Application of Biotechnogy to process industries

advertisement

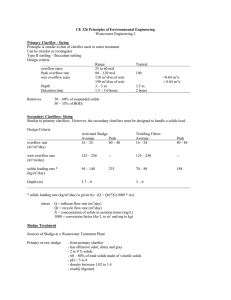

Process biotechnology application to industrial wastewater treatment plants PROF AVN SWAMY, Vice Principal, JNTUACE Pulivendula Clarifier Anaerobic Digester Typical clarifier PPS compact clarifier Typical ETP flow sheet Aeration tank-Diffused aeration Bioeactors • This unique stand-alone Bioreaction system can be placed into almost any Hydrokleen wastewater treatment system. This unit will dramatically assist existing treatment systems. The HE-BR-500 can be added to any system where light hydrocarbons, high concentrations of oils and grease, antifreeze, pesticides, organic nitrogen and other liquids are a problem. Moving bed Bioreactor • • • As contaminated water enters the Bioreactor it is slowed down to allow for solids to fall to the bottom of the tank and evenly coat the biomass. Being a moving bed reactor the biomass is systematically rotated allowing all portions of the media to be exposed to the influent. These provide the biodigesters an unlimited surface area for bio-reaction to occur. Pre-packaged in a liquid form, the HydroBiodigesters are dispensed automatically into the biomass. Automatic dosing allows precise use of the biological product for maximum digestion of waste. Water passes from the system automatically where it can be discharged for reuse or sanitary sewer. Head pressure purges the accumulated sludge, eliminating the requirement to manually remove solids. Dual 5500 gallon Bioreactors for use in high-flow wastewater recycling or pretreatment for discharge to sanitary sewer. Bioreaction take time, the flow rate and substrate to be broken down determine the size of the system. This big guy is 5500 gallons. The 5500 can be set up to break down hydrocarbons, high concentrations of oils and grease, antifreeze, pesticides, organic nitrogen and other organics. Contact us for a quote on your requirement. Airlift eactors • • • • • • • • • • • • • • • • • • Since one of the recognized characteristics of airlift reactors is the potential for scaling up and the relatively low power consumption for agitation and oxygenation, it is only natural that many processes related to wastewater treatment use this type of reactors. Jin et al. (2002) used an airlift reactor in a comprehensive pilot plant system for starch processing wastewater reclamation. The starch was utilized by Aspergilius orizae. Simultaneously to a 95% COD, 93% BOD and 98% suspended solids removal, an important production of -amylase (~50 EU/ml) was obtained (Jin et al. 1998). An interesting point in this paper is the dependence of fungal morphology on ALR fluid dynamics. In this type of processes, morphology of the fungal biomass is extremely important. Free mycelial growth (wild growth) increases strongly the • • • • • • • • • • • The solution that has been almost universally adopted for this problem, which attains to citric and other organic acids, antibiotics, etc., is to find the conditions under which the biomass takes the form of fungal pellets. The advantage in gas-liquid transfer rate because of the decrease in viscosity usually overweighs the added resistance stemming from the itraparticle diffusion of oxygen. But the formation of pellets in optimal size and compactness is a very complex matter. MBR GE • • The ZeeWeed membrane bioreactor (MBR) process is a GE technology that consists of a suspended growth biological reactor integrated with an ultrafiltration membrane system, using the ZeeWeed hollow fiber membrane. Essentially, the ultrafiltration system replaces the solids separation function of secondary clarifiers and sand filters in a conventional activated sludge system. ZeeWeed ultrafiltration membranes are immersed in an aeration tank, in direct contact with mixed liquor. Through the use of a permeate pump, a vacuum is applied to a header connected to the membranes. The vacuum draws the treated water through the hollow fiber ultrafiltration membranes. Permeate is then directed to disinfection or discharge facilities. Intermittent airflow is introduced to the bottom of the membrane module, producing turbulence that scours the external surface of the hollow fibers. This scouring action transfers rejected solids away from the membrane surface. MBR • ZeeWeed membrane bioreactor technology effectively overcomes the problems associated with poor settling of sludge in conventional activated sludge processes. ZeeWeed MBR technology permits bioreactor operation with considerably higher mixed liquor solids concentrations than conventional activated sludge systems that are limited by sludge settling. The ZeeWeed MBR process is typically operated at a mixed liquor suspended solids (MLSS) concentration in the range of 8,000 to 10,000 mg/L. Elevated biomass concentrations allow for highly effective removal of both soluble and particulate biodegradable material in the waste stream. The ZeeWeed MBR process combines the unit operations of aeration, secondary clarification and filtration into a single process, producing a high quality effluent, simplifying operation and greatly reducing space requirements.