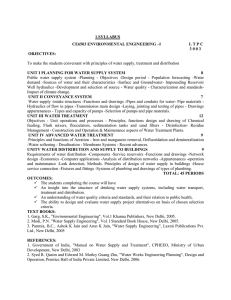

ANNA UNIVERSITY CHENNAI :: CHENNAI 600 025 UNIVERSITY DEPARTMENTS

advertisement