WORKSHEET 2 FORCES, MOMENTS, LOADS & SUPPORTS

advertisement

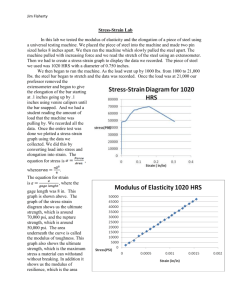

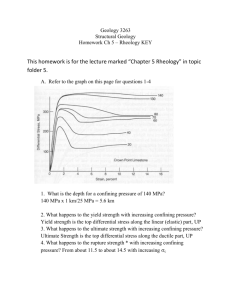

WORKSHEET 3 Material Behaviour Q1 Give units where applicable a) what is stress? internal force intensity as result of external forces, force per unit area - Pa, kPa, MPa - 1Pa = 1 N / m2 b) what is strain? change in size or shape relative to original state, e.g. change in length relative to original length e = DL / L - dimensionless c) what is the Modulus of Elasticity, E? linear relationship between stress and strain slope of line, d, where tan d = stress /strain - same units as stress Q2 A footbridge is supported by 25mm dia. aluminium rod 3 m long. Each rod carries a load of 40 kN added to its end. Neglecting the self-weight of the rod and given the Modulus of Elasticity of aluminium as 70,000 MPa: a) what is the stress in the rod? area of rod = p x D2 / 4 = p x 25 x 25 / 4 = 490.9 mm2 stress = Force / Area = 40000 / 490.9 = 81.5 N/mm2 = 81.5 MPa (keep units to Newtons, MPa and mm2 for simplicity) b) what is the strain in the rod? E = stress / strain strain = stress / E = 81.5 / 70,000 = 0.00116 (1.2 x 10-3) Q2 c) how much does the rod lengthen? strain = DL / L DL = L x strain = 3000 x 0.00116 = 3.5 mm d) what happens when we take the weight off? typical yield strength of aluminium is up to 150MPa so still within elastic range the rod goes back to its original length e) Given that the maximum allowable tensile stress for aluminium is 120 MPa, is the rod strong enough? stress in rod = 81.5 MPa max allowable stress of aluminium = 120 MPa stress in rod < maximum allowable stress yes - the rod is strong enough Q3 What does: a) elastic behaviour mean? • material responds to stress in linear way. • the deformation , i.e. strain is linearly proportional to the stress applied. • the deformation is reversible. b) plastic behaviour mean? • material deformation great with respect to stress applied. • material can be bent and reshaped - e.g. plasticene. • deformation is permanent. Still have strength c) brittle behaviour mean? • material fails suddenly. Very soon after elastic behaviour • usually weak in tension - strong in compression 5/22 Q4 Is steel: a) elastic? yes - it has a linear relationship between stress and strain up to the yield stress b) plastic? yes - after the elastic range it becomes plastic until ultimate failure c) brittle? no Draw the stress/strain curves for:(Mark the yield point, area of plasticity, and point of failure) stress Q5 a) an elasto-plastic material yield stress ultimate failure elastic plastic strain range range stress b) a brittle material yield point failure yield stress yield point elastic strain range Q6 What are the advantages of elasto-plastic materials? after the yield stress is reached, large deformations take place but material does not immediately fail. can take more stress until ultimate failure. large deformations - visible to naked eye give warning that reaching danger stage. Q7 a) Name two brittle materials concrete, glass, masonry, brick, cement b) How does one cure brittleness? by introducing elastic material to take care of tensile stresses. in reinforced concrete steel reinforcement resists tensile stresses while concrete resists the compressive stresses Q8 What does a material with a high value of E do? • for a given stress it will have less change in size or shape. • i.e. it will deform less under the same loading conditions for the same geometrical properties. • a steel wire of the same diameter and length as a rope will stretch less under the same load. • a steel beam will deflect less than a timber or reinforced concrete beam of the same span and cross-section given other things being equal. 10/22 Q9 A ground-floor reinforced concrete column in a multi-storey building is 3m high and carries a load 3.2 MN. Given that the max. allowable compressive stress for concrete is 30MPa and the Modulus of Elasticity, E, of concrete is 25,000MPa: a) What dimensions should the column be (nearest 25mm)? stress = Force / Area Area = Force / stress = 3.2 x 106 /30 square column = √106,667 mm2 = 326.6 round column = 106,667 mm2 = 350 x 350 mm pD2 /4 = 106,667 D2 = 135,813 D = √ 135,813 = 375 mm dia. Q9 A ground-floor reinforced concrete column in a multi-storey building is 3m high and carries a load 3.2 MN. Given that the max. allowable compressive stress for concrete is 30MPa and the Modulus of Elasticity, E, of concrete is 25,000MPa: b) What is the actual stress in the column? stress = Force / Area = 3.2 x 106/ (350 x 350) = 26.12 N/mm2 = 26.1 MPa c) What is the strain in the column? Strain = stress / E = 26.12/25,000 = 0.001 d) By how much does the column shorten? Strain = change in length / original length change in length = strain x original length = 0.001 x 3000 = 3.0 mm Q10 a) what are safety factors and why do we use them • factors of safety are factors by which we over-design a structure to allow a margin of safety • in building, nothing is exact, nothing is certain • adequate margins of safety must be used so that failure becomes extremely unlikely without the building being grossly over-designed • the minimum margins of safety required are given in Codes of Practice b) what do factors of safety allow for? • uncertain loading conditions - unexpected loads in unexpected places • uncertain material properties - imperfections in materials, variability • inexact workmanship - slightly undersized members • assumptions in theories and imprecise calculations Q10 c) what value of safety factors do we use in buildings? • vary from 1.5 to 2.5 • depend on type of building and material d) would a steel structure require a higher or lower safety factor than a reinforce concrete structure? Why? • a steel structure would have a lower factor of safety than a concrete one • because the properties of steel vary much less than those of concrete. That is the tolerances are much smaller and thus a smaller margin of error exists Q11 What are the advantages and disadvantages of the following when used as structural materials and when would you use them: 15/22 Q11 a) timber advantages • good in tension & compression - medium strength - yield stress 10-50MPa (as used) • low weight 600-1000kg/m3 - good strength to weight ratio • easy to cut to length on site - easily joined • reasonably inexpensive - except for special e.g. glulam • may be attractive - use for appearance disadvantages • low Modulus of Elasticity 8000-15000MPa - large deformations - creeps • hard to create rigid joints - pinned and semi-rigid joints • strength time dependent - varies across grain (except for plywood, particleboard) •swells with moisture •small spans (except for glulam) • flammable (very large sections ok) - when fire resistance not an issue usage • framing, post & beam, trusses, panels, floors • small structures usually - glulam can be used for larger spans Q11 b) brick / block advantages • reasonably inexpensive • nonflammable - when fire resistance is an issue • good sound proofing - use for sound isolation (cavity walls) • may be attractive - use for appearance disadvantages • low strength - yield stress 3-20MPa - very weak in tension - brittle • medium Modulus of Elasticity 10000-25000MPa • heavy: ~1900 kg/m3 • not waterproof usage • use in compression • walls, piers, footings, retaining walls, arches, vaults(not so much today) Q11 c) steel advantages • high strength - yield stress 250-300MPa up to 1000MPa for high strength wires • good in tension and compression • high Modulus of Elasticity 200000 MPa - small deformations • small variability - lower factor of safety • can be easily manufactured in many shapes - rolled, cast disadvantages • heavy: 7800 kg/m3 • nonflammable but loses strength under heat - needs to be fireproofed • rusts - needs protection (stainless steel possible but expensive) • buckling may be a problem - thin elements • expensive - use efficiently e.g. I-beams usage • where tensile strength is required - reinforcement • for long spans, large loads • frames mainly but also floor decking & roofing as sheets Q11 d) reinforced concrete advantages • medium strength - yield stress 20-50MPa • medium Modulus of Elasticity 20000 - 30000 MPa - medium deformations • nonflammable • good sound proofing - use for sound isolation (floors) • can be formed into many shapes • waterproof if made properly - else needs protection • generally inexpensive - forms the fabric disadvantages • heavy: 2400 kg/m3 - use efficiently • large variability - lower factor of safety • slow construction usage • medium spans • frames, slabs, shells, footings, retaining walls Q11 e) prestressed concrete advantages • high strength - yield stress 20-50MPa • Modulus of Elasticity similar to Reinforced Concrete • other properties similar to Reinforced Concrete • smaller sections than Reinforced Concrete - lighter • often precast - faster construction disadvantages • expensive - use efficient shapes • lighter than R.C. but still fairly heavy usage • long spans • frames, slabs, shells 20/22 Q11 f) aluminium advantages • high strength - yield stress varies - up to 150MPa - increased by alloying • good in tension and compression • medium Modulus of Elasticity 200000 MPa - small to medium deformations • light (with respect to strength): 2700 kg/m3 - use for lightweight structures • corrosion resistant - good in exposed conditions (may need protection) • can be easily manufactured in many shapes - rolled, drawn, extruded • may be attractive - use for appearance • nonflammable but loses strength under heat - needs to be fireproofed • small variability - lower factor of safety disadvantages • expensive - use efficiently • buckling may be a problem usage • long spans, medium loads • lightweight structures, frames, space frames 21/22 Q11 g) glass advantages • low strength as used ~ 15 MPa (due to surface cracks) • may be used as fibreglass - much stronger - eliminates chance of cracks • medium to high Modulus of Elasticity 200000 MPa - small to medium deformations • transparent - use for functionality / effect disadvantages • brittle, poor in tension • heavy: 2700 kg/m3 - use efficiently • expensive - use efficiently usage • use mainly in compression or small spans • use where effect is main consideration • sheets, blocks, roofing, window-walls including lateral support 22/22