managerial accounting and business environment chapter one

advertisement

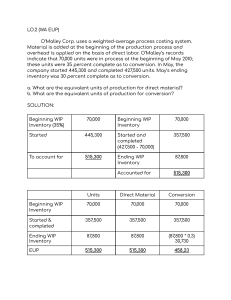

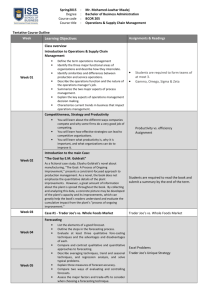

MANAGERIAL ACCOUNTING AND BUSINESS ENVIRONMENT CHAPTER ONE DIFFERENCE BETWEEN FINANCIAL AND MANAGERIAL ACCOUNTING Financial Reports for Users Past Activities Comparison Accuracy Entire Organization BS, IN, CF, SE YES GAAP External Reports Managerial Reports for Decision Mks Future Activities Relevance Fast Information Segments Dept, Cust, Vend, Empl, Pro NO GAAP Reports when needed TRADITIONALLY “Idleness Waste Money” or if manpower and machine are not running you are losing money PUSH THROUGH PRODUCTION---OLD PUSH through Production –old way Three inventories: Raw Materials (RM), Work in Process(WIP), Finished Goods (FG) RM Company | WIP Queque FG Results in Large Inventory waiting to be sold THREE APPROACHES FOR IMPROVEMENT Lean Production Theory of Constraints Six Sigma LEAN PRODUCTION Lean means Less Costs Advantages: Lower Inventory required Fewer Defects Less Wasted Effort Quicker Customer Response LEAN PRODUCTION CON’T Summaries Value all theories into 1 Added Flow Chart of Activities Manufacturing Cell Just in Time (JIT) Supply Chain Management and Continuous Improvement VALUE ADDED Value Chain pg 12 Activities that add value per customer Chip Box vs Dove Box FLOW CHART List Processes or Activities How It Is Made TRADITIONAL PRODUCTION Several large Machines with only one job each Mixing Machine Cutting Machine Wrapping Machine MANUFACTURING WORK CELL One Machine performing several jobs Several Multi-job Machines Each Machine Mixes-Cuts-Wraps JUST IN TIME (JIT) Pull Through Production--- Customer initiates RM WIP FG (Customer order) Shipped immediately to customer No queing of inventory SUPPLY CHAIN MANAGEMENT AND CONTINUOUS IMPROVEMENT Suppliers responsible for Quality of Incoming Parts and Materials Production Workers responsible for Quality during WIP THEORY OF CONSTRAINTS Control of Bottlenecks Increase capacity to remove bottleneck where process has smallest capacity Freeway system --- Norwalk on Interstate 5 Throughput time--- Cycle time to manufacture a product SIX SIGMA OR ZERO DEFECTS Non Value Added Identify process that do not add value or those customer is not willing to pay for Eliminate Non Value Activities Activities that use resources but do not add value