TENORM IN IRON AND STEEL INDUSTRY presentation NORM

advertisement

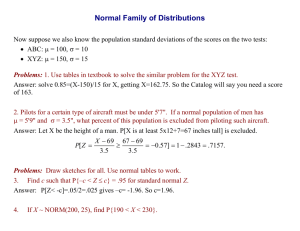

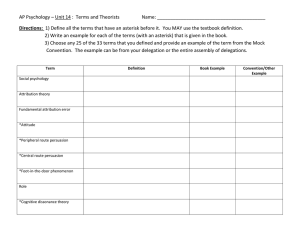

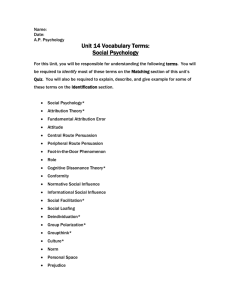

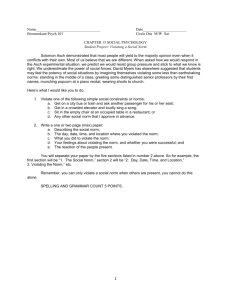

TENORM IN IRON AND STEEL INDUSTRY KHATER A., BAKR W. King Saud University- Saudi Arabia Nuclear and Radiological Regulatory Authority- Egypt Iron and steel industry • It has been ranked as the largest industrial source of environmental contamination. • About 2-4 tones of various wastes per ton of steel production. 22-04-2013 NORM 7, Beijing- china , 2013 2 World crude steel production reached 1,548 Mt for 2012, up by 1.2% compared to 2011. This is a record for global crude steel production 3100 -6200 Mt wastes NORM 7, Beijing- china , 2013 3 Iron and steel industry • These wastes contain a considerable amount of NORM and other contaminant ( such as Pb, Cd and Zn) • NORM 7, Beijing- china , 2013 4 Iron and steel industry Iron Ore Coke Scrap Sinter Pre-reduction Pellets Coal Blast Furnace O2 Hot metal (pig iron) Scrap Smelting reduction (Corex) O2 O2 Electric arc furnace Hot metal Scrap O2 converter (Basic oxygen furnace) Steel NORM 7, Beijing- china , 2013 5 Iron and steel industry NORM 7, Beijing- china , 2013 6 Sintering and pelletizing • Input: • Iron ore, dolomite, coke and recycled dust • Temp. to 1400 oC in combustion zone • Output: • Iron ore sinters • Dust • Slug NORM 7, Beijing- china , 2013 7 Blast Furnace (BF) Inputs : sintered, pelletized and Iron ore, limestone and coke hot air (up to 1400oC) Outputs: Molten (pig) iron and wastes (i.e. Slag, residue of BF washing and dust) NORM 7, Beijing- china , 2013 8 Blast Furnace (BF) • 1.6 t ore + 0.7 t coke + 0.25 t limestone +3.6 t of air (1600oC) • 1 t of pig iron + ? t wastes The US steel industry produces 13–15 Mt of BFS annually, while in Europe 26.2 Mt of BFS is produced every year. Approximately, 300–350 kilograms of BFS is generated for each ton of steel production. NORM 7, Beijing- china , 2013 9 Smelting reduction (Corex) NORM 7, Beijing- china , 2013 10 Basic oxygen furnace (BOF) • Input: • Molten (pig) iron and scrap • Output: • Steel and wastes (e.g., Slag and dust) NORM 7, Beijing- china , 2013 11 Electric Arc Furnace • Input: • Scrap • Output: • Steel and wastes (e.g., slag, dust and scale NORM 7, Beijing- china , 2013 12 Experimental Work NORM 7, Beijing- china , 2013 13 Sampling and samples preparation Factory A: - Iron ore - Dust (sinter plant-SP & BF) - Residue of ore washing (OW) - Slag (sinter plant & BF & BOF) Factory B: - Dust (EAF) - Slag (EAF) Factory C: - Dust (EAF) - Scale (EAF) - Slag (EAF & water treatment-WT) Factory D: - Iron ore Raw materials: - Limestone - sludge & Dolomite & Feldspar Khater- NORM 7, Beijing- china , 2013 & coke 14 -Iron Ore (2) • SP • BF • BOF • EAF • WT - Scale (1) NORM 7, Beijing- china , 2013 Residue (2) Slag (5) Dust (4) • SP • BF • EAF • OW • BFW - Sludge (1) 15 Analytical Techniques: Gamma-ray spectrometer based on HPGe detector; 238U, 226Ra, 210Pb & 228Ra & 40K Alpha particle spectrometer based on PIPS detector; 210Po Laser Fluorometer; U ICP-MS (ALS- Chemex, Vancouver- Canada); U, Th, K and other elements NORM 7, Beijing- china , 2013 16 Gamma-ray spectrometer: Coaxial Configuration :Relative Efficiency : 35% Resolution :1.9 keV ( 1332.3 keV of 60Co) Efficiency Calibration: 226Ra Point source- KCl Standard solution N.F (K-40) = Wt *16.28/CR R.E(Y)= A0+A1Y+A2Y2+… N.F (Y)= R.E(K-40)*BR(k-40)* N.F(K-40) R.E.(Y) *BR(Y) Activity = N.F (Y)* CR/d Radionuclide -Iines (keV) Intensity% U-238 (Th-234) 63.3 43.8 Pb-210 46.5 4.0 Ra-226 series Pb-214 Bi-214 Bi-214 Bi-214 351.9 609.3 1120.3 1764.5 37.3 46.3 15.0 16.0 Th-232 series Ac-228 Ac-228 Tl-208 338.4 911.1 583.0 12.0 29.0 30.9 K-40 1460.7 10.7 Radiochemical Separation of 210Po Dried sample materials Add yield tracer Po-209 and Digestion with HNO3 acid and HF Evaporate to dryness Dissolve in 0.5M HCL Heating to boiling and add 0.2gm Ascorbic acid Po deposition on the rotated stainless steel disc Alpha spectrometry Set-up Diagram of Alpha Spectrometer Energy and Efficiency Calibration : Am-141, Pu-239 and Cm-244 A(Po-210)= C(Po-210) * A(Po-209) C(Po-209)*m(kg) Sample Preparation for Laser Flourimetry Measurements Radiochemical Separation of Uranium Ashed Sample 5ml Conc. HNO3+5ml 40% HF Evaporate to dryness and Repeat 5ml Conc. HNO3 Evaporate to dryness 5 ml 2 M HNO3 Evaporate to dryness Evaporate to dryness 2ml 2M HNO3+10 ml Ca-EDTA and then filtrate Set-up Diagram of Laser Flourimetry Calibration : Standard Solution of Uranyl Nitrate C(U)ppm = RS * Cstand* Vstan/Vsample RS+St-RS RESULTS & DISCUSSION NORM 7, Beijing- china , 2013 24 Iron ore samples Bq/kg This variation is because hematite occurs in many different types of host-rocks. It occurs associated with vein deposits (igneous, metamorphic, and sedimentary rocks) and as product of the weathering of magnetite. 150 O-1 140 O-2 130 120 110 100 90 80 70 60 50 40 30 20 10 0 U-238 Ra-226 Pb-210 Po-210 Fe2O3 % Therefore, NORM concentrations vary according to their geochemical properties and their concentrations in source rock materials NORM 7, Beijing- china , 2013 25 18 Ratio (O1/O2) Also, the increase of Fe 16 content in the ore would 12 absorbed uranium (Ahmed et al., 2007). Ratio (O1/O2) increase the originally 14 10 8 6 4 2 0 U-238 Ra-226 Pb-210 Po-210 Fe2O3 % On the other hand, an increase of silica content in the ore indicates an increase in the amount of detrital quartz grains and hence a possible increase in heavy radioactive detrital (Ahmed et al., 2007). NORM 7, Beijing- china , 2013 26 140 130 120 110 100 90 Fe2O3 U238T U238L 40 30 20 10 0 Ore-1 Ore-2 The radioactivity of the ore depends on a balance between two complex factors: [Gindy, 1962] • Uranium originally absorbed in the hematite particles and other microcrystalline matter , • Uranium fixed in some of the minute detrital heavy grains. O-1 40 O-2 Bq/kg 30 20 10 0 Th-232 Ra-228 K-40 Fe2O3 % E NORM 7, Beijing- china , 2013 28 Factory (A) U-238 Th-232 K-40 U-238-G Ra-226 Ra-228 Pb-210 Po-210 ORE 135 5 28 114 133 15 50 25 RES. F. WASHING 24 3 13 98 157 25 4238 5656 RED. OF ORE WASHING 109 6 34 57 87 6 186 200 BLAST FUR DUST 77 7 85 80 70 5 2340 470 SINTER DUST 60 5 110 57 70 8 19 65 SINTER SLAG 80 7 63 34 65 6 30 87 TRANSFORMER SLAG 35 4 22 43 46 7 14 BLAST FUR. SLAG 289 29 135 297 552 56 45 International topical conference on Po and Radioactive Pb isotopes Ashraf Khater Activity concentration of Po-210 and Pb-210 in B.F. dust depends on their concentration in ore and their enrichment during thermal process. Their conc. In B.F. dust is high comparing to Ttotti (2004) study (59 and 50 Bq/kg, respectively). While their concentration is much lower comparing to Trotti et al., study, 42867 and 47243 Bq/kg , respectively. NORM 7, Beijing- china , 2013 30 100% 18.6 90% 50.21 30.4 80% 60% 46.2 182.6 70% 133.3 96.7 64.25 4238.2 50% 2340 40% 87.2 30% 42.8 20% 114.4 57.4 43.2 10% 56.9 157 97.8 0% Iron ore Sinter dust Sinter slag Residue of ore washing U-238 Ra-226 70.1 79.6 Residue of furnace Blast furnace dust washing pb-210 The Distribution of the Activity Concentrations of the Selected Isotopes Transformer slag NORM 7, Beijing- china , 2013 SC © S1 S- (S 2 S- (B A) 3 F( S- BO A) 4 F(E A S- AF ) 5 S- (W C) 6 T(E C AF ) -B ) -4 D -3 D -2 D -1 D -2 R -1 -2 -1 R O O RaEq Radium Eq. Of different samples 600 500 200 100 0 32 U (L) NORM 7, Beijing- china , 2013 © 300 S C S -1 S (S -2 S (B A) -3 F ( S BO A) -4 F (E -A S AF ) -5 S (W C) -6 T (E -C A ) FB ) -4 D -3 D -2 D -1 D -2 R -1 -2 -1 R O O U-238, Bq/kg Effect of the processing on the leachability of U U (T) 250 125 100 75 50 25 0 33 U-238 series disequilibrium U-238 series PO/Pb Pb/Ra Ra/U ORE 0.5 0.4 1.2 9.2 RES. F. WASHING RED. ORE WASHING 1.3 1.1 27.0 2.1 1.6 1.5 6.3 14.5 BF - DUST SINTER - DUST 0.2 3.4 33.4 0.2 0.9 1.7 13.2 12.7 SINTER SLAG BOF- SLAG BF- SLAG 2.9 0.5 1.9 1.1 1.9 10.6 7.1 9.9 Activity Ratios Ra6/Ra8 CONCENTRATION FACTOR B.F. WASH ORE WASH Sint. DUST B.F DUST Sint. SLG B.F. SLG TRANS. SLAG U-238 -0.8 -0.2 -0.6 -0.4 -0.4 1.1 -0.7 Th-232 -0.4 0.2 0.0 0.4 0.2 4.5 -0.3 K-40 -0.6 0.2 2.9 2.0 1.2 3.8 -0.2 U-238, T -0.1 -0.5 -0.5 -0.3 -0.7 1.6 -0.6 Ra-226 0.2 -0.3 -0.3 -0.5 -0.5 3.1 -0.7 Ra-228 0.7 -0.6 -0.5 -0.6 -0.6 2.8 -0.6 Pb-210 83.8 2.7 -0.6 45.8 -0.4 Po-210 225.2 7.0 1.6 17.8 2.5 0.8 -0.4 PO/Pb 1.7 1.2 5.8 -0.6 4.8 •Po relative solubility (washing Res.) - Valorization of Po in BF temp (1600 oc) • in sintering process Po > ppb although Pb>po in the ore ??? Exposure pathways External Exposure From the plume From ground Internal Exposure Inhalation (contaminated Foodstuffs) Radiological Dose Assessment In general, the total annual effective dose is determined by means of the following equation: Htotal = Hext + Hinh + Hing where Hext, Hinh and Hing are the annual effective doses (mSv/y) NORM 7, Beijing- china , 2013 37 Scenarios for workers Road construction Outdoor storage Transport (long distances) (earthwork application) External Inhalation Ingestion External Inhalation Ingestion External Inhalation Ingestion NORM 7, Beijing- china , 2013 NASDK Co El-Ezz Rebars Co. El-Delta for Steel Co. 2.4 2.2 2 1.8 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 Egptian Iron& Steel Co. Annual Dose Rate ( Micro Sv) The Average Annual Effective Dose of Operating Personnel Due to Gamma Radiation ( the Four Factories) 38 Other Toxic elements NORM 7, Beijing- china , 2013 39 Toxic Elements in Iron and Steel industry wastes As Cd Cr Cu Hg Ni Pb Zn MAC TAV D R 15-20 10-65 41-70 58-95 1-5 2-10 20-401 2-38 50-200 50-450 162-1120 66-187 60-150 60-500 134-3200 11-18 0.5-5 1.5-10 0.1-2.4 0.04-0.08 20-60 75-150 27-153 10-30 20-300 50-300 2020- >10000 129-3130 100-300 200-1500 > 10000 5720- >10000 NORM 7, Beijing- china , 2013 S <2-52 2-6 95-2510 16-450 0.02-0.16 11-50 133-366 1275-6650 40 NORM 7, Beijing- china , 2013 41 CONCLUSIONS NORM 7, Beijing- china , 2013 42 Conclusions 1 • Iron and steel industries produce a huge amount of wastes 2 • TENORM is extremely high in some wastes. Their radioecological impacts should be investigate deeply to ensure the safety aspects 3 • Toxic heavy element impacts should be considered as associated risk with TENORM NORM 7, Beijing- china , 2013 43 “It is unlikely to pose any significant adverse health impacts, according to the cited national and international legislation and guidance used for comparison” ( Ugur et al., 2013). It is nice >>>It is very good >>>>it s very scientific Is it enough? NORM 7, Beijing- china , 2013 44 Best radioecolgical Practice Achieve safe disposal and recycle Risks to Worker or Public & environment Wastes Time NORM 7, Beijing- china , 2013 45 Thank you for your attention!