ISQM 377

advertisement

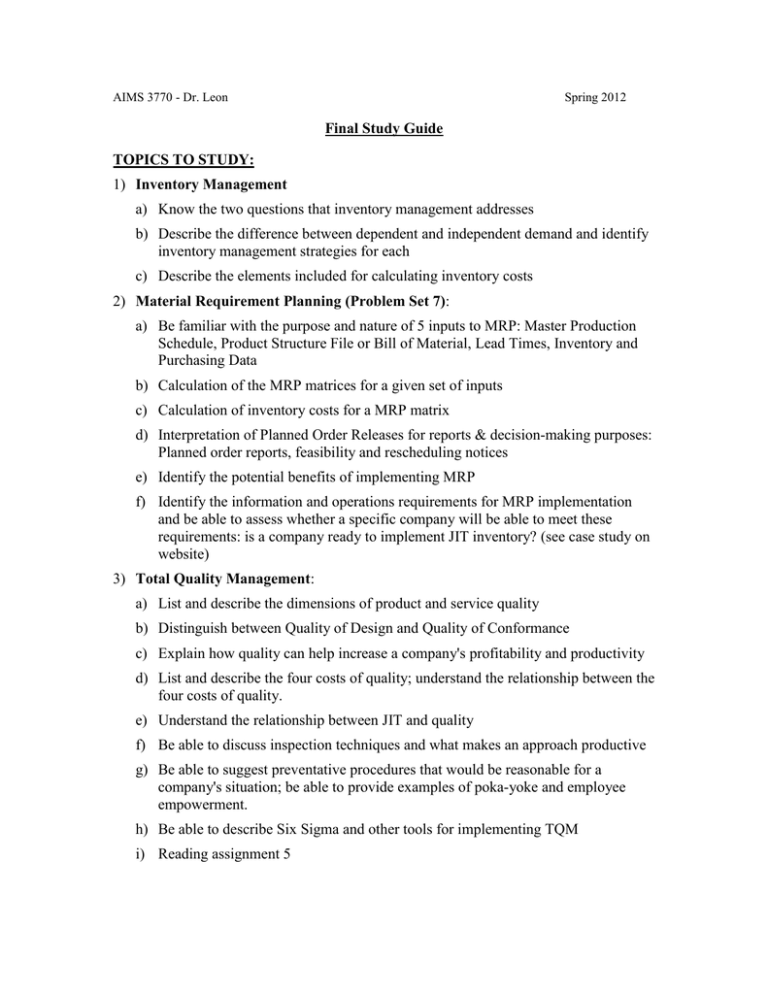

AIMS 3770 - Dr. Leon Spring 2012 Final Study Guide TOPICS TO STUDY: 1) Inventory Management a) Know the two questions that inventory management addresses b) Describe the difference between dependent and independent demand and identify inventory management strategies for each c) Describe the elements included for calculating inventory costs 2) Material Requirement Planning (Problem Set 7): a) Be familiar with the purpose and nature of 5 inputs to MRP: Master Production Schedule, Product Structure File or Bill of Material, Lead Times, Inventory and Purchasing Data b) Calculation of the MRP matrices for a given set of inputs c) Calculation of inventory costs for a MRP matrix d) Interpretation of Planned Order Releases for reports & decision-making purposes: Planned order reports, feasibility and rescheduling notices e) Identify the potential benefits of implementing MRP f) Identify the information and operations requirements for MRP implementation and be able to assess whether a specific company will be able to meet these requirements: is a company ready to implement JIT inventory? (see case study on website) 3) Total Quality Management: a) List and describe the dimensions of product and service quality b) Distinguish between Quality of Design and Quality of Conformance c) Explain how quality can help increase a company's profitability and productivity d) List and describe the four costs of quality; understand the relationship between the four costs of quality. e) Understand the relationship between JIT and quality f) Be able to discuss inspection techniques and what makes an approach productive g) Be able to suggest preventative procedures that would be reasonable for a company's situation; be able to provide examples of poka-yoke and employee empowerment. h) Be able to describe Six Sigma and other tools for implementing TQM i) Reading assignment 5 4) Bottleneck Analysis: a) Be able to define the four process strategies and provide examples of products and companies for each one (Chpt. 7) b) Be able to analyze a system’s capacity and identify bottlenecks (Chpt S7 homework and class M&M simulation); Suggest a system modification that will increase throughput c) Be able to calculate and interpret system process time and system cycle time 5) Simulation (Problem Set 6 and Project 3): a) Perform Monte Carlo Simulation to simulate values for a random variable i) Identify random number intervals for a probability distribution ii) Look up random numbers to simulate values for a variable manually iii) Program the random number intervals in Excel with vlookup functions and the Randbetween() function b) Waiting Line Analysis: i) Be able to simulate the logic for a one teller system by filling in a table for a specified number of arrivals by hand ii) Be able to calculate and program key measures of performance in Excel for a waiting line system and interpret a system’s effectiveness c) Computer Simulation i) Program the formulas necessary to model the logic of a perishable product inventory problem (similar to the Bakery model studied in class) ii) Perform a specified number of runs in Excel, summarize the runs into a meaningful set of information and interpret the expected results and risks associated with a particular strategy. iii) Understand what impact the number of runs has on the quality of decision made 6) Forecasting a) Perform the 10 steps of the forecasting process (Problem Set 1) b) Decompose a time series into its behavioral components (trend, seasonality, random movement) c) Calculate forecasts using the following time series models: i) Moving Averages ii) Simple Exponential Smoothing iii) Trend Projections d) Calculate and interpret the MAD and MAPD e) Plot a line graph in Excel that compares actual data and forecasts on the same graph. Properly document the different information presented in the graph (titles, legends, units) f) Compare and contrast different forecasts and defend with specific reasons (graph interpretation, measure of performance) which forecast you prefer 7) Aggregate Planning a) Understand the decision variables (also referred to as tools or options) for balancing supply and demand b) Describe benefits and drawbacks of each decision variable (reading assignment) c) Describe the difference between level and chase demand production plan strategies d) Calculate capacity, workforce requirements and unit production costs e) Chart a given strategy by hand and calculate associated costs. (Problem set 2) EXAM STRUCTURE: 34 points of the exam will test operation principles for Quality Management, Productivity, Material Requirement Planning and Inventory Management. This part of the exam will include one case analysis with questions that expect answers specific to the company described in the case. General philosophies and buzz words will not earn you any partial credit unless it is specifically explained why your answer is applicable to the company on hand. The more direct and simplistic your suggestion is, the more credit you are likely to receive in answering the case questions. This part of the exam will also include some short answer, multiple choice and True/False questions. 66 points will be distributed between quantitative problems on material requirement planning, simulation, bottleneck analysis, forecasting and aggregate planning. Simulation and forecasting will require the use of Excel. You are allowed to bring in a cheat sheet for this exam. This cheat sheet may not be bigger than 8-1/2” x 11” and not have anything stapled or taped to it. You may write/print on both sides of this sheet if you want.