Int. J. Production Economics 131 (2011) 383–391

Contents lists available at ScienceDirect

Int. J. Production Economics

journal homepage: www.elsevier.com/locate/ijpe

Using a mathematical programming model to examine the marginal price

of capacitated resources

Ali Kefeli, Reha Uzsoy , Yahya Fathi, Michael Kay

Edward P. Fitts Department of Industrial and Systems Engineering, North Carolina State University, Campus Box 7906, Raleigh, NC 27695-7906, USA

a r t i c l e in fo

abstract

Article history:

Received 13 August 2008

Accepted 29 March 2010

Available online 14 April 2010

Accurate information on dual prices of capacitated resources is of interest in a number of applications,

such as cost allocation and pricing. To gain insight we focus on the dual prices of capacity and demand

in a single-stage single-product production-inventory system, and discuss their interpretation. In

particular, we examine the behavior of two different production planning models: a conventional

linear programming model and a nonlinear model that captures queuing behavior at resources in an

aggregate manner using nonlinear clearing functions. The classical linear programming formulation

consistently underestimates the dual price of capacity due to its failure to capture the effects of

queuing. The clearing function formulation, in contrast, produces positive dual prices even when

utilization is below one and exhibits more realistic behavior, such as holding finished inventory at

utilization levels below one.

& 2010 Elsevier B.V. All rights reserved.

Keywords:

Production planning

Linear programming

Clearing functions

Dual prices

Marginal prices

1. Introduction

While linear programming (LP) models have been used

extensively for production planning problems since the 1950s

(e.g., 1974; Missbauer and Uzsoy, in press), their limitations have

been increasingly discussed in recent years. Since these

approaches do not explicitly model work-in-process (WIP)

inventories, as opposed to finished intermediate inventories

between stations, they assume that resources can operate at full

utilization while maintaining fixed cycle times, which contradicts

both empirical observations and predictions of queuing models.

Another anomaly is that a resource can have a nonzero dual price

only when the associated capacity constraint is tight or, in

queuing terminology, utilization of that resource reaches one.

However, it is well known from industrial experience and queuing

models that manufacturing performance measures such as the

expected WIP and cycle time increase nonlinearly with utilization.

This suggests that with an appropriate objective function,

additional capacity can improve system performance even when

utilization is less than one, implying a nonzero dual price for the

resource at lower utilization levels. Since most production

systems are governed to a large degree by queuing behavior, this

inconsistency between the LP models used for capacity allocation

among products and the queuing models used to describe

Corresponding author. Tel.: + 1 919 513 1681; fax: + 1 919 515 5281.

E-mail addresses: akefeli@ncsu.edu (A. Kefeli), ruzsoy@ncsu.edu (R. Uzsoy),

fathi@ncsu.edu (Y. Fathi), kay@ncsu.edu (M. Kay).

0925-5273/$ - see front matter & 2010 Elsevier B.V. All rights reserved.

doi:10.1016/j.ijpe.2010.03.018

steady-state behavior poses an interesting research direction that

has not been explored extensively.

In this paper we examine the behavior of an alternative

mathematical programming model based on nonlinear clearing

functions (CFs) suggested by Karmarkar (1989) in a simple singlestage single-product production-inventory system. While models

of this type have been successfully applied to multi-product

multi-stage systems (e.g., Asmundsson et al., 2006, 2009), we

focus on a single-stage single-product system in order to maintain

the paper’s focus on insights into the different dual prices

obtained by the two models.

Our results show that the CF model explicitly captures the

nonlinear relationships between performance measures and

system workload, providing a more accurate representation of

actual capabilities of the production system. We derive

closed-form expressions for the dual prices of capacity and

demand and illustrate qualitative differences in both production

plans and dual prices between those from the CF model and the

conventional LP model with numerical examples. We conclude

the paper with a summary and some directions for future work.

2. Previous related work

The use of mathematical programming models for production

planning has a long history, dating back to the seminal work of

Modigliani and Hohn (1955). The majority of these are LP

formulations, where the planning horizon is divided into discrete

time periods and two principal sets of constraints are used to

384

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

represent the operation of the production system. One set of

constraints represents conservation of material flow into and out

of finished goods inventories (FGIs) at the end of each planning

period, assuming that production and demand rates are uniform

within each period. A second family of constraints limits the total

amount of work a resource, such as a machine, can perform in a

period. A wide range of such models has been presented in the

literature over the years (e.g., Hackman and Leachman, 1989;

Johnson and Montgomery, 1974; Voss and Woodruff, 2003).

However, these LP models have a number of drawbacks. Since

they assume all production rates are constant in a planning

period, they do not model WIP at all, and do not assign it a cost in

the objective function. Hence they allow resources to change their

production rates with complete flexibility as long as utilization is

less than one. For the same reason, when backlogging is not

allowed, these models will hold FGI only when demand exceeds

resource capacity in some period. Although queuing models and

industrial experience suggest that when capacity is fully utilized,

very high cycle times and WIP levels will result, the LP models

assume that resources can maintain a fixed cycle time independent of utilization. Finally, they will only permit nonzero dual

prices only for capacity constraints when that constraint is tight

at optimality, implying a utilization level of one for that resource

during that period.

The marginal or dual price of a production resource with limited

capacity, which represents the potential change in objective function

as additional capacity becomes available, is of interest in several

situations. One example is in short-term scheduling and dispatching,

where a number of authors have proposed dispatching rules based

on cost–benefit ratios, where the value of processing a job at a given

time is contrasted with the marginal price of the resource consumed

by scheduling it at that time (e.g., Morton et al., 1988). Yet another

related area is in the estimation of setup costs. It can be argued that

many of the costs related to setup changes, such as manpower, are

fixed relative to the decision whether or not to set up at a particular

point in time. In many cases, the principal cost of the setup is the lost

revenue due to output not being produced during the setup. If

utilization is low and demand can still be met when the setup is

performed, the lost revenue, and thus cost of the setup, will be zero.

However, if utilization is high the opportunity cost of a long setup

can be quite substantial. Another potential use of the marginal price

of capacity has been suggested in the accounting literature

(e.g., Kaplan and Thompson, 1971), where overhead costs are

allocated among products based on their consumption of capacity at

key resources.

The elegant duality theory associated with LPs (e.g., Bazaraa

et al., 2004) directly yields the marginal price of a capacitated

resource in a planning period as the optimal value of the dual

variable associated with that capacity constraint. However, by the

LP optimality conditions, a dual variable will only take a nonzero

dual value when the associated capacity constraint is tight at

optimality, i.e. when the resource utilization is equal to one. This

suggests that there is no benefit to the objective function from

adding capacity to resources that are not fully utilized. However,

this contradicts observations from industrial practice, simulation models, and queuing models of manufacturing systems

(e.g., Buzacott and Shanthikumar, 1993; Hopp and Spearman,

2001). All these suggest that performance measures of a

production system, especially WIP levels and cycle times, increase

nonlinearly with resource utilization, and that significant

increases in these quantities can be observed even at utilization levels substantially below one. Since many manufacturing

resources such as machines exhibit queuing behavior, this inconsistency between the production planning models used for

capacity allocation over time and the queuing models representing the behavior of resources is troubling.

The queuing results would appear to suggest that even at

utilization levels below one, adding capacity to the system ought

to result in improved performance due to reduced WIP levels and

cycle times under at least some conditions. This, in turn, implies

that we ought to observe nonzero dual prices on capacity

constraints at utilization levels less than one. A number of

authors (Graves, 1986; Karmarkar, 1989; Srinivasan et al., 1988)

have proposed mathematical programming models for resource

allocation that exhibit such behavior.

Several alternative approaches to estimating the dual prices of

production resources have been proposed in the literature.

Morton et al. (1988) propose a dispatching rule for job shop

scheduling based on a cost–benefit ratio, where the cost of a unit

of machine time at a particular point in time is estimated as the

increase in tardiness penalties caused by a differential delay in

machine availability. The latter estimates are obtained by

simulating the shop to the end of the current busy period, the

time at which the machine will be idle. Roundy et al. (1991)

propose an alternative approach, where an aggregate planning

model is used to estimate costs of performing a particular

operation at a particular point in time; the dispatching module

then dispatches jobs based on these costs. The costs are estimated

as values of the Lagrange multipliers associated with machine

capacity constraints in each time interval. Hoitomt et al. (1993)

present a similar formulation for job shop scheduling, where time

intervals are reduced in length, giving a dual price for each

individual time unit. These approaches focus on estimating the

dual price of capacity, noting that the dual price of a resource will

depend on the state of the system at that point in time.

Another approach to estimating the dual price of capacity has

been through queuing models, yielding an average price over a

long period in which the system is in steady state. Banker et al.

(1986) use an M/G/1 queuing model of a production system with

lot sizing to examine the effects of adding new products to an

existing facility, focusing on the costs of holding WIP. They study

the marginal benefits of adding capacity and show that it is

beneficial to add capacity at all levels of utilization, but that the

benefit decreases as utilization decreases. This, in our context,

corresponds to a dual price of capacity that increases with

utilization. Morton and Singh (1988) approach the same problem

using a variation of the busy period methodology from Morton

et al. (1988), and show that under steady state assumptions they

obtain the same dual prices for capacity as Banker et al. (1986).

It is important to bear in mind that the nature of a dual price will

depend on the objective function or performance measure of the

model from which it is derived. The short-term dispatching and

scheduling approaches outlined above, as well as the steady-state

queuing models, do not consider the effects of FGI that is held due to

insufficient capacity to meet demand in a specific time period. The

LP models of production planning, on the other hand, explicitly

consider the possibility of meeting future demand by building FGI in

earlier periods, but do not consider the effects of resource utilization

on queue lengths within the production system. Clearly both types

of costs, those due to WIP accumulating in the system as well as FGI

that is held to address temporary capacity shortfalls, are relevant,

and hence a model that integrates both would appear to be

desirable. In this paper we explore this issue for a single-product

single-stage production-inventory system, which has not been done

before to the best of our knowledge.

3. Classical LP formulation

In this section we present the classical LP production planning

model we use as a benchmark. For simplicity of exposition and

without loss of generality, we shall assume that all production

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

initiated in a planning period can be completed in that period; for

a treatment of the case where cycle times may exceed one period

see Hackman and Leachman (1989). We shall adopt the simple

objective function of minimizing the total production and

inventory holding cost over a planning horizon of T periods. We

shall denote the demand in period t by Dt, and the available

number of machine hours in period t by Ct. Since we have only a

single product, we assume without loss of generality that each

unit of the product requires 1 h of machine time. If we define Xt to

be the amount of production in period t and It to be the amount of

FGI on hand at the end of period t, we obtain the following

well-known formulation (e.g., Johnson and Montgomery, 1974):

T

X

minimize

ðpt Xt þht It Þ

ð1Þ

t¼1

subject to

Xt r Ct

8t

ð3Þ

8t

ð4Þ

where pt and ht denote the unit cost coefficients of production and

FGI holding. We can rewrite this formulation to eliminate the

inventory variables by noting that

It ¼ I0 þ

t

X

t

X

Xt t¼1

Dt

t¼1

where I0 is the ending inventory at time 0. Making this

substitution for It in the objective function and discarding

constants that are independent of the decision variables yields

the following aggregate formulation:

"

!#

T

T

X

X

Xt pt þ

ht

minimize

ð5Þ

t¼t

t¼1

subject to

t

X

Xt Z

t

X

Dt I0

t¼1

t¼1

Xt r Ct

8t

Xt Z 0

8t

CFs, proposed by Graves (1986), Karmarkar (1989), and

Srinivasan et al. (1988), express the expected throughput of a

capacitated resource over a given period of time as a function of

workload of the resource over that period, which, in turn, is

defined by the amount of work available for the resource to

process in that period. For now we shall use the term ‘‘WIP’’ and

the generic variable W to denote any reasonable measure of the

WIP inventory level, whether carried over from a previous period

or released during the current one.

To motivate the use of a nonlinear CF, it is helpful to begin with

a single resource that can be modelled as a G/G/1 queuing system

in steady state. The expected number in system, or, equivalently,

the expected WIP, for a single server is given by Medhi (1991) as

ðst Þ

ðca2 þcs2 Þ r2

þr

2

ð1rÞ

ð9Þ

ð2Þ

8t

Xt ,It Z0

4. Clearing function formulation

W¼

It ¼ It1 þ Xt Dt

385

8t

ðgt Þ

ð6Þ

ð7Þ

ð8Þ

The absolute value of the dual price of constraint (7)

represents the rate of reduction in the objective function with

added capacity in period t.

Some observations on this model are in order. The model does

not represent WIP in any form; material is released to production

and emerges into FGI in the same period. In addition, and of more

interest to this paper, by the complementary slackness conditions

for LP optimality, capacity will only have a nonzero dual price in a

given period if constraint (7) is satisfied at equality. As Banker

et al. (1986), Srinivasan et al. (1988), and others have pointed out,

this is not an accurate representation of the actual situation for

resources governed by queuing behavior, and arises from the LP

model’s failure to represent WIP correctly. As pointed out by

Missbauer and Uzsoy (in press), this problem remains even when

lead times in excess of one period are modelled; in period t,

only the portion of the WIP that was released in period t–L is

available for processing, where L is an exogenous parameter. The

formulation in the following section addresses these issues.

where ca and cs denote the coefficients of variation of interarrival

and service times, respectively, and r is the utilization of the

server. Setting c ¼ ðca2 þ cs2 Þ/2 and rearranging (9) we obtain a

quadratic in W, whose positive root yields the desired r value.

Solving for r with c 41, we obtain

qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

ðW þ1Þ2 þ 4Wðc2 1ÞðW þ 1Þ

ð10Þ

r¼

2ðc2 1Þ

which has the desired concave form. When 0rco1, the other root

of the quadratic will always give positive values for r. When c¼1,

(9) simplifies to yield r ¼W/(1+W) again of the desired concave

form. If we use utilization as a surrogate for output, we see that for a

fixed c value, utilization, and hence throughput, increases with WIP

but at a declining rate. Utilization, and hence output, decreases with

c due to variability in service and arrival rates.

Several authors discuss the relationship between throughput and

WIP levels in the context of queuing analysis, where the quantities

studied are long-run steady-state expected throughput and WIP

levels. Agnew (1976) studies this type of behavior in the context of

optimal control policies. Spearman (1991) presents an analytic

congestion model for closed production systems with increasing

failure rate processing time distributions that describes the relationship between throughput and WIP. Hopp and Spearman (2001)

provide a number of illustrations of CFs for a variety of systems.

Srinivasan et al. (1988) derive the CF for a closed queuing network

with a product form solution. In addition to the queuing approaches

outlined above, clearing functions can also be estimated using

industrial data, or data obtained from a simulation model of the

system under study, as suggested by Karmarkar (1989), Asmundsson et al. (2006), and Srinivasan et al. (1988). These methods involve

collecting observations of average resource workload and throughput and then fitting a clearing function to these data.

Different methods of generating CFs for optimization models

have different advantages and disadvantages. A CF estimated by a

steady-state queuing model assumes at least approximate steady

state behavior of the queue being modelled in a planning period,

which may be problematic in systems with long cycle times at

individual resources. On the other hand, while CF estimation

through simulation and industrial data do not require steady state

assumptions, they are only as valid as the simulation model or data

they are derived from and will require updating as products or

processes change. The development of methods for deriving and

validating non-steady state clearing functions remains an active area

of research (Asmundsson et al., 2009; Selc- uk et al., 2007; Riaño,

2003). An extensive discussion of the issues related to clearing

functions and their use in production planning models is given by

Pahl et al. (2005) and Missbauer and Uzsoy (in press). In this paper

386

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

we shall assume that an appropriate clearing function can be

obtained using techniques suggested in these references, and focus

on the behavior of the resulting planning models.

Our starting point is the single-product single-stage model of

Karmarkar (1989). Let us define the following decision variables:

Xt ¼ number of units of the product produced in period t,

Rt ¼ number of units of the product released into the stage at

the beginning of period t,

Wt ¼number of units of the product in work in process (WIP)

inventory at the end of period t,

It ¼ number of units of the product in finished goods inventory

(FGI) at the end of period t.

Let f(.) denote the clearing function and Dt the demand for the

product (in units) in period t. Then Karmarkar’s formulation is as

follows:

minimize

T

X

Zt ¼ 1

8t

ð17Þ

Although these additional variables and constraints may seem

redundant, they help us to better characterize the dual prices of

capacity in the CF formulation. Following Asmundsson et al.

(2006) and Missbauer (2002), we approximate the CF f(.) using

outer linearization and incorporate (16) and (17) into our

formulation, yielding the following LP:

T

X

minimize

ðrt Rt þ wt Wt þ pt Xt þ ht It Þ

ð18Þ

t¼1

subject to

ðrt Rt þwt Wt þ pt Xt þht It Þ

ð11Þ

t¼1

subject to

Wt ¼ Wt1 þ Rt Xt

It ¼ It1 þXt Dt

Wt ¼ Wt1 þRt Xt

8t

ð12Þ

It ¼ It1 þ Xt Dt

8t

ð13Þ

Xt rf ðWt1 þRt Þ

8t

ð14Þ

Rt ,Wt ,Xt ,It Z 0

In a multi-product formulation, these variables are defined for

each product and period to allocate the available output of a

production resource among different products that use it. By

definition, the summation of these variables over all products for

a given resource should be equal to 1. Since we have a single

product, we add one additional constraint to our formulation:

ð15Þ

where rt, wt, pt, and ht denote the unit cost coefficients of raw material

releases, WIP holding, production, and FGI holding, respectively, and T

is the final period in the planning horizon. We follow Karmarkar in

writing our CF as a function of the sum Wt 1 +Rt, the resource load for

period t, or, in other words, the total amount of work that becomes

available for processing during the period. Since the formulation

distinguishes between WIP and FGI, flow conservation constraints

(12) and (13) are required for both quantities, which serve distinct

purposes. In periods when demand cannot be satisfied due to limited

capacity, it can be met with FGI carried over from previous periods.

WIP, on the other hand, accumulates in front of the resources as jobs

in queue and in process. This approach differs from traditional LP

models since it links the expected throughput of the resource in

period t to the resource load (incoming WIP and new releases) in that

period.

The solution to the CF formulation provides the decision maker

with a time-phased release plan, i.e. how many new jobs to

release to the production resource in each period, specified by the

decision variables Rt. We assume that job releases are under

complete control of the decision maker and that raw material

availability is not a constraint. This allows us to study the dual

prices of capacity in isolation from the effects of external factors,

allowing more intuitive results to be obtained. Another contrast to

the LP formulations such as those of Hackman and Leachman

(1989) is that lead times do not appear in the formulation;

releases and lead times are jointly optimized, allowing lead times

to vary over the planning horizon.

At this point, in order to obtain a more complete characterization

of the dual prices, we introduce an additional set of decision

variables to our formulation, motivated by the multi-product CF

model of Asmundsson et al. (2006). We define

Zt ¼fraction of the maximum output in period t, as defined by

the clearing function, allocated to the product,

and modify (14) to include these decision variables as follows:

Xt rZt f ðWt1 þ Rt Þ

8t

ð16Þ

ð19Þ

8t

ð20Þ

Xt r ac ðWt1 þ Rt Þ þ Zt bc 8c; t

ð21Þ

Zt ¼ 1

ð22Þ

8t

Rt ,Wt ,Xt ,It ,Zt Z 0

8t

8t

8t

ð23Þ

where ac is the slope and bc the intercept of segment c of the

piecewise linearized CF. The first linear segment (c¼1) will have a

slope of one (a1 ¼1) since at low utilization all work in the system

can be completed within a planning period, and an intercept of

zero (b1 ¼0), since production cannot take place without some

WIP being present. The last linear segment (c¼n) will have a slope

of zero (an ¼ 0) since increasing the load of the resource will

not increase output. To capture the concavity of the clearing

function, successive segments will have strictly increasing intercepts ðb1 o b2 o b3 o o bn Þ and strictly decreasing slopes

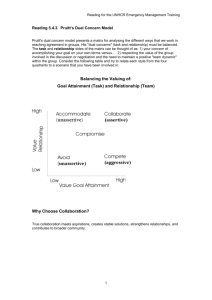

ða1 4 a2 4 a3 4 4 an Þ as seen in Fig. 1.

Eliminating the Wt and It variables in a similar fashion to that

used for the LP model in the previous section, making appropriate

substitutions in the objective function and capacity constraints,

and defining boundary conditions, we obtain the following

formulation that will be the basis of our analysis:

! #

"

!

T

T

T

X

X

X

minimize

rt þ

wt Rt þ pt þ

ðht wt Þ Xt

ð24Þ

t¼t

t¼1

t¼t

subject to

t

X

t¼1

t

X

Xt Z

Dt I0

8t

ðgt Þ

ð25Þ

t¼1

t

X

Xt þ

t¼1

t

X

Rt Z W0

8t

ðGt Þ

ð26Þ

t¼1

Output

(Xt)

2

n

1

n

f(x)

2

1

Resource Load

(Wt-1 + Rt)

Fig. 1. A typical CF and outer linearized segments.

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

t1

X

ac

Xt Xt þ ac

t¼1

t

X

Rt Z ac W0 Zt bc

ðsct Þ

ð27Þ

t¼1

X1 þ ac R1 Z ac W0 Z1 bc

Zt ¼ 1

8c,t a1

8t

Rt ,Xt ,Zt Z 0

ðsc1 Þ

8c

ð28Þ

ðlt Þ

ð29Þ

8t

ð30Þ

where the dual prices associated with each constraint set are

given in parentheses. We now proceed to analyze the dual of this

formulation.

by K ¼ fs, s þ1, s þ2, . . . ,s0 g such that Ws 1 ¼0, Wt 40 for all tAK,

and Ws0 + 1 ¼0.

We first note, by the complementary slackness condition of LP

optimality, that Wt 40 implies that Gt ¼0 for all tAK in the

optimal dual solution. Assume that for all tAK we have Rt 40,

which in turn implies that Xt 40, i.e. if we release any work in

period t, then there must be some production in that period, since

otherwise we can release the work in a later period and save the

WIP holding cost. Under these assumptions, constraints (32) and

(34) (and constraint (33), if TAK) are satisfied as equalities for all

tAK, i.e.

T

X

T

X

gt t¼t

¼ pt þ

ð31Þ

gt t¼t

T

X

c

ðht wt Þ

t ¼ tþ1 c

8t aT

ðXt Þ

ð32Þ

X

scT r pT þ hT wT ðXT Þ

ð33Þ

c

T

X

Gt þ

t¼t

lt þ

X

T

X

t¼t c

t¼t

ac sct rrt þ

c

b sct r0 8t ðZt Þ

wt

8t

ðRt Þ

ð34Þ

lt free 8t

ð38Þ

T X

X

T

X

t¼t c

t¼t

wt

8t A K

ð39Þ

ð40Þ

We now use these relationships to derive expressions for the

optimal values of sct, gt, and lt in a congested interval. For brevity

P

let Ft ¼ cacsct and rewrite (39) as

T

X

T

X

Gt þ

Ft ¼ rt þ

t¼t

T

X

wt

8t A K

ð41Þ

t¼t

Writing (41) for successive periods from s0 to s and solving

recursively yields

8t A K\fs0 g

Ft ¼ ðrt rt þ 1 Þ þ wt

ð35Þ

Under time stationary

pt ¼ p 8tÞ this simplifies to

ð36Þ

Ft ¼ w 8t A K\fs0 g

ð37Þ

To derive the values of gt, we return to (38) with the additional

assumption that Rs0 + 1 40. We can then write (39) for period t+ 1

and substitute that in (38) to obtain

!

T

T

T

T

X

X

X

X

X

gt Gt sct rt þ 1 þ

wt Gt

c

gt , Gt , sct Z0 8t

8t A K

ac sct ¼ rt þ

Gt þ

t ¼ s0 þ 1

T X

X

ðht wt Þ

ac sct

t ¼ tþ1 c

c

t¼t

gT GT c

If TAK the corresponding expression for t ¼T is

X

gT scT r pT þhT wT

T

X

X

X

Gt sct ac sct r pt

T

X

t¼t

þ

T

X

t ¼ s0 þ 1

subject to

T

X

T

X

T

X

X

sct t¼t

c

t¼1

t¼1

X

Gt t ¼ s0 þ 1

5. Analysis of the CF formulation

The dual of this formulation (24)–(30) is given by

"

!

#

T

t

X

X

X

minimize

Dt I0 gt W0 Gt ac W0 sct þ lt

387

Note that any production plan will consist of congested periods

where Wt 40, non-congested periods where Wt ¼0 and Xt 40, and

idle periods where Wt ¼0 and Xt ¼0. Since there is no work release,

production, or WIP in idle periods, they are not of great interest. In

non-congested periods, production takes place but no WIP is

carried from one period to the other. This is possible if the system

operates at low utilization such that all work released into the

system is processed in the same period, implying that the first

segment (c ¼1) of the CF is tight (see Fig. 1). In congested periods,

on the other hand, all work available to the resource cannot be

completed in one period due to congestion, and some is carried

over to the next period as WIP. This means the system is operating

at higher utilization and a segment of the CF with index c 41 is

tight. (In certain extreme cases, where demand falls very sharply

in a short period of time, it is possible to have a congested period t

with Xt ¼0 due to the presence of high WIP levels that was needed

to meet high demand in earlier periods but for which demand no

longer exists. In the remainder of this paper we shall assume

demand is sufficiently regular to avoid this extreme behavior.)

We will assume W0 ¼0 throughout our analysis since feasibility can be ensured by an appropriate I0. As stated earlier, our

objective is to explore the behavior of dual prices in the context

of this LP model. To this end, we first examine the behavior of

the system in a congested interval, defined as a collection of

consecutive congested periods, starting with a period s and

ending with a period s0 4s. We denote such a congested interval

t¼t

¼ pt þ

ðrt ¼ r, wt ¼ w, ht ¼ h, and

ð42Þ

c

t ¼ s0 þ 1

T

X

costs

ðht wt Þ

t ¼ tþ1

t ¼ s0 þ 1

8t A K

t¼t

T

X

t¼t

gt ¼

X

T

X

c

t¼t

sct þ pt þ rt þ 1 wt þ

ht

8t A K

ð43Þ

Following the same recursive approach for (43) as we used for

(41) we obtain

X

X

gt ¼ ht þ

sct sc,ðt þ 1Þ þ ðpt pt þ 1 Þðwt wt þ 1 Þ

c

c

þðrt þ 1 rt þ 2 Þ

8t A K\fs0 g

which under time stationary costs simplifies to

X

X

gt ¼ h þ

sct sc,ðt þ 1Þ 8t A K\fs0 g

c

ð44Þ

c

We now concentrate on (42) and (44). To obtain more general

forms of these relationships, we note that in an optimal solution,

for a given period t, no more than two segments of the CF can be

tight. For the time being, without loss of generality, let two

segments c*(t)oc*(t)+ 1 of the CF be tight in the optimal solution

for a given period t. By complementary slackness, the dual prices

388

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

of segments c that are not tight in an optimal solution in period t

must be equal to zero, i.e. sct ¼ 0 8c ac ðtÞ and c ac ðtÞ þ 1.

Hence

X

Ft ¼

ac sct ¼ ac ðtÞ sc ðtÞ,t þ ac ðtÞ þ 1 sc ðtÞ þ 1,t

ð45Þ

c

X

sct ¼ sc ðtÞ,t þ sc ðtÞ þ 1,t

ð46Þ

c

If we also assume that there are two tight segments of the CF

in period t + 1 we obtain the following general forms of (42) and

(44):

Ft ¼ w ¼ ac ðtÞ sc ðtÞ,t þ ac ðtÞ þ 1 sc ðtÞ þ 1,t

ð47Þ

gt ¼ h þ½ðsc ðtÞ,t þ sc ðtÞ þ 1,t Þðsc ðt þ 1Þ,t þ 1 þ sc ðt þ 1Þ þ 1,t þ 1 Þ

ð48Þ

Recall that (47) and (48) both hold for a period t such that

t A K\fs0 g, i.e. with Wt 40 by definition and with the assumption

Rt 40, which implies Xt 40. Expression (48) also requires

Rs0 + 1 40.

If we further assume positive FGI carried over from period t to

period t+ 1, i.e. It 40, by complementary slackness applied to (25),

we will have gt ¼ 0. Thus (48) will reduce to

h ¼ ðsc ðt þ 1Þ,t þ 1 þ sc ðt þ 1Þ þ 1,t þ 1 Þðsc ðtÞ,t þ sc ðtÞ þ 1,t Þ

t A K\fs0 g

ð49Þ

This implies that as long as work is released and FGI is carried

in consecutive periods in a congested interval, the sum of the

nonzero dual prices of capacity increases by h for each

consecutive time period the system holds FGI.

It is clear that sct is related to the dual price of capacity.

However, the fact that two segments of the CF may be tight in a

given period renders an intuitive expression hard to obtain. We

now argue that the dual variables lt are a more informative

estimate of the dual price of capacity in our CF formulation. An

optimal solution to our CF formulation will have at most two

segments of the CF tight, yielding two different sct values for a

given period. While these values are governed by (42), they do not

provide a single number that can be used as the dual price of

capacity. However, the extra decision variables Zt in Eq. (16)

multiply the output corresponding to the resource load; therefore

an arbitrarily small increase in the right hand side of (29) will

increase our capacity as well for all linear segments related to that

period. Therefore, the dual variable associated with (29), lt,

provides one unique number, which represents the dual price of

capacity in a given period for the CF model. To derive values for lt,

note that in any given optimal solution we need to have Zt ¼1.

Therefore, by complementary slackness applied to (35) we have

X c

ð50Þ

b sct ¼ lt

c

This expression defines one dual price of capacity for each

period in a clearly structured fashion that incorporates all positive

sct values. An added advantage of (50) is that it does not require

any assumptions and is valid for any given optimum solution.

To sum up our findings so far, the dual price of capacity in a

congested interval is jointly defined by expressions (47), (49), and

(50). On reflection, this is intuitive—the dual prices depend on the

shape of the clearing function embodied in the slopes ac and

intercepts bc of the linear segments, the holding cost w of WIP,

and the holding cost h of FGI. Suppose we have a demand spike in

some period that exceeds the capacity of the system. Since

backlogging is not allowed, both the CF and the LP models will

produce earlier and carry inventory in the periods prior to the

spike. If the system operates at high enough utilization to create

a congested interval, our assumptions for (49) hold and the

marginal benefit of an additional unit of capacity in a period

increases. Additional capacity becomes more and more desirable,

i.e. has a higher dual price, as we get closer to the demand spike;

an additional unit of capacity later in the congested period will

save us from having to hold inventory in the first period of the

congested interval and carry it until the current period.

In contrast to the LP model, however, the decision to hold

FGI in the CF model is linked to the holding cost of WIP. The LP

model will not hold FGI until capacity in a period is fully utilized

since WIP costs are not modelled. In the CF model, however, the

amount of WIP required to maintain high levels of utilization will

eventually require very high levels of additional WIP for very little

increase in output. In this situation, eventually the cost of

additional WIP will exceed the cost of carrying FGI for several

periods. Thus the CF model may hold FGI at utilization levels less

than one.

We now examine the behavior of the system in non-congested

periods.

6. Non-congested periods

So far, we have studied congested periods, where we have

Wt 4 0 and Gt ¼ 0. For completeness, we will now consider noncongested periods (see Table 1), where the system works just in

time—utilization is low, so work is released and processed into

output in the same period without WIP being carried between

periods.

Using (21) for simplicity of exposition, we consider a noncongested period with demand dt. Since backlogging is not

allowed, Xt ¼dt. By the definition of a non-congested period, only

the first segment of the CF is tight, yielding

Xt rWt1 þ Rt

8t=

2K

ð51Þ

and an optimal solution will give Wt ¼Wt 1 ¼ It ¼0 and

Rt ¼Rt +Wt 1 ¼Xt ¼dt. Hence this is a highly degenerate solution,

where all four constraints (25), (26), (27), and (29) are tight. In

this situation the critical binding constraint is (25), the demand

constraint, since until demand increases to the point that the

second segment of the CF becomes tight, there is no benefit to

additional capacity or releases. This fact is clearly reflected in

(50)—since in a non-congested period only first segment of the

CF is tight we have sct ¼ 0; 8c a1 and b1 ¼ 0. This clearly

implies lt ¼0. Therefore, the non-congested periods do not yield

any interesting insight on the dual price of capacity, following the

behavior of the LP model when demand is below capacity and no

inventory is required in the future.

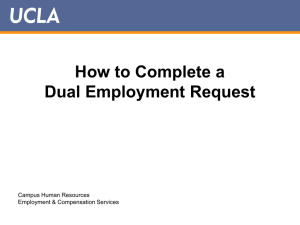

7. Numerical examples

In order to illustrate the differences in the dual information

obtained from the LP and the CF models under different

conditions, we examine a numerical example with one product,

one resource, and a planning horizon of T¼50 periods. We

consider the demand scenario shown in Fig. 2, where demand

remains below the theoretical capacity in the first 30 periods, and

then increases to exceed capacity several times in the latter part

Table 1

Different cases and corresponding variable relationships.

Idle periods

Non-congested periods

Congested periods

Utilization

Wt

Xt

Rt

It

0

Low

High

¼0

¼0

40

¼0

40

40

¼0

40

Z0

¼0

40

Z0

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

Fig. 2. Demand data for numerical examples.

389

Fig. 4. Dual prices from Scenarios 1 and 2.

Table 2

Parameters of linear functions approximating CFs.

CF segment c

1

2

3

4

5

6

7

8

Scenario 2

Scenario 3

Scenario 4

ac

bc

ac

bc

ac

bc

1

0.5

0.1

0

0

10

12

15

1

0.44

0.11

0

0

1.67

6.67

15

1

0.74

0.51

0.33

0.18

0.08

0.02

0

0

0.31

1.23

2.76

4.9

7.65

11.02

15

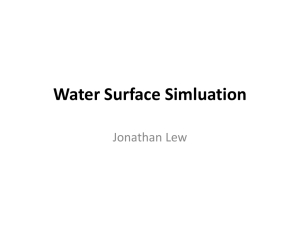

Fig. 3. CFs used in numerical examples.

of the horizon. In all cases we assume costs and the CF are

constant over time.

We solve four different scenarios and compare the dual price

of capacity obtained from each. All scenarios assume the same

demand pattern and theoretical capacity of ct ¼15 units per

period, but differ in the way capacity constraints are implemented. In Scenario 1 we make use of the classical LP formulation with

a fixed capacity of 15 units as seen in Fig. 2. In the remaining three

scenarios we use the CF formulation with different settings.

Scenario 2 uses a CF with 4 segments, whereas Scenario 3 utilizes

the same number of segments to represent a more congested

resource (a CF that is more gradual). Scenario 4 uses the same CF

as Scenario 3, but uses 8 linear segments, making our outer

linearization a more exact representation of the underlying

nonlinear concave function. Table 2 lists the CF parameters and

Fig. 3 illustrates the three different CFs used.

We solved each scenario using the ILOG OPL (2007) environment. The dual prices obtained are plotted in Figs. 4 and 5. For the

classical LP model, we report st and for CF models we report lt.

Since in the first half of the horizon the demand never reaches

the maximum possible output in a period, the conventional LP

model in Scenario 1 yields dual prices of zero for capacity in all

Fig. 5. Dual prices from Scenarios 3 and 4.

periods in this portion of the horizon. In contrast, the dual prices

yielded by all CF model Scenarios 1–3 are positive whenever

production takes place, and increase or decrease based on

resource utilization even though utilization is well below one.

This suggests that at utilization levels below one, the conventional

LP representation of capacity provides limited dual information.

In Fig. 4 we observe that during periods 27–39 and 40–47,

when utilization is high, CF dual prices are consistently higher

than those from the LP model when FGI is present. In these

periods the capacity constraint of the LP model is tight, and in

Scenario 2, we use the dual prices corresponding to the segment

c¼2 being tight. It is interesting, however, that the dual prices

from the two scenarios coincide quite closely. At first sight, this

appears anomalous; at high utilization we would expect long

queues to form, and given the ability of CF models to capture this

effect, the dual price of capacity to be considerably higher in CF

models. In fact, a careful investigation of Fig. 5 reveals that as we

add more segments to the piecewise linearization (Scenario 3

versus Scenario 4) the CF model becomes more sensitive to the

queuing behavior and dual prices start to climb. These observations suggest that Scenario 2 underestimates the dual price of

capacity in regions of high utilization due to the piecewise linear

approximation and limited number of segments.

Examining the output from the first and second scenarios in

Fig. 6 we see that the LP model runs longer at full capacity, while

the CF model elects to hold FGI and run below full capacity in

periods 28–33 and 40–48. This latter behavior is frequently

observed in real systems, where full utilization is never achieved

but inventories are frequently present.

These observations suggest that in order to obtain more

accurate dual prices, the piecewise linearization of the CF must be

more detailed in the region corresponding to higher utilization

levels. For intuition, we can consider expression (47) for the dual

prices when a single linear segment is tight at optimality. Since

the slope ac ðtÞ of the clearing function is in the denominator,

small changes in this parameter, especially as it approaches zero

with higher values of Wt 1 +Rt, will lead to large changes in the

390

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

Fig. 6. Production (Xt) comparison of Scenarios 1 and 2.

dual price. Hence the use of a limited number of linear segments

will lead to underestimation of the dual price of capacity at high

utilization levels, despite the fact that previous studies have not

shown this to be a major issue when CF models are used purely

for production planning.

8. Managerial insights

Our results suggest that in congested periods, the dual price of

capacity in the CF model depends on the shape of the CF and the

holding costs of WIP and FGI in a tightly coupled manner.

The shape of the CF in our model embodies the characteristics of

the production resource under consideration, effectively determining how much WIP is required for a given output level.

Clearly, the dual price of capacity increases as the resource

utilization increases, since both b and 1/a increase with utilization. Moreover, the dual price of capacity increases linearly when

FGI is held in congested periods. In non-congested periods, where

resource utilization is low, the solution is degenerate, and the CF

model does not yield any interesting insights on dual behavior.

Relative to the body of work summarized earlier that utilizes

dual prices of capacity in decision-making, the main feature of our

paper is to point out the deficiencies of traditional LP models in

estimating the value of capacity. We further show that CF

formulations provide richer dual information that is consistent

with queuing models and industrial experience. Therefore,

decision makers should be aware of the problems associated

with certain production planning models that do not capture

queuing effects. This is of particular interest in applications where

dual prices of resources may be informative, such as estimation of

setup costs, dispatching, and overhead allocation mentioned

earlier.

9. Conclusions

We have presented a comparison of the dual prices for

capacity yielded by a conventional LP model and a model based

on clearing functions under some simplifying assumptions. The

dual prices generated by the CF model have the desirable property

that positive dual prices are obtained at utilization levels less than

one, while the conventional model yields zero prices. On the other

hand, the use of piecewise linear approximation to the clearing

function can result in underestimation of true prices at high

utilization levels. Our results also show that the CF model exhibits

more realistic behavior than the classical LP model, holding FGI at

utilization levels of less than one.

The results in this paper show that the CF model effectively

addresses several of the conceptual difficulties associated

with classical LP models of production facilities. Extensive

experimental studies in multi-stage, multi-product environments,

i.e. Asmundsson et al. (2006) and Missbauer (2002), have shown

that when the CF is fitted appropriately, the CF models yield

significantly more realistic results than classical LP models. In

more complex production-inventory systems with multiple

stages and multiple products, multiple interactions between

WIP, demand, CF shape, and finished goods inventories between

production stages render concise analytical expressions for dual

prices hard to obtain, although numerical values of dual prices are

straightforward. A systematic study of the relationships between

prices obtained from our CF model and those obtained by other

methods, such as the queuing-based approaches of Banker et al.

(1986) and Morton and Singh (1988), is also an interesting

direction for future work.

Acknowledgements

The research of Reha Uzsoy was partially supported by the

National Science Foundation under Grant number DMI-0559136

and a research grant from the Intel Research Council. The research

of Yahya Fathi was partially supported by the National Science

Foundation under Grant number DMI-0321635.

References

Agnew, C., 1976. Dynamic modeling and control of some congestion prone

systems. Operations Research 24 (3), 400–419.

Asmundsson, J.M., Rardin, R.L., Turkseven, C.H., Uzsoy, R., 2009. Production

planning models with resources subject to congestion. Naval Research

Logistics 56, 142–157.

Asmundsson, J.M., Rardin, R.L., Uzsoy, R., 2006. Tractable nonlinear production

planning models for semiconductor wafer fabrication facilities. IEEE Transactions on Semiconductor Manufacturing 19, 95–111.

Banker, R.D., Datar, S., Kekre, S., 1986. Relevant costs, congestion and stochasticity

in production environments. Journal of Accounting and Economics 10,

171–197.

Bazaraa, M.S., Jarvis, J., Sherali, H.D., 2004. Linear Programming and Network

Flows. John Wiley, New York.

Buzacott, J.A., Shanthikumar, J.G., 1993. Stochastic Models of Manufacturing

Systems. Prentice-Hall, Englewood Cliffs, NJ.

Graves, S.C., 1986. A tactical planning model for a job shop. Operations Research

34, 533–552.

Hackman, S.T., Leachman, R.C., 1989. A general framework for modeling

production. Management Science 35, 478–495.

Hoitomt, D., Luh, P.B., Pattipati, K.R., 1993. A practical approach to job shop

scheduling problems. IEEE Transactions on Robotics and Automation 9 (1),

1–13.

Hopp, W.J., Spearman, M.L., 2001. Factory Physics: Foundations of Manufacturing

Management. Irwin/McGraw-Hill, Boston.

ILOG, 2007. ILOG OPL-CPLEX Development System. Retrieved January 12, 2008

from /http://www.ilog.com/products/oplstudio/S.

Johnson, L.A., Montgomery, D.C., 1974. Operations Research in Production

Planning, Scheduling and Inventory Control. John Wiley, New York.

Kaplan, R.S., Thompson, G.L., 1971. Overhead allocation via mathematical

programming models. The Accounting Review 46 (2), 352–364.

Karmarkar, U.S., 1989. Capacity loading and release planning with Work-inProgress (WIP) and lead-times. Journal of Manufacturing and Operations

Management 2, 105–123.

Medhi, J., 1991. Stochastic Models in Queuing Theory. Academic Press.

Missbauer, H., 2002. Aggregate order release planning for time-varying demand.

International Journal of Production Research 40, 688–718.

Missbauer, H., Uzsoy, R. Optimization models for production planning. In: Kempf,

K.G., Keskinocak, P.,Uzsoy, R. (Eds.), Planning Production and Inventories in the

Extended Enterprise: A State of the Art Handbook. Springer, Norwell, MA, in

press.

Modigliani, F., Hohn, F.E., 1955. Production planning over time and the nature of

the expectation and planning horizon. Econometrica 23 (1), 46–66.

Morton, T.E., Lawrence, S.R., Rajagopalan, S., Kekre, S., 1988. SCHED-STAR: a pricebased shop scheduling module. Journal of Manufacturing and Operations

Management 1, 131–181.

Morton, T.E., Singh, M.R., 1988. Implicit costs and prices for resources with busy

periods. Journal of Manufacturing and Operations Management 1,

305–332.

Pahl, J., Voss, S., Woodruff, D.L., 2005. Production planning with load dependent

lead times. 4OR: A Quarterly Journal of Operations Research 3, 257–302.

A. Kefeli et al. / Int. J. Production Economics 131 (2011) 383–391

Riaño, G., 2003. Transient Behavior of Stochastic Networks: Application to

Production Planning with Load-Dependent Lead Times. School of Industrial

and Systems Engineering, Georgia Institute of Technoogy, Atlanta, GA.

Roundy, R.O., Maxwell, W.L., Herer, Y.T., Tayur, S.R., Getzler, A.W., 1991. A pricedirected approach to real-time scheduling of production operations. IIE

Transactions 23 (2), 149–160.

Selc- uk, B., Fransoo, J.C., de Kok, A.G., 2007. Work in process clearing in supply

chain operations planning. IIE Transactions 40, 206–220.

391

Spearman, M.L., 1991. An analytic congestion model for closed production systems

with IFR processing times. Management Science 37 (8), 1015–1029.

Srinivasan, A., Carey, M., Morton, T.E., 1988. Resource Pricing and Aggregate

Scheduling in Manufacturing Systems. Graduate School of Industrial Administration, Carnegie-Mellon University, Pittsburgh, PA.

Voss, S., Woodruff, D.L., 2003. Introduction to Computational Optimization

Models for Production Planning in a Supply Chain. Springer, Berlin,

New York.