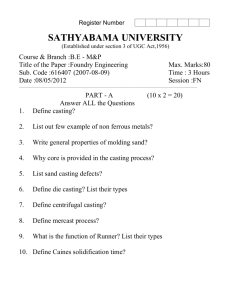

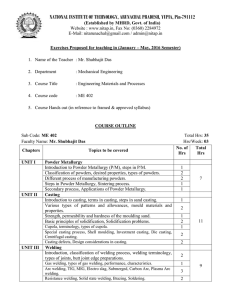

Tutorial for Lecture 5: Casting Processes

advertisement

Tutorial for Lecture 5: Casting Processes QUESTIONS Moodle XML: Some questions in 10107 Processing 1. Define all the glossary terms. 2. List 2 advantages that casting offers over other manufacturing processes. 3. List in a table the advantages/disadvantages of casting processes: Sand, investment, gravity die and high pressure die. Include melting point, accuracy, setup costs, production costs, design limitations. 4. Sand casting pattern and sand mould costs $1900 and each part costs $50 in labour. Die casting mould (die) costs $25000 and per part is $10. Calculate the break-even quantity where die-casting becomes cheaper than sand casting. 5. Explain the following casting terms: Flash, porosity, feeder, runner, draft, ejectors, cores. Glossary Binders Break Even Charge Cope Core Draft Drag Feeder Fettling Flash Gas Porosity Gate Green Sand Impurity Inclusion Investment Casting Ladle Lost Foam Parting Line Pattern Riser Sand Casting Shrinkage Shrink Hole Sink Marks Slag. Sprue Vacuum Casting © TAFE NSW Higher Education 2012 Version: X | Day-Month-Year 1