Chemistry in Biomass Combustion “ChemCom” 2005-2007

advertisement

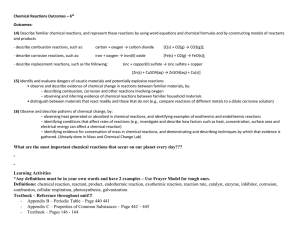

Chemistry in Biomass Combustion “ChemCom” 2005-2007 Åbo Akademi University (ÅA/PCC) Helsinki University of Technology (TKK) Tampere University of Technology (TUT) Umeå University (UU) Tekes Andritz Oy Foster Wheeler Energia Oy International Paper Inc. Metso Power Oy Oy Metsä-Botnia Ab Vattenfall Utveckling AB IV Liekkipäivä, Tampere, January 2008 Project Objectives • Produce detailed knowledge concerning chemical phenomena that will influence on the biomass combustion technology development • The purpose is not to solve present acute problems, but instead the topics are connected to long-term questions • The results are, as a principal rule, public, e.g. as doctoral, licentiate and masters theses, journal articles, etc. Project Organisational Structure Fundamental Research on Chemistry in Biomass Combustion Project Co-ordination (ÅA) Project Steering Group Experiment Modelling Helsinki University of Technology Information Tampere University of Technology Project Research Structure 15 workpackages Biomass Black Liquor Waste Experiment E1 Modelling Information E2 M1 E3 E4 E5 E6 E7 E8 I1 I2 I3 I4 M2 M3 ChemCom Workpackages E1. Experimental combustion facilities for fuel characterisation E2. Experimental combustion analysis of black liquor E3. Experimental combustion analysis of biomass E4. Mineral Matter and Trace Elements in Biofuels E5. Fundamental study of high temperature corrosion mechanisms in biomass co-firing and black liquor combustion E6. Fly Ash Behaviour of Fuel Mixtures E7. Experimental black liquor spray characterisation (Järvinen, TKK) E8. In-situ diagnositics of biofuel combustion chemistry (Hernberg, TUT) M1. Application specific submodel development for CFD simulations (Järvinen, TKK) M2. Collection and improvement of thermodynamic data for trace metal prediction in combustion and gasification systems M3. Kinetic simulations for studying gas-phase combustion chemistry in biomass conversion systems I1. Extension and utilisation of the ÅA fuel-, char- and ash databases I2. Manganese (Mn) chemistry in biomass utilisation I3. Analysis and evaluation of novel chemical recovery processes I4. National and international collaboration Development of a Laboratory Corrosion Test Method and Evaluation of the Results Part of workpackage E5 Corrosion Test Method 1. Preparation of salts – synthetic ash • Chosen carefully – known melting behaviour and composition • Melted and grinded for homogeneity • Analyzed to confirm the composition and melt behaviour Corrosion Test Method, cont. 2. Sample preparation for experiment • Polish • Oxidation • Synthetic ash 2 cm Before heat treatment Corrosion Test Method, cont 3. Tube furnace test Sample holder Tube furnace Corrosion Test Method, cont. 4. Sample preparation for SEM/EDX analysis The alloy is then cast in epoxy, cut, polished and cleaned. Corrosion Test Method, cont 5. Analysis of SEM results and determination of oxide layer thickness 140 120 100 80 60 40 20 Corrosion Test Results (1/2) Oxide layer thickness, µm 140 120 100 Synthetic ash #1 T0 = 884oC 0% Cl 0% K 80 60 40 20 0 #1 2 l ee el # #3 t S e l St tee el #4 #5 6 S e l t S ee el # t S e St 60 o 575 o 0 C 550 o C 525 o C 500 o C 450 o C C Corrosion Test Results (2/2) Oxide layer thickness, µm 140 120 100 Synthetic ash #6 T0 = 522oC 1.3% Cl 10% K 80 60 40 20 0 #1 2 l ee e l # # 3 t S e l St tee el #4 #5 6 S e l t S ee el # t S e St 600 o 575 o C 550 o C 525 o C 500 o C 450 o C C Ash Behaviour of Fuel Mixtures Part of workpackage E6 • • Air-cooled probe deposits and corrosion Co-firing peat and wood • • Superheater deposits Co-firing coal and straw 60 min. 10 h Ref.:F.Frandsen DTU Why do the fuels interact? Mechanical reasons abrasion/erosion of deposits with e.g. silica rich fuel ash Chemical reasons e.g. sulphation of alkali chlorides (the troublemakers in combustion systems => deposits, corrosion) Deposition Rate Interactions between Fuels ion t c ra e t in no positive interaction 0 100% Fuel B 20 40 60 Fuel A (wt%) 80 100 0% Fuel B Ref. M. Theis Entrained Flow Reactor - University of Toronto Sample feeder Gas burner Particles 9m Furnace Probe Balance VCR Case: Co-firing Peat and Straw - example taken from Mischa Theis´ Ph.D. Thesis, 2006 Peat ash (900oC) 20 µm Straw ash (900oC) Probe Surface after 40 min. (Toronto, Canada) 100% Peat 40% Peat, 60% Straw 20% Peat, 80% Straw 100% Straw Deposit Growth when Co-firing Peat and Straw – Positive Interaction 160 2 Deposition (g/m h) 140 120 100 80 60 40 20 0 0 20 40 60 80 Straw fraction in feed (wt-%) 100 ÅA/PCC Personnel in ChemCom 2005-2007 Mikko Hupa Åbo Akademi Process Chemistry Centre Patrik Yrjas (from Aug. 2006) Christian Mueller (until Aug. 2006) Bengt-Johan Skrifvars Rainer Backman Anders Brink Mikael Forssén Jukka Konttinen Maria Zevenhoven Edgardo Coda Zabetta Daniel Lindberg (diss. 2007) Mischa Theis (diss. 2006) Vesna Barisic (diss. 2007) Johan Werkelin Markus Engblom Dorota Bankiewicz Patrycja Derda Micaela Westén-Karlsson Tarja Talonen Tor Laurén Johan Lindholm Combustion and Materials Chemistry Prof. Mikko Hupa Chemistry Ida Combustion Mann Kjell Strandström Bingzhi Li Chemistry HaoMaterials Wu Marco Grava Oskar Karlström Peter Backman Luis Bezerra Piia Leppäsalo Jaana Paananen Linus Silvander Mia Mäkinen Eva Harjunkoski + a number of visiting scientists and students