Advanced Tools for Managing Work In Process

advertisement

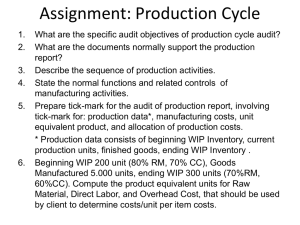

Advanced Repetitive – Advanced Tools for Managing WIP California User Group October 11, 2011 Santa Barbara, CA Paul Rubin AGENDA Introduction Overview of Adv Rep & WIP Visibility & Valuation Management / Processing Lot/Serial Tracking & Traceability WIP Lot Trace Q&A Setup • • • • • • • • Advanced Repetitive Enabled – 18.22.24 Item with M or L code – 1.4.7 or 1.4.17 Routing Required - 14.13.1 or 14.13.2 BOM with Operation Step - 13.5 Operation Cost Calculation - 14.13.17 Item on Production Line – 18.22.1.1 Employee created – 2.7.1 Can create location = work center - 1.1.18 Routing Maintenance - 14.13.2 Milestone & Non Milestone Operations Must report production at milestone All previously non milestones are backflushed at next milestone WIP Queues • Input Queue • Output Queue • Reject Queue Product Structure Maintenance – 13.5 Required for Adv Rep backflush Cost Roll Ups • Routing Cost Roll-Up – 14.13.13 • Product Structure Cost Roll-Up – 13.12.13 • Operation Cost Calculation – 14.13.17 Operation Cost Report – 14.13.19 Repetitive: Using it Demand Sales Orders Gross Requirements Cus tom er’s Scheduled Requirements Dis tribution Center’s Requirements Foreca st Schedule Requirements MRP (( Menu Menu 23) 23) Line Line Sequencing Sequencing (Menu (Menu 18.22.1) 18.22.1) Master Scheduler Repetit Repetitive ive Schedule Schedule Repetit Repetitive ive Explos Explosion ion (Menu (Menu 18.22.2) 18.22.2) (18.22.2.4) (18.22.2.4) July 1994 Sun Mon Tue Wed Thu Fri Sat 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Repetit Repetitive ive Picklis Picklistt 31 Inventory (Menu (Menu 18.22.3) 18.22.3) Production Reporting Repetit Repetitive ive Reporting Reporting (Menu (Menu 18.22.4) 18.22.4) Finished Items Backflush Cum Cumulative ulative Order Order Close Close (18.22.10) (18.22.10) Processing • • • • • • Backflushing Rejects Rework Scrap Move Subcontract Shipper Backflush – 18.22.13 Rejects Can report during backflush: 18.22.13 Can report at non – milestones: 18.22.16 Reject during Backflush – 18.22.13 Rejects can be entered during backflush transaction with up to 10 reason codes and are included in the Qty Processed. The rejects are placed in the Reject Operation queue indicated in Reject To Op. Strategic Information Group Copyright © 2007 Reject Transaction – 18.22.16 Rejects can be entered for non-milestone operations; up to 10 reason codes can be entered by checking Multi Entry box Strategic Information Group Copyright © 2007 Rework Can rework previously rejected items 18.22.17 Can charge labor and/or issue additional components Rework Transaction – 18.22.17 The Qty Reworked is required. You can enter rework hours and issue additional components. However, no automatic backflushing takes place.. If you used additional components, check Modify Backflush. You can modify the default Operation an Queue reworked items to be moved to. Strategic Information Group Copyright © 2007 Rework Transaction cont. Select items which were used and appropriate quantities Strategic Information Group Copyright © 2007 Move Transaction – 18.22.19 Move Transaction (18.22.19) transfers quantities from an operation’s output queue to the following operation’s input queue. For the final operation, items are moved to finished material inventory. Must be used with Subcontracting PO’s where serial or lot number required on inventory receipt or when final operation item are reworked. Strategic Information Group Copyright © 2007 Sub Shipper Maintenance – 18.22.5.5 Moves item from output queue of previous operation to input queue Sub Shipper Issue – 18.22.5.11 Enter in Ship-From (Site) and Shipper ID; this process any previous non milestone operations and moves the quantity to the input queue of the subcontract routing operation. Scrap Can record during backflush: 18.22.13 Can record out of queue 18.22.18 Scrap Transaction – 18.22.18 Use Backflush Transaction (18.22.13) for most of your scrap reporting. It backflushes the scrapped units and records all costs at the operation. Use Scrap Transaction (18.22.18) to scrap or remove quantities from any queue of an operation without backflushing. Strategic Information Group Copyright © 2007 WIP Inventory Management See inventory in operation queue’s in WIP Status Inquiry (18.22.13) or WIP Status Report (18.22.4.11) See WIP Valuation Report (18.22.4.13) for inventory $ Can adjust WIP inventory in 18.22.21 (change quantities in one of the queues) WIP Status Report – 18.22.4.11 The WIP Status Report shows the quantities and activities in the various queues Strategic Information Group Copyright © 2007 WIP Adjust Transaction – 18.22.21 Use WIP Adjust Transaction (18.22.21) to adjust quantities at an operation’s input, output or reject queues. Change to correct quantity. Similar to cycle count transaction. Strategic Information Group Copyright © 2007 Lot/Serial Traceability * Required if Lot/Serial field is L or S in 1.4.5 * Modify Backflush frame appears in 18.22.13 and requires lot/serial number to process the transaction - This is for components; receipt screen for parent * Serialization traceability requires one for one * Work Orders vs. Advanced Repetitive * Lot Trace Reports - Lot Transactions by Date - Lot Actual Bill Inquiry WIP Lot Trace * Part of Pro Plus Functionality * Ability to track lot/serial numbers within a cum order or work order including multiple lots at subcontractor * Flexible registration to track what components and what operations * Cannot be used to track at Non Milestone Operations * Control of combining or splitting lots WIP Lot Trace - continued * Can restrict the size of lots * System assigned lot/serial numbers from Number Range * Can trace lot references * WIP Inventory Reports * WIP Traceability Reports WIP Lot Trace Setup Registering Routing Exceptions Registering BOM Exceptions Using WIP Lot Trace * Destination Work Center and Machine * Recording Lot Input and Issue Data Destination Work Center and Machine WIP Lot Input and Issue Data WIP Lot Output and Receipt Data Reporting Reject Data Reporting Scrap Data Additional WIP Lot Windows * Recording Rework Data * Recording Lot Move Data WIP Lot Reports * WIP Lot Inventory Status Report * Item Lot Ship Transaction Report * WIP Lot Convert Transaction Report * WIP Lot Non-Convert Transaction Report * WIP Lot Inquiry * WIP Lot Where Used Report * WIP Lot Actual Bill Report Inventory Status Report Summary Advanced Repetitive provides for tracking of WIP inventory. Allows rejects, rework and scrap. WIP Lot Trace provides additional functionality for traking and managing lots within a cum order or work order.