Product design principles for efficient manufacturing

advertisement

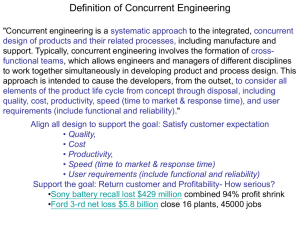

Translating Customer Requirements into Product Design By Dr Mohammed Arif – licensed under the Creative Commons Attribution – Non-Commercial – Share Alike License http://creativecommons.org/licenses/by-nc-sa/2.5/ Translating Customer Requirements into Product Design Contents Section[1] ................................................................................................................................................ 3 Concurrent Engineering – Introduction and History ............................................................................ 3 Background ......................................................................................................................................... 3 Concurrent Engineering (CE) – Definition ........................................................................................... 4 Different Aspects of CE.................................................................................................................... 5 Managerial and human aspect ........................................................................................................ 5 Technological aspects ..................................................................................................................... 5 Soft & Hard Factors of CE ............................................................................................................... 5 Implementation related issues in CE ............................................................................................... 6 Section[2] ................................................................................................................................................ 7 Quality Function Deployment (QFD): Definition and history ............................................................... 7 Section[3] ................................................................................................................................................ 9 Product Development in Off-Site Construction ................................................................................... 9 (DESIGN FOR MANUFACTURING) ................................................................................................... 9 Introduction: ......................................................................................................................................... 9 The Design for Manufacture (DFM) process: ...................................................................................... 9 DFM objectives: ................................................................................................................................. 10 Versions of the DFM: ......................................................................................................................... 10 DFM Methodology: ............................................................................................................................ 11 Basic principles of designing for economical production: .................................................................. 13 Product design principles for efficient manufacturing: ....................................................................... 14 CASE STUDY .................................................................................................................................... 17 REFERENCES .................................................................................................................................. 17 Translating Customer Requirements into Product Design By Dr.Mohammed Arif School of the Built Environment University of Salford Section[1] Concurrent Engineering – Introduction and History Background There is a growing awareness of the need for changes within the construction industry in its current practices and processes of project development which include design, procurement, construction, project delivery etc. This is mainly caused by the following: 1. The dramatically decreasing construction costs through standardisation of construction processes (CIRIA Report,1999); 2. The increasing demand and sophistication of clients (de Graaf et al., 1996); 3. The rising requirements for project functionality through growing competition; 4. The rapid developments in communication and information technologies; and 5. The recommendations in UK Government-initiated reports such as the Latham Report (1994) and the Egan Reports (1998, 2002). Many construction companies are responding to this increasing importance of project development processes by incorporating concurrent engineering practices to improve their project development capability (de Graaf and Sol, 1994). Not only the construction industry, but also other industries are increasingly challenged with growing competition, reduced product life cycle, and changing market and customer demands. To meet these demands, organisations within these industries are forced to develop new products, which have to be cheaper, delivered faster and provide greater functionality. The product development process in many organisations, however, presents many problems with respect to the required product quality, time-to-market, and costs. To achieve a better performance level, a new or better configuration of processes and technology, consisting of people and means, is needed. Concurrent Engineering is considered to offer a solution to the problems encountered. The practice of Concurrent Engineering is known to combine high quality, low cost and a short time to market (de Graaf et al., 1996). Other possible effects of implementation of CE could be a good product development practice, which includes innovation and organisational learning (Bergman and Ohlund, 1995). In the manufacturing sector, a great improvement in performance and productivity has been achieved through the application of Concurrent Engineering (CE). This application refers to a design process where all life cycle stages of a product are considered simultaneously, from the conceptual stage through the detailed design stage to construction, operation, and eventual disposal of a facility (Tummala, 1996). The CE approach to manufacturing aims to increase product quality and reduce cost and development time, by integrating diverse specialities into a unified development process. The CE approach to product development seeks continuous process improvement. This includes increased organisational effectiveness and efficiency, the elimination of non-value added activities that is waste, and continuous optimisation or refinement of the entire system which includes design, manufacturing, production and marketing for an improved productivity and quality (Love and Gunasekaran, 1997). The popularity in CE use is, no doubt, a result of the associated benefits in adopting its principles. These includes (de Graaf et al., 1996; Tummala, 1996; Kamara et al., 1997): A reduction in product development time and time to market; An overall cost saving; Products that match customers needs; Assured quality; and Low service cost throughout the life of the product. These improvements in productivity, through the use of CE in manufacturing, provide a basis for the adoption of its principles in other industries such as construction. Due to the similarities between the construction and manufacturing industries, developments in manufacturing processes that have led to improvements in the productivity can also be used in the construction processes. These similarities include fulfilling the customers/clients requirements, delivering assured product/project, minimum lead time, cost saving etc. (Kamara et al., 1997). Furthermore, the changing environment within which the construction industry operates, and the growing demand for more units of construction for fewer units of expenditure, are similar to some of the challenges which led to the adoption of the concurrent engineering in the manufacturing industry. And especially, for manufactured construction, these concepts are extremely relevant because of similar processes adopted. It is therefore, argued that, concurrent engineering can provide a suitable framework to improve the construction process. However, while there are similarities, there are also marked differences between manufacturing and construction which should be taken into consideration if CE is to be effectively implemented in the construction industry and its processes (Kamara et al., 1997). While Concurrent Engineering (CE) is gaining acceptance, some implementation efforts have not realised their full potential for reducing costs and improving time-to-market for product development efforts. This is due in part to weak planning to support the implementation (Componation and Byrd, 1996). One method that has been used successfully to improve planning is to conduct a readiness assessment of an organisation prior to the introduction of CE. Some studies have been conducted in manufacturing and software organisations using a range of techniques. Similar studies have been conducted in the construction industry by Khalfan et al (2005). Concurrent Engineering (CE) – Definition The UK Government initiated reports such as the Latham Report (1994) and the Egan Reports (1998, 2002) have recommended the improvement of the construction industry’s business performance. The need for greater co-ordination and integration within the industry has led to the adoption of various concepts from other industries. One of these, which offers major scope for effective co-ordination and integration within the industry, is Concurrent Engineering (Kamara et al., 2000). Concurrent Engineering, sometimes called simultaneous engineering, or parallel engineering has been defined in several ways by different authors. The most popular one is that by Winner et al. (1988), who state that concurrent engineering “…is a systematic approach to the integrated, concurrent design of products and their related processes, including manufacture and support. This approach is intended to cause the developers, from the outset, to consider all elements of the product life cycle from conception through disposal, including quality, cost, schedule, and user requirements.” Another definition is by Broughton (1990) who defines simultaneous (concurrent) engineering as “…an attempt to optimise the design of the product and manufacturing process to achieve reduced lead times and improved quality and cost by the integration of design and manufacturing activities and by maximising parallelism in working practices.” Different Aspects of CE There are eight basic elements of CE, which are divided into two aspects as follows (Bergman and Ohlund, 1995; Chen, 1996, Componation and Byrd, 1996; de Graaf and Sol, 1994; Khalfan and Anumba, 2000c; Prasad, 1997): Managerial and human aspect Managerial and human aspect covers team development, leadership, and organisational philosophy. It includes: The use of cross-functional, multidisciplinary teams to integrate the design of products and their related processes; The adoption of a process-based organisational philosophy; Committed leadership and support for this philosophy; and Empowered teams to execute the philosophy. Technological aspects This includes use of technology for design and manufacturing, communication, coordination, and developing standards. It covers: The use of computer aided design, manufacturing and simulation methods to support design integration through shared product and process models and databases; The use of various methods to optimise a product’s design and its manufacturing and support process; The use of information sharing, communication and co-ordination systems; and The development and/or adoption of common protocols, standards, and terms within the supply chain. Soft & Hard Factors of CE CE encompasses a number of business method, which comprises a series of interconnecting practices relating to people, processes, computer-based support tools, and formal method (see Figure 1). Broadly speaking, the model can be divided into those ‘soft’ or psychological aspects of CE such as team working and team leadership, and those ‘hard’ factors or systems of CE such as formalised methods, e.g. QFD, FMEA and computer-based support tools (Dann et al., 1996). Cross-functional teams Team Leadership Team Development Reward and Recognition Structures Co-location Process Project Management Formal NPD procedures Customer/Supplier integration Formal Team Briefings Organisation Redesign Tools Computer Networks CAD CAE Simulation Formal Methods QFD Design of Experiment DFM FMEA People ‘Soft’ factors of CE Concurrent Engineering (CE) ‘Hard’ factors of CE Figure 1: Characterisation of Concurrent Engineering (Dann et al., 1996) Implementation related issues in CE In order to compete and cut down the lead-time for introducing new products, many of the large automotive industries in the western world are adopting this integrated approach to product development. The theory of simultaneous engineering is simple, the implementation however has proved to be a difficult task. Attempts to implement simultaneous engineering can result in restructuring and reorganisation of a company. The major issue involved with implementation can be summarised as follows (Sya, 1997): a) b) c) d) e) Senior management commitment; People management; Product costing; Monitoring, feedback and control; and Financial Justification. Implementing Concurrent Engineering, however, is not straightforward, but requires welldesigned improvement cycles. In Figure 2 the four successive stages in an improvement cycle are depicted. These stages are awareness, readiness, deployment and improvement. In the awareness stage, the potential benefits of Concurrent engineering are becoming known. In the readiness stage, the company is measured with respect to certain performance criteria. These measurements lead to decisions concerning adaptation to the organisation, the technology and the process, composing the product development process. In the deployment stage, specific improvement plans are made and implemented. In the improvement stage, the progress is measured and the improvement cycle is closed by re-entering the readiness stage for further improvement (de Graaf et al., 1996). Improvement Deployment Readiness Awareness Figure 2: The improvement cycle (de Graaf et al., 1996) Chen (1996) has described two basic issues, which are very important for the success of implementation of CE: organisational management and human issues. Organisational management and human issues can be further sub-divided into other issues at three levels: individual level, team level, and organisation level (see Figure 3). A brief description on each of these levels is presented below (Brooks and Foster, 1997; Chen, 1996; de Graaf et al., 1996; Deasley and Lettice, 1997; Johansson et al., 1999; Thamhain, 1994; Tummala et al., 1996): Section[2] Quality Function Deployment (QFD): Definition and history Quality Function Deployment (QFD) is a process where a multi-functional team translate Voice of the Customer to Voice of the developer. This translation is accomplished by developing customer needs into product characteristics and, subsequently, developing process specifications from product characteristics. Profitable revenue growth is a pursuit shared by all commercial enterprises even by the higher education establishments. Organisations holding high share of the markets they operate are generally better suited to see higher revenue growths as they exercise some influence over the market or market segment. High customer satisfaction and customer loyalty helps organisations to establish/strengthen the position of market leadership and more importantly in their pursuit of higher revenue growth. And, customer is satisfied if they get what they want (if not all, even the few important ones, ‘must-be’s). Customers possibly buy the same product/service if they have experience of previous satisfaction. Therefore, meeting the customer needs is essential to any business. Meeting customer needs should therefore be fundamental to all measures of quality. There are two broad aspects of quality: negative and positive. You can assess whether customer needs were met after the product/service is developed or before. Most of the efforts on quality have focussed on negative quality perceptions of existing products (e.g. correcting deficiencies) through use of Statistical Process Control (SPC). Japan took a different approach in the form of Company-Wide Quality Control (CWQC) which is largely acknowledged as one of the key foundations of Japanese manufacturing success. Development of CWQC is attributed to Ishikawa, Demming and Juran. CQQC’s approach to quality is articulated by Ishikawa (1985): To practice quality control is to develop design, produce and service a quality product which is most economical, most useful and always satisfactory to the consumer. This understanding of ensuring customer demand for quality being addressed during the product development process (against ensuring quality after the product development) is expressed in the findings of MIT Commission on Industrial Productivity in 1986. The commission emphasised the need for all segments of organizations to work toward greater functional integration. This can be accomplished through multi-functional teams which can work with greater speed in product development and better respond to changing markets (Dertouzous, Lester, Solow; MIT Commission on Industrial Productivity, 1989). This lays the foundation of concurrent engineering, where marketing, manufacturing, engineering, procurement and supply, finance and other disciplines necessary to develop a new product simultaneously design product and processes to manufacture that product from its concept stage. Traditionally, sequential product development process involved (Hinckley, 1993): 1. Senior management outlining a concept for new product 2. Concepts being refined by product planners and stylist 3. Specifications developed and tested by product engineering 4. Manufacturing and purchasing manufacturing the product. Sequential model of product development process is handicapped by communication problems, long product development time and, frequent and costly product changes. Concurrent engineering aims to overcome these handicaps of traditional product development process including costly product changes in particular but it needed a structure and medium to address communication problems during product development. Quality Function Deployment (QFD) provides that structure and medium to facilitate communication where the multi-functional product development team deploys requirements from the Voice of the Customer to the following: 1. Critical product control characteristics 2. Component characteristics 3. Process control characteristics 4. Operation instructions This could be better understood in the context of using QFD in manufacturing (Crowe and Cheng, 1996). Crowe proposed four stages: functional strategies, manufacturing priorities, action plans and detail tasks. In the first stage all functional level strategies are realized and they become the whats for the next stage (i.e. component characteristics). In the second stage, all parallel functional level strategies are their potential customers. For example, marketing requirements can be an input to the QFD matrix and the output would be a set of manufacturing priorities to fulfil the requirements. In the third stage, broad manufacturing priorities are translated into detailed action plans for implementation (i.e. process control characteristics). The last stage is identifying specific tasks (i.e. operation instructions) to realize the plans. Section[3] Product Development in Off-Site Construction (DESIGN FOR MANUFACTURING) Introduction: Design for manufacture (DFM) represents a new awareness of the importance of design as the first manufacturing step. It recognises that a company cannot meet quality and cost objectives with isolated design and manufacturing engineering operations. To be competitive in today’s marketplace requires a single engineering effort from concept to production. The essence of the DFM approach is therefore the integration of product design and process planning into one common activity, Kuo, et.al, (2001). The DFM approach embodies certain underlying imperatives that help maintain communication between all components of the manufacturing system and permit flexibility to adapt and to modify the design during each stage of the product’s realisation. Chief among these is the team approach or simultaneous engineering, in which all relevant components of the manufacturing system including outside suppliers are made active participants in the design effort from the start. The team approach helps ensure that total product knowledge is as complete as possible at the time each design decision is made. Other imperatives include a general attitude that resists making irreversible design decisions before they absolutely must be made and a commitment to continuous optimisation of product and process. The Design for Manufacture (DFM) process: The DFM process begins with a proposed product concept, a proposed process concept, and a set of design goals. All three of these inputs would be generated by a thorough product plan developed using the team approach. Design goals would include both manufacturing and product goals. Each of the activities within the DFM process addresses a particular aspect of the design. Optimisation of the product/process concept is concerned with integrating the proposed product and process plan to ensure inherent ease of manufacture. The simplification activity focuses on component design for ease of assembly and handling. This activity can often be rapidly effective because the integrated product and process requirements and constraints help identify problem areas. The third activity ensures conformance of the design to processing needs. For example, if an assembly is to be built on a particular flexible assembly (FAS), it is important that the assembly be designed in such a way that it can be assembled using the programmable gripper engines, flexible fixtures, and assembly operations available within the FAS. Finally, functional optimisation considers appropriateness of material selection and parameter specification that maximise the design objectives. By reversing the process, this DFM approach helps ensure that all of the design constraints, including assembly, material transformation processes, and material handling requirements are included as part of the functional optimisation of the design. In this way, the DFM process enables the designer or design team to consider all aspects of the product’s design and manufacture in the early stages of the design cycle, so that design iteration and accompanying engineering changes can be made easily and cost effectively. Finally, by integrating the product and process design, it is possible to include manufacturing recommendations and a process plan as part of the engineering release package. This has great advantages because it leads to few, or no, manufacturing surprises. Also, both manufacturing and engineering share equally in ownership of and ultimate commitment to design. DFM objectives: The objectives of the design for manufacture approach are to: 1- Identify product concepts that are inherently easy to manufacture. 2- Focus on component design for ease of manufacture and assembly. 3- Integrate manufacturing process design and product design to ensure the best matching of needs and requirements. Meeting these objectives requires the integration of an immense amount of diverse and complex information. This information includes not only considerations of product from, function, and fabrication, but also the organisational and administrative procedures that underline the design process and the human psychology and cognitive processes that make it possible. Versions of the DFM: Many different versions of the DFM process have been proposed. Each version is likely to be similar in the issues addresses and the concepts embodied. One proposed version of the DFM process is shown in Figure (1), (Stoll, 1988). The four activities comprising this process are arranged in a circular fashion to emphasise the iterative nature of the process. Traditionally, many products have been designed by starting with functional optimisation of the product design itself, followed by detail design of each part to be made by a particular process, then simplification, and finally design of a process to manufacture and assemble the product. As shown by the arrows, the progression of steps in the proposed DFM process is just the reverse of the more traditional design approach. Proposed product concept Proposed process plan Design goals Optimise Product/Proce ss Concept Engineering Release Package: - Part Drawings - Part List - Assembly Drawings - Process Plan Simplif y Produ ct Design Imperatives: - Team Approach - Least Commitment - Continuous Optimisation Of Product and Process Optimis e Product Functio n Ensure Product/Proces s Conformance Figure (1) Typical DFM Process (Stoll, 1988) DFM Methodology: The development and use of design methodologies that help the design team achieve an optimised design solution is an important part of the DFM approach (Boothroyd, et.al. 2002). DFM is a relatively new way of looking at a very old problem. To appreciate the problem and to understand where DFM is today and what needs to be done in the future, it is necessary to look briefly at traditional practice and at some of the organisational issues which are involved in the DFM approach. The importance of manufacturability in product design has been recognised for years. For its importance, is illustrated by the well-known fact that up to 80% or more of production decisions are directly determined by the product design (Ertas & Jones, 1993), which leaves very little freedom of choice for process planning. The concept of design for manufacture is predicted on the recognition that: iii- Design is the first step in product manufacture. Every design decision, if not carefully considered, can cost extra manufacturing effort and productivity loss. iii- The product design must be carefully matched to advanced flexible manufacturing, assembly, quality control and material-handling technologies in order to fully realise the productivity improvements promised by these technologies. To maximise the quality of early design decisions and thereby minimise the amount of engineering change, the DFM approach seeks to involve input from as many manufacturing system activities as possible as early as possible. Ideally, convergence to ‘globally optimal’ product and process decisions should occur at the early, low-cost stages of the project. This approach requires the simultaneous engineering model depicted in Figure (2). In a study addressing integration of design and manufacturing during deployment of advance manufacturing technology, Corbett et al., (1991) identified five mechanisms which illustrate trends in administrative innovation: 12345- Design-manufacturing team; Common CAD systems for design and tooling; Common reporting position for computerisation; Philosophical shift to DFM; Development and promotion of the engineering generalist. Market analysis Product Design Sales and distribution Production System design Manufacturin g Figure (2) Simultaneous engineering model (Corbett, J. 1991) Basic principles of designing for economical production: The following principles, applicable to virtually all manufacturing processes, will aid designers in specifying components and products that can be manufactured at minimum cost; 1- Simplicity: Other factors being equal, the product with the fewest parts, the least intricate shape, the fewest precision adjustments, and the shortest manufacturing sequences will be the least costly to produce. Additionally, it usually will be the most reliable and the easiest to service. 2- Standard materials and components: Use of widely available materials and off-the-shelf parts enables the benefits of mass production to be realised by even low-unit-quantity products. Use of such standard components also simplifies inventory management, eases purchasing, avoids tooling and equipment investments, and speeds the manufacturing cycle. 3- Standardised design of the product itself: When several similar products are to be produced, specify the same materials, parts, and subassemblies for each as much as possible. This procedure will provide economies of scale for component production, simplify process control and operator training, and reduce the investment required for tooling and equipment. 4- Liberal tolerances: Although the extra cost of producing too tight tolerances has been well documented, this fact is often not appreciated well enough by product designers. The higher costs of tight tolerances stem from factors such as; (a) extra operations such as grinding, honing, or lapping after primary machining operations, (b) higher tooling costs from the greater precision needed initially when the tools are made and the more frequent and more careful maintenance needed as they wear, (c) longer operating cycles, (d) higher scrap and rework costs, (e) the need for more skilled and highly trained workers, (f) higher materials costs, and (g) more sizable investments for precision equipment. 5- Use of the most processible materials: Use the most processible materials available as long as their functional characteristics and cost are suitable. There are often significant differences in processibility (cycle time, optimal cutting speed, flowability, etc.) between conventional material grades and those developed for easy processibility. However, in the long run, the most economical material is the one with the lowest combined cost of materials, processing, and warranty and service changes over the designed life of the product. 6- Teamwork with manufacturing personnel: The most producible designs are provided when the designer and manufacturing personnel, particularly manufacturing engineers, work closely together as a team or otherwise collaborate from the outset. 7- Avoidance of secondary operations: Consider the cost of operations, and design in order to eliminate or simplify them whenever possible. Such operations as deburring, inspection, plating and painting, heat treating, material handling, and others may prove to be as expensive as the primary manufacturing operation and should be considered as the design is developed. For example, firm, non-ambiguous gauging points should be provided; shapes that require special protective trays for handling should be avoided. 8- Design appropriate to the expected level of production: The design should be suitable for a production method that is economical for the quantity forecast. For example, a product should not be designed to utilise a thin-walled die casting if anticipated production quantities are so low that the cost of the die cannot be amortised. Conversely, it also may be incorrect to specify sand-mould aluminium casting for a mass-produced part because this may fail to take advantage of the labour and materials savings possible with die castings. 9- Utilising special process characteristics: Wise designers will learn special capabilities of the manufacturing processes that are applicable to their products and take advantage of them. For example, they will know that injection-moulded plastic parts can have colour and surface texture incorporated in them as they come from the mould, that some plastics can provide “living hinges” that powdermetal parts normally have a porous nature that allows lubrication retention and obviates the need for separate bushing inserts, etc. utilising these special capabilities can eliminate many operations and the need for separate, costly components. 10- Avoiding process restrictiveness: On parts drawings, specify only the final characteristics needed; do not specify the process to be used. Allow manufacturing engineers as much latitude as possible in choosing a process that produces the needed dimensions, surface finish, or other characteristics required. Product design principles for efficient manufacturing: The following DFM principles are discussed to illustrate their global nature and to provide insight into how such principles can be used to aid the product-development team. i) Minimise total number of parts: Fewer parts mean less of everything that is needed to manufacture a product. This includes engineering time, drawings and part numbers; production control records and inventory; number of purchase orders, vendors, etc; number of bins, containers, stock locations, buffers, etc; amount of material-handling equipment, containers, number of moves, etc; amount of accounting details and calculations; service parts and catalogues; number of items to inspect and type of inspections required; and amount and complexity of part production equipment, and facilities, assembly and training. Put another way, a part that is eliminated costs nothing to make, assemble, move, handle, orient, store, purchase, clean, inspect, rework, service. It never jams or interferes with automation. It never fails, malfunctions, or needs adjustment. A part is a good candidate for elimination if there is: abcd- No need for relative motion; No need for subsequent adjustment between parts; No need for service or repair ability; No need for materials to be different. However, part reduction should not exceed the point of diminishing return where further part elimination adds cost and complexity because the remaining parts are too heavy, or too complicated to make and assemble, or are too unmanageable in other ways. Perhaps the best way to eliminate parts is to identify a design concept which requires few parts. Integral design, or the combining of two or more parts into one, is another approach (Fisher, 1993). Besides the advantages given above, integral design reduces the amount of interfacing information required, and decreases weight and complexity. One-piece structures have no fasteners or joints, and fewer points of stress concentration. Conversely, structural continuity leads to high strength and light weight. Plastic is a major key to integral design. Plastic is available for making springs, bearings, cam and gears, fasteners, hinges and optical elements. Powder metallurgy (P/M) is a good alternative if plastic parts do not have adequate strength, heat resistance or cannot be held to the tolerance needed (Boothroyd, & Alting, 1992). Although switching to a different manufacturing process may lead to a more costly part, experience with part integration has shown that a more costly part often turns out to be more economical when assembly costs are considered (Precision Metal, 1975). ii) Develop a modular design: A module is a self-contained component with a standard interface to other components of a system (Chow, 1978). Modular design offers the ability to standardize diversity because it allows a product to be customized by using different combinations of standard components. Modular design resists obsolescence and shortens the redesign cycle. A new generation product can realize most of the old modules. Change is provided via a few, new, or improved modules. Cost and ease of service and repair are enhanced because a defective module can be quickly replaced by a good one. Most importantly, modular design simplifies final assembly because there are fewer parts to downside, modular design can add cost and complexity because of extra fittings and interconnections required. Therefore, modular design should not be used unless its advantages are needed. iii) Use standard components: A stock item is always less expensive than a custom-made item. Standard components require little or no lead time and are more reliable because characteristics and weaknesses are well known. They can be ordered in any quantity at any time. They are usually easier to repair and replacements are easier to find. Use of standardized components puts the burden on the supplier and makes the supplier do more. iv) Design parts to be multi-functional: Combine function wherever possible. For example, design a part to act both as a spring and a structural member, or to act both as an electrical conductor and a structural member. An electronic chassis can be made to act as an electrical ground, a heat sink and a structural member. Less obvious combinations of functions might involve guiding, aligning and/or selffixturing features to a part to aid in assembly, or providing a reflective surface or recognizable feature to facilitate vision inspection. These latter examples illustrate inclusion of functions which are only needed during manufacture. Such function combinations are often the result of DFM awareness. v) Design parts for multi-use: Many parts can be designed for multi-use. For example, the same mounting plate can be designed to mount a variety of components, (Stoll, 1986). One approach involves sorting all parts (or a statistical sample) manufactured or purchased by the company into two groups consisting of: 1. Parts which are unique to a particular product or model. 2. Parts which are generally needed in all products and/ or models Each group is then divided into categories of similar parts (part families). Multi-use parts are then created by standardizing similar parts. In standardizing, the designer should sequentially seek to: (1) Minimize the number of part categories; (2) Minimize the number of variations within each category; (3) Minimize the number of design features within each variation. Once developed, the family of standard parts should be used wherever possible in existing products and used exclusively in new product designs. Also, manufacturing processes and tooling based on a composite part containing all design features found in a particular part family should developed. Individual parts can then be obtained by skipping some steps and features in the manufacturing process (Chow, 1978). 1- Design parts for ease of fabrication: This principle requires that individual parts be designed using the least costly material that just satisfies functional requirements (including style and appearance) and such that both material waste and cycle time are minimized. This in turn requires that the most suitable fabrication process available be used to make each part and that the part be properly designed for the chosen process. Use of near-net shape processes is preferred whenever possible. Likewise, secondary processing (finish machining, painting, etc.) should be avoided whenever possible. Secondary processing can be avoided by specifying tolerances and surface finish carefully and then selecting primary processes (precision casting, P/M, etc.) which meet requirements. Also, material alternatives which avoid painting, plating, buffing, etc., should be considered. This principle is based upon the recognition that higher material and/or unit process cost can be accepted if it leads to lower overall production cost. 2- Minimize handling: Position is the sum of location (x, y, z) and orientation (α, β, ɣ). Position costs money. Therefore, parts should be designed to make position easy to achieve and the production process should maintain position once it is achieved. Design in features which facilitate product and component packing. Use standard outer package dimensions for machine feeding and strong, design packaging adequately to protect and ensure quality at all stages of handling, and design packing for easy handling. Consider material flows within the production facility including product flow, workplace flow, supply flow, hardware flow, bulk material flow, container flow and fixture flow. For each flow, consider how the product, subassembly, component or part can be designed to simplify or eliminate the flow (Stoll, 1986). CASE STUDY You are the new Chief Design Officer (CDO) of a company engaged in manufactured construction. Your company has had a reputation of producing NOT SO GOOD quality products. Now that you are in-charge of product design you have taken upon yourself to change the image of your company. You have decided that from now on, all the new products being designed will have to be customer focussed and high quality. Discuss how you will make your organisation customer centric, using the topics documented in this package. REFERENCES Broughton, T. (1990), “Simultaneous Engineering in Aero Gas Turbine Design & Manufacture”, Proceedings of the 1st International Conference on CE, 4-5 December 1990, London, pp. 25-36. Bergman, L. and Ohlund, S. (1995), “Development of an Assessment Tool to Assist in the Implementation of Concurrent Engineering”, Proceedings of Conference on Concurrent Engineering: A Global Perspective, 1995, 499-510. Brooks, B. M. and Foster, S. G. (1997), “Implementing Concurrent Engineering”, Concurrent Engineering – The Agenda for Success, Medhat, S. (Ed.), Research Studies Press Ltd. Boothroyd, G., Dewhurst, P. and Knight, W., (2002), “Product Design for Manufacture and Assembly, 2nd Edition”, Marcel Dekker, New York, Boothroyd, G., and Alting, L. (1992), “Design for assembly and Disassembly”. Keynote paper, Annals of CIRP, 41 (2), 625-636.CII (1986) “Constructability: A primer.” Publication3-1. Construction Industry Institute, University of Texas, Austin. CIRIA Report (1999), “Standardisation and pre-assembly: Adding Value to Construction Projects”, CIRIA Report No. 176, 1999, CIRIA, London. Chen, G. (1996), “The Organisational Management Framework for Implementation of Concurrent Engineering In the Chinese Context”, Advances in Concurrent Engineering, Proceedings of 3rd ISPE International Conference on Concurrent Engineering: Research & Applications, University of Toronto, Ontario, Canada, 26-28 August 1996, pp.165-171. Chow, W. W. C. (1978). “Cost Reduction in product Design”. New York: Van Nostrand Reinhold. Componation P. J. & Byrd Jr., J. (1996), “A Readiness Assessment Methodology for Implementing Concurrent Engineering”, Advances in Concurrent Engineering, Proceedings of 3rd ISPE International Conference on Concurrent Engineering: Research & Applications, University of Toronto, Ontario, Canada, 26-28 August 1996, pp.150-156. Corbett, J., Dooner, M., Meleka, J. And Pym, C., (1991), “Design for Manufacture”, Strategies, Principles and Techniques, Addison-Weskey Publishers Ltd. Thomas J. Crowe, Chao-Chun Cheng, (1996) "Using quality function deployment in manufacturing strategic planning", International Journal of Operations & Production Management, Vol. 16 Iss: 4, pp.35 - 48 Dann, Z.; Poolton, J.; Barclay, I. and Holroyd, P. (1996), “Benchmarking CE Best Practices: Development of a Framework”, Advances in Concurrent Engineering, Proceedings of 3rd ISPE International Conference on Concurrent Engineering: Research & Applications, University of Toronto, Ontario, Canada, 26-28 August 1996, pp.181-186. de Graaf, R. & Sol, E. J. (1994), “Assessing Europe’s Readiness for Concurrent Engineering”, Proceedings of Conference on Concurrent Engineering: Research & Application, 1994, pp.77-82. de Graaf, R.; Wognum P. M.; Stoeten, B. J. B. & Kerkhof M. (1996), “PMO-RACE: A Combined Method for Assessing Organisations for CE”, Advances in Concurrent Engineering, Proceedings of 3rd ISPE International Conference on Concurrent Engineering: Research & Applications, University of Toronto, Ontario, Canada, 26-28 August 1996, pp.113-120. de Graaf, R. and Sol, E. J. (1994), “Assessing Europe’s Readiness for Concurrent Engineering”, Proceedings of Conference on Concurrent Engineering: Research & Application, 1994, 77-82. de Graaf, R.; Wognum P. M.; Stoeten, B. J. B. and Kerkhof M. (1996), “PMO-RACE: A Combined Method for Assessing Organisations for CE”, Advances in Concurrent Engineering, Proceedings of 3rd ISPE International Conference on Concurrent Engineering: Research & Applications, University of Toronto, Ontario, Canada, 26-28 August 1996, pp.113-120. Deasley, P and Lettice, F (1997), “A Concurrent Engineering Approach to Construction: Learning from Cases in Manufacturing Industry”, Concurrent Engineering in Construction, Proceedings of 1st International Conference on Concurrent Engineering in Construction, Anumba, C. J. & Evbuomwan, N. F. O. (Eds.), The Institution of Structural Engineers, London, 3 & 4 July 1997, pp. 269-305. Egan, J (2002), “Accelerating Change”, Department of the Environment, Transport and the Regions, London. Ertas, A., & Jones, J. C. (1993), “The engineering design process”, New York: Wiley. Fisher, M. (1993), “Automating Constructability Reasoning with a Geometrical and topological project Model.” Computing Systems in Engineering, 4 (2-3), 179-192. Hinckley, C. M., (1993) A Global Conformance Quality Model - A New Strategic Tool for Minimizing Defects Caused by Variation, Error, and Complexity, Stanford, Stanford University Dissertation, Ishikawa, K., (1985), “What is Total Quality Management? Japanese Way”, Prentice Hall, New Jersey, USA Johansson, C. ; Legge, D. and Wappling, A. (1999), “Concurrent Engineering in the Supply Chain”, Proceedings of Advances in Concurrent Engineering (CE99), Bath, UK, pg. 51-56. Kamara J. M. and Anumba, (2001), “ClientPro: A Prototype Software for Client Requirements Processing in Construction”, Advances in Engineering Software, 32 (2001), 141-158 Kamara J. M, Anumba C. J. and Evbuomwan N. F. O. (1997), “Considerations for the Effective Implementation of Concurrent Engineering in Construction”, Concurrent Engineering in Construction, Anumba C. J. & Evbuomwan N. F. O. (Eds.), Institution of Structural Engineers, London, July 1997, pp 33-44. Kamara, J. M.; Anumba, C. J. and Evbuomwan, N. F. O. (2000), “Developments in the Implementation of Concurrent Engineering in Construction”, International Journal of Computer Integrated Design and Construction, Vol.2, No.1, February 2000, 68 – 78. Khalfan, M. M. A. and Anumba, C. J. (2000c), “A Comparative Review of Concurrent Engineering Readiness Assessment Tools and Models”, Concurrent Engineering 2000 (CE 2000) Conference, Lyon, France, 17–20 July 2000, 578-585. Khalfan, M. M. A.; Anumba, C. J. and Carrillo, P. M (2005), The BEACON Model: Concurrent Engineering Readiness Assessment Tool for the Construction Industry, The Journal of Architectural Engineering and Design Management, Vol. 1, Issue 3, pp. 163 – 179. Kuo, T.C, Huang, S.H. and Zhang, H. C., (2001), “ Design for manufacture and design for X”, Computers & Industrial Engineering 41, PP. 241-260. Love, P. E. D. & Gunasekaran, A. (1997), “Concurrent Engineering in the Construction Industry”, Concurrent Engineering: Research & Applications, Vol. 5, No. 2, June 1997, pp.155-162. Latham, M. (1994), “Constructing the Team”, Final Report on Joint Review of Procurement and Contractual Agreements in the UK Construction Industry, HMSO, London. Egan, J. (1998), “Rethinking Construction”, Report of the Construction Task Force on the Scope for Improving the Quality and Efficiency of UK Construction Industry, Department of the Environment, Transport and the Regions, London. Prasad, B. (1997), “Seven Enabling Principles of Concurrency and Simultaneity in Concurrent Engineering”, Concurrent Engineering in Construction, Proceedings of 1st International Conference organised by The Institution of Structural Engineers Informal Study Group on Computing in Structural Engineering, 3 & 4 July 1997, London, pp.1-12. Precision Metal, (1975), “Design for assembly”, July, 8-26. Stoll, H.W., (1986), “Product design for efficient manufacture”. Industrial Tech. Inst., Ann Arbor, MI. Stoll, H.W., (1988), “Design for Manufacture”, ME, PP. 23-29. Sya, C. S. (1997), “Concurrent Engineering: Key Issues in implementation and practice”, Concurrent Engineering in Construction, Proceedings of 1st International Conference organised by The Institution of Structural Engineers Informal Study Group on Computing in Structural Engineering, 3 & 4 July 1997, London, pp.13-21. Thamhain, H. J. (1994), “Concurrent Engineering: Criteria for Effective Implementation”, Industrial Management, Vol. 36, No. 6, Nov./Dec. 1994, pp. 29-32. Tummala, V. M. R.; Chin K. S. and Ho S. H. (1996), “Assessing Success Factor for Implementing CE: A Case Study in Hong Kong Plastic Products Industry Using AHP”, Advances in Concurrent Engineering, Proceedings of 3rd ISPE International Conference on Concurrent Engineering: Research & Applications, University of Toronto, Ontario, Canada, 26-28 August 1996, pp.395-402. Winner, R. I.; Pennell, J.P.; Bertrend, H.E. and Slusarczuk, M. M. G. (1988), “The Role of Concurrent Engineering in Weapons System Acquisition”, IDA Report R-338, Institute for Defence Analyses, Alexandria, VA.