Standard Operating Procedures for Small Sputtering Machine

advertisement

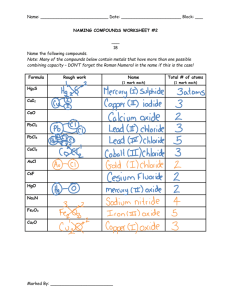

CENTER FOR NANOSCALE SCIENCE AND ENGINEERING Standard Operating Procedures Small Sputtering Machine Ross Levine With revisions by: Brian Wajdyk Version 1.1 Page 1 of 15 Important Gloves should be worn while handling substrate and deposition to reduce contamination. You can only use CeNSE laboratories and equipment if you have been approved by Brian or Chuck, reserved the tool on the calendar, and filled out a form. No Exceptions! If the equipment is acting unusual STOP! Please discuss with Brian or Chuck before proceeding and leave a note on the machine. Any accidental damage must be reported immediately. All CeNSE laboratories are protected by video surveillance. Version 1.1 Page 2 of 15 Machine Exterior Version 1.1 Page 3 of 15 Other Parts of the Machine Version 1.1 Page 4 of 15 Figure 2d: Chamber lid Version 1.1 Page 5 of 15 Operating Procedure 1. Preparation 1.1. Before beginning, be sure to wear gloves to reduce contamination and to protect the hands. 2. Load the sample and target 2.1. Open the chamber lid: 2.1.1. Disable the turbo pump by flipping the switch downward on the main panel (figure 1a). 2.1.2. Disable the rough pump by flipping the switch downward on the main panel (figure 1a). 2.1.3. Look through the chamber window and ensure that the shutter is directly below the gun; if it is not, the shutter will collide with the chamber wall. 2.1.4. Wait until the chamber is vented. There will be no obvious signs, but the chamber lid will not open if the chamber is not fully vented. Venting time is typically between 5-7 minutes. 2.1.5. Using a step ladder, unscrew the RF cable (Figure 2d) by turning the textured part of the connector counterclockwise while holding another part of the connector with the other hand. Place the cable out of the way. Do not put stress on the cable. 2.1.6. Grab the chamber lid handle and open the chamber lid completely; it will sit upsidedown on its own pole. 2.2. Place the sample on the stage inside the chamber (figure 2b). Ensure that the side on which the deposition will take place is facing upwards. 2.3. Place your target on the gun, with the magnetic keeper facing the gun (figure 2a). 2.4. Close and prepare the chamber: 2.4.1. Close the chamber lid using the handle; ensure the lid is centered over the chamber. 2.4.2. Replace the RF cable (Figure 2d) by screwing it back in. Turn the textured part of the connector clockwise while holding another part of the connector with the other hand. 2.4.3. Turn on the rough pump by flipping the switch upward on the main panel (figure 1a). 2.4.4. Wait about a minute; then turn on the turbo pump by flipping the switch upward. 3. Configure the deposition 3.1. Set the deposition thickness: 3.1.1. Press and hold the thickness button on the deposition monitor (figure 2c). 3.1.2. Use the increase and decrease buttons to set the desired thickness (figure 2c). 3.2. Set the material density: 3.2.1. Use the chart in Appendix A to find the density of the deposition material. 3.2.2. Press and hold the density button on the deposition monitor (figure 2c). 3.2.3. Use the increase and decrease buttons to set the density (figure 2c). 3.3. Set the material’s acoustic impedance: 3.3.1. Use the chart in Appendix A to find the acoustic impedance of the deposition material. 3.3.2. Press and hold the acoustic impedance button on the deposition monitor (figure 2c). 3.3.3. Use the increase and decrease buttons to set the density (figure 2c). 3.4. Set the tooling factor: Version 1.1 Page 6 of 15 3.4.1. Tooling factor must be found experimentally and varies by material. (If you do not know what tooling factor to use, consider performing an experimental deposition on a glass slide or similar sample first.) 3.4.2. Press and hold the tooling factor % button on the deposition monitor (figure 2c). 3.4.3. Use the increase and decrease buttons to set the tooling factor (figure 2c). 3.5. Press the start button on the deposition monitor. Operating Procedure, continued 4. Set the output power 4.1. 4.2. 4.3. 4.4. Press the modify button on the power supply. Use the wheel to select “set point.” Press the modify button again. Turn the wheel knob to set the wattage. Using over 200 W is not permitted without permission from the machine administrator. 4.5. Press the enter button to confirm and set the wattage. 5. Set the gas flow 5.1. Enable the argon flow: 5.1.1. Press the button on the argon MFC. 5.1.2. Press the button twice. 5.1.3. Use the and buttons until the screen option “Change Valve Operation” is shown. 5.1.4. Press the button. 5.1.5. Use the button to select “Automatic.” 5.1.6. Press the button. 5.1.7. Use the button to select “Yes.” 5.1.8. Press the button. 5.1.9. Using the menu, set the desired flow of argon using the “Change Setpoint” option. 5.1.10. Press the button to exit the menu. 5.2. Disable the air flow: 5.2.1. Press the button on the air MFC. 5.2.2. Press the button twice. 5.2.3. Use the and buttons until the screen option “Change Valve Operation” is shown. 5.2.4. If the Valve Operation is already set to “Valve closed,” skip to step 5.3.10. 5.2.5. Press the button. 5.2.6. Use the button to select “Valve closed.” 5.2.7. Press the button. 5.2.8. Use the button to select “Yes.” 5.2.9. Press the button. 5.2.10. Press the button to exit the menu. Version 1.1 Page 7 of 15 Operating Procedure, continued 6. Start the sputtering process 6.1. 6.2. 6.3. 6.4. 6.5. 6.6. 6.7. 6.8. Wait until the green light is on. Ensure that the valve is open on the argon tank. Turn on the “gas” switch. Wait for the vacuum to stabilize inside the chamber. If desired, turn on the “stage” switch to allow the stage to rotate. Check the RF source display for the letters “IL,” to ensure the interlocks are open. Press the “RF” button (Figure 1) to start the plasma. Presputter with the shutter closed to remove surface contaminants from the target. 1-2 minutes is usually a good amount of time to presputter. 6.9. When you are ready to begin, turn the shutter fully clockwise open, and quickly press start again on the deposition monitor to re-zero the measurement. The thickness monitor will automatically turn off the RF power when the desired thickness is reached. 7. End the sputtering process 7.1. Turn off components, in this order: 7.1.1. Turn off the “timer” switch. 7.1.2. Turn off the “stage” switch. 7.1.3. Turn off the turbo pump. 7.1.4. Turn off the rough pump. 7.2. Move the shutter back over the gun. 7.3. Wait for the chamber to repressurize. 7.4. Open the chamber lid as described in steps 2.1.3 through 2.1.5. 7.5. Turn off the gas: 7.5.1. Turn off the “gas” switch. 7.5.2. Close the valve on the argon tank. 7.6. Unload the sample if you are done with it (using gloves). 7.7. If it is no longer needed, remove the target and put it back in its container. If necessary, carefully use the tool that is attached to the machine to pry it out. Be careful to not scratch the gun. 8. When you are done with the machine 8.1. Close the chamber lid using the handle; ensure the lid is centered over the (empty) chamber. 8.2. Turn on the rough pump by flipping the switch upward. 8.3. Wait about a minute; then turn on the turbo pump by flipping the switch upward. Version 1.1 Page 8 of 15 Appendix A: Material Properties Use the chart below1 to find the properties of the deposition material for step 3 in the Operating Procedure. Formula Ag AgBr AgCl Al Al2O3 Al4C3 AlF3 AlN AlSb As As2Se3 Au B B2O3 B4C BN Ba BaF2 BaN2O6 BaO BaTiO3 BaTiO3 Be BeF2 BeO Bi Bi2O3 Bi2S3 Bi2Se3 1 Density 10.5 6.47 5.56 2.70 3.97 2.36 3.07 3.26 4.36 5.73 4.75 19.3 2.37 1.82 2.37 1.86 3.5 4.886 3.244 5.72 5.999 6.035 1.85 1.99 3.01 9.8 8.9 7.39 6.82 Z-Ratio 0.529 1.18 1.32 1.08 0.336 ? ? ? 0.743 0.966 ? 0.381 0.389 ? ? ? 2.1 0.793 1.261 ? 0.464 0.412 0.543 ? ? 0.79 ? ? ? Acoustic Impedance 16.69 7.48 6.69 8.18 26.28 11.88 9.14 23.18 22.70 4.20 11.13 7.00 19.03 21.43 16.26 11.18 SQM-160 User’s Guide, Version 4.06. Sigma Instruments, Inc. 2000-2008. Version 1.1 Page 9 of 15 Material Name Silver Silver Bromide Silver Chloride Aluminum Aluminum Oxide Aluminum Carbide Aluminum Fluoride Aluminum Nitride Aluminum Antimonide Arsenic Arsenic Selenide Gold Boron Boron Oxide Boron Carbide Boron Nitride Barium Barium Fluoride Barium Nitrate Barium Oxide Barium Titanate (Tetr) Barium Titanate (Cubic) Beryllium Beryllium Fluoride Beryllium Oxide Bismuth Bismuth Oxide Bismuth Trisuiphide Bismuth Selenide Formula Bi2Te3 BiF3 C C C8H8 Ca CaF2 CaO CaO-SiO2 CaSO4 CaTiO3 CaWO4 Cd CdF2 CdO CdS CdSe CdTe Ce CeF3 CeO2 Co CoO Cr Cr2O3 Cr3C2 CrB Cs Cs2SO4 CsBr CsCl CsI Cu Cu2O Cu2S Cu2S CuS Dy Dy2O3 Er Version 1.1 Density 7.7 5.32 2.25 3.52 1.1 1.55 3.18 3.35 2.9 2.962 4.1 6.06 8.64 6.64 8.15 4.83 5.81 6.2 6.78 6.16 7.13 8.9 6.44 7.2 5.21 6.68 6.17 1.87 4.243 4.456 3.988 4.516 8.93 6 Cu2S Cu2S CuS Dy Dy2O3 Er Z-Ratio ? ? 3.26 0.22 ? 2.62 0.775 ? ? 0.955 ? ? 0.682 ? ? 1.02 ? 0.98 ? ? ? 0.343 0.412 0.305 ? ? ? ? 1.212 1.41 1.399 1.542 0.437 ? 5.6 5.8 4.6 8.55 7.81 9.05 Acoustic Impedance 2.71 40.14 3.37 11.39 9.25 12.95 8.66 9.01 25.74 21.43 28.95 7.29 6.26 6.31 5.73 20.21 1.58 1.52 1.92 1.03 1.13 0.98 Page 10 of 15 Material Name Bismuth Telluride Bismuth Fluoride Carbon (Graphite) Carbon (Diamond) Parlyene (Union Carbide) Calcium Calcium Fluoride Calcium Oxide Calcium Silicate (3) Calcium Sulfate Calcium Titanate Calcium Tungstate Cadmium Cadmium Fluoride Cadmium Oxide Cadmium Sulfide Cadmium Selenide, Cadmium Telluride Cerium Cerium (III) Fluoride Cerium (IV) Dioxide Cobalt Cobalt Oxide Chromium Chromium (III) Oxide Chromium Carbide Chromium Boride Cesium Cesium Sulfate Cesium Bromide Cesium Chloride Cesium Iodide Copper Copper Oxide Copper (I) Sulfide (Alpha) Copper (I) Sulfide (Beta) Copper (II) Sulfide Dysprosium Dysprosium Oxide Erbium Formula Er2O3 Eu EuF2 Fe Fe2O3 FeO FeS Ga Ga2O3 GaAs GaN GaP GaSb Gd Gd2O3 Ge Ge3N2 GeO2 GeTe Hf HfB2 HfC HfN HfO2 HfSi2 Hg Ho Ho2O3 In In2O3 In2Se3 In2Te3 InAs InP InSb Ir K KBr KCl KF Version 1.1 Density Er2O3 Eu EuF2 7.86 5.24 5.7 4.84 5.93 5.88 5.31 6.1 4.1 5.6 7.89 7.41 5.35 5.2 6.24 6.2 13.09 10.5 12.2 13.8 9.68 7.2 13.46 8.8 8.41 7.3 7.18 5.7 5.8 5.7 4.8 5.76 22.4 0.86 2.75 1.98 2.48 Z-Ratio 8.64 5.26 6.5 0.349 ? ? ? 0.593 ? 1.59 ? ? ? 0.67 ? 0.516 ? ? ? 0.36 ? ? ? ? ? 0.74 0.58 ? 0.841 ? ? ? ? ? 0.769 0.129 10.189 1.893 2.05 ? Acoustic Impedance 1.02 1.68 1.36 25.30 14.89 5.55 13.18 17.11 24.53 11.93 15.22 10.50 11.48 68.45 0.87 4.66 4.31 Page 11 of 15 Material Name Erbium Oxide Europium Europium Fluoride Iron Iron Oxide Iron Oxide Iron Sulphide Gallium Gallium Oxide (B) Gallium Arsenide Gallium Nitride Gallium Phosphide Gallium Antimonide Gadolinium Gadolinium Oxide Germanium Germanium Nitride Germanium Oxide Germanium Telluride Hafnium Hafnium Boride, Hafnium Carbide Hafnium Nitride Hafnium Oxide Hafnium Silicide Mercury Holminum Holminum Oxide Indium Indium Sesquioxide Indium Selenide Indium Telluride Indium Arsenide Indium Phosphide Indium Antimonide Iridium Potassium Potassium Bromide Potassium Chloride Potassium Fluoride Formula KI La La2O3 LaB6 LaF3 Li LiBr LiF LiNbO3 Lu Mg MgAl2O4 MgAl2O6 MgF2 MgO Mn MnO MnS Mo Mo2C MoB2 MoO3 MoS2 Na Na3AlF6 Na5AL3F14 NaBr NaCl NaClO3 NaF NaNO3 Nb Nb2O3 Nb2O5 NbB2 NbC NbN Nd Nd2O3 NdF3 Version 1.1 Density 3.128 6.17 6.51 2.61 5.94 0.53 3.47 2.638 4.7 9.84 1.74 3.6 8 3.18 3.58 7.2 5.39 3.99 10.2 9.18 7.12 4.7 4.8 0.97 2.9 2.9 3.2 2.17 2.164 2.558 2.27 8.578 7.5 4.47 6.97 7.82 8.4 7 7.24 6.506 Z-Ratio 2.077 0.92 ? ? ? 5.9 1.23 0.778 0.463 ? 1.61 ? ? 0.637 0.411 0.377 0.467 0.94 0.257 ? ? ? ? 4.8 ? ? ? 1.57 1.565 0.949 1.194 0.492 ? ? ? ? ? ? ? ? Acoustic Impedance 4.25 9.60 1.50 7.18 11.35 19.07 5.48 13.86 21.48 23.42 18.91 9.39 34.36 1.84 5.62 5.64 9.30 7.40 17.95 Page 12 of 15 Material Name Potassium Iodide Lanthanum Lanthanum Oxide Lanthanum Boride Lanthanum Fluoride Lithium Lithium Bromide Lithium Fluoride Lithium Niobate Lutetium Magnesium Magnesium Aluminate Spinel Magnesium Fluoride Magnesium Oxide Manganese Manganese Oxide Manganese (II) Sulfide Molybdenum Molybdenum Carbide Molybdenum Boride Molybdenum Trioxdide Molybdenum Disulfide Sodium Cryolite Chiolite Sodium Bromide Sodium Chloride Sodium Chlorate Sodium Fluoride Sodium Nitrate Niobium (Columbium) Niobium Trioxide Niobium (V) Oxide Niobium Boride Niobium Carbide Niobium Nitride Neodynium Neodynium Oxide Neodynium Fluoride Formula Ni NiCr NiCrFe NiFe NiFeMo NiO P3N5 Pb PbCl2 PbF2 PbO PbS PbSe PbSnO3 PbTe Pd PdO Po Pr Pr2O3 Pt PtO2 Ra Rb Rbl Re Rh Ru S8 Sb Sb2O3 Sb2S3 Sc Sc2O3 Se Si Si3N4 SiC SiO SiO2 Version 1.1 Density 8.91 8.5 8.5 8.7 8.9 7.45 2.51 11.3 5.85 8.24 9.53 7.5 8.1 8.1 8.16 12.038 8.31 9.4 6.78 6.88 21.4 10.2 5 1.53 3.55 21.04 12.41 12.362 2.07 6.62 5.2 4.64 3 3.86 4.81 2.32 3.44 3.22 2.13 2.648 Z-Ratio 0.331 ? ? ? ? ? ? 1.13 ? 0.661 ? 0.566 ? ? 0.651 0.357 ? ? ? ? 0.245 ? ? 2.54 ? 0.15 0.21 0.182 2.29 0.768 ? ? 0.91 ? 0.864 0.712 *1000 ? 0.87 1 Acoustic Impedance 26.68 7.81 13.36 15.60 13.56 24.73 36.04 3.48 58.87 42.05 48.52 3.86 11.50 9.70 10.22 12.40 10.15 8.83 Page 13 of 15 Material Name Nickel Nichrome Inconel Permalloy Supermalloy Nickel Oxide Phosphorus Nitride Lead Lead Chloride Lead Fluoride Lead Oxide Lead Sulfide Lead Selenide Lead Stannate Lead Telluride Palladium Palladium Oxide Polonium Praseodymium Praseodymium Oxide Platinum Platinum Oxide Radium Rubidium Rubidium Iodide Rhenium Rhodium Ruthenium Sulphur Antimony Antimony Trioxide Antimony Trisulfide Scandium Scandium Oxide Selenium Silicon Silicon Nitride Silicon Carbide Silicon (II) Oxide Silicon Dioxide Formula Sm Sm2O3 Sn SnO2 SnS SnSe SnTe Sr SrF2 SrO Ta Ta2O5 TaB2 TaC TaN Tb Tc Te TeO2 Th ThF4 ThO2 ThOF2 Ti Ti2O3 TiB2 TiC TiN TiO TiO2 Tl TlBr TlCl TlI U U3O8 U4O9 UO2 V V2O5 Version 1.1 Density 7.54 7.43 7.3 6.95 5.08 6.18 6.44 2.6 4.277 4.99 16.6 8.2 11.15 13.9 16.3 8.27 11.5 6.25 5.99 11.694 6.32 9.86 9.1 4.5 4.6 4.5 4.93 5.43 4.9 4.26 11.85 7.56 7 7.09 19.05 8.3 10.969 10.97 5.96 3.36 Z-Ratio 0.89 ? 0.724 ? ? ? ? ? 0.727 0.517 0.262 0.3 ? ? ? 0.66 ? 0.9 0.862 0.484 ? 0.284 ? 0.628 ? ? ? ? ? 0.4 1.55 ? ? ? 0.238 ? 0.348 0.286 0.53 ? Acoustic Impedance 9.92 12.20 12.15 17.08 33.70 29.43 13.38 9.81 10.24 18.24 31.09 14.06 22.08 5.70 37.10 25.37 30.87 16.66 Page 14 of 15 Material Name Samarium Samarium Oxide Tin Tin Oxide Tin Sulfide Tin Selenide Tin Telluride Strontium Strontium Fluroide Strontium Oxide Tantalum Tantalum (V) Oxide Tantalum Boride Tantalum Carbide Tantalum Nitride Terbium Technetium Tellurium Tellurium Oxide Thorium Thorium (IV) Fluoride Thorium Dioxide Thorium Oxyfluoride Titanium Titanium Sesquioxide Titanium Boride Titanium Carbide Titanium Nitride Titanium Oxide Titanium (IV) Oxide Thallium Thallium Bromide Thallium Chloride Thallium Iodide (B) Uranium Tri Uranium Octoxide Uranium Oxide Uranium Dioxide Vanadium Vanadium Pentoxide Formula VB2 VC VN VO2 W WB2 WC WO3 WS2 WSi2 Y Y2O3 Yb Yb2O3 Zn Zn3Sb2 ZnF2 ZnO ZnS ZnSe ZnTe Zr ZrB2 ZrC ZrN ZrO2 Version 1.1 Density 5.1 5.77 6.13 4.34 19.3 10.77 15.6 7.16 7.5 9.4 4.34 5.01 6.98 9.17 7.04 6.3 4.95 5.61 4.09 5.26 6.34 6.49 6.08 6.73 7.09 5.6 Z-Ratio ? ? ? ? 0.163 ? 0.151 ? ? ? 0.835 ? 1.13 ? 0.514 ? ? 0.556 0.775 0.722 0.77 0.6 ? 0.264 ? ? Acoustic Impedance 54.17 58.48 10.57 7.81 17.18 15.88 11.39 12.23 11.47 14.72 33.45 Page 15 of 15 Material Name Vanadium Boride Vanadium Carbide Vanadium Nitride Vanadium Dioxide Tungsten Tungsten Boride Tungsten Carbide Tungsten Trioxide Tungsten Disulphide Tungsten Suicide Yttrium Yttrium Oxide Ytterbium Ytterbium Oxide Zinc Zinc Antimonide Zinc Fluoride Zinc Oxide Zinc Sulfide Zinc Selenide Zinc Telluride Zirconium Zirconium Boride Zirconium Carbide Zirconium Nitride Zirconium Oxide