Acetylene Torch Set: With appropriate cutting and welding tips Air Compressor: Min. of 120 psi. @ 20 CFM with tank and accessories Drive Impact Wrenches: ½”, ¾” and 1” impact sockets to 3 inch Hand tool set: to accomplish normal field repairs on heavy construction equipment Jack Stands: 2 each 12 Ton Capacity Hydraulic Jacks: 2 each 12 Ton Capacity Portable Lighting: Auxiliary or Vehicle powered for field work Jumper Cables: 20 foot Heavy Duty Hazardous Material Spill Kit: Minimum, 10 gallon spill containment capability Misc. Drain Pans Combination Vice: Min. 4 ½ inch jaw Battery Tester Volt / Ohm Meter Yes No VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 Minimum Requirements Continued 22 23 24 25 26 27 Drill with Bits: ½ inch drill, with drill bits to ¾ inch Fuel Pressure Testing Kit Tap and Die Set: to 1 inch Electric Grinder: 4 inch Hydraulic Pressure Testing Kit Hydraulic Crane: Minimum of 2 ton capacity, (hand or powered) 28 29 30 31 32 33 34 35 Consumable Goods (D.2.2) Commonly used SAE and Metric Nuts and Bolts: up to ½ x 3 inch Assorted electrical connections: for commonly used wire sizes on all equipment Assorted electrical wire: Sizes commonly found on all types of equipment Assorted common electrical fuses and bulbs Assorted lubricants and cleaners used by field mechanics Assorted metal fasteners, machine screws, self-tapping screws: up to #12 x 1 ½“ Air Brake Fittings: Commonly used, up to 5/8 inch. Shop Towels Mechanics Service Truck (D.2.3.2) Fire Extinguisher: Multi-Purpose, 1A 10 BC, Securely Mounted, and Accessible. Also has 36 current annual inspection tag 37 Back-Up Alarm: Rear facing. Switches to activate alarm are not allowed 38 Reflectors: Triangle bi-directional, 1 set of 3 39 Wheel Chocks: (minimum one pair) 40 Shovel 41 42 43 PPE: Boots Hard Hat Gloves Eye Protection Headlamp with batteries Welding Chaps: 1 pair Fire Shelter: New generation Flame Resistant Clothing: Two Full Sets Equipment meets agreement specifications Hearing Protection (D.2.2.1) (D.2.2.1) (D.2.2.1) Equipment does not meet agreement specifications Inspector: Date: (Print and sign) Contractor: Date: (Print and sign) Contractor given the opportunity to correct noted deficiencies (See Remarks) Contactor successfully corrected noted deficiencies Inspector: Date: VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 REMARKS:_______________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________