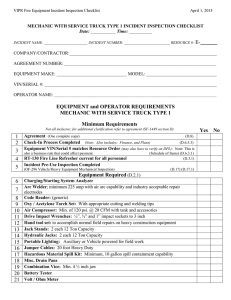

MECHANIC, Type Two # Minimum Requirements Pass Fail

advertisement

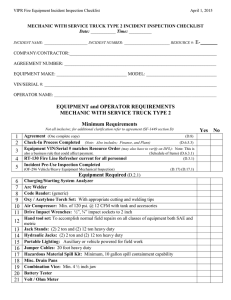

EQUIPMENT KIND: MECHANIC/SERVICE TRUCK, TYPE 2 DATE: ____________TIME:______ CONTRACT FIRE EQUIPMENT - INCIDENT INSPECTION CHECKLIST FIRE NAME: _________________________INCIDENT NUMBER: ________________________RESOURCE #:______ COMPANY/CONTRACTOR: __________________________________________________________________ CONTRACT / AGREEMENT NUMBER: ________________________________________________________ VIN#:__________________________________LICENCE PLATE, State and #: MECHANIC NAME: __________ __ _____ ________________ Exp.__ _ ___ _ DRIVERS LICENCE, State and #: _____ _____ _____Exp:_______ Class:_______Endorsements:______ EQUIPMENT and OPERATOR REQUIREMENTS – MECHANIC, Type Two # Minimum Requirements (Not all inclusive, for additional items and clarification refer to contract – Section D) --1 Two copies of complete Contract/Agreement. One copy to finance, one copy in truck. Pass Fail ---- ---- (D.8) 2 3 4 5 6 7 --8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Mechanic on Contract/Agreement and Resource Order matches Mechanic assigned to this incident. Name:____________________________________ (D.3.1) (D.6.2) Completed Check-In Process: Which includes Finance and Plans. (D.8) (D.6.5.3) Vehicle successfully completed Mechanical, OF-296 Inspection (Vehicle/Heavy Equipment Safety Inspection) at this incident, completed OF-296 form in vehicle (D.17) (D.17.1) Vehicle licensing requirements. (Valid registration tags, etc.) (D.2.3.2_1) (D.4) Operator of Vehicle Properly licensed. (D.6.6) RT-130 Fire Line Refresher including Fire Shelter (current). (D.3.1_4) DATE:__________________AGENCY/LOCATION:______________________________ Equipment Required: (D.2.1) - Type Two (2) 1. Charging/Starting System Analyzer 2. Arc Welder 3. Code Reader 4. Oxy / Acetylene Torch Set: With appropriate cutting and welding tips 5. Air Compressor: Min. of 120 psi. @ 12 cfm. With accessories 6. Impact Wrenches: ½”, ¾”, and 1 inch, and Impact Sockets to 2 inch 7. Hand Tool Set: Normal field repairs on all classes of equipment, SAE & Metric 8. Jack Stands: Two (2) each - 2 ton, and Two (2) each - 12 ton heavy duty 9. Hydraulic Jacks: Two (2) each - 2 ton, and two (2) each - 12 ton heavy duty 10. Portable Lighting: Auxiliary or Vehicle powered for field work 11. Jumper Cables: 20 foot – Heavy Duty 12. Hazardous Material Spill Kit: Minimum, 10 gallon spill containment capability 13. Misc. Drain Pans 14. Combination Vice: Min. 4 ½ inch jaw 15. Battery Tester 16. Volt / Ohm Meter 17. Drill with Bits: 3/8 inch drill, with drill bits to 1/2 inch 18. Fuel Pressure Testing Kit ----- ----- EQUIPMENT KIND: MECHANIC/SERVICE TRUCK, TYPE 2 DATE: ____________TIME:______ # Minimum Requirements - continued 19. Tap and Die Set: Tap and Die Set to 5/8 inch 26 20. Electric Grinder: 4 inch 27 21. Brake and Clutch: Bleeder system, self contained 28 29 Welding Chaps: At least One (1) pair Consumable Goods (D.2.2) --1. Commonly used SAE and Metric Nuts and Bolts, up to ½ inch x 3 inch 30 2. Assorted electrical connections for commonly used wire sizes on all equipment 31 3. Assorted sizes of electrical wire commonly found on all types of equipment 32 4. Assorted common electrical fuses and bulbs 33 5. Assorted lubricants and cleaners used by field mechanics 34 6. Assorted medal fasteners, machine screws, self tapping screws. 35 7. Air Brake Fittings: Commonly used, up to 5/8 inch. 36 8. Shop Towels 37 Mechanics Service Truck - All vehicles shall: (D.2.3.2) --1. See Vehicle Requirements, inspection line items # 4 and #5 above --2. Fire Extinguisher: Multi Purpose, 1A 10 BC, Securely Mounted, and Accessible. 38 39 40 41 42 43 44 45 46 Pass Fail ----- ----- ----- --------- ----- Also has current annual inspection tag 3. Back-Up Alarm: Rear facing. Switches to activate alarm are not allowed 4. Reflectors: Triangle bi-directional, 1 set of 3 5. Wheel Chocks, two, (minimum one pair) 6. Shovel PPE: Boots, Hard Hat, Gloves, Eye Protection, Hearing Protection, Headlamp with batteries (D.2.2_A_1,2,3,5,6,7) Fire Shelter: New generation (D.2.2_A_8) Flame Resistant Clothing: Two Full Sets (D.2.2_A_9) Condition of Vehicle/Equipment: Maintained in good repair by Contractor (D.1), (D.2) Remarks: ____________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ Yes Contract Deficiencies Found No Contract Deficiencies Found Contractor is given the opportunity (Optional), to correct noted deficiencies. May be given up to 24 Hours as of: Date: _______________ Time: ____________ See Remarks (D.7.1.1) (D.17) Contactor successfully corrected noted deficiencies: Date: ______________Time:____________ Inspector: ___________________ CONTRACTOR REPRESENTATIVE: _______________________________________Title: ______________ (Print and Sign) GOVERNMENT INSPECTOR:______________________________________________Title:______________ (Print and Sign)