E-

advertisement

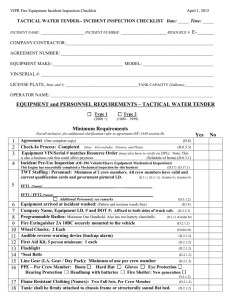

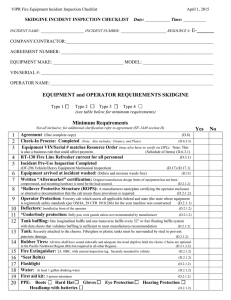

VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 SUPPORT WATER TENDER INCIDENT INSPECTION CHECKLIST Date: _____ Time: ____ INCIDENT NAME: ___________________ INCIDENT NUMBER: ____________________ RESOURCE #: E- COMPANY/CONTRACTOR:_________________________________________________________________ AGREEMENT NUMBER: ___________________________________________________________________ EQUIPMENT MAKE: _______________________________ MODEL: _______________________________ VIN/SERIAL #: ____________________________________________________________________________ OPERATOR NAME: ______________________________________________________________________________________ EQUIPMENT and OPERATOR REQUIREMENTS SUPPORT WATER TENDER Type 1: 4,000+ gallons Type 2: 2,500 → 3,999 gallons Type 3: 1,000 → 2,499 gallons Minimum Requirements Not all inclusive; for additional clarification refer to agreement (SF-1449 section D) 1 2 3 is also a business rule that could affect payment. 4 Yes Agreement (One complete copy) (D.8) Check-In Process: Completed (Note: Also includes; Finance, and Plans) (D.6.5.3) Equipment VIN/Serial # matches Resource Order (may also have to verify on DPL): Note: This (Schedule of Items) (D.6.3.1) Incident Pre-Use Inspection Completed (OF-296 Vehicle/Heavy Equipment Mechanical Inspection) (D.17) (D.17.1) 13 14 15 RT-130 Fire Line Refresher including Fire Shelter (current): (D.3.1_1) Equipment arrived at incident washed: (Debris and noxious weeds free) (D.15) Company Name and Equipment I.D. #: Permanently affixed to both sides of truck (D.2.2.3) Programmable Radio: If handheld, needs two fully charged battery packs (clamshells) (D.2.3) (Exhibit M) First aid kit: 5 person minimum (D.2.1.2) (Exhibit M) Flashlight/Portable Hand Light (working): (D.2.1.2) (Exhibit M) Fire extinguisher: Multi-purpose 2A 10BC securely mounted to the vehicle. (D.2.1.2) PPE: Boots Hard Hat Gloves Eye Protection Hearing Protection Headlamp with batteries (D.2.1.2) Fire Shelter: New generation (D.2.1.2) Flame Resistant Clothing (Nomex): Two Full Sets (D.2.1.2) Tank baffling: One longitudinal baffle and one transverse baffle every 52” or free floating baffle system 16 with data sheets that validates baffling is sufficient to meet manufactures recommendation Tank: Securely attached to the chassis. 17 Equipment Inventory (Exhibit M) Equipment inventory: Permanently marked with vendor/company identification. In 5 6 7 8 9 10 11 12 addition, the vendor is to maintain a complete inventory list. 18 19 20 21 22 23 Nozzle combination Fog/Strait Stream (1 ½ NH female): 1each Reducer, 1 ½ inch NH female to 1 inch NPSH male: 1 each Adapters 1 ½ inch NPSH female to 1 ½ inch NH male: 2 each Adapters 1 ½ inch NH female to 1 ½ inch NPSH male: 2 each Reducers 2 ½ inch NH female to 1 ½ inch NH male: 2 each Double male 1 ½ inch NH: 1 each (D.2.1.2) (D.2.1.2) (D.2.1.2) No VIPR Fire Equipment Incident Inspection Checklist April 1, 2015 Double Female 1 ½ inch NH: 1 each Gated “Y” 1 ½ NH: 1 each Fire Hose Clamp 2 ½ inch: 1 each Spanner Wrench, Combination 1 ½ inch to 2 ½ inch: 1 each Adjustable Hydrant Wrench: 1 each Shovel – Size 0 or 1: 1 each Pulaski: 1 each 100 foot – 1 ½ inch Cotton/Synthetic Hose NH Thread (D.7.1.3) 50 Foot – 2 ½ inch Cotton/Synthetic Hose NH Thread (D.7.1.3) Suction hose with strainer or screened foot valve: 20 foot minimum (D.7.1.3) Wheel Chocks: At least one pair, meeting specifications Dump Valve: Minimum 4 inch. Extends past rear of vehicle (D.2.1.2.2) Pump: Discharge Pressure Gauge: (D.2.1.2) Auxiliary pump (if equipped): Fuel to operate for at least 12 Hours 2 ½ inch Discharge Outlet, national hose thread: 1 each 1 ½ inch Discharge Outlet, national hose thread: 2 each Spray Bar head(s) operational: (D.2.1.2.2.1) (Exhibit J) (Exhibit M) Spray Bar Configuration: Front Rear Both / Gravity or Pressure (D.2.1.2) 41 Back-Up Alarm: Audible reverse warning device. *Item may be waived if inspection successfully performed on the OF-296 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 Equipment meets agreement specifications Equipment does not meet agreement specifications Inspector: Date: (Print and sign) Contractor: Date: (Print and sign) Contractor given the opportunity to correct noted deficiencies (See Remarks) Contactor successfully corrected noted deficiencies Inspector: Date: REMARKS:__________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________