Construction Field Operations Automation

advertisement

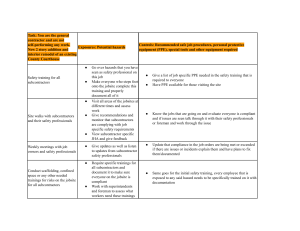

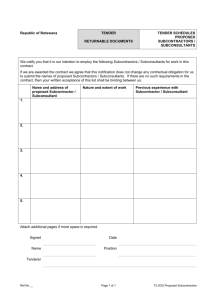

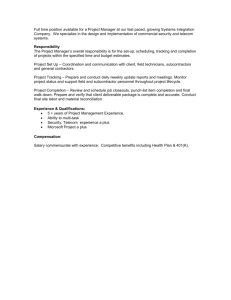

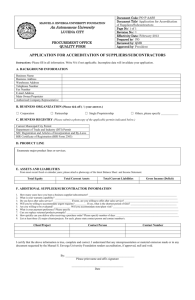

Construction Field Operations Management Automation Igor Starkov, Vice President, Latista Email: istarkov@latista.com 703-391-1070 extension 116 www.latista.com Why Focus on Field Operations Automation? Demands for higher worker productivity and/or cost cutting • More work is demanded of fewer qualified subcontractors and employees because of either constraints of a growing market or emerging cost cutting initiatives by builders. • Fewer workers require higher levels of quality and safety because reduced error rates lead to freed up resources to focus on building. • Fully 84% of best-in-class companies said that they are striving to do more with less. • More work with fewer field workers is only achievable through waste reduction and increased productivity per worker. Key Performance Category Average Improvement Worker productivity 27% Customer satisfaction/retention 19% Overall profitability 17% Source: Aberdeen Group, December 2005 Why Focus on Automating Quality/Safety at Jobsite? Governments Compliance and Penalty Reductions, Litigation Support, Insurance Premium Reduction Government compliance can be enhanced through standardization of processes, procedures, and documentation to help meet OSHA, LEED, SPIRIT, and new regulations and guidelines in addition to state and local and foreign governments regulations Government penalties can be reduced in certain areas of construction if company is proven to have implemented systems for quality and safety improvements Litigation support and avoidance through the use of digital images (properly formatted and coded) and documentation Insurance premiums may be reduced through improved reporting, analytics and resulting improvements in performance for safety / quality functions Automate Field Operations Management to Reduce Rework Measuring and Classifying Construction Field Rework: A Pilot Study - Department of Civil and Environmental Engineering University of Alberta May 2003 Why Focus on Work Order Management? Fast and efficient work order resolution improves profitability Faster response times and more first-call resolutions are building blocks of increased field technician productivity. Source: Aberdeen Group, December 2005 Impact of Poor Field Operations Management Issue Impact to the Process Phone-based communications between dispatchers and field workers •Superintendents/QA managers dispatched late or in error •Excess travel time incurred •Fewer work orders completed per day, per employee/subcontractor •Emergency service calls not escalated properly Inadequate access to customer and project data •Service orders issued with errors •More time spent figuring out the problem •Best practices for scenario resolution are not captured and shared •Missed revenue opportunities from targeted cross-selling Inadequate reporting and analytics •No visibility into employee/sub/vendor performance (i.e. time spent at the construction site, # of defects, travel time etc.) •Inability to track and monitor productivity •Missed opportunities for performance based incentives Paper-based or simple systems of record •Excess time spent closing job tickets and receiving new tasks •Missed opportunities for organic process improvement •Error-prone data management processes Critical Success Factors in Jobsite Automation Solutions • Issue (error) or Corrective Actions Capture: • Issue or Corrective Actions Resolution: • Communications: • Equipment Should be Tailored to Environment: • – Fast, accurate and easy – Standardized descriptions – Automatic checking and rechecking to ensure completion – Tracked and noted for cycle times and redundancy – Automatic and full-proof wireless synchronization – Take into consideration locations w/out Internet (local client with synchronization capability) – In native language of subcontractors (i.e. Spanish) – Two-way (both builder and sub have involvement) – Involves customer (if appropriate) – Outdoors – used in direct sunlight and rain – Rugged – expect drops on concrete and tough treatment Enterprise Approach: – Organizational-wide involvement (reporting, status) – Allows for coordination of schedules and effective dispatching – Must integrate into your existing back-office systems Which Device is Best for Field Operations? Hardware Smart Phones / Blackberry Tablet PCs Number of devices 500 500 Per unit cost of each device $500 $2000 Total annual cost of devices $250,000 $1,000,000 OS and related software, device/year (excludes other applications) $75 / month $100 / month Total software costs, per year $37,500 $50,000 Voice and data charges, device / month (data only for Tablet PC) $122.50 $55 Total connectivity costs, per year $735,000 $330,000 Employee average wage (IT fully burdened) cost per hour $50 $50 Hours of training per employee / month (excludes field employee time) 7.5 4.0 Hours of support per employee / month (excludes field employee time) 10 6.0 Annualized training and support cost $437,500 $250,000 Year I Total Cost of Ownership $1,460,000 $1,630,000 Year II Total Cost of Ownership $1,022,000 $537,900 Year III Total Cost of Ownership (avg. life of blackberry 18 months) $1,460,000 $537,900 Total Cost of Ownership Over Three Years $3,942,000 $2,705,800 Software Connectivity Support Total Cost of Ownership Sources: Gartner, Forrester * Other cost issues: lost additional income during training, wide availability of additional software for Tablet PCs, easier upgrades for Tablet PCs, etc. Note: Smart Phones and BlackBerry-like devices are useful for work order notifications for subcontractors and superintendents, where small screen is OK Rugged Equipment and Mobility • Used in bright sunlight conditions • Wireless synchronization with back-office systems • Water tight (can handle pouring rain, submersion) • Handles extreme shocks (drops plywood, concert) • Handles extreme climates (temperatures) • Full PC functionality • Supports Industrial Use Including Unique Docking Stations, Carrying Options, Hand Straps, etc. • Handles Future Needs Such as Integrated GPS, Bar Coding Latista:Field Solution Overview Latista:Field Framework Tablet PC-based solution (local client) for field related personnel that synchronizes wirelessly with a HQ server web-based solution for office personnel and dynamically generates work-orders to be sent via fax and email (and optional vendor portal) in English-Spanish to subcontractors ** Latista:Field Core Features Feature Feature Description Benefit Tablet PC Synchronization Engine Local client on tablets synchronizes with office central server Uninterrupted field work without requiring Internet connection Work Order and Corrective Actions Management Dynamically generate work orders, assign to subcontractors and track Saves time, increases accuracy, and measures performance Job Completion Tracking for Work Orders and Tasks Tracks which jobs have been completed and handles escalations Reduces response times and ensures job completion Foreign Language Translation for Work Orders Dynamic translation English-Spanish and 10 other languages for subs. Saves costs and time by reducing errors in repairs Resource Assignment and Dispatching (Leveling) Dashboard view of all resources in the field and if desired even subs. Increases productivity in the field and coordinates activities Customer Management and Jobsite History Creates full history for all customer and job (issues) related information Fast customer resolution and jobsite history for sub’s ratings Operations Reporting Built-in Daily office and jobsite (tablet) operational reports Fast and accurate jobsite status and work order statuses Subcontractor Management Setup, rate and manage subcontractor work orders Accurately manage current performance and rate past issues Document Management Add project documents such as CAD drawings, plans, specifications Eliminate the need to carry heavy rolls of plans and documents Workbench or Task Management Assigns task to appropriate system users for completion / follow-up Keeps employees focused on tasks at hand and follow ups Integration Engine to Backoffice Systems Integration engines to back office systems such as JDE, SAP, Timberline No double entry or management of data – ability to account for chargebacks, etc. for subs. Case Study: Clark Construction – Galen Center • • • • • • Project: Galen Event Center City: Los Angeles, CA Owner: University of Southern California Cost: $100,000,000+ Size: 210,000 SQF Summary: Phase two of the project - construction of the Athletic Pavilion, consists of a 75,000-square-foot, two-story structure with coaches’ offices, administrative space, meeting rooms and storage space on the lower floor. The upper floor will house practice courts. The Pavilion will connect to Galen Center at both levels. Case Study: Clark Construction – Galen Center • • Contractor: Clark Construction Description: Founded in 1906, Clark Construction Group, LLC is today one of the nation's most experienced and respected providers of construction services, with over $2 billion in annual revenue and major projects throughout the United States. • • Field Management System: Latista:Field Application Areas: project closeout, punchlists, work orders management, quality control checklists, etc. Some Facts: – More than 20,000 issues recorded in the field – Issues dispatched wirelessly to the central office – Work orders generated at midnight and emailed/faxed to subcontractors – Extensive use of digital pictures embedded into issue description within the work order Results: – Closeout Phase reduced by several days – Improved quality of construction • • LATISTA - Company Overview • History: Doubling in size every year since founding in 2001 • Industry Focus: Construction and Real Estate • LATISTA Focus – number one in field operations automation software solutions for construction • LATISTA Services – Consulting, Software, Customization, Training, Implementation and Support