Document

advertisement

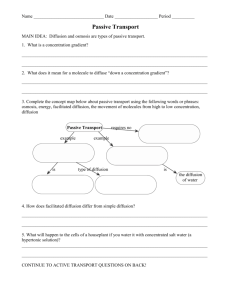

ME 210 Exam 2 Review Session Dr. Aaron L. Adams, Assistant Professor Re-cap of topics for Test #2 Chap 6 Fick’s Laws What are Fick’s Laws of Diffusion? Can you define the terms and units? (Know how to apply to solve mathematical problems) How can the rate of diffusion be predicted for some simple cases? How does diffusion depend on structure and temperature? Chap 6 Diffusion in Solids How does diffusion occur? How is activation energy calculated? (Know how to apply to solve mathematical problems) How is diffusion used in processing of materials? Chap 10 Phase Diagrams What is a phase? What is thermodynamic equilibrium? What three components need to be used (established) to define the equilibrium? How to determine the composition and fraction of a phase in a two-phase regime (Lever Rule). Chap 10 Microstructural development How can we use a phase diagram to predict microstructure? What is the consequence of solidification in an alloy (coring)? Fick’s 1st Law for steady-state diffusion dc J D dx ►It tells you the flow rate (i.e., “flux”) of a diffusing species due to a concentration gradient. ►J is the flux ►D is the diffusivity (e.g., m2/s, cm2/s, etc…) ►(dc/dx) is the concentration gradient – i.e., change in amount/distance (e.g., g/m, %/mm, etc…) Flux ► Flux is essentially the amount or rate of diffusion moles (or mass) diffusing mol kg J Flux or 2 surface area time cm s m2s M l dM J At A dt Diffusion Coefficient • Refers to the amount of material flowing through an area over a period of time. Qd D Do exp RT D = diffusion coefficient [m2/s] Do = pre-exponential [m2/s] Qd = activation energy [J/mol or eV/atom] R = gas constant [8.314 J/mol-K] T = absolute temperature [K] degrees K C 273 • This is an Arrhenius equation (very common to materials science; used to describe the statically probability of an event) A relevant problem: A differential nitrogen pressure exists across a 2-mm-thick steel bulkhead. After some time, steady-state diffusion of the nitrogen is established across the wall. If the nitrogen concentration on the high-pressure surface of the wall is 2 kg/m3 and on the low-pressure surface is 0.2 kg/m3, what is the flow of nitrogen through the wall (in kg/m2h)? The diffusion coefficient for nitrogen in this steel is 1.0 10-10 m2/s at its operating temperature. This is a flux problem… Draw the system… Then solve… c High J x D 2 kg/m3 x c chigh clow 2.0 0.2 kg/m 4 900 kg / m x xhigh xlow 0 2.0 103 m Low 0.2 kg/m3 3 Make sure units are consistent D 1.0 10 10 2 1.0 1010 m 2 3.6 103 s 7 m m /s 3.6 10 1 s 1 h h 2 Substitute D into flux equation 2 c kg kg 7 m J x D 900 4 3.6 10 3.24 104 2 x h m m h 2 mm Diffusion and Temperature 300 600 1000 10-8 1500 D has exponential dependence on T Q D Do exp d RT T(C) Dinterstitial >> Dsubstitutional D (m2/s) C in a-Fe C in g-Fe 10-14 Al in Al Fe in a-Fe Fe in g-Fe Adapted from Fig. 5.7, Callister & Rethwisch 8e. (Date for Fig. 5.7 taken from E.A. Brandes and G.B. Brook (Ed.) Smithells Metals Reference Book, 7th ed., Butterworth-Heinemann, Oxford, 1992.) 10-20 0.5 1.0 1.5 1000 K/T Interstitial diffusion is much faster. WHY? Interstitial atoms are smaller and more mobile. Also there are more empty interstitial positions than vacancies. This increases the probability of interstitial diffusion. Diffusion and Crystal Structure 300 600 1000 10-8 1500 D has exponential dependence on T T(C) Q D Do exp d RT DBCC >> D (m2/s) C in a-Fe DFCC C in g-Fe 10-14 Adapted from Fig. 5.7, Callister & Rethwisch 8e. (Date for Fig. 5.7 taken from E.A. Brandes and G.B. Brook (Ed.) Smithells Metals Reference Book, 7th ed., Butterworth-Heinemann, Oxford, 1992.) 10-20 0.5 1.0 1.5 1000 K/T Interstitials diffuse is much faster in BCC than FCC. WHY? BCC structures are less dense (i.e., less close packed). There is more room for interstitials to move. Diffusion Data Constant (aka ‘fixed’) Energy to cause diffusion Diffusivity Depends on T (not fixed) Example: At 300ºC the diffusion coefficient and activation energy for Cu in Si are: Q D Do exp d RT D(300ºC) = 7.8 x 10-11 m2/s Qd = 41.5 kJ/mol What is the diffusion coefficient for Cu in to Si at 350ºC? collect data transform data D ln D Temp = T 1/T Transform data for each temperature: Qd lnD2 = lnD0 R æ1ö çç ÷÷ è T2 ø and Plot and determine slope of line: D2 Qd \ lnD2 - lnD1 = ln =D1 R 10 Qd lnD1 = lnD0 R æ 1 1ö çç - ÷÷ è T2 T1 ø æ1ö çç ÷÷ è T1 ø 5 BASIC MATH Y = MX + B M = slope = Y/X 2 Y = ln D Y X 1 X = 1/T Plot and determine slope of line: Qd ln D2 ln D1 Y slope of line X R 1 1 T2 T1 11 Example (cont.) Solve for unknown value: Qd D2 D1 exp R 1 1 T2 T1 T1 = 273 + 300 = 573 K Remember to convert from °C to K T2 = 273 + 350 = 623 K D2 (7.8 x 10 11 41,500 J/mol 1 1 m /s) exp 8.314 J/mol - K 623 K 573 K 2 D2 = 15.7 x 10-11 m2/s 3 12 Phase Diagrams: Determination of phase compositions • If we know T and C0, then we can determine: -- the compositions of each phase. (Just read them) Consider C0 = 35 wt% Ni At TA = 1320°C: Only Liquid (L) present CL = C0 ( = 35 wt% Ni) At TD = 1190°C: Only Solid (a) present Ca = C0 ( = 35 wt% Ni) At TB = 1250°C: Both a and L present CL = C liquidus ( = 32 wt% Ni) Ca = C solidus ( = 43 wt% Ni) 13 C0 = C Cu-Ni system T(oC) • Examples: alloy ( = 35 wt% Ni) A TA 1300 tie line L (liquid) B TB 1200 TD 20 D 3032 35 CL C0 wt% Ni a (solid) 40 4 3 50 Ca Adapted from Fig. 10.3(a), Callister & Rethwisch 4e. (Fig. 10.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Phase Diagrams: Determination of phase weight fractions (We use the Lever Rule) • If we know T and C0, then can determine: -- the amount (i.e., weight fraction) of each phase. (Calculate them) • Examples: Consider C0 = 35 wt% Ni S R +S Wa R R +S 14 43 - 35 = = 0.73 43 - 32 = 0.27 A TA At TA : Only Liquid (L) present WL = 1.00, Wa = 0 At TD : Only Solid ( a) present WL = 0, W a = 1.00 At TB : Both a and L present WL Cu-Ni system T(oC) 1300 tie line L (liquid) B TB S R 1200 TD 20 a (solid) D 3032 35 CL C0 wt% Ni 40 4 3 Adapted from Fig. 10.3(a), Callister & Rethwisch 4e. (Fig. 10.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Ca 50 The Lever Rule (gives us the ‘amounts’ of phases that are present) ► Tie line – connects the phases in equilibrium with each other – also sometimes called an isotherm T(oC) What fraction of each phase? Think of the tie line as a lever (i.e., teeter-totter) tie line 1300 L (liquid) B TB a (solid) 1200 R 20 30CL Ma ML S C0 40 Ca wt% Ni R 50 Adapted from Fig. 10.3(b), Callister & Rethwisch 4e. Ca - C0 ML S WL = = = ML + Ma R + S Ca - CL S Ma S M L R C0 - CL R Wa = = R + S Ca - CL WL Wa 1 (i.e., 100%) 15 Binary Phase Solidification Solubility limits can change as function of temperature. This affects microstructure. Alloys above solubility limit but below max solubility (far from the eutectic). The solidification path is: L: C0 wt% Sn T(oC) 400 L 300 L+a LL+aa aab 100 a: C0 wt% Sn a 200 TE L a a b a+ b 0 10 2 (sol. limit at T room ) 20 C0 Pb-Sn system 30 C, wt% Sn 18.3 (Max sol. limit at TE) 16 Adapted from Fig. 10.12, Callister & Rethwisch 4e. Eutectic Solidification T(oC) Pure Elements Eutectic Pure Elements L: C0 wt% Sn 300 L Pb-Sn system a 200 L+a Lb b 183°C TE 100 Adapted from Fig. 10.13, Callister & Rethwisch 4e. ab 0 Pb 20 18.3 40 b: 97.8 wt% Sn a: 18.3 wt%Sn 60 CE 61.9 80 100 97.8 Sn C, wt% Sn L a + b ; a saturated with Sn and b saturated with Pb must form at the same time. Requires diffusion. Mix of A & B17has lower melting point than pure A or pure B. Microstructural Developments • For alloys for which 18.3 wt% Sn < C0 < 61.9 wt% Sn • Result: a phase particles and a eutectic microconstituent T(oC) L: C0 wt% Sn L 300 Pb-Sn system a 200 R TE α L L+ a L+β b S S R 0 Pb 20 18.3 primary a eutectic a eutectic b 40 60 61.9 C, wt% Sn Adapted from Fig.18 10.16, Callister & Rethwisch 4e. • Just above TE : Ca = 18.3 wt% Sn CL = 61.9 wt% Sn S = 0.50 = Wa R+S WL = (1- Wa) = 0.50 • Just below TE : a+b 100 a L 80 100 97.8 Ca = 18.3 wt% Sn Cb = 97.8 wt% Sn Wa = S = 0.73 R+S Wb = 0.27 Hypoeutectic & Hypereutectic T(oC) 300 Adapted from Fig. 10.8, Callister & Rethwisch 4e. (Fig. 10.8 adapted from Binary Phase Diagrams, 2nd ed., Vol. 3, T.B. Massalski (Editor-in-Chief), ASM International, Materials Park, OH, 1990.) a 200 L+ a a+b 100 20 40 hypoeutectic: C0 = 50 wt% Sn a a L+b b TE 0 (Figs. 10.14 and 10.17 from Metals Handbook, 9th ed., Vol. 9, Metallography and Microstructures, American Society for Metals, Materials Park, OH, 1985.) (Pb-Sn System) L a 60 80 eutectic 61.9 hypereutectic: (illustration only) b b a Adapted from Fig. 10.17, Callister & Rethwisch 4e. 19 C, wt% Sn eutectic: C0 = 61.9 wt% Sn a a 175 mm 100 b b b b 160 mm eutectic micro-constituent Adapted from Fig. 10.14, Callister & Rethwisch 4e. Adapted from Fig. 10.17, Callister & Rethwisch 4e. (Illustration only) Understand how Microstructures Evolve Hypo-eutectoid alloys form primary a on prior grain boundaries. These alloys have low to medium strength, and good ductility. Hyper-eutectoid alloys form primary Fe3C on prior grain boundaries. These alloys are brittle, but strong. They also have excellent wear resistance. Summary ► Study your notes, assessments, and in book example problems. ► Exam #2 will have 7 questions. ► There will be NO true/false or multiple choice questions. ► All calculations AND short answer. ► Know how to do the types of problems that we’ve covered and you can do quite well. ► Good luck!