Technology Offer Title: Mobile wastewater treatment plant with

advertisement

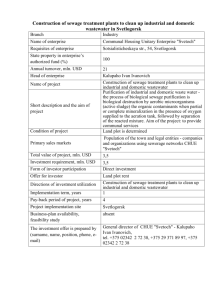

Technology Offer Title: Mobile wastewater treatment plant with membrane bioreactor technology for reusing treated water as process water (Ref: 10 AT 0106 3IXO ) Abstract: An Austrian SME has developed a fully biological mobile container waste water treatment plant (WWTP) with membrane bioreactor technology. Advantages of complete biological reclamation of water from the sewage in a very compact unit without air pollution. Suitable for small urban districts, military and humanitarian uses etc. Searching for partners interested in manufacturing the container plants and also companies interested in further development. Description: An Austrian SME specialising in the design and construction of waste water treatment plants and mobile treatment systems for a maximum of 20,000 persons has developed a new mobile waste water treatment plant. The present situation: Generally, mobile waste water treatment systems use chemicals and detergents to clean and disinfect the screening membranes. These detergents have a debilitating effect on the biocoenosis (interacting organisms living together in a specific habitat or biotope). The new Technology: The new technology is a fully biological container waste water treatment plant (WWTP) with state of the art membrane bioreactor technology. The sewage treatment plant is based on the proven activated sludge process for the biological purification of wastewater and additional ultra-filtration membranes to separate water from active sludge and to purify the water. Ultra-violet treatment ensures that the water is free of germs. This process can be operated without the addition of permanent chemicals. The membrane bioreactor technology also allows for a higher concentration of sludge to be processed free of suspended particles. This processed water can be returned to the natural water cycle. The technology and resulting purification system is biological and aerobic and no digester gas can be formed. Influent fluctuations can be buffered through a special controlling system depending on the working load. A biological phosphor elimination also ensures a high level of waste water treatment and there no air pollution is produced. The plant operates odourless and can be situated near public buildings or industrial complexes, humanitarian or military camps. These compact, mobile container waste water treatment plants were tested and modified in independent research projects. The aim of the development was to design a compact unit where a maximum of sewage can be purified and the treaded and the process water reused for irrigation, cleaning etc. - Production of process water from wastewater. - No permanent chemicals are necessary for operation. The technology was developed and tested with two container sizes – 20ft and 40 ft. Innovations and advantages of the offer Innovation: The technology is a non-permanent chemical water treatment process (biological) to produce water from wastewater featuring the most modern membrane bioreactor technology in a mobile compact format. - Using standardised containers with CFC- certification (Chlorofluorocarbon, a compound consisting of Chorine, Fluorine, and Carbon. Technicians who repair or service R-12 or R-134a refrigerant must be trained and certified by an EPA-approved organisation) - Production process water from wastewater - Non permanent chemical for operation are necessary - No external buffer tanks are necessary - No air pollution during the biological process - Easy to maintain and low operational cost - High degree of water purification - The plant systems can be used in areas without drainage ditches and limited water supply Current and Potential Domain of Application Industrial applications for recirculation of process water. Suitable for urban districts, smaller communities etc. Also suitable for hotels, mountain shelters, farms, campsites, golf courses, marinas and industrial plants, military and humanitarian bases etc. Mobile units for military operations, disaster and aid relief operations. List of Keywords Technology Industrial Manufacture Plant Design and Maintenance Process Plant Engineering Apparatus Engineering Market Pollution and Recycling Related Water treatment equipment and waste disposal systems Current Stage of Development Already on the market Exploitation of RTD Results National Programmes Collaboration Type License Agreement Joint further development Assembly Engineering Technical consultancy Maintenance Comments - Type of partner sought: Industrial manufacturing, distribution companies. - Specific area of activity of the partner: Steel construction, know-how in the field of environmental technologies, especially for wastewater purification. Partners should have the technical expertise to manufacture and assemble. - Task to be performed by the partner sought: Partners should be in a position to manufacture, assemble and offer product maintenance, and have an interest in bringing the product to market. Manufacturing under license. A commercial agreement with technical assistance to improve the product.