Operations Process Flow Structures

advertisement

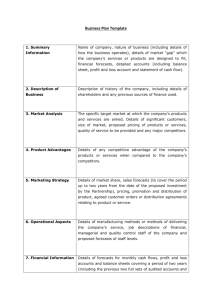

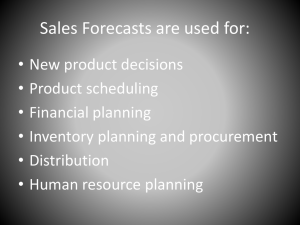

MGMT250 Notes October 1, 2002 1. Initial Stuff A. Schedule 1. Brief Discussion of Continuous Improvement 2. Finish up Continuous Improvement next class with Tip Top Markets Case. 3. May Begin Process and Capacity Analysis if we have time today. Otherwise, next time. 1. Continuous Improvement (CI) - Kaizen Definition: Philosophy that seeks to make never-ending improvements to the process of converting inputs to outputs (i.e. systems). Similar to TQM and other Strategic Programs, to be successful CI must be supported by Upper Level Management and changes to culture. Take a look at the CI Process. How many steps are in this process and what are they? Three important elements to the CI Process: 1. Standardization - What is meant by this term? 2. The Plan-Do-Check (STUDY)-Act Cycle (also known as the Deming Wheel) (Figure 11.1) 3. Methods and Tools - many exist some possible applications in the CI process are described here.. A. 5W2H - What, Why, Where, When, Who, How, How Much. Finding the right questions to ask to help define and improve processes. Identify the Problem. B. Flowcharts - Standardization and Documentation of As-Is and To-Be processes. Describe the Processes. C. Part of the selection of process to study is defining where the problems are and their importance two techniques are Check Sheets and Pareto Analysis. D. To help Identify Problems you can use Ishikawa (Cause-Effect) Diagrams, Brainstorming and Interviewing. E. To help improve and design processes - you can use - Benchmarking, Brainstorming, Quality Circles, Fail-Safing. F. To help monitor and evaluate you can use - Control Charts, Run Charts. 2. Process Selection and Capacity Planning Why are we concerned with these issues in operations? These are long-term basic decisions that will drive the organization’s operations. Process Selection: Inputs to this decision process are forecasts and products. Forecasts do not necessarily mean numerical forecasts, but likelihood that you will be in market and market exists. Outputs of process selection decision include: Capacity Planning, Type of Facilities, Layout...etc. Part of the decision is what do we do when we need a new part or product to be introduced? We can MAKE or BUY. Some factors to consider. 1. Do we have enough capacity? 2. Do we have the expertise 3. Can we provide good quality? 4. Demand for part/service is steady or long-term. 5. Cost savings? These are issues that need to be modeled for organizational decisions. What are some additional problems that may be encountered if we subcontract? Review Product/Process matrix issues Operations Process Flow Structures: Fixed Site - Project environment, where product does not move, processes do. Job Shop - small batch production of a large number of products. Functional Layout. Batch Flow - "Standardized" Job shop, larger batches of relatively stable product lines, similar flow patterns exist. Assembly Line (Dedicated Flow) - Controlled rate, fewer product variations, same sequence for all products. Continuous Flow Same sequence little variety in raw materials, typically associated with conversion processes, products are continuous rather than discrete. High fixed costs, low variable costs). Operations Product (development/inventory) Strategies Make to order - provide the technical ability to produce specialty products. (Low inventory, long-lead time) Assemble to order - Supply a large variety of final products from standard subcomponents and subassemblies (component inventory, shorter lead time) Make-to-stock - Immediate delivery of lower-cost off-the-shelf, standard items. (low lead time, high finished product inventory). 3. Technology. Processes Selected could be very automated to very manual. We will not get into the area of technology, other than to say that many organizations need to decide on these new technologies that have tangible and intangible benefits. 4. Capacity Capacity is how much “load” (in terms of time, volume, etc), that a process or system can handle. Similar to productivity, units may be misleading. But, you need to be consistent for managerial purposes. Capacity Planning includes: 1. Type of capacity required (very dependent on process/product/or service) - e.g. take-out versus sit-down restaurants will require different capacities. One is for atmosphere and quality, the other is capacity to minimize waiting time. 2. How much capacity. 3. When is it needed. (long-term, short-term capacity planning).