IAE 1 Answer Key

advertisement

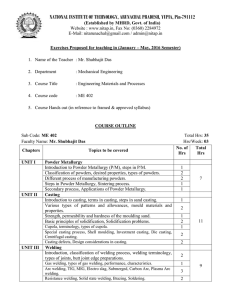

Internal Assessment Examinations-1 ME6302-Manufacturing Technology-1 Answer key Part-A 1.Casting Molten metal into mould cavity Allowing to solidify 2.Pattern & types Model of required casting Types-single piece , spilt , loose , piece , match plate , sweep , skeleton , segmental , shell . 3.Cast the large truck components Investment casting & centrifugal casting 4.Properties of good molding sand Porosity or permeability , plasticity or flowability , adhesiveness , strength or cohesiveness , refractoriness , collapsibility . 5.Function of core Core is to designed to accommodate for shrinkage 6.Arc welding Heat is developed by an electric arc. Joining by melting metals . It is strong then gas welding. Gas welding Employed for gases are acetylene , hydrogen , propane , and butane. Flame melt the metals. It is not so strong as arc welding. 7.Application of carburizing flame Welding very low carbon steel , monel metal , alloy steels , nonferrous materials , etc.. Part-B 1.(a) (i) Green sand mould Sand preparation , pattern is placed inside the drag box, facing sand, green sand ramming , leaving vent holes , tilt, core box place, poring sand, pin & runner, same steps to be follow for core box, removing core & drag box, removing the pattern, pouring mould cavity . (ii) Properties of moulding sand 1.Porosity or permeability: Sand allows streams & gases to pass. 2.Plasticity or Flowability: Molding sand to flow around & over the pattern and uniformly fills the pattern. 3.Adhesiveness: Sand which sticks to another body. 4.Strength or cohesiveness: Sand is stick together. 5.Refractoriness: Sand with stands high temperature. 6.Collapsibility: Lack of this property leads to formation of cracks. (b) (i) Casting defects, their causes & remedies i) Shrinkage: Depression on casting surface. Causes: Improper solidification, faulty gating, runner,etc…, Remedies: Provide proper solidification, modify gating, runner ,etc…, ii)Blow holes: Blow holes are formed on the interior of the casting. Causes: Excess moisture , hard ramming, excess binder, etc.., Remedies: Ram properly control binder, iii)Scab: Erosion or breaking down. Causes: Uneven ramming, High velocity of pouring. Remedies: Provide uniform ramming, Pour at correct velocity. iv)Swell: Enlargement of casting. Causes: Soft ramming, Quick pouring. Remedies: Ram properly, pour at correct velocity. v)Hard spots: Surface become hard. Causes: Rapid cooling, pouring at low temperature. Remedies: Uniform cooling, correct temperature. vi) Run out: Leakage of metal. Causes: Faulty molding ,improper parting line. Remedies: Modifying molting system, proper parting line. vii)Honey combing: Small cavities presents on the casting surface. Causes: Soft ramming, faulty gating. Remedies: Provide correct ramming, correct gating. (b) (ii) Cupola furnace Vertical ,cylinders shell 10mm thick, refractory bricks inside. Oil waste and wooden pieces fried, coke charged & added up to tuyere level, burn for ½ an hour. Lime stone is added to remove impurities. 25:1 & 10:1 iron socked for 1 hour. Molten metal collect at sand bed again full core & repeat the same process. Application: Melt cast iron Advantages: Simple design, operation & maintenance are simple. 9.(a) (i) Investment casting: Master pattern wax, wax pattern are more number, attached to wax runner, ceramic slurry dip more times, heating up to 1000 degree C, hot ceramic, pouring molding metal, cooling finishing project. Application: Costume jewellry, aircraft engines , nozzles , buckets , etc. Advantages: Good surface finish high accuracy. Disadvantage: Small size casting is made, more expensive. (ii) Cold casting die-casting: Melting n separate furnace, brought to pouring , cold chamber cylindrical shape, hydraulic plunger, molten metal injection cylinder, plunger moves with force , molten metal to die cavity , immediate solidified , dies separated , finished cavity removed by ejector pin. Application: House hold equipments, auto mobile parts , toys , etc. Advantage: Less Casting defects, stored & used for long time. Disadvantage: Small parts made, equipment cost is high. (b)(i) Pattern making allowances: 1.Shrinkage: Pattern larger than required casting, extra size provide not given casting become smaller. 2. Machining or finishing: Machining to get required finishing surface, metals are removed so extra size is given. 3. Draft or taper: Perpendicular to parting line , edges are damaged , vertical faces made taper. 4. Distortion or camber: Distort or warp cooling , all surface not shrink uniformly , un equal thickness reason , will not get required shape, slightly bent opposite direction& get correct shape. 5. Rapping or shake: detach , cavity become larger , made slightly smaller required casting. (ii) Centrifugal casting process: Hollow castings, without core , metal mould to rotate trolley , closed by end cores, centrifugal force metal through walls, immediately solidifies . Application: water pipes , bush bearing , fly wheels. Advantage: Core is not required, made thin casting. Disadvantage: suitable only cylindrical shapes, equipment cost is high. 10.(a) (i)Oxy-acetylene gas welding: Flux during welding prevent oxidation remove impurities, 2mm to 50mm thick are welded, flames hotness 3200 degree C, O2 – C2H2 at high pressure , oxygen compressed to 120 atm pressure , acetylene not compressed than 1.5 atm . Cac2+2H2o Ca(oH)2+ C2H2+127.3KJ/mol Welding torch 0.66 to 1bar. (ii)Flame characteristics: 1. Neutral flame: Equal quantity O2 & C2H2 , inner cone melt metals ,flame 3200 degree C. Application: Cast iron , copper , aluminum. 2. Carburising flame: Reducing flame, acetylene is more than O2, flame has sharp inner cone, intermediate cone, outer cone. Application: low carbon steel , alloys steel, non ferrous materials . 3. Oxidising flame: Oxygen is more than acetylene, flames inner cone, outer cone, inner cone is not sharp. Application: Brass ,bronze. (b)(i) Resistance Welding: Jointed on plastic state, flow electric current , mechanical pressure to weld , copper electrodes, current supply is given metal to red hot plastic condition , applied pressure to weld, 4 to 12 volt , 6 to 18 KW/cm3. Spot welding: 0.02mm to 1.25mm thickness welded, metal between copper electrodes , current passed, spot is become plastic state ,mechanical pressure , electrodes are cooled prevent over heating.