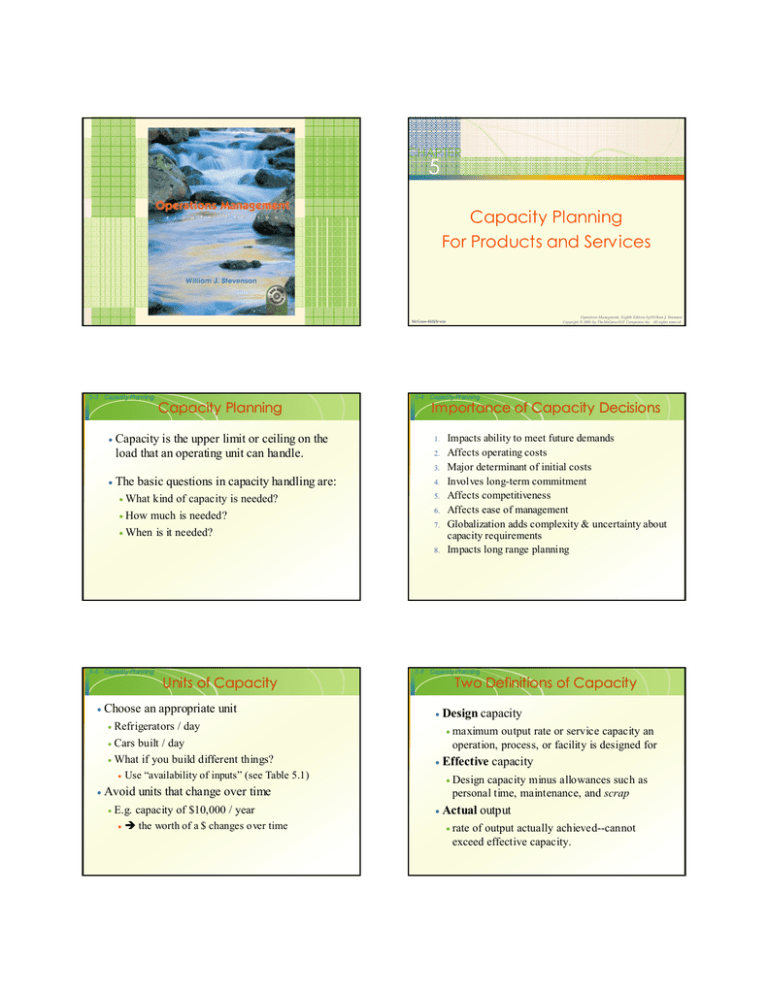

5-1 Capacity Planning

5-2 Capacity Planning

CHAPTER

Operations Management

5

Capacity Planning

For Products and Services

William J. Stevenson

8 th edition

Operations Management, Eighth Edition, by William J. Stevenson

Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserv ed.

McGraw-Hill/Ir win

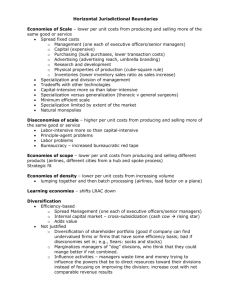

5-3 Capacity Planning

•

Capacity Planning

Capacity is the upper limit or ceiling on the

load that an operating unit can handle.

5-4 Capacity Planning

Importance of Capacity Decisions

1.

2.

3.

•

The basic questions in capacity handling are:

• What

kind of capacity is needed?

• How much is needed?

• When is it needed?

4.

5.

6.

7.

8.

5-5 Capacity Planning

•

Units of Capacity

Choose an appropriate unit

5-6 Capacity Planning

Two Definitions of Capacity

•

•

Refrigerators / day

• Cars built / day

• What if you build different things?

•

•

output rate or service capacity an

operation, process, or facility is designed for

•

Use “availability of inputs” (see Table 5.1)

E.g. capacity of $10,000 / year

•

Î the worth of a $ changes over time

Design capacity

• maximum

Effective capacity

• Design

capacity minus allowances such as

personal time, maintenance, and scrap

Avoid units that change over time

•

Impacts ability to meet future demands

Affects operating costs

Major determinant of initial costs

Involves long-term commitment

Affects competitiveness

Affects ease of management

Globalization adds complexity & uncertainty about

capacity requirements

Impacts long range planning

•

Actual output

• rate

of output actually achieved--cannot

exceed effective capacity.

5-7 Capacity Planning

Efficiency and Utilization

Efficiency =

5-8 Capacity Planning

Efficiency/Utilization Example

Actual output

Design capacity = 50 trucks/day

Effective capacity

Effective capacity = 40 trucks/day

Actual output = 36 units/day

Actual output

Utilization =

Actual output

Design capacity

=

36 units/day

Efficiency =

= 90%

Effective capacity

Both measures expressed as percentages

Utilization =

Actual output

40 units/ day

=

Design capacity

5-9 Capacity Planning

Determinants of Effective Capacity

5-10 Capacity Planning

Ca pa city =

•

•

•

•

•

•

•

Facilities (location, layout, etc)

Product and service factors (limited products /

services Î more efficiency)

Process factors (effect of quality reqs.)

Human factors (motivation)

Operational factors (bottlenecks)

Supply chain factors (effect of changes on the supply

chain)

External factors (EPA, unions)

Product

#1

#2

#3

•

= 72%

Example 2 (pg 177)

2000

Annual

Demand

400

300

700

Cl ea r

Standard

Proc essing

Time

5

8

2

Tota l =

•

36 units/day

50 units/day

Proce ssing

Time

Needed

2000

2400

1400

Proces s

Requirements

1

1.2

0.7

5800

2.9

Capacity per machine is 2000 hours per year

Three products’ demands are listed

•

How much capacity (in machine hours per year) are needed

to cover this forecast? Î How many machines needed?

See Table 5.2 in text

5-11 Capacity Planning

Homework Due M onday before class

•

•

Page 192, problems 1, 2 and 5

I will provide “feedback” on your problem solving

technique

•

At this time: The HW grade is not posted nor

included in final grade

5-12 Capacity Planning

Make or Buy

Having determined capacity required do you make or

buy? Factors affecting this decision are:

5.

Available capacity

Lack of expertise

Quality considerations for special items

Nature of demand (unusual demand)

Cost (fixed & per-unit)

6.

Risk (loss of control?)

1.

2.

3.

4.

•

Cost-Volume analysis, See solved problem #1

5-13 Capacity Planning

Economies of Scale (Optimal Operating Levels)

5-14 Capacity Planning

Evaluating Alternatives

•

Economies of scale

•

•

Average cost per unit

Figure 5.3

If the output rate is less than the optimal level,

increasing output rate results in decreasing

average unit costs

Diseconomies of scale

•

If the output rate is more than the optimal level,

increasing the output rate results in increasing

average unit costs

Production units have an optimal rate of output for

minimal cost.

Minimum average cost per unit

Minim um

cost

0

Rate of output

Fixed cost spread out over fewer units Å | Æ machine breakdown, worker fatigue, etc.

Economies of scale Å Æ diseconomies of scale

5-15 Capacity Planning

Evaluating Alternatives

Figure 5.4

Average cost per unit

Minim um cost & optimal operating rate are

functions of size of pr oduction unit.

0

Small

plant

Medium

plant

Large

plant

Output rate

5-16 Capacity Planning

Cost--Volume Equations

Cost

Profit = Total_Revenue – Total_Costs

P = TR – TC

TR = Revenue/unit * #_units = R * Q

TC = Fixed_costs + variable_cost/unit * #_units

TC = FC + v * Q

Profit = P = Q ( R – v ) – FC

Required Volume Q for a profit P is

Q = (P+FC)/ (R-v)

QBEP = FC / (R-v)

Larger plants have a higher minimum point ( more economies of scale)

5-17 Capacity Planning

Assumptions of CostCost-Volume Analysis

5-18 Capacity Planning

Cost--Volume Relationships

Cost

1.

2.

3.

4.

5.

6.

One product is involved

Everything produced can be sold

Variable cost per unit is the same regardless

of volume

Fixed costs do not change with volume

Revenue per unit constant with volume

Revenue per unit exceeds variable cost per

unit

Amount ($)

Figure 5.5a

0

C

+F

C)

VC

=

t (V

t

os

os

c

c

le

t al

ab

To

ari

v

t al

To

Fixed cost (FC)

Q (volume in units)

5-19 Capacity Planning

5-20 Capacity Planning

Figure 5.5b

Figure 5.5c

Cost--Volume Relationships

Cost

0

ue

e

nu

f it

ve

e

r

Pro

al

t

t

cos

To

t al

To

Amount ($)

Amount ($)

n

ve

re

l

ta

To

Cost--Volume Relationships

Cost

0

Q (volume in units)

5-21 Capacity Planning

BEP units

Q (volume in units)

5-22 Capacity Planning

Break--Even Problem with Step Fixed Costs

Break

Figure 5.6a

Break--Even Problem with Step Fixed Costs

Break

Figure 5.6b

+V

FC

How many machines

should w e purchase

(or set up for running)?

# of machines

purchased/running

affects your fixed costs

in a stepped (discrete)

fashion.

+

FC

FC

+V

C=

V

C=

TC

$

BEP

3

TC

C=

TC

BEP2

TC

3 machines

3

TC

TC

2 machines

2

TR 1

1 machine

Quantity

Quantity

Multiple break-even points

Step fixed costs and variable costs.

The BEP needs to be calculated separately for each number of machines (then

compare it to the capability of the machine(s) or the anticipated demand levels).

5-23 Capacity Planning

Financial Analysis

•

Cash Flow - the difference between cash received

from sales and other sources, and cash outflow for

labor, material, overhead, and taxes.

•

Present Value - the sum, in current value, of all

future cash flows of an investment proposal.

•

Is $1000 received today =, <, or > $1100 received in

two years?

•

Depends on interest rate (which is typically uncertain

over a period of time)

5-24 Capacity Planning

•

Supplement to Ch 5