Commodity Products - Pustaka Asep MuSa

Commodity Products

CHEMICAL PRODUCT ENGINEERING

ASEP MUHAMAD SAMSUDIN

Chemical Products

Category of

Product

Class of Product

Specialty chemicals Surfactant

Example

Ammonium lauryl sulfate

Exfoliating gel Formulated products

Cosmetic

Bio-based concepts Drug

Devices

Alendronate sodium

Biomedical device Blood oxygenator

Virtual chemical products

Technology-based consumer goods

Key Attribute

Molecular structure

Microstructure

Biological activity

Software to simulate chemical processes

Health care consumer goods

Aspen Plus

Disposable diaper

Materials and assembly

Computational performance

Materials and assembly

R. Costa and G. D. Moggridge

R. Costa, G. D. Moggridge, P. M. Saraiva. Chemical Product Engineering: An Emerging Paradigm Within Chemical Engineering. AIChE Journal, 52 (2006) :1979

Chemical Products

Based on the characteristic size scale which is critical to their performance

Examples

Scale

Key

Basis

Risk

Commodities Chemical Devices

Artificial kidneys

Meters

Molecular

Products

Penicillin

Microstructures

Products

Sunscreen Ethylene, ammonia

Continuum

Cost Convenience

Nanometers Micrometers

Discovery

Reaction Engineering,

Unit operations

Feedstock

Reaction Engineering,

Unit operations

Chemistry

Intellectual Property Discovery

Function

Recipe

Science

Cussler and Moggridge

Cussler EL, Moggridge GD. Chemical product design. 2 nd edition. Cambridge: Cambridge University Press; 2011.

Critical size of Chemical

Products

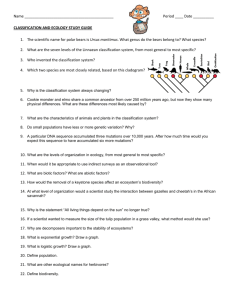

Commodity Products

The core of the chemical industry. Simple molecules produced in large quantities (over 10,000 tons/year) at the lowest possible cost.

Fewer than 50 of the more than 30,000,000 compounds which are known.

The molecular weights are typically less than 100 daltons.

The king of these product is liquid fuel: gasoline, petrol, diesel

The key chemical and physical properties of the commodity products : key scale, chemical reactivities and volatilities.

We can use the same design template of needs, ideas, selection and manufacture to improve manufacturing itself.

Product Design Procedures

Cussler & Moggridge, 2011

Example 1

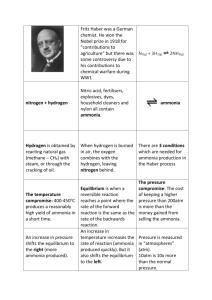

Ammonia from nitrogen and hydrogen

Needs

A product purity above 95%.

An amount over 10,000 tons/year.

Price already defined by the market.

A production cost perhaps 20% less than the price

Example 1

Ammonia from nitrogen and hydrogen

Ideas

Derive from the four step outline suggested by Douglas (1988)

Batch Vs. Continuous

Process

Inputs and Outputs

Reactors and Recycles

Separation and Heat

Integration

Example

Ammonia from nitrogen and hydrogen

First : decide weather we use a batch of continuous one

Experience suggests that for commodities a continuous process will almost always be cheaper.

Second : draw a flow diagram. A chart illustrating the flow of different chemical stream in the reactor.

𝑁

2

+ 3𝐻

2

↔ 2𝑁𝐻

3

Example

Ammonia from nitrogen and hydrogen

Third: recognize that this process will not involve complete reaction

For the conventional Haber process, only get perhaps 20% conversion.

The process must have a reactor followed by some sort of separator.

Example

Ammonia from nitrogen and hydrogen

Fourth: Douglas suggests more detailed identification of separation required.

The gases from the reactor are chilled to 10 o C to condense liquid ammonia, and the non-condensables are recycled.

Part of this recycle is purged to get rid of the argon.

Significant amounts of nitrogen and hydrogen dissolve in the liquid ammonia.

One the pressure is released (to about 20 bar), the dissolved gases can be removed by simple distillation for recycle and recompression.

Example

Ammonia from nitrogen and hydrogen

IDEAS.

1.

2.

3.

Seek better catalyst.

Get rid the argon and so not waste the hydrogen and nitrogen necessarily discarded with the purge.

Invent a better, more selective separation

Example

Ammonia from nitrogen and hydrogen

SELECTION

The catalyst, the firs area for study, has received the greatest effort. The original Iron oxides used by Haber as catalyst.

The activity of catalyst can be enhanced by trace quantities of many metals, especially ruthenium.

Removing argon, which is the second area of interest, would certainty possible by liquefying air and distilling off the nitrogen. While the separation of argon from oxygen is difficult because the difference in boiling points is so small.

We can infer that this distillation is too expensive, costing much more than purging the argon and wasting some nitrogen and hydrogen.

Example

Ammonia from nitrogen and hydrogen

SELECTION

We may decide to focus on the third area, a better separation of ammonia from the other gases.

We may select three good idea : A membrane 100 times more permeable to ammonia than to nitrogen and hydrogen at room temperature

A similar membrane selective and stable at reactors temperature

An adsorbent selective for ammonia at reactor conditions.

Example

Ammonia from nitrogen and hydrogen

MANUFACTURE