- Sacramento

advertisement

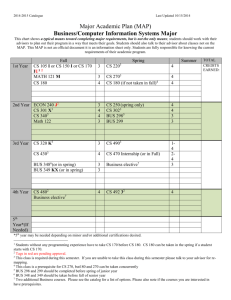

DISTRIBUTION SUBSTATION BUS DESIGN FOR OPTIMAL RELIABILITY AND ECONOMICS A Project Presented to the faculty of the Department of Electrical and Electronic Engineering California State University, Sacramento Submitted in partial satisfaction of the requirements for the degree of MASTER OF SCIENCE in Electrical and Electronic Engineering by Zachary Jay Cramer SPRING 2013 DISTRIBUTION SUBSTATION BUS DESIGN FOR OPTIMAL RELIABILITY AND ECONOMICS A Project by Zachary Jay Cramer Approved by: __________________________________, Committee Chair Mohammad Vaziri, Ph.D., P.E. __________________________________, Second Reader Mahyar Zarghami, Ph.D. ____________________________ Date ii Student: Zachary Jay Cramer I certify that this student has met the requirements for format contained in the University format manual, and that this project is suitable for shelving in the Library and credit is to be awarded for the project. __________________________, Graduate Coordinator Preetham Kumar, Ph.D. Department of Electrical and Electronic Engineering iii ___________________ Date Abstract of DISTRIBUTION SUBSTATION BUS DESIGN FOR OPTIMAL RELIABILITY AND ECONOMICS by Zachary Jay Cramer The purpose of this paper is to formulate, document and present a novel optimal distribution substation bus design methodology considering reliability and economics. A simple test system is used to evaluate and compare four common distribution substation bus configurations. Capital, maintenance and operating costs including the costs of system losses as well as the expected customer outage costs have been considered in the formulation. A standard 115 kV/12.47 kV sample system having two alternative configurations for the high voltage side and two alternatives for the low voltage side has been used with this formulation. The results for the optimal design selections have been presented. ____________________________, Committee Chair Mohammad Vaziri, Ph.D., P.E. _______________________ Date iv TABLE OF CONTENTS Page List of Tables ........................................................................................................................... vi List of Figures ........................................................................................................................ vii Chapter 1. INTRODUCTION .......................……………………………………………………….. 1 2. POWER SYSTEM MODEL AND UTILITY COSTS ....................................................... 6 Distribution System Expansion – Constraints and Capital Costs ................................ 6 Operating and Maintenance Costs ............................................................................... 7 The Cost of Losses ....................................................................................................... 7 3. RELIABILITY MODEL AND CUSTOMER COSTS ..................................................... 11 Customer Outage Costs ............................................................................................. 11 Component Reliability Models .................................................................................. 12 Failure Effect Analysis .............................................................................................. 13 Reliability Metrics ..................................................................................................... 15 4. FORMULATION AND SIMULATION MODEL ........................................................... 17 Objective Function ..................................................................................................... 17 Optimization Technique ............................................................................................ 17 Overview of the Simulation Model............................................................................ 18 Input Data .................................................................................................................. 19 5. RESULTS ......................................................................................................................... 24 6. CONCLUDING REMARKS ............................................................................................ 27 References ............................................................................................................................... 29 v LIST OF TABLES Tables Page 1. Bus Failure Customer Restoration Times…………….……………………………… 14 2. Breaker and MOAS Failure Customer Restoration Times…………………………... 15 3. Transformer Failure Customer Restoration Times….……………………………….. 15 4. Common Parameter Values……………………….…………………………………. 21 5. Component Capital and O&M Unit Costs…….………………………………...…… 22 6. Component Failure Rates………………………….…………………………………. 22 7. Alternative Capital Costs………………………….…………………………………. 23 8. Optimal Expansion Plans (By Year of Construction)………………………………... 25 9. Net Present Values……………………………….…………………………………... 25 10. Lifetime Average Reliability Performance……….………………………………….. 26 vi LIST OF FIGURES Figures Page 1. Bus Designs for 115 kV…………………………… .. .………………………………. 3 2. Bus Designs for 12 kV……………………………….… ……………………………. 4 3. Substation Design Alternatives……… ....………….…………………………………. 6 4. Load Forecast……………………………….……… ........ …………………………. 20 5. Feeder Numbering Convention…………………….……… .. ……………………… 24 vii 1 CHAPTER 1. INTRODUCTION Selection of the economically optimal bus configuration for a new substation is a challenging task. It requires careful consideration of the various costs involved. For distribution substations, this entails calculating the Utility's capital, maintenance, and operating costs, as well as the customers' interruption costs over the life of each substation design alternative. Once these costs are known, an economic analysis can be performed to determine the optimal alternative. This problem is further complicated by the fact that the cost of each design is inextricably linked to the sequence of distribution system and substation expansions. Power system reliability and automated power system expansion planning have been extensively studied over the last several decades. In many instances reliability is included in the expansion planning problem formulation. Extremely advanced commercial software packages are now available to perform this analysis. Some Utilities as well as a few regulatory agencies have begun to make use of this technology. However, the majority has yet to adopt it or to begin collecting the necessary data. Until these programs are adopted, the Utilities still need to make proper design decisions that are justifiable to the regulators. This substation bus design methodology was developed with this situation in mind. It requires minimal data, provides reasonable accuracy and takes customer related costs and preferences into account. While there is a great deal of literature on expansion planning and substation reliability, there are few publications that consider bus arrangement as a decision variable in the planning problem. Similarly, expansion sequences are rarely considered in published substation reliability studies. The objective of this paper is to formulate, document and present a methodology for selecting the optimal bus design of a new distribution substation considering reliability and expansion planning. For background on distribution expansion planning and substation reliability consult [1] and [2], respectively. 2 This project has a focused scope. It is limited to determination of the optimal substation bus configuration considering a small set of options. It does not attempt to re-examine all of the Utility's substation and distribution system design standards. These standards have been carefully crafted and refined over many years. It is assumed that these standards are nearly optimal for their intended applications. The substation considered in this project is a 115 kV/12.47 kV distribution substation with an ultimate design consisting of three 30 MVA, three-phase, transformers with Load Tap Changers (LTC) on the 12 kV side. Due to excessive levels of short circuit currents, parallel operation is avoided for the low voltage windings of the transformers. Each transformer may supply up to four 7.5 MVA, 12.47 kV feeders. Such a substation will most likely serve a suburban/urban area. The distribution system will be operated in a “radial” fashion and will have limited capacity back-ties. A radial configuration refers to a feeder having a “single source” and containing no “closed loops”. Feeders and transformers will be added as needed to meet expected demand. Load will be shared between feeders as evenly as possible. The high side configuration of the substation considered is known as the “looped” design. The two alternative designs for the high side bus will be the “standard loop” and the “super loop” configurations suggested by Figure 1. All devices are normally closed except those specifically denoted as Normally Open (N.O.). 3 Figure 1 - Bus Designs for 115 kV. Both configurations will have line sectionalizing breakers and will provide reasonably good reliability at relatively low costs. The standard loop design will have a lower cost. In addition, its reliability performance will be nearly identical to the reliability performance of the super loop design when considering sustained outages. However, the Motor Operated Air Switches (MOAS) in the standard loop design can only operate when de-energized. As a result, the entire substation will be subjected to a momentary outage to isolate most substation faults. In the super loop design, the extra breakers will eliminate such momentary outages. The question is whether or not the additional cost of using breakers instead of MOAS is justified by the improvement in reliability. It should be noted that this reliability improvement also depends on the configuration of the low side bus. This means that the high side configurations cannot be analyzed independently of the low side configurations. The two alternative designs being considered for the low side bus are known as the Double Bus Single Breaker (DBSB) and the Main and Auxiliary bus (MA) configurations. The 4 ultimate arrangements for each design consist of three transformers, twelve feeders and three bus sections. Each bus section will connect one transformer and four feeders. The center bus section of the MA and DBSB designs are shown in Figure 2. Switch status and bus sectionalizing switches are not shown. Figure 2 - Bus Designs for 12 kV. In the DBSB station feeders are usually split evenly between buses. In the MA station feeders are normally served through the main bus. The MA configuration is simpler and requires less equipment. As a result it has a lower cost. However, the auxiliary bus can only be used to serve one feeder at a time. The MA station has less operating flexibility, lower reliability and is more difficult to maintain or expand as compared to the DBSB station. In both stations, the breakers can be maintained easily. However, bus maintenance is considerably more problematic for the MA station. 5 Extensive switching of the distribution system and/or customer interruptions may preclude bus maintenance. Both the frequency and duration of customer interruptions will be larger for the MA station. In the DBSB station feeders can be split between the two buses, reducing the exposure of customers to outages. The second main bus will also allow for faster restoration after a bus fault, since customers can be restored through switching within the substation while repairs are being conducted. In the MA station, only one feeder can be transferred to the auxiliary bus. The remaining feeders must wait for the bus to be repaired before they can be reconnected. The main question as mentioned above is whether or not the reliability improvement is worth the additional investment cost. Since the high side reliability is dependent on the low side configuration, four alternatives will be considered: 1) standard loop with DBSB, 2) standard loop with MA, 3) super loop with DBSB and 4) super loop with MA. An algorithm that answers the question will be discussed and presented in the following sections. The remainder of this report will be comprised of the following sections. Chapter 2 identifies the power system model and the various components of the utility costs. System reliability and the value of service for the customers are modeled and formulated in Chapter 3. The overall problem formulation and simulation models are given in Chapter 4. Results and concluding remarks will be presented in Chapters 5 and 6, respectively. 6 CHAPTER 2. POWER SYSTEM MODEL AND UTILITY COSTS The power system model was developed to be as simple as possible while still providing an acceptable level of accuracy. The four alternative substation designs mentioned above are represented in Figure 3. Figure 3 - Substation Design Alternatives. A. Distribution System Expansion – Constraints and Capital Costs The next input to this model is the substation area's aggregate load forecast. Since the Utility has an obligation to serve the load, this forecast will impose constraints on the expansion planning problem. Simply stated capacity must be greater than or equal to load for all years. This 7 constraint will be enforced by making sure that the total transformer and feeder capacities are greater than or equal to load for all years. Every time a feeder is added, an expansion algorithm will be invoked. This algorithm will search the ultimate configuration to determine what components must be added to the model in the current year to serve the newly added feeder(s). The total capital cost (CC) to add the new components will be incurred during the year before they come into service. In addition to the expansion costs for each piece of equipment, there is also a way to input initial investment costs. Parameters can be input separately for each configuration. This algorithm ensures sufficient transformer and feeder capacity. Transmission capacity is assumed adequate and not a concern. B. Operating and Maintenance Costs The term maintenance is an umbrella that covers a wide range of asset management functions including actions such as equipment inspection, testing, repair and replacement. For our substation evaluation model, operating costs will refer to all costs incurred by the Utility related to the operation of specific equipment, except the costs of maintenance and losses. They may include costs such as taxes, fees, labor and others. The per unit Operation and Maintenance (O&M) costs designated by CO&M for each component are inputs to the model. These costs are incurred each year, beginning with the year a component is placed in service. The cost of losses (CL) is an operating cost, but will be accounted for separately since it is a function of the substation's load and topology. C. The Cost of Losses The cost of losses has two components; demand and energy. The demand component is 8 the cost of providing the generation, transmission and distribution capacity to supply losses during peak load. This component will be much smaller than the energy component and will be incurred whenever losses increase above their previous peak. Energy losses which are integrated over the entire period of operations will be much more significant. They are typically on the same order of magnitude as the capital costs. These losses depend on load and system design. They can be classified as load and no-load losses. All components have load related losses. These losses are often referred to as I2R or copper losses and are proportional to the square of the power flowing through a device. In addition to load losses, components such as transformers also have no-load losses (also referred to as iron or core losses). These losses represent the power needed to establish the magnetic flux linkages enabling these devices to operate. They remain constant regardless of loading on the device. In our model, the feeder represents everything downstream of the substation, including service transformers. As a result, the feeder losses will be composed of both no-load and load related losses. The substation transformer losses will also include both no-load and load related losses. The cost of feeder no-load losses, Cf,nll, is defined by [3] as 𝐶𝑓,𝑛𝑙𝑙 = 𝑛𝑓 ∙ α ∙ 𝑓𝑐𝑎𝑝 ∙ 8760 ∙ 𝐶𝐸 , (1) where; nf is the number of feeders, fcap is the capacity of the feeder in MVA, α is a coefficient relating the feeder capacity to no-load loss, CE is the cost of energy in $k/MWh and 8760 is the number of hours in a typical year. The cost of feeder load losses, Cf,ll, is defined by [3] as 𝑓 2 𝐶𝑓,𝑙𝑙 = ∑𝑛𝑓 β ∙ 𝑓𝑐𝑎𝑝 ∙ 8760 ∙ 𝐶𝐸 (𝑓 𝑝𝑘 ) 𝐿𝐹 2 , 𝑐𝑎𝑝 (2) 9 where; β is a coefficient relating the feeder capacity to load loss when operating at capacity, fpk is the peak load the feeder experiences and LF is the load factor which is defined as average load divided by peak load. The cost of transformer no-load losses, Ct,nll, is defined by [3] as 𝐶𝑡,𝑛𝑙𝑙 = 𝑛𝑡 ∙ γ ∙ 𝑡𝑐𝑎𝑝 ∙ 8760 ∙ 𝐶𝐸 , (3) where; nt is the number of feeders, tcap is the capacity of the transformer in MVA and γ is a coefficient relating the transformer capacity to no-load loss. The cost of transformer load losses, Ct,ll, is defined by [3] as 𝑡𝑝𝑘 𝐶𝑡,𝑙𝑙 = ∑𝑛𝑡 δ ∙ 𝑡𝑐𝑎𝑝 ∙ 8760 ∙ 𝐶𝐸 (𝑡 𝑐𝑎𝑝 2 ) 𝐿𝐹 2 , (4) where; δ is a coefficient relating the transformer capacity to load loss when operating at capacity and tpk is the peak load the transformer experiences during the year. The demand cost of losses, Cdemand, is defined by [3] as 𝐶𝑑𝑒𝑚𝑎𝑛𝑑 = ε ∙ ∆+ 𝑝𝑘 𝑙𝑜𝑠𝑠 , (5) where; ε is the cost of additional system capacity in $/kW and ∆+ 𝑝𝑘 𝑙𝑜𝑠𝑠 is the incremental increase in peak MW losses above the previous peak. If peak losses decrease, there is no demand cost of losses for that year. The total cost of losses in a given year is defined by [3] as 𝐶𝐿 = 𝐶𝑓,𝑛𝑙𝑙 + 𝐶𝑓,𝑙𝑙 + 𝐶𝑡,𝑛𝑙𝑙 + 𝐶𝑡,𝑙𝑙 + 𝐶𝑑𝑒𝑚𝑎𝑛𝑑 . (6) 10 It is assumed that the load will be divided evenly among feeders. The peak load on the transformers is determined as the sum of the simultaneous feeder loads that it serves. This is determined by the system topology. 11 CHAPTER 3. RELIABILITY MODEL AND CUSTOMER COSTS A. Customer Outage Costs The cost of interruptions to customers is determined through surveys that ask customers about the price they would be willing to pay for reliability and/or how much money they would lose for outages of various durations. The results of these surveys are used to create Sector Customer Damage Functions (SCDF). The Composite Customer Damage Function, CCDF, is the aggregation of SCDF at specified load points, that is, the weighted sum of sector peak loads (L) and SCDF for all sectors h at the load point i [3]-[6] 𝐶𝐶𝐷𝐹𝑖 = ∑ℎ 𝐿𝑖ℎ 𝑆𝐶𝐷𝐹𝑖ℎ . (7) SCDF and CCDF are both functions of outage duration. The composite customer damage function is the equation of a line where the Variable Costs (VC) correspond to the slope and the Fixed Costs (FC) correspond to the intercept. The Expected outage COST (ECOST) is the sum of the outage costs to all customer loads i due to failure of all components j in all failure modes k [3]-[6] 𝐸𝐶𝑂𝑆𝑇 = ∑𝑗 ∑𝑘 ∑𝑖 λ𝑗𝑘 (𝐹𝐶𝑖 +𝑉𝐶𝑖 ∙ 𝑟𝑖𝑗𝑘 ) , (8) where λjk is the failure rate of component j in failure mode k, and rijk is the mean time to restore load i following a failure of component j in mode k. A single CCDF will be used for all load points. It will represent the forecasted mix of customers in the area. 12 B. Component Reliability Models Component failure rates are another important input to the model. To predict failure rates for components that fail infrequently such as substation equipment we analyze the entire population and try to define relationships between factors we can measure and the probability of failure. The most obvious indicator is component age. When more detailed information is available, it can be used to predict component failures based on an equivalent age. Failure rates do tend to increase as components age. However, most power system components have failure rates that are nearly constant over their useful life as a result of maintenance practices. Due to a lack of detailed component failure data, constant failure rates will be employed here. The active failure rate will be denoted by λa, and the passive failure rate is λp, both in units of failures per year. Active failures such as short circuits cause the protection system to operate. On the other hand, passive failures such as false tripping of a circuit breaker do not cause operation of the protection system. All components are subject to active failures. Circuit breakers are the only components subject to passive failures. Only breaker, MOAS, transformer, and bus failures will be simulated. The failure rates of all other components will be lumped with the failure rates of these four components based on their failures impacts on the system. Buses will be used to represent the bus conductor as well as other equipment connected to that bus. The equation for the equivalent failure rate of a bus section, λ𝑒𝑞 , is defined by [3]-[6] as λ𝑒𝑞 = λ𝑏𝑢𝑠 + ∑𝑛𝑏𝑎𝑦 λ𝑏𝑎𝑦 = λ𝑏𝑢𝑠 + 𝑛𝑏𝑎𝑦 λ𝑏𝑎𝑦 , (9) where; λbus is the active failure rate of the bus, nbay is the number of bays closed into the bus, and λbay represents the active failure rate of all other components in a bay between the bus and 13 breaker, MOAS or transformer. The equivalent failure rate will have a fixed component and a variable component that is proportional to the number of elements closed into the bus. This should provide sufficient modeling flexibility. C. Failure Effect Analysis Failure Effect Analysis (FEA) is used to determine the impact of component outages on customers for the purpose of accumulating reliability metrics. In the model used for this project, delivery point failure occurs whenever there is a loss of continuity between source and load. Capacity constraints are neglected. Since the substation components usually have very high reliabilities, the minimum cut-set approximation will be employed to limit the analysis to first order outages (single contingencies). The error associated with using these approximations will be on the order of 1%. The sequence of events modeled by the FEA is as follows: For each component subject to active failures o Simulate the protection system's response to the fault o Determine which customers are interrupted o Simulate automatics o Determine which customers were restored (suffered a momentary outage), which customers suffer sustained outages and accumulate reliability metrics o Simulate sequential restoration within the substation to determine customer outage durations and accumulate reliability metrics For each component subject to passive failures o Simulate passive failure o Determine which customers are interrupted 14 o Accumulate appropriate reliability metrics using single step restoration process Tables 1, 2 and 3 outline the sequential restoration procedures for bus, breaker and transformer outages, respectively. The customer restoration times are defined in terms of the mean time to travel and diagnose (t), the mean time to switch (s), the mean time to restore a bus (rbus), and the mean time to restore a transformer (rXfmr). TABLE 1 Bus Failure Customer Restoration Times Bus Failure Restoration Times 1st Feeder 2nd Feeder nth Feeder 1 Transformer rbus + s rbus + ns rbus + ns >1 Transformer t+s t + 2s t + ns Bus 1 or Bus 2 t+s t + 2s t + ns Main Bus t+s rbus + s rbus + (n-1)s Aux Bus N/A N/A N/A Loop DBSB MA 15 TABLE 2 Breaker and MOAS Failure Customer Restoration Times CB and MOAS Failure Restoration Times 1st Feeder 2nd Feeder nth Feeder Passive Failure t t t Active Failure t+s t + 2s t + ns Active Failure t+s t + 2s t + ns Circuit Breaker MOAS TABLE 3 Transformer Failure Customer Restoration Times Transformer Failure Restoration Times 1st Feeder 2nd Feeder nth Feeder 1 Transformer rXfmr + s rXfmr + ns rXfmr + ns >1 Transformer t+s t + 2s t + ns D. Reliability Metrics The most important reliability metric is ECOST, as defined above. ECOST measures the total cost of unreliability and accounts for both sustained and momentary interruptions. However, ECOST does not provide an intuitive measure of reliability performance as measured by the frequency and duration of outages. To provide a more thorough analysis of reliability performance a number of secondary system reliability metrics will be accumulated. These are the Momentary Average Interruption Frequency Index (MAIFI), System Average Interruption 16 Frequency Index (SAIFI), and Customer Average Interruption Duration Index (CAIDI). MAIFI, SAIFI and CAIDI are defined as [4]-[6] 𝑀𝐴𝐼𝐹𝐼 = (∑𝑗 ∑𝑘 ∑𝑖 λ𝑗𝑘 ∙ 𝐶𝐸𝑀𝑂𝑖 )⁄𝑁𝐶 , (10) 𝑆𝐴𝐼𝐹𝐼 = (∑𝑗 ∑𝑘 ∑𝑖 λ𝑗𝑘 ∙ 𝐶𝐸𝑆𝑂𝑖 )⁄𝑁𝐶 , (11) and 𝐶𝐴𝐼𝐷𝐼 = ∑𝑗 ∑𝑘 ∑𝑖(λ𝑗𝑘 ∙𝑟𝑖𝑗𝑘 ∙𝐶𝐸𝑆𝑂𝑖 ) ∑𝑗 ∑𝑘 ∑𝑖(λ𝑗𝑘 ∙𝐶𝐸𝑆𝑂𝑖 ) , (12) respectively, where λjk is the failure rate of component j in failure mode k, and rijk is the mean time to restore load point i following a failure of component j in mode k. CEMOi is the number of “Customers Experiencing a Momentary Outage” at load point i as a result of a failure of component j in mode k, CESO is the number of “Customers Experiencing a Sustained Outage” and NC is the total “Number of Customers” in the system. It is assumed that the load and customers are evenly divided between feeders. 17 CHAPTER 4. FORMULATION AND SIMULATION MODEL A. Objective Function To compare the costs of different expansion plans, engineering economics is employed. Engineering economics is used to bring future expenditures to an equivalent present value. This allows the time value of money to be included in the analysis and provides for a convenient way to compare projects with different cash flows. The usual approach is to select the expansion plan with the lowest Net Present Value (NPV) of costs defined by [7] as; 1+𝑒𝑟 𝑖 𝑁𝑃𝑉 = ∑𝑛𝑖=0(𝐶𝐶,𝑖 + 𝐶𝐿,𝑖 + 𝐶𝑂&𝑀,𝑖 + 𝐶𝑅,𝑖 ) (1+𝑑𝑟) , (13) where; n is the length of the study period, er is a cost escalation rate, dr is the discount rate, and i is the year. For this project the study period was selected as 40 years. The objective is to find the expansion plan that minimizes NPV, subject to the constraint that capacity is greater than or equal to load in each year. B. Optimization Technique To determine the optimal expansion plan for each alternative, a Genetic Algorithm (GA) was developed. A GA is a meta-heuristic that mimics the process of evolution. This approach was selected because it is effective at solving discrete nonlinear optimization problems and is easy to implement. The GA starts by randomly initializing a population of potential solutions. Each individual solution is described by a solution vector containing values for all of the variables. At 18 each generation, the fitness of each individual is determined by evaluating the objective function. To create the next generation, individuals are selected using a random number generator. An individual's fitness determines its likelihood of successfully reproducing. Genetic operations such as recombination and mutation are then applied to create the next generation. This new generation is evaluated and less fit solutions are replaced [8]. Several genetic operators were developed to solve this particular problem as reliably and efficiently as possible. Operators were selected to provide balance between local and global search. Since some of these operators may result in infeasible solutions, a feasibility adjustment algorithm was developed. This algorithm ensures all solutions are confined to the feasible space before being evaluated. C. Overview of the Computer Simulation Model The substation reliability and economic analysis procedure starts with collecting data used to determine starting points for input parameters as well as historical system performance metrics used to benchmark the model. The model is then calibrated to provide an accurate system representation by iteratively adjusting input parameters. Next the optimization program is run for each alternative and the results are used to select a substation design. The main program is described by the following pseudo-code. For each alternative configuration o Read input data and initialize data structures o Initialize a population of potential solutions o For each generation Perform feasibility adjustment and evaluate the fitness of each individual Create the next generation using the predefined genetic operators 19 o Output optimal expansion plan, cost and reliability metrics for each year as well as summary statistics The objective function evaluation is delineated by the pseudo-code shown below For each year o Expand the active network model as dictated by feeder additions o Compute capital costs o Compute cost of losses o Compute O&M costs o Compute reliability performance metrics, including expected customer outage costs Run an engineering economic analysis on the resulting cash flow D. Input Data Before model development commenced, an effort was made to collect data. While some of the desired data was suitable for use; most was missing, incomplete, in a format that made it difficult to use, or exhibited a large degree of uncertainty. To work around this problem, estimated values were solicited from the experts. These estimates were compared to industry data and adjusted accordingly. This provided starting values for the model parameters. These values were then iteratively updated to calibrate the model to match statistics on historical system performance. The input data is summarized in this section starting with the load forecast suggested by Figure 4. 20 Load Forecast 90 Load (MW) 75 60 45 30 15 0 0 5 10 15 20 25 30 35 40 Year Figure 4 - Load Forecast. Many of the input values will be identical for each alternative. Table 4 provides a summary of the parameter values which are common to each alternative. 21 TABLE 4 Common Parameter Values Input Parameters Common to all Alternatives Value Feeder Capacity (MVA) 7.5 Transformer Capacity (MVA) 30 Ultimate Substation Capacity (MVA) 90 Transformer No-Load Loss Coefficient 0.001 Transformer Load Loss Coefficient 0.0033 Feeder No-Load Loss Coefficient 0.0064 Feeder Load Loss Coefficient 0.06 Cost of Energy ($/kWh) 0.13 System Capacity Cost ($/kW) 80 Load Factor 0.65 Fixed Customer Outage Cost ($/kW) 8.1 Variable Customer Outage Cost ($/kWh) 11.7 Discount Rate 0.08 Escalation Rate 0.025 Study Period (yrs) 40 Population Size 100 Number of Generations 200 Random Number Seed 0 Mean time to travel and diagnose (hr) 1 Mean time to switch (hr) 0.4 Mean time to repair a bus (hr) 3 Mean time to repair a transformer (hr) 24 Data for DBSB and MA component capital costs, O&M costs and failure rates have minor differences. This data has been summarized in Tables 5 and 6, respectively. 22 TABLE 5 Component Capital and O&M Unit Costs DBSB Capital and O&M Costs MA Capital Cost ($x1,000) O&M Cost ($x1,000) Capital Cost ($x1,000) O&M Cost ($x1,000) Breaker 500 4 400 4 MOAS 200 2 200 2 Transformer 7500 85 7500 85 Feeder 2500 25 2500 25 Bus 50 1 50 1 Initial Cost 6000 N/A 5000 N/A Capital costs for breakers include costs of associated switches, resulting in a lower capital cost for breakers in the MA station. The MA station also has a lower initial cost. TABLE 6 Component Failure Rates DBSB Component Failure Rates MA λp (1/yr) λa (1/yr) λp (1/yr) λa (1/yr) Breaker 0.005 0.0075 0.005 0.0075 MOAS N/A 0.0075 N/A 0.0075 Transformer N/A 0.01 N/A 0.01 Feeder N/A N/A N/A N/A Bus (fixed) N/A 0.005 N/A 0.01 Bus (per element) N/A 0.0025 N/A 0.0025 23 The fixed bus failure rate for the MA station is slightly higher than for the DBSB station because the MA main bus cannot be cleared for maintenance or construction. The last input to the model is the substation type and its ultimate configuration. These can be seen in Figure 3. Table 7 summarizes the difference in total capital costs between the alternatives. Differences in total capital cost are attributed solely to bus arrangement. TABLE 7 Alternative Capital Costs Capital Costs ($x1,000) Super Loop/ DBSB Loop/ DBSB Super Loop/MA Loop/MA Total 68450 67850 65550 65150 Feeders 30000 30000 30000 30000 Transformers 22500 22500 22500 22500 Bus Arrangements 15950 15350 13050 12650 Bus Cost Relative to Loop/MA 1.26 1.21 1.03 1.00 24 CHAPTER 5. RESULTS The optimal expansion plans are shaped by the relatively dominant capital costs. Capacity is added just in time to meet the demand. There is a slight difference in the two DBSB expansion plans. The optimal plan for the standard loop sacrifices SAIFI performance to reduce MAIFI. Figure 5 illustrates the feeder numbering convention. The same convention is applied to all other alternatives and used to track the optimal expansion plans shown in Table 8. In Table 8 the expansion plan is summarized by the year of construction of each feeder. It is assumed that construction of the feeder and any associated equipment takes one year. The equipment comes into service the following year. Figure 5 - Feeder Numbering Convention. 25 TABLE 8 Optimal Expansion Plans (By Year of Construction) Expansion Plan (Construction Years) Super Loop/ DBSB Loop/DBSB Super Loop/ MA Loop/MA 1101 0 0 0 0 1102 2 2 0 0 1103 0 0 2 2 1104 5 5 5 5 1105 8 10 8 8 Feeder Node 1106 12 14 10 10 Reference Number 1107 10 8 12 12 1108 14 12 14 14 1109 17 23 17 17 1110 23 28 20 20 1111 20 17 23 23 1112 28 20 28 28 Table 9 summarizes the final results of the study and is used for decision making. TABLE 9 Net Present Values NPV ($x1,000) Super Loop/DBSB Loop/DBSB Super Loop/MA Loop/MA Total 83930 84123 85769 86297 Capital 46143 45823 43906 43692 Losses 29113 29113 29113 29113 O&M 6229 6198 6229 6198 Reliability 2445 2990 6522 7294 26 The super loop/DBSB alternative is the preferred alternative. It has the lowest total NPV of total costs at $83,930,000. The general trend in the data shows that higher initial capital costs are definitely offset by the reliability improvements. The costs of losses and O&M are similar for the alternatives due to their nearly identical expansion sequences. Table 10 summarizes the typical reliability of the alternatives. TABLE 10 Lifetime Average Reliability Performance Average Reliability MAIFI SAIFI CAIDI (hr) Super Loop/DBSB 0.0000 0.0934 2.381 Loop/DBSB 0.0880 0.0940 2.377 Super Loop/MA 0.0000 0.1065 6.312 Loop/MA 0.1278 0.1065 6.312 Table 10 confirms that the main advantage of the super loop is that it eliminates momentary outages. The superiority of DBSB over MA was also clearly demonstrated. However, it should be noted that the DBSB alternatives were calibrated to historical system reliability indices, while the MA alternatives were calibrated to conform to the subject matter experts' opinions. This was necessary due to lack of quality data on the historical performance of the MA stations. 27 CHAPTER 6. CONCLUDING REMARKS A novel decision making methodology for selections of distribution bus arrangement using GA was introduced. The formulation considered fixed and variable costs of equipment as well as customer defined prices for desired reliability. The algorithm was tested using available empirical data for two of the commonly used configurations producing results aligned with the expectation of experts. Capital costs dominate the objective function. As a result, the optimal expansion plans are those in which capacity is added just in time to meet demand, confirming conventional wisdom. Ranking of alternatives also agreed with expectations. The higher capital cost of DBSB stations were offset by reliability improvements relative to MA stations. We can be confident in this result since the margin was fairly large. DBSB offers significantly better reliability than MA. This is mainly due to the reduced outage durations, but DBSB is also superior in terms of failure frequency. The decision between loop and super loop was less obvious. However, the improved reliability of the super loop made up for its higher capital cost. The recommended alternative for this project is the super loop with DBSB. It is the least total cost design and its advantage continues to increase beyond the end of the study period. This model relies on numerous assumptions and approximations. More weight could be lent to the results if some of these assumptions and approximations were investigated. However, in light of the fact that this model was not extensively tested, the next logical step would be to perform a sensitivity analysis. This would provide insights into the behavior of the model and would aid in the decision making process. If this problem was to be pursued further the most important task would be collecting additional and finer quality data. A better data set would allow us to investigate the validity of the assumptions underlying this model and would also provide numerous opportunities for future research. The problem of 28 determining the appropriate level of detail in modeling is known to be non-trivial. It would be interesting to investigate whether or not a more detailed model would result in a different design decision. However, it may be more beneficial to retain a coarse model and transition from an analysis of expected values to an analysis of probability distributions. This could be accomplished fairly easily and would provide added value by validating the existing model and measuring risks. For this study calibration was done manually by trial and error. Developing an automated and theoretically rigorous calibration methodology presents another interesting direction for further research. Lastly, only a small subset of the potential substation configurations was considered. Another obvious direction for future work would be to examine other combinations of low and high side bus configurations. 29 References [1] M. Vaziri, K. Tomsovic and A. Bose, "A directed graph formulation of the multistage distribution expansion problem," IEEE Transactions on Power Delivery, , Vol. 19, No. 3, July 2004, pp. 1335-1341. [2] T. O'neal and M. Vaziri, "Novel substation bus arrangement metrics," IEEE Power and Energy Society General Meeting, 2012. [3] H. Lee Willis, Aging Power Delivery Infrastructures, New York: Marcel Dekker, Inc, 2001. [4] Turan Gonen, Electric Power Distribution System Engineering, California: Power International Press, 1998. [5] Turan Gonen, Electric Power Transmission System Engineering, John Wiley & Sons Inc., 1988. [6] R. Billinton and R. N. Allan, Reliability Evaluation of Power Systems, Plenum Press, 1996. [7] Donald G. Newman, Ted G. Eschenbach, Jerome P. Lavelle, Engineering Economic Analysis, Ninth Edition, Oxford: Oxford University Press, 2004. [8] Leonard L. Grigsby, Power System Control and Stability, 2nd Edition, Florida: CRC Press, Taylor & Francis Group, 2007. [9] Averill M. Law, Simulation Modeling and Analysis, Fourth Edition, New York: McGraw-Hill, 2007. [10] H. Lee Willis, Spatial Electric Load Forecasting 2nd Edition, New York: Marcel Dekker, Inc, 2002. [11] R. Billinton, R. N. Allan, Reliability Evaluation of Engineering Systems: Concepts and Techniques, Plenum Press, 1992. 30 [12] Papoulis, Athanasios, Probability, Random Variables and Stochastic Processes, New York: McGraw-Hill, Inc. 1991. [13] Timothy A. Davis, Direct Methods for Sparse Linear Systems, Philadelphia: Society for Industrial and Applied Mathematics, 2006. [14] Ziemer, Rodger, Elements of Engineering Probability and Statistics, New Jersey: Prentice Hall, 1997.